Used ESEC / ZEVATECH CT2000 #125453 for sale

URL successfully copied!

Tap to zoom

ID: 125453

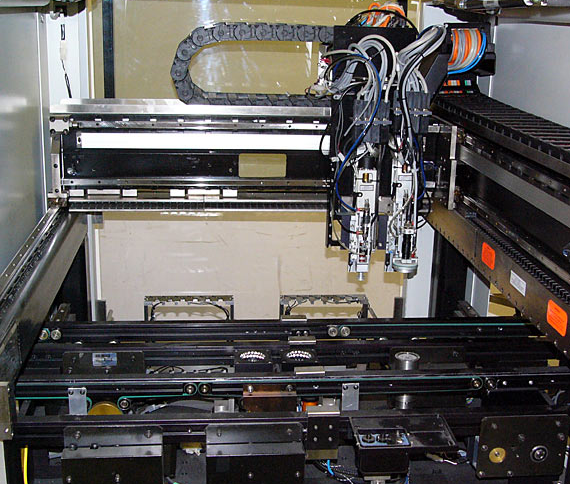

Assembly system robot, parts system

No computer monitor

XYZ work cell 23" x 27" x 4"

Substrate sized 3"x3" up to 12"x20"

Vision-driven accuracy +/-0.002"

Speed: 60"/sec X & Y axes, 20"/sec Z axis, 360º/sec theta

Resolution: 2 microns X & Y axes, 0.97 mircons Z axis, 0.001º

Repeatability: 0.02mm X/Y 0.01mm Z 0.01º

Accuracy: 0.038mm X & Y (mapped)

Top & Bottom vision system with programmable lighting

Geometry recognition and placement offset calculation capability

Bottom edge belt conveyor

Includes:

Adept Model 133 Teach/Control pendant with LCD screen

Adept MV-19 VME-based computer/bus system

Western Servo Design servo motor drive system

Manuals:

Installation/Maintenance Manual

ATMI CT-2000 Substrate Placer System Configuration Guide

ESEC CT-Series Installation and Maintenance manual

Adept V+ Operating System User's Guide.

ESEC / ZEVATECH CT2000 Die Attacher is an automated, precision tool for attaching and bonding dies to wafer and leadframes. This advanced machine is capable of handling a wide range of die sizes, from the very small to the very large, allowing for a variety of applications. With a top speed of 4,000 die/hr, it delivers incredibly fast and accurate attachment and bonding. ESEC CT2000 is equipped with an optimized integrated vision equipment, which can accurately detect and recognize dies of various shapes and sizes, so that the correct die-to-wafer or leadframe alignment and positioning is achieved. Additionally, it has a powerful XY motion system which corrects for any misalignments automatically, ensuring that the dies are accurately and precisely attached. ZEVATECH CT2000 also offers an integrated Active Vibration unit which helps to reduce wire sweep and emulsifier scrubbing, resulting in improved die quality. It also features an Internal Heat Sink that manages heat travel both on the die and leadframe, maximizing the thermal interface material performance, and increasing heat dissipation. CT2000 Die Attacher is fast and efficient enough to handle a high event rate to maximize productivity. It has multi-tone alarm machine which quickly alerts users to any discrepancies. Furthermore, it has additional features such as Stacking Control Measurement, which takes into account the unevenness of the top surface of stacked dies and adjusts the height of the nozzle in order to achieve the best performance. Overall, ESEC / ZEVATECH CT2000 Die Attacher is a reliable and robust die attach tool designed to meet the most demanding requirements for the highest quality bonding and attachment of dies to wafers and leadframes. It offers a wide range of features to enable extremely fast and accurate attachment, plus an intuitive user interface for easy operation and integration. This die attacher is an ideal solution for electronics manufacturers requiring reliable, high-speed die attach and bonding.

There are no reviews yet