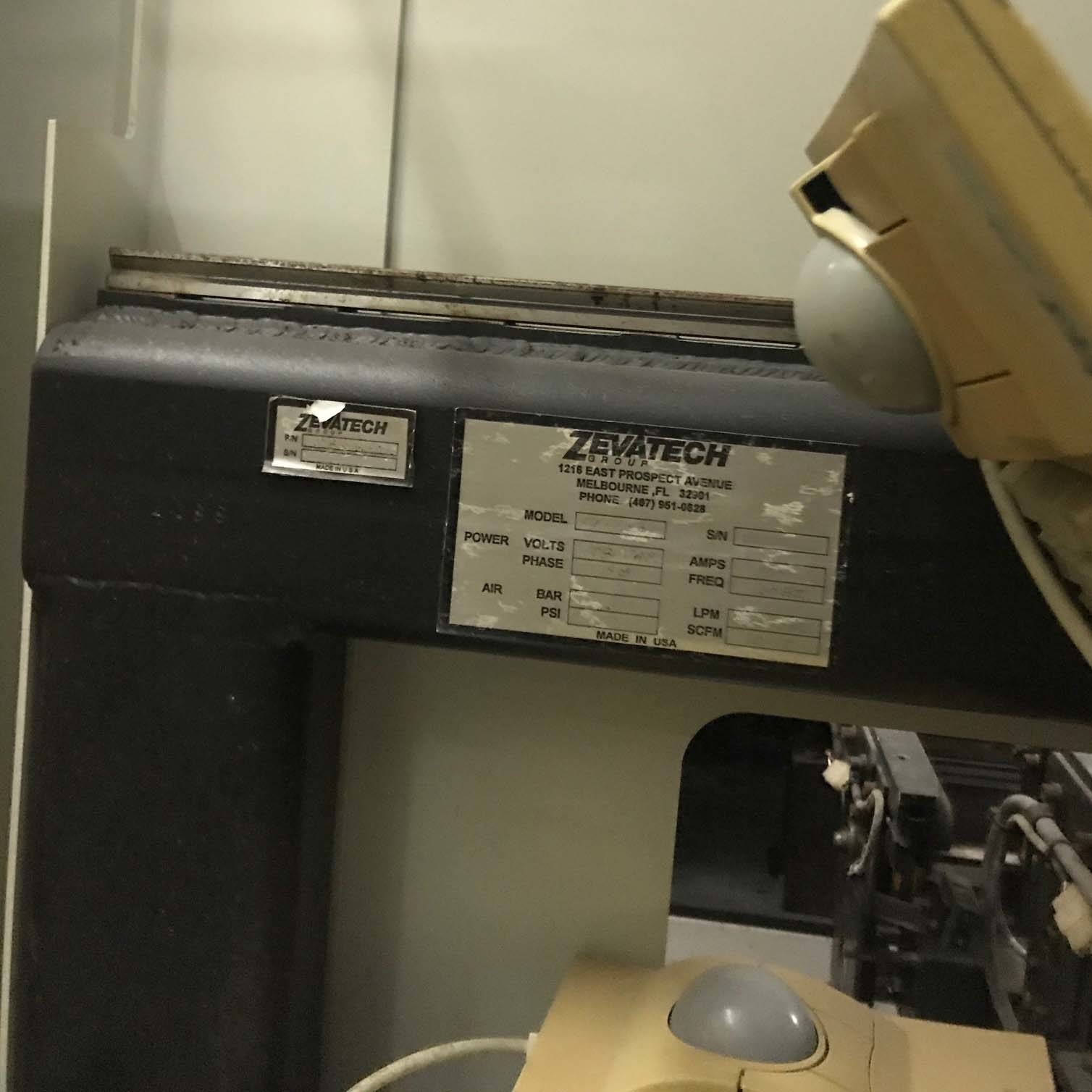

Used ESEC / ZEVATECH CT2000 #145839 for sale

URL successfully copied!

Tap to zoom

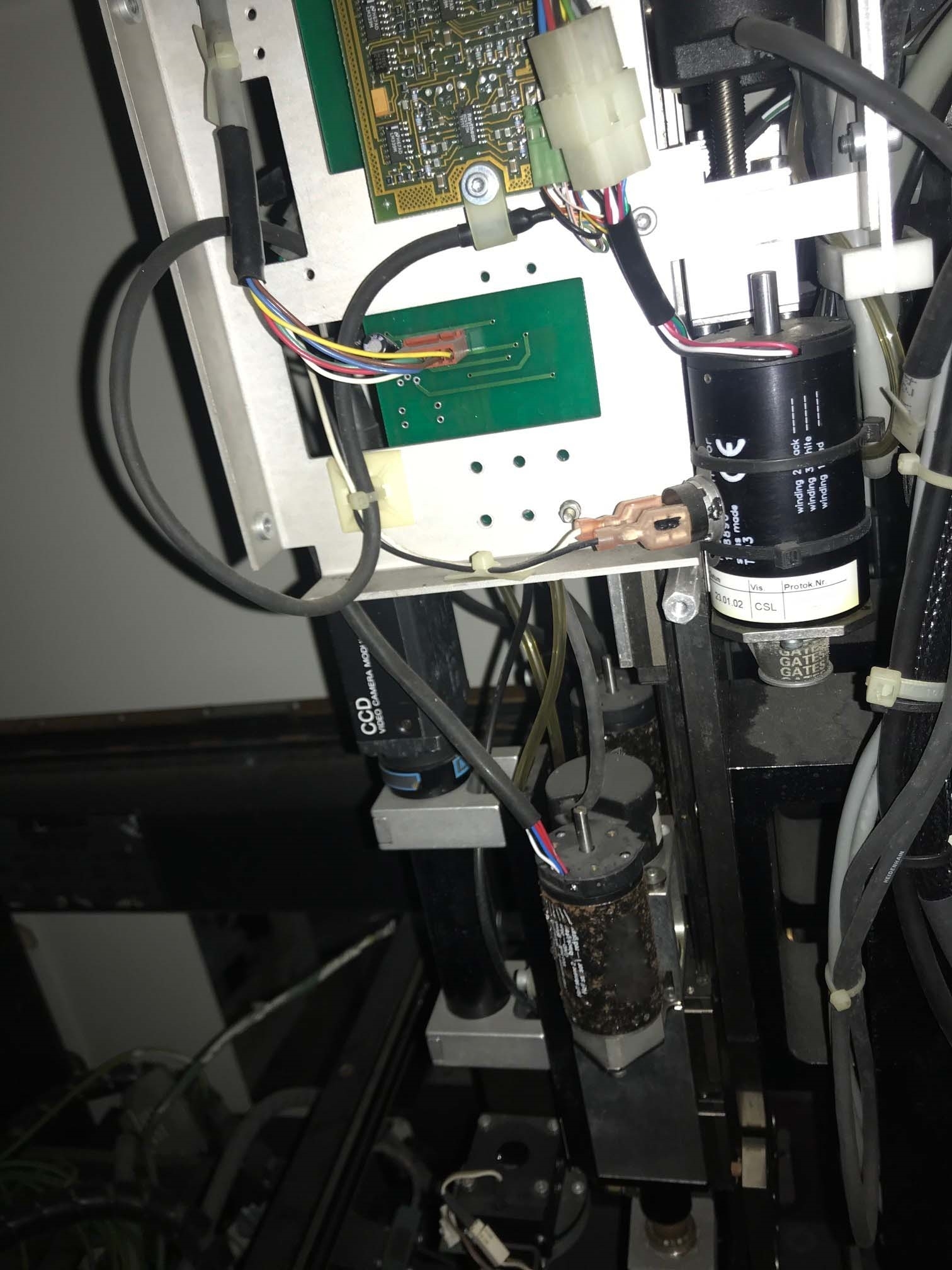

ESEC / ZEVATECH CT2000 is a highly efficient and accurate automatic die attacher for fast and reliable die bonding. This equipment is designed for rapid and efficient assembly of chips, packages and components. It utilizes an advanced, high-speed die-handling system to accurately place and secure die to components, providing high throughput rates and superior accuracy. The unit features an intuitive user interface and requires little operator input, making it user friendly and ideal for fast production needs. Multiple die head designs are available, allowing it to accommodate various types of components and packages. The machine is capable of mounting a wide variety of devices, including leaded and leadless chip carriers, cavity packages, and flat-pack components. The tool is designed for maximum flexibility. A wide range of loaders, tapers, and drivers are available to meet specific production needs. The taper can be adjusted to fit most any size of die, while a lead pitch adjustment makes it possible to adjust the die position relative to the component. The driver is adjustable for fast and secure die attachment, making it easy to meet tight production deadlines. The asset features a highly reliable and accurate precision laser vision model, which is used to precisely position the die and components. The equipment is also highly configurable, allowing the user to customize settings, such as cycle times, die pitch, and die diameter, as needed. The system is fully automated, eliminating the need for manual intervention and labor. An optional remote-controlled interface allows the unit to be monitored and controlled from a remote location. Additionally, the machine can be monitored and adjusted from a computer via RS-232 or Ethernet connection. The tool also features both safety and process monitoring controls for reliable operation. ESEC CT2000 is designed for high-volume production environments and is capable of providing consistent and reliable die bonding performance. It is an ideal die boding asset for assembly lines with tight production requirements, making it an essential piece of equipment for modern production activities.

There are no reviews yet