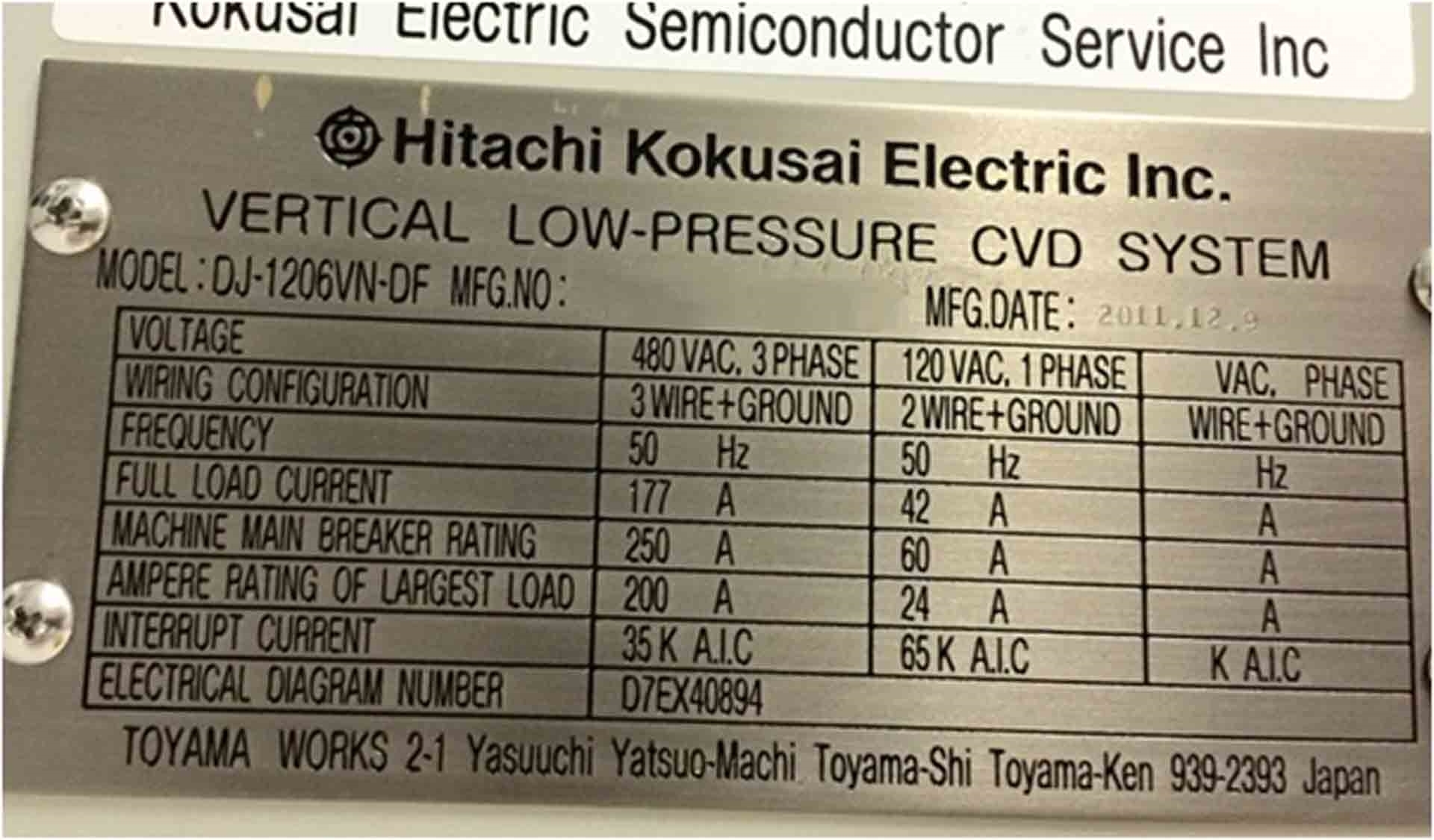

Used HITACHI / KOKUSAI DJ-1206VN-DF #9241673 for sale

URL successfully copied!

Tap to zoom

ID: 9241673

Vintage: 2011

Diffusion furnace

Process: Poly_DS

System configuration:

Furnace unit:

(5) T/C Heater controls

(5) T/C for over temperature protections

5-P T/C for cascade controls

Cartridge heater

Controller:

(2) Gas flow pattern panels

(2) Temperature controllers

Main controller (OU)

Main operation unit

Sub operation unit

Process module controller

MFC / Pressure unit

FOUP Loader controller unit

Wafer handling controller unit

Valve / Interlock control unit

Switching unit

Signal tower (Front)

Drive mechanisms:

(2) Wafer detections

I/O Shutter

AGV/PGV/OHT Stage

FOUP Loader

Rotation FOUP storage

Foup opener

Wafer transfer

Variable wafer pitch converter

Boat elevator

Boat changer

Furnace port shutter

Boat rotation

Gas system:

Gas unit (IGS)

Exhaust system:

(3) Valve heaters

Dry pump & mechanical booster pump

Pressure sensor (1000 Torr)

Pressure sensor (10 Torr)

Pirani sensor

Main valve

Exhaust piping

Exhaust dilution line

Reactor tube press leak line

Jacket heater pipe exhaust pipe

Tape heater for exhaust pipe

Inlet heater

Safety: Light curtain system

Other:

(2) OHT I/F Units

(2) Chemical filters

Gateway-HSMS

RF ID Reader

N2 Purge load lock system:

O2 Monitor / Detector

FOUP Opener N2 purge system

Loading area N2 flow control MFC

Loading area N2 purge line

FOUP Opener N2 purge line

Power supply: 120 VAC, 1 Phase

2011 vintage.

HITACHI / KOKUSAI DJ-1206VN-DF is a diffusion furnace and accessory equipment used for the production of heat treated metal parts. This system is designed to provide accurate, repeatable and high-quality results in the diffusion coating process. The furnace uses a vertical-tilting design to provide an efficient, cost effective, and space-saving solution for heat treating. Designed for use in a variety of production environments, the unit boasts a heated chamber with a diameter of 50 cm and a length of 200 cm. This chamber can hold up to 6 parts at one time, with a load capacity of 480 kg in total. This machine is also able to provide a wide range of temperatures from 850°C to 1150°C. The tool is highly energy efficient due to its use of insulated ceramic fiber bricks, with an ultra-low-leakage design and a 40mm-thick door to maximize efficiency. The accessory package that comes with the asset is designed to provide a safe and efficient working environment when composing parts. It includes floor-mounted support stands for the diffusion furnace, an exhaust hood, a temperature controller unit, protective clothing, and several other accessories. Each component is engineered to provide an efficient and precise working environment. The control model for the diffusion furnace is designed to be easy to use. The onboard k-type thermocouple is capable of accurately monitoring temperature profiles, while a time-programmed digital controller is used to set all the parameters required for a successful diffusion coating. In addition to providing a safe and efficient working environment, HITACHI DJ-1206VN-DF also meets all of the safety standards required by ISO 9001. All of the components within the equipment have been certified to be of the highest quality and will stand up to repeated cycles of use. KOKUSAI DJ-1206VN DF is a powerful diffusion furnace and accessory package designed to provide an efficient, cost effective, and safe way of producing quality heat treated parts. With its efficient design, easy-to-use control system, and certified high-quality components, this unit is sure to provide reliable results for any production environment.

There are no reviews yet