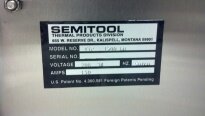

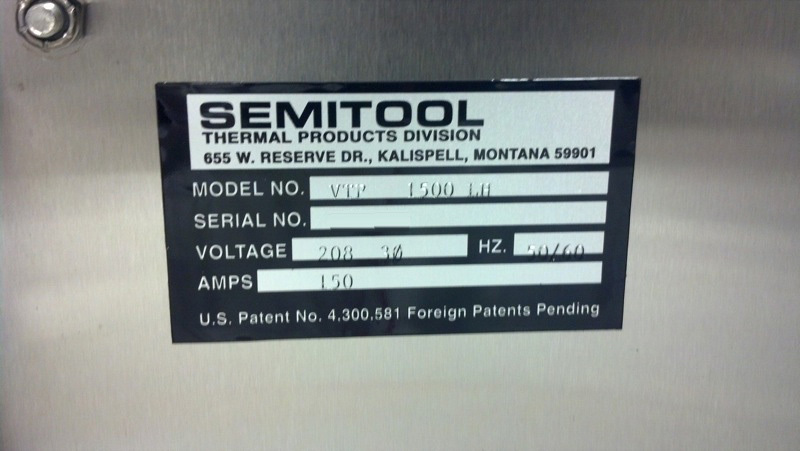

Used SEMITHERM / SEMITOOL VTP 1500 LH #9025672 for sale

URL successfully copied!

Tap to zoom

ID: 9025672

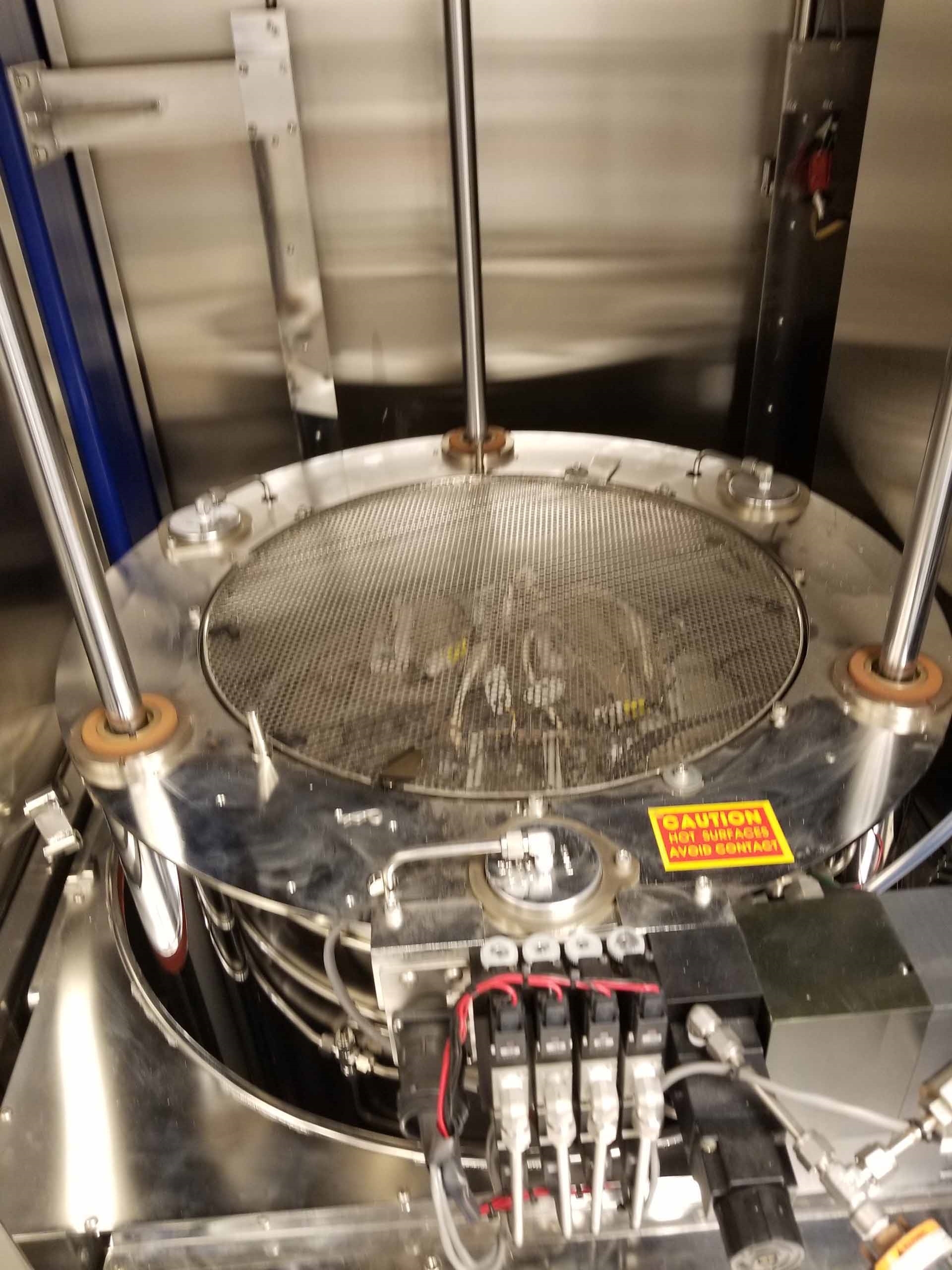

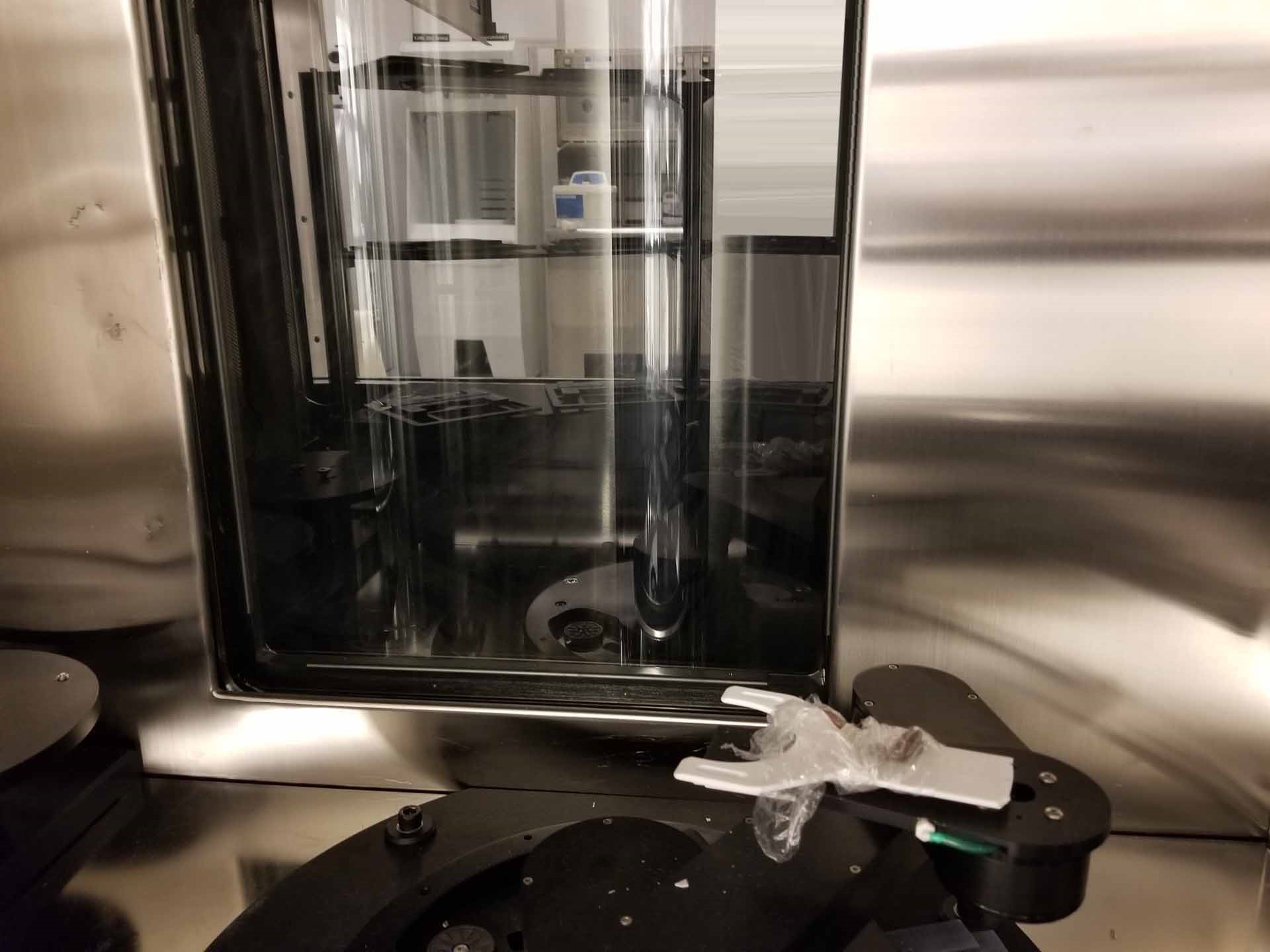

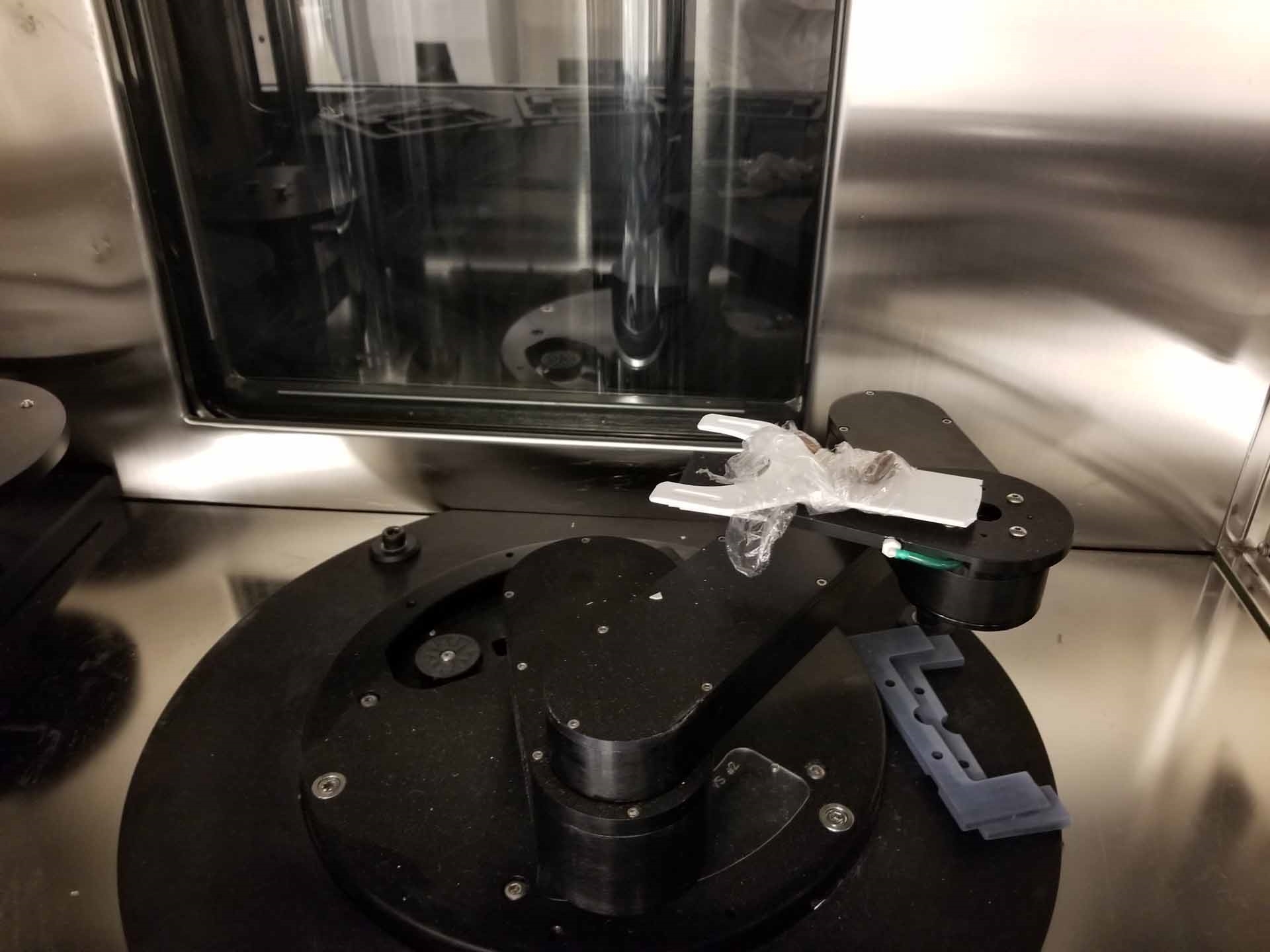

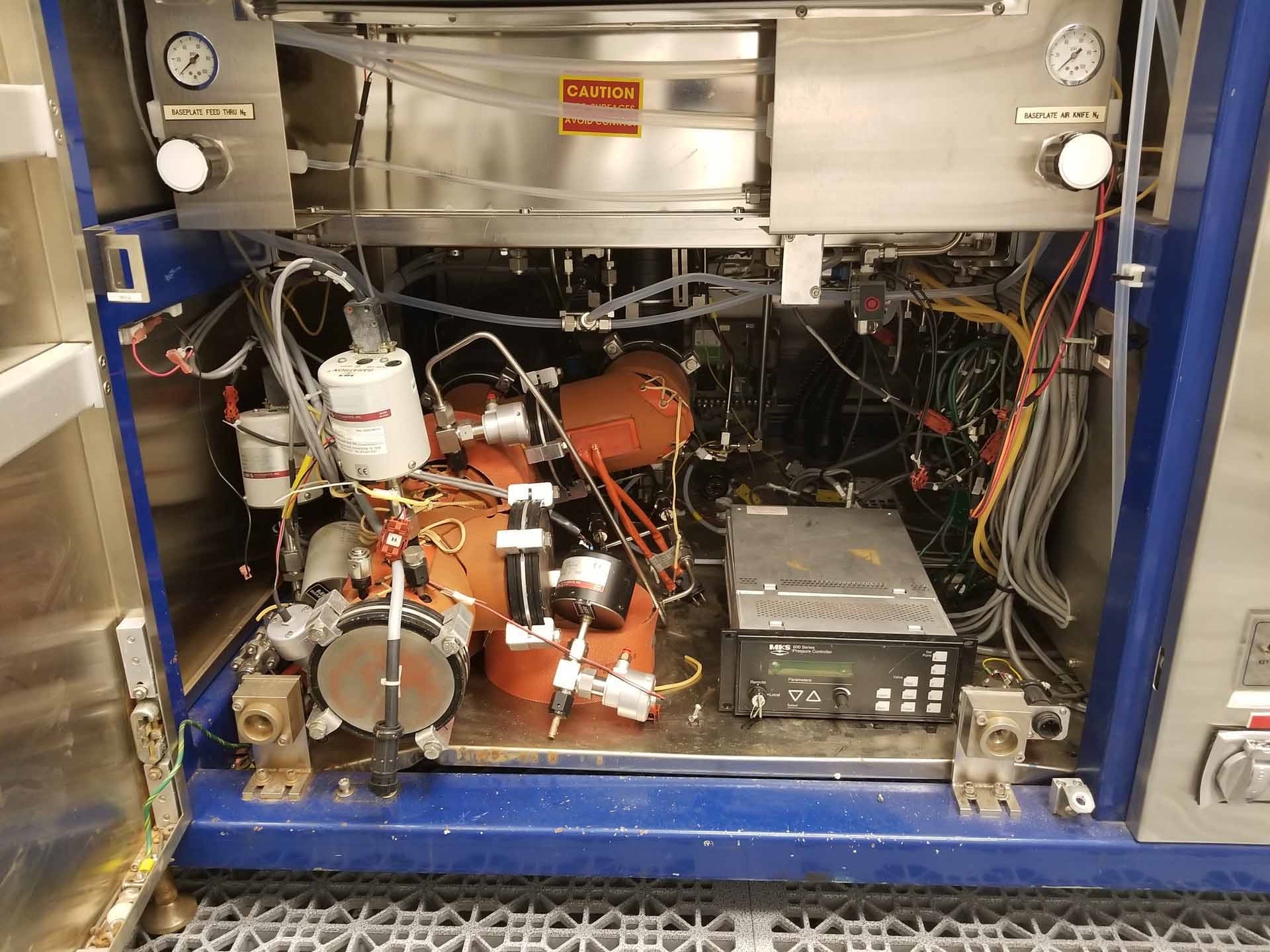

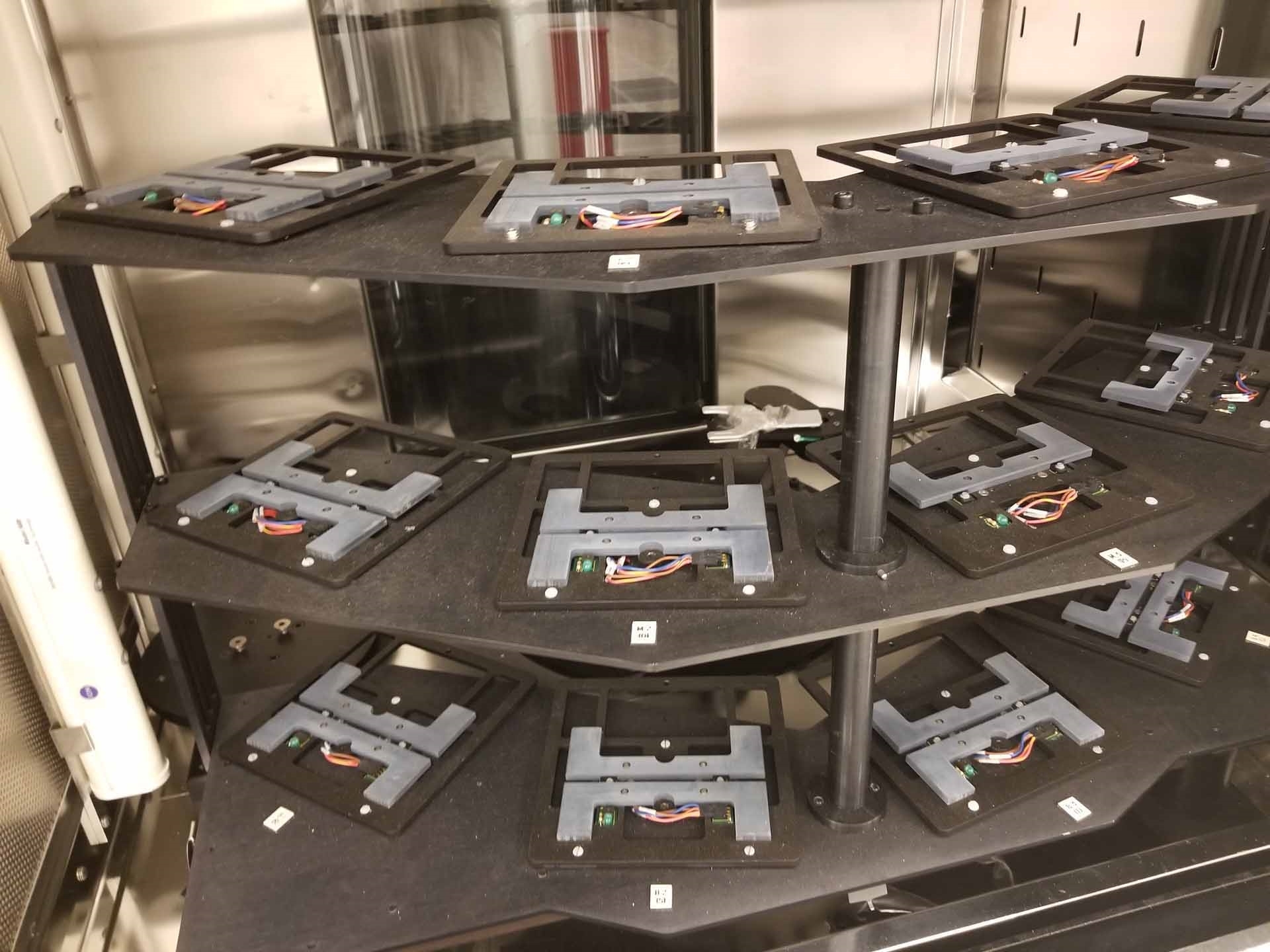

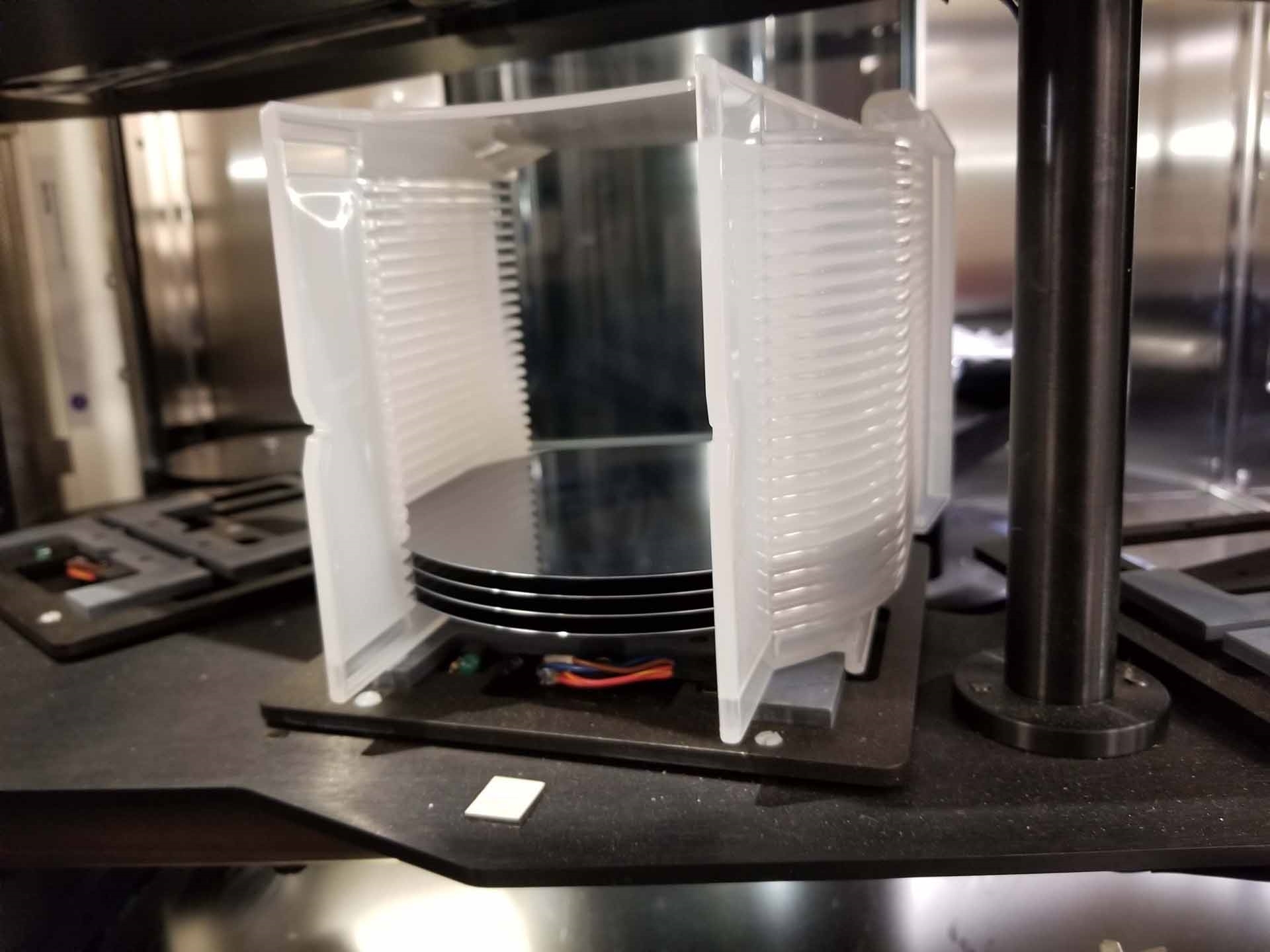

LPCVD Reactor furnace

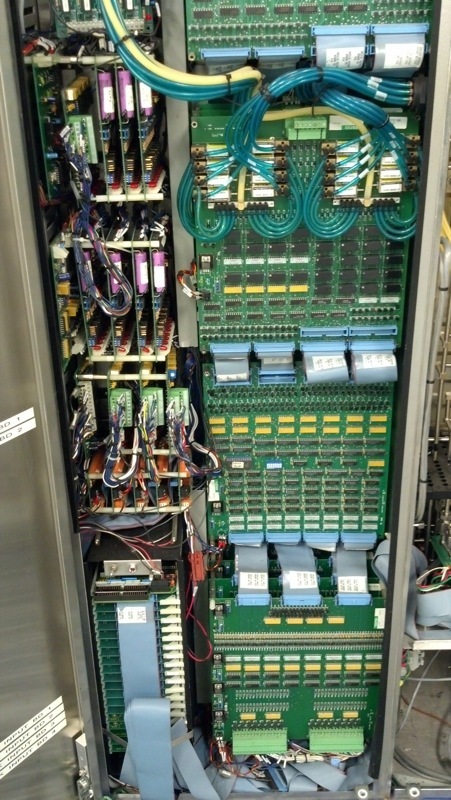

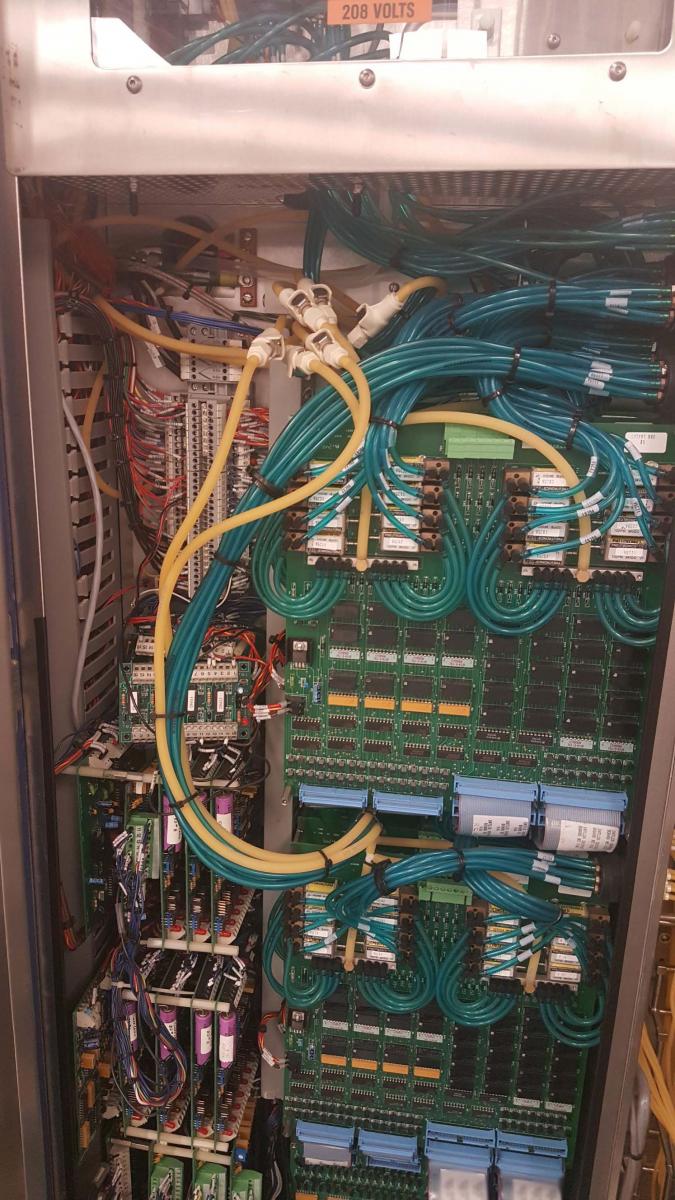

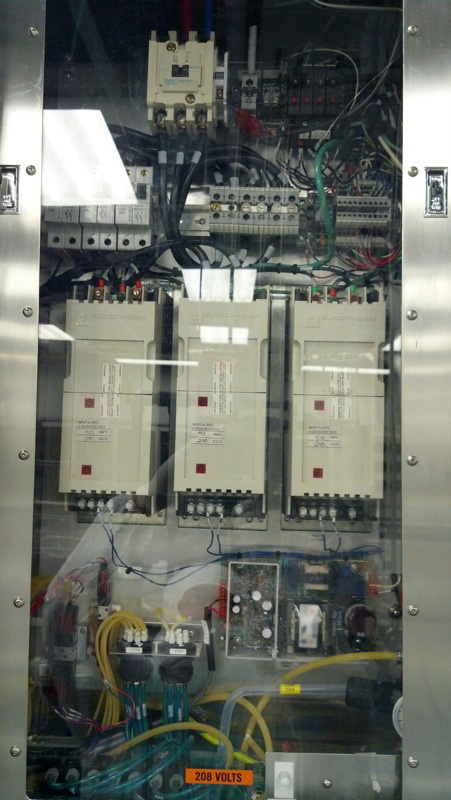

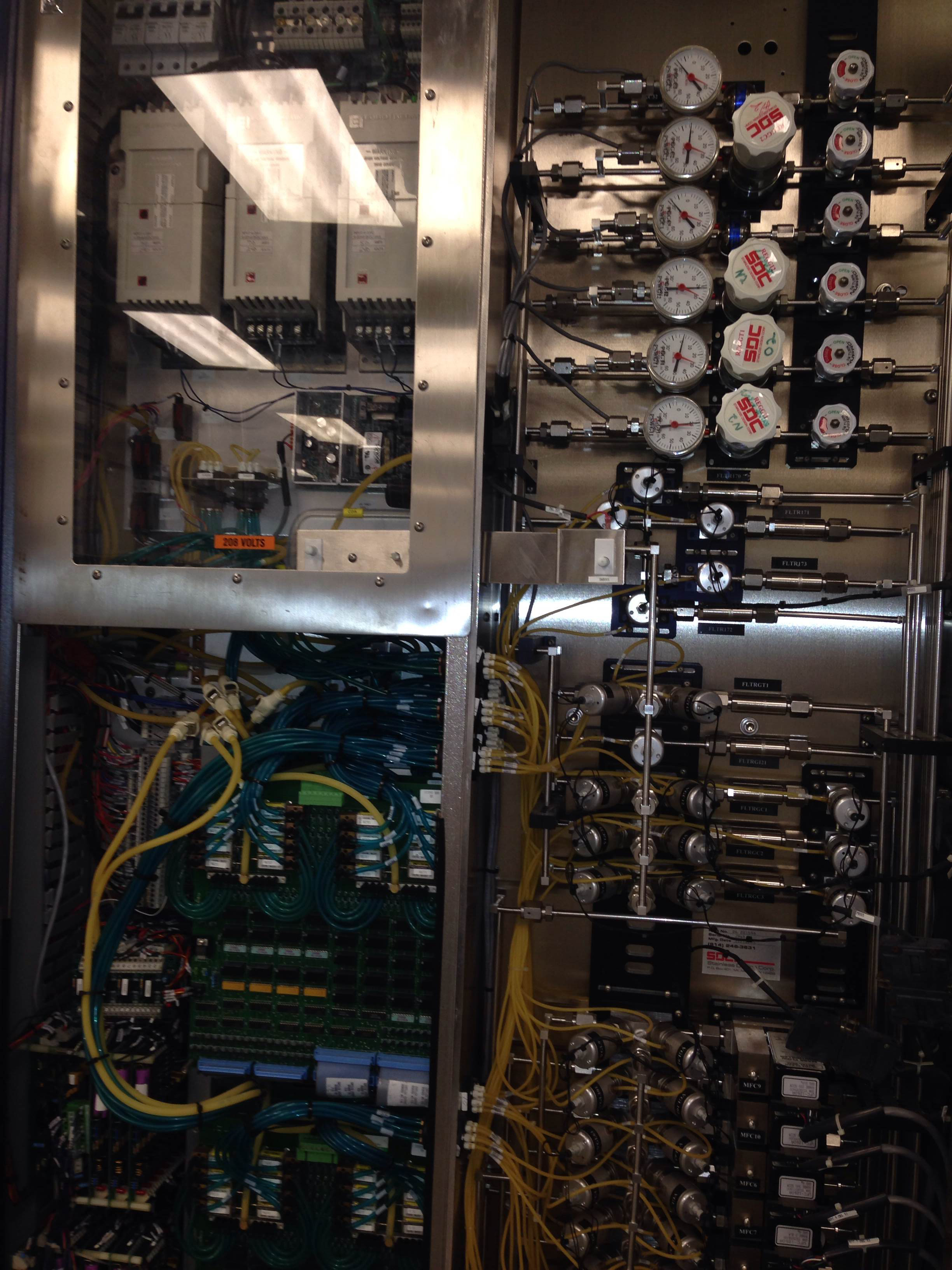

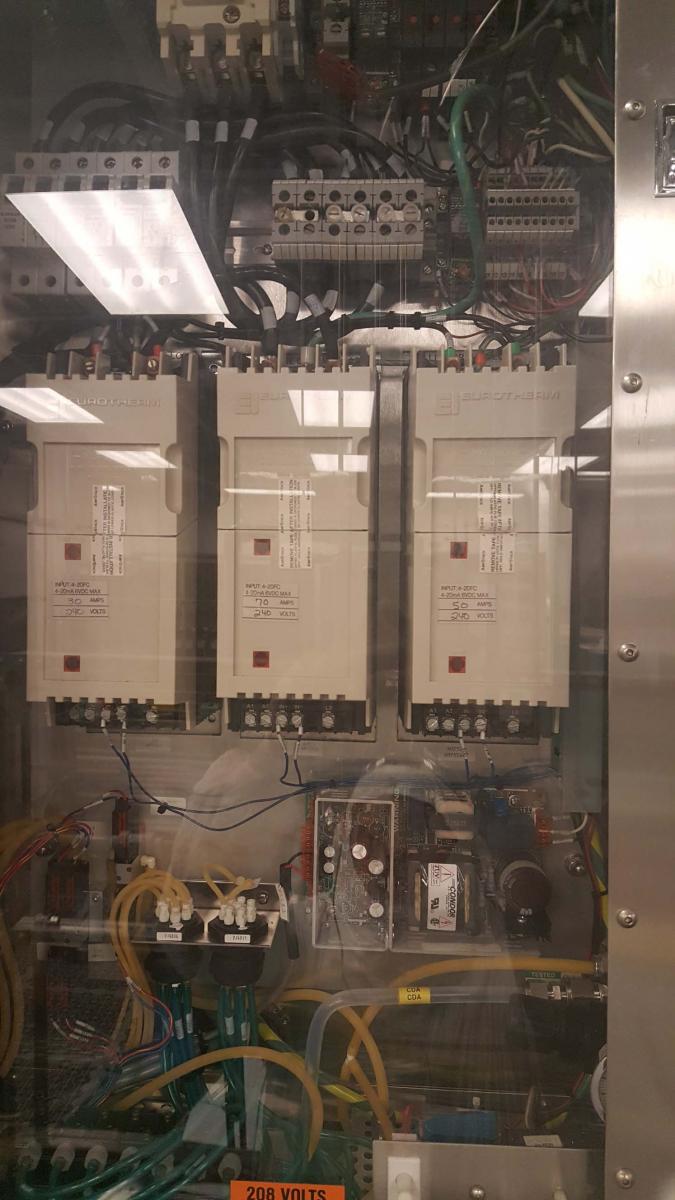

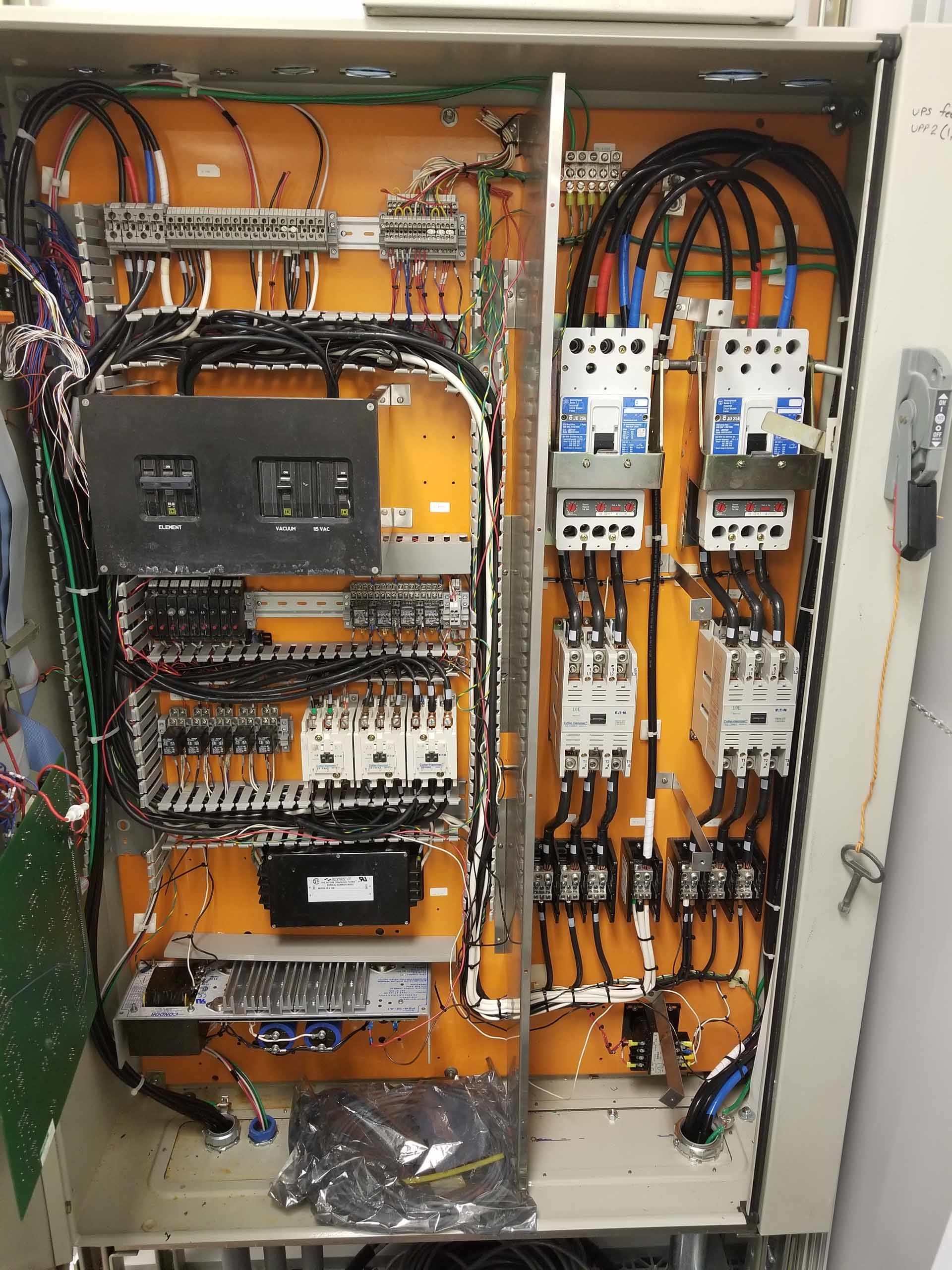

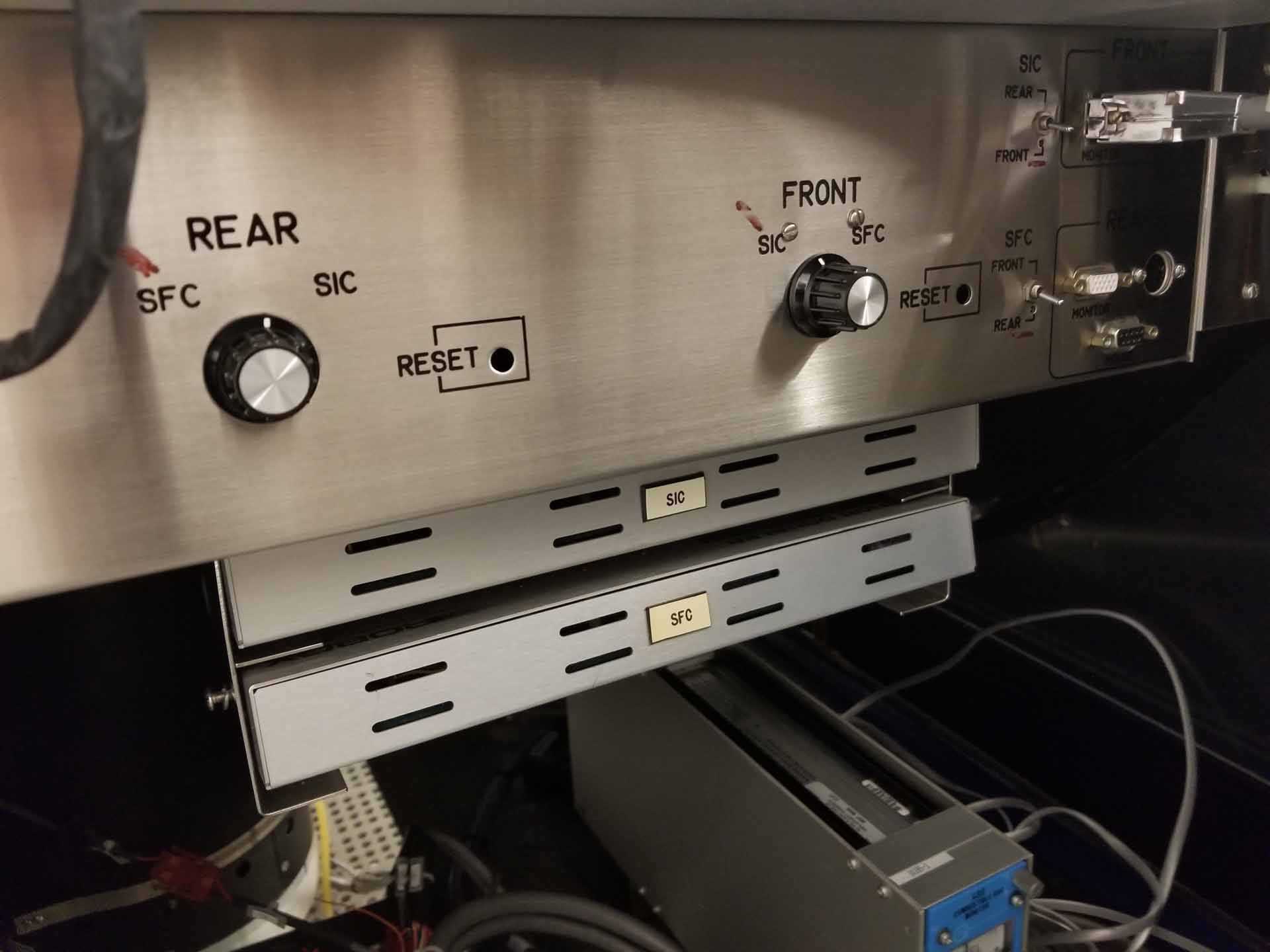

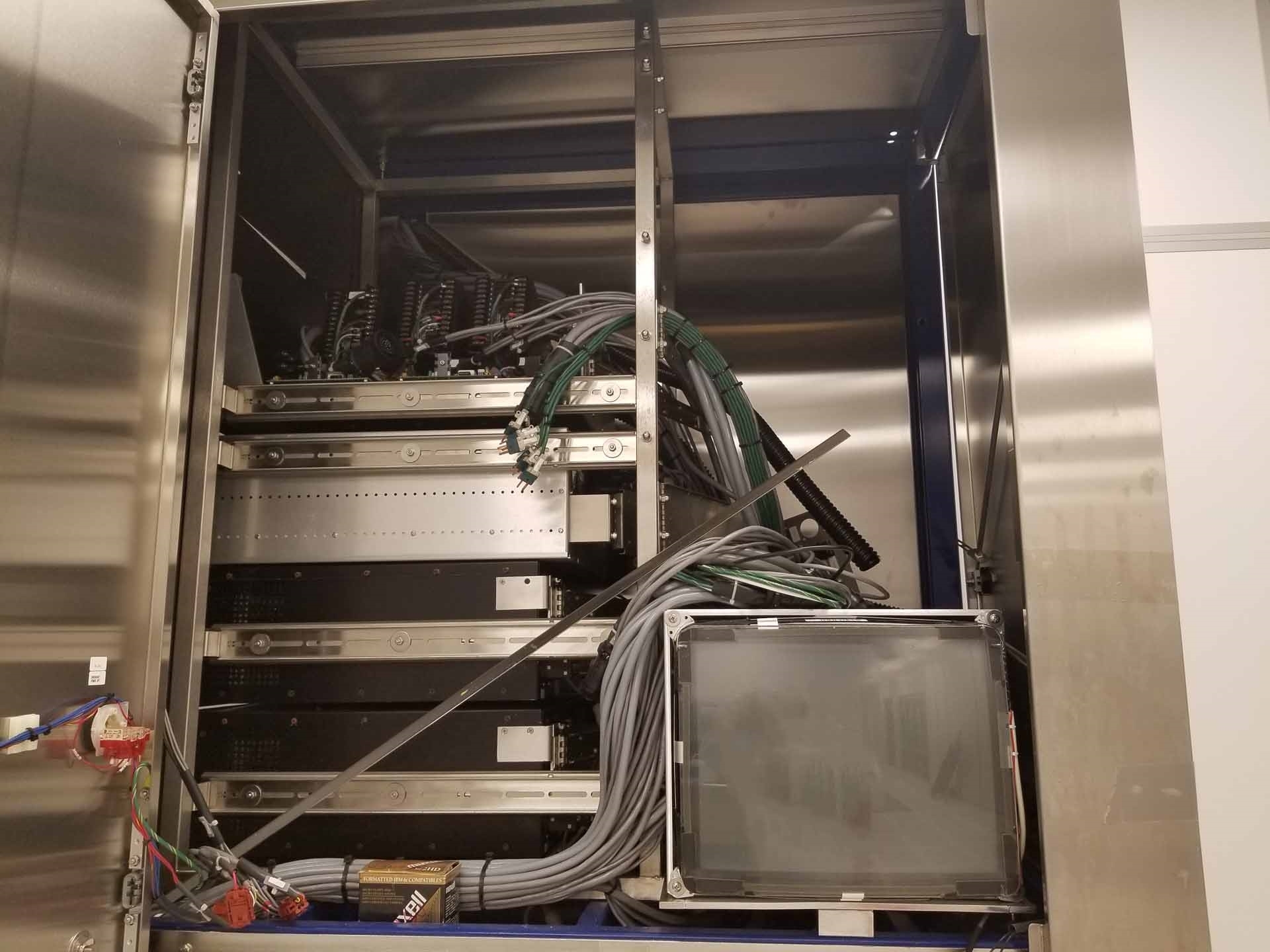

Control unit

Manual

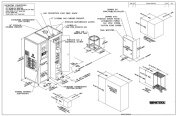

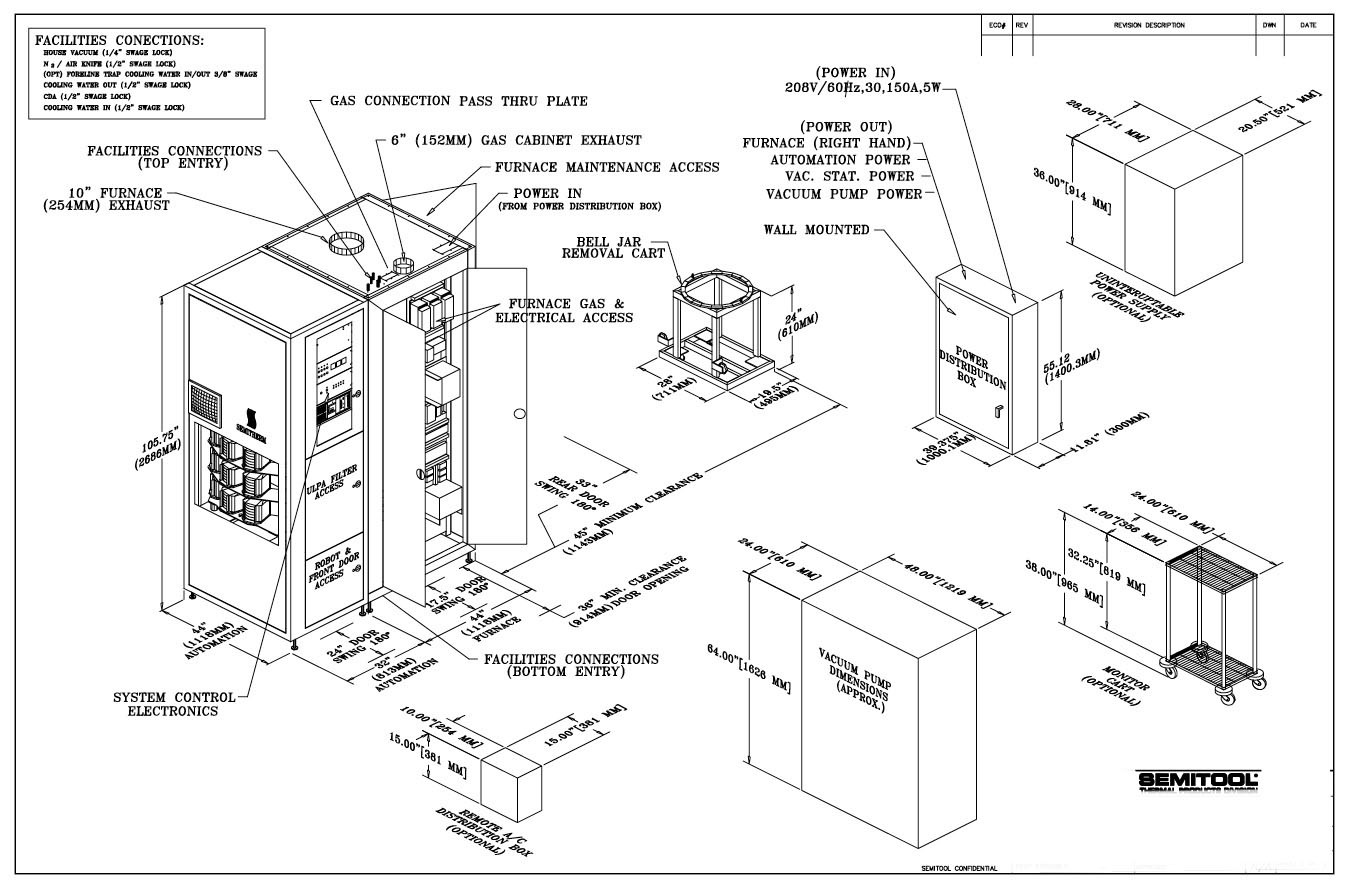

Facility requirements:

Furnace: 150 Amps

Vacuum pump: 150 Amps

Nominal voltage: +/- 15%

Nominal frequency: +/- 5%

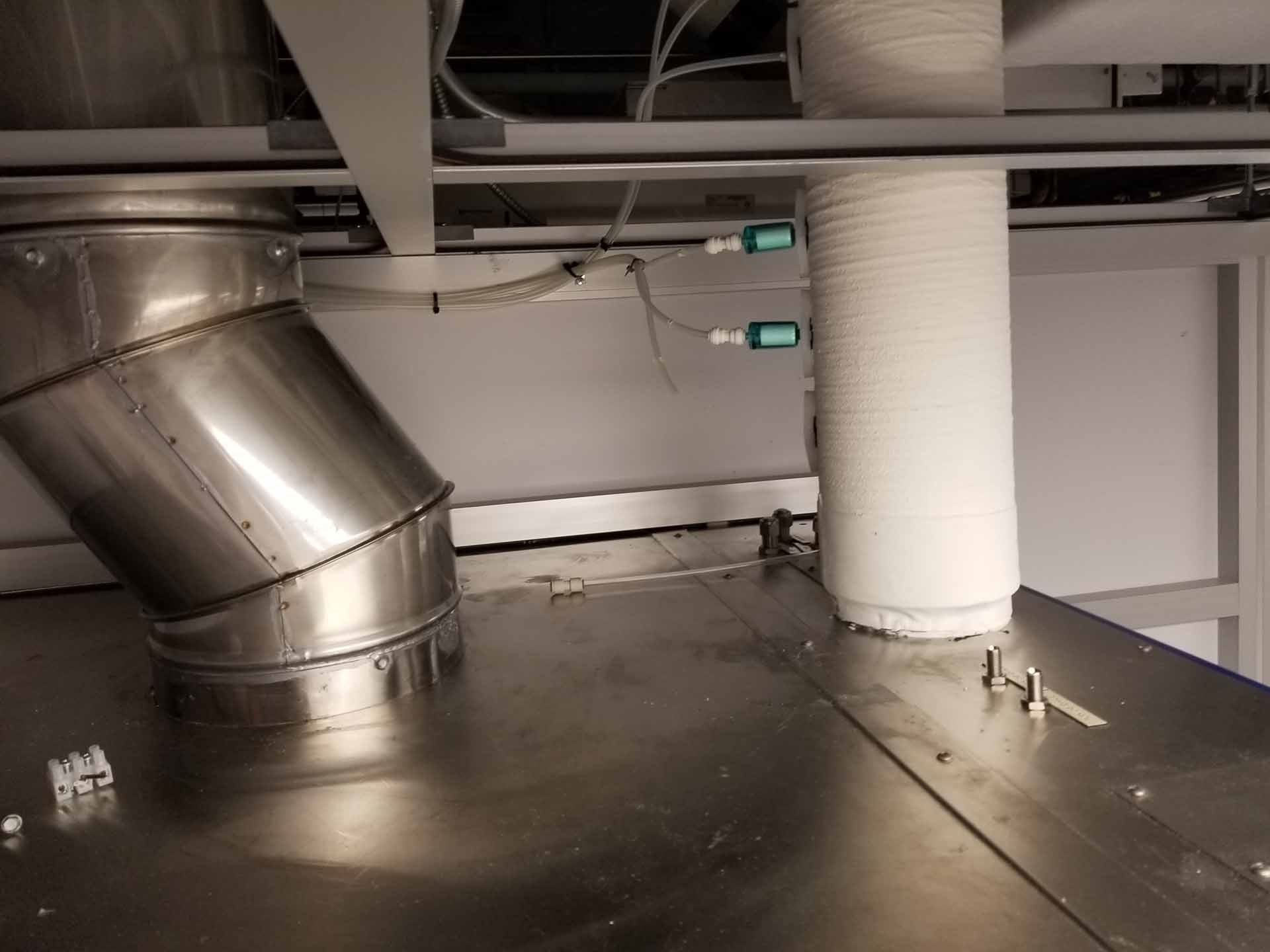

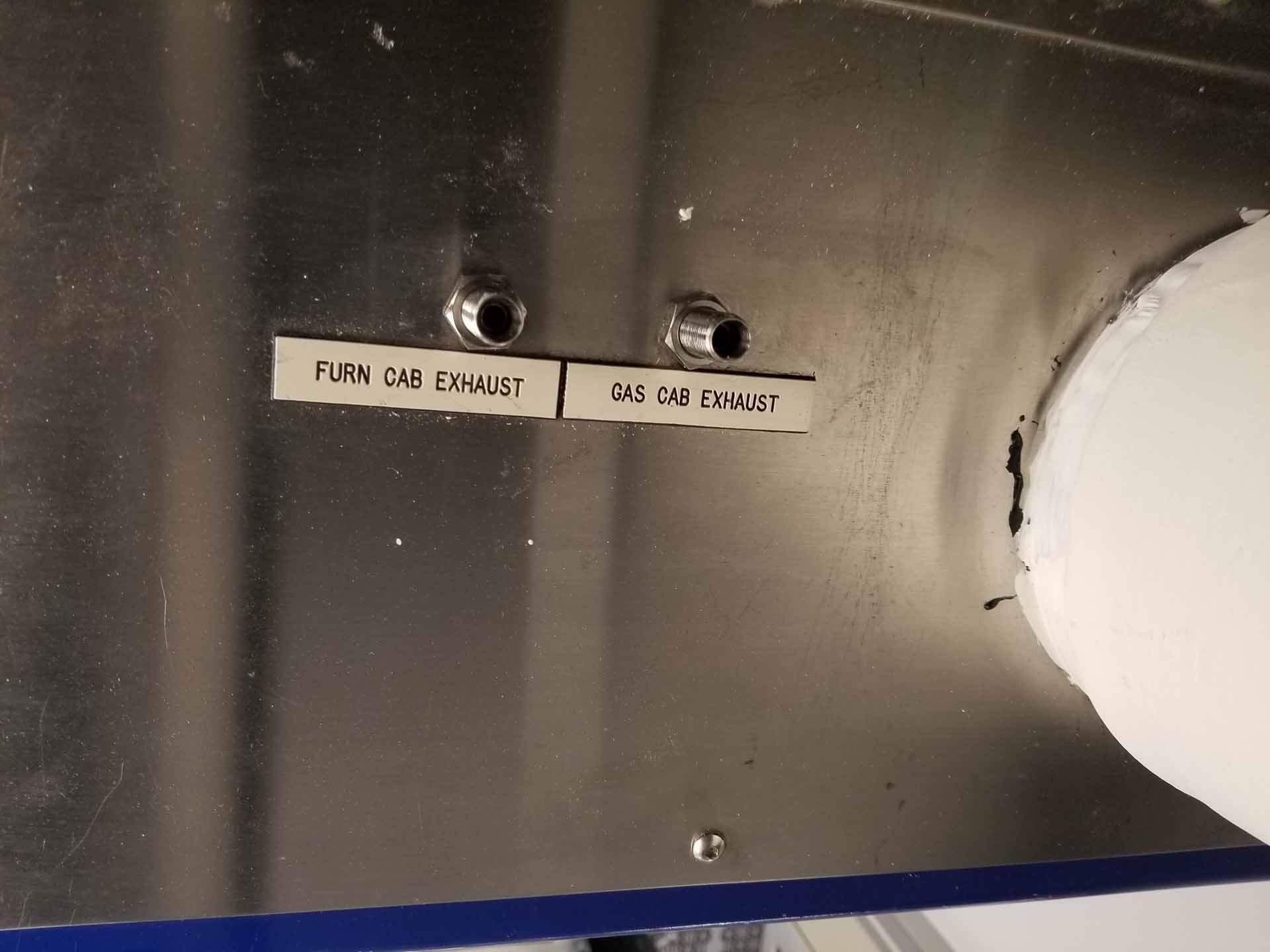

Exhaust:

Furnace cabinet exhaust: 10" Duct

Minimum pressure: (-.5 in) at 900 CFM

Gas cabinet: 6" Duct

Minimum pressure: (-.5 in.) at 250 CFM

Process chamber:

1/2" Swagelock:

Minimum pressure: (-.5 in.) at < 1 CFM

3/4" Swagelock

Minimum pressure: (-.5 in.) at 5 CFM

Vacuum:

Wafer handling: 1/4" Swagelock - 24" HG static

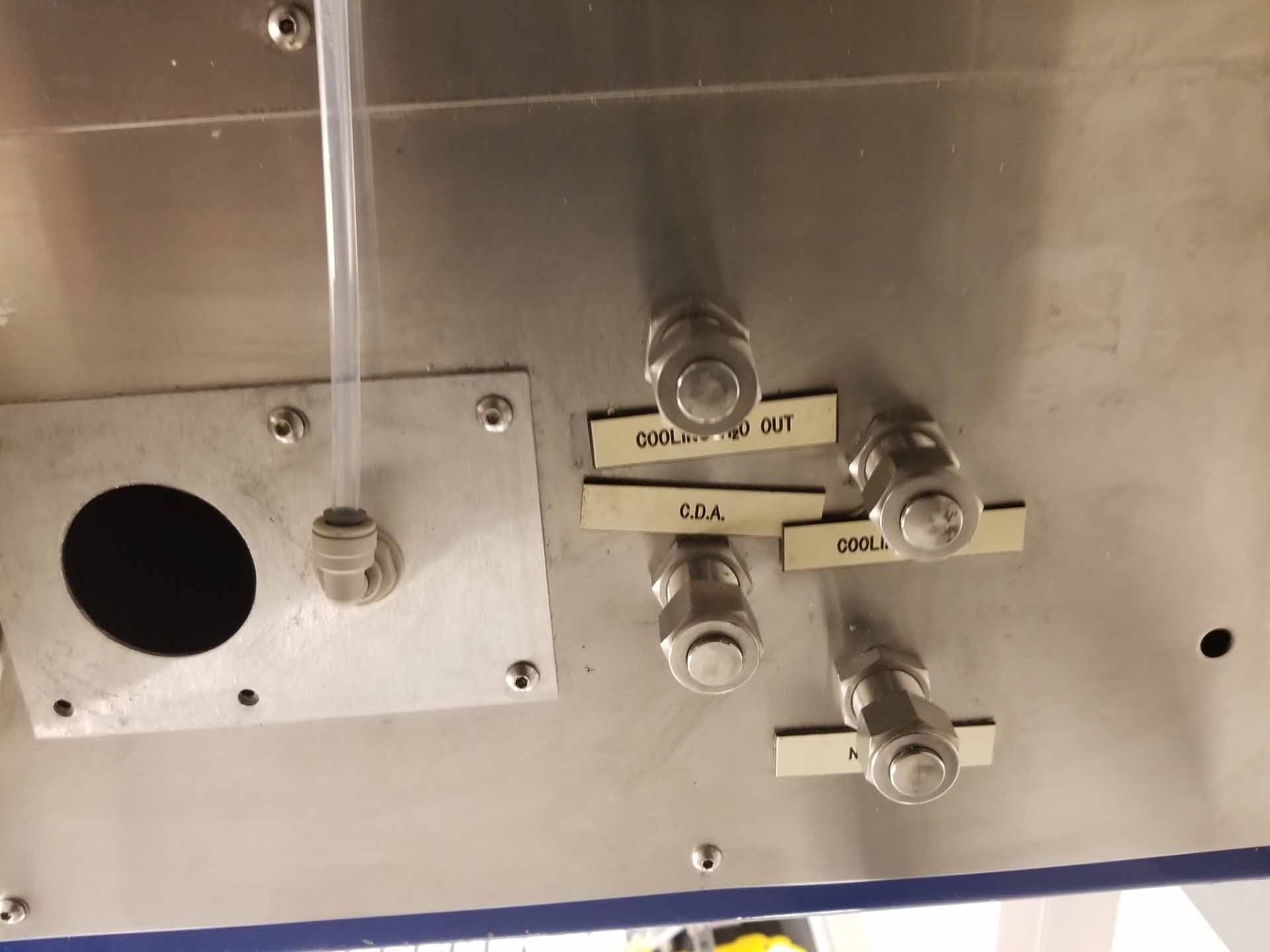

Cooling water:

Cannister and baseplate:

1/2" Swagelock - 2 GPM at 20 psi inlet to outlet differential pressure

Maximum differential pressure: 40 PSI

Maximum inlet pressure:100 PSI

Swagelock return line, 1/2"

Drains:

Acid drain (Optional on wet ox)

Teflon tubing: 1/2"

Clean dry compressed air:

1/2" Swagelock - 80 PSI Minimum

5 CFM: Typical

20 CFM: Peak (100 PSI Max)

5 CFM Used for pneumatic control

15 CFM Used for element / Jar movement

Nitrogen - non process:

1/2" Swagelock - 80 PSI Minimum

5 CFM: Typical

30 CFM: Peak (100 PSI Max)

5 CFM: Baseplate (Used at high temp only)

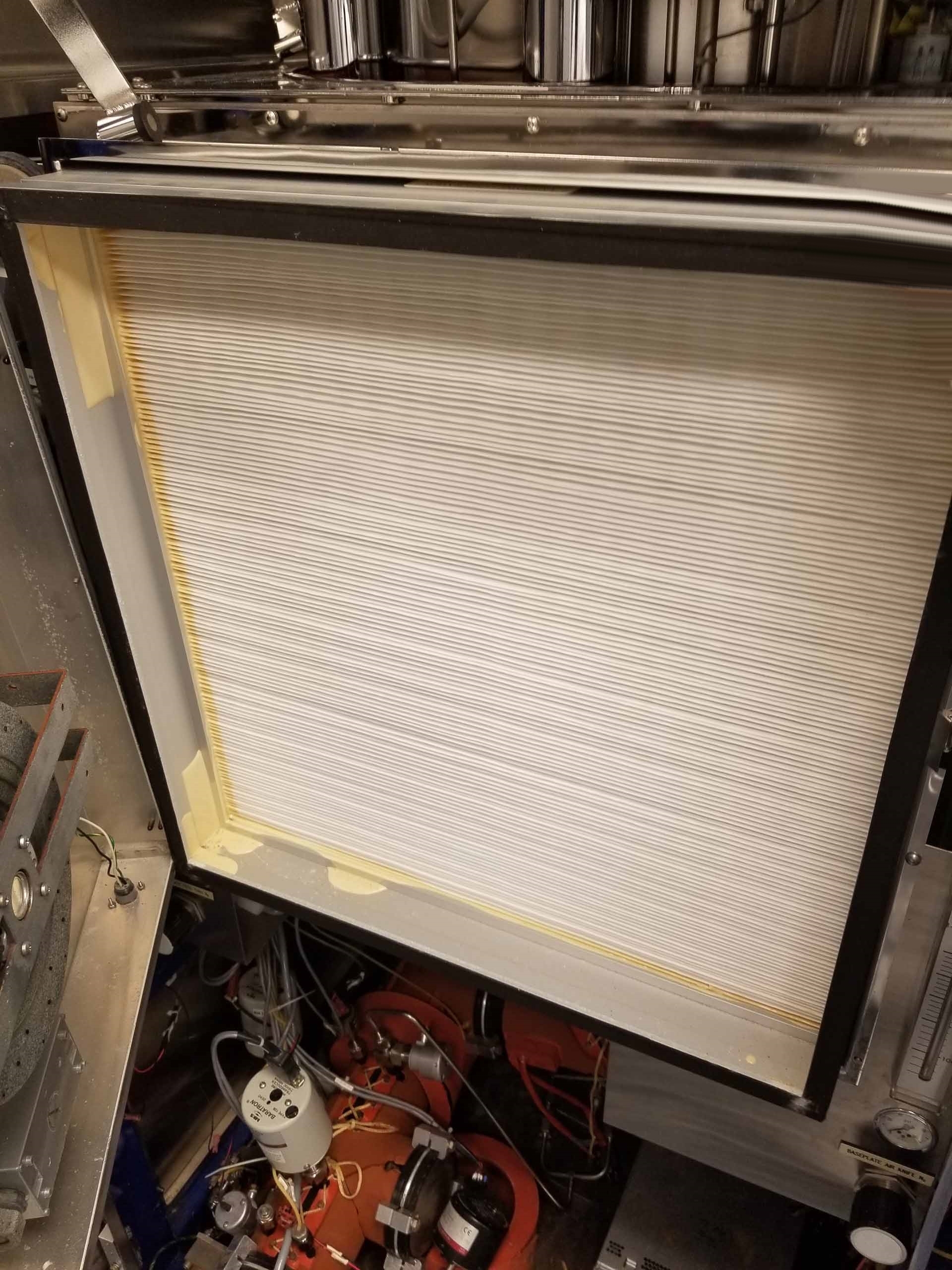

25 CFM: Furnace filter (Used only when filter or fan fails)

30 CFM: Non-process nitrogen

Power supply: 208 V, 3-Phase, 60/60 Hz, 150 A.

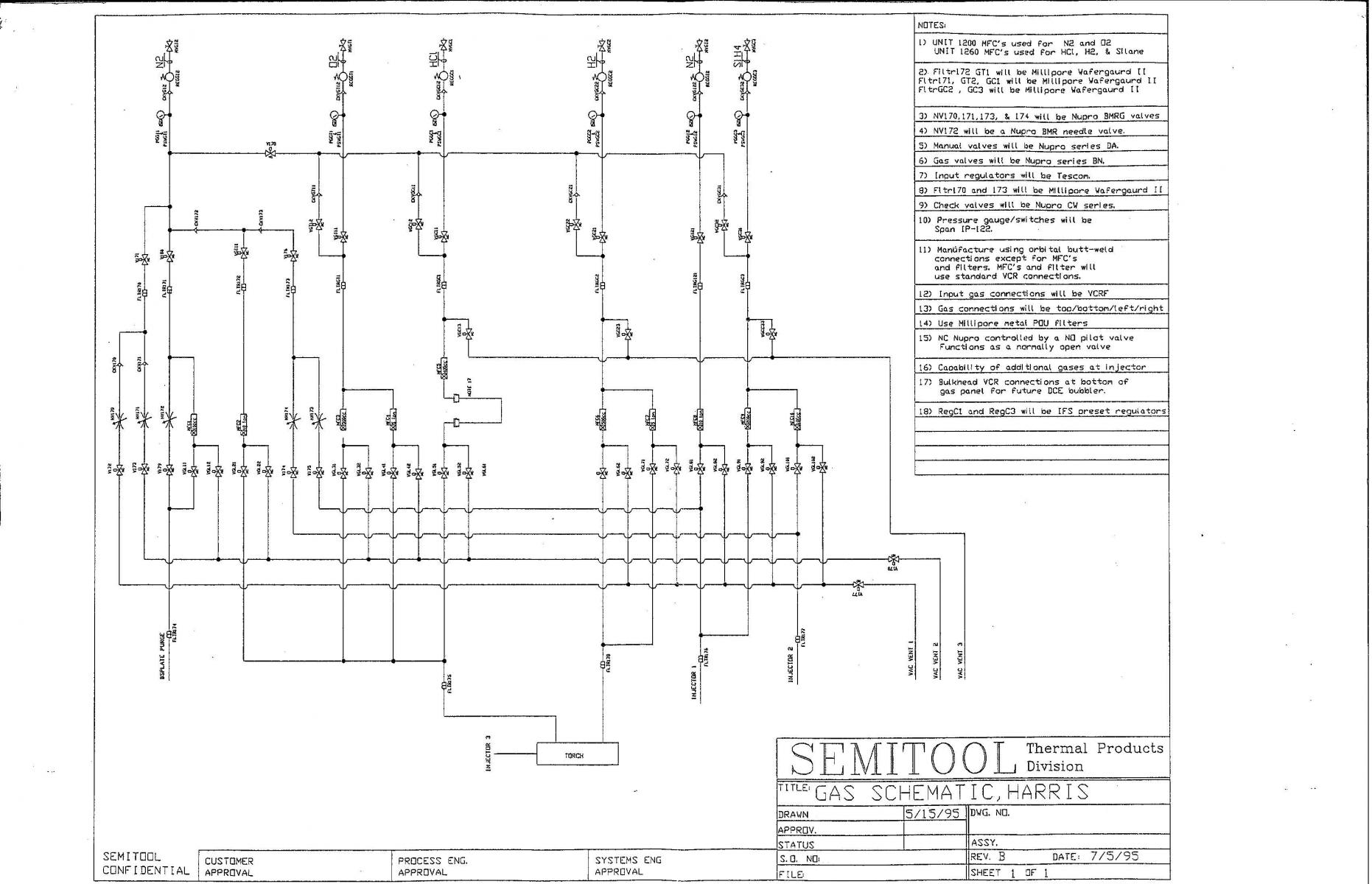

SEMITHERM / SEMITOOL VTP 1500 LH is a diffusion furnace that is equipped with a low-hearth design for smaller parts and a large hearth design for larger parts. It is ideal for mass production of semiconductor wafers. The diffusion furnace is designed with multiple zone temperature control, giving users precise control over their thermal processing. This equipment features integrated temperature sensors that allow for a higher-level of accuracy and reproducibility within each zone. The system also features low-temperature soaking capability and advanced furnace programming, both of which provide optimal furnace control. Additionally, SEMITOOL VTP 1500 LH includes several accessories for improved user convenience. Load manipulation is made easy with the included articulated and manual lift systems, which can be used to quickly and safely move parts within the furnace. A horizontal convection fan helps ensure proper air circulation and uniform heating throughout the furnace. Users also have the option of adding an automated fan-shutter unit, motion-control bell machine, lehr, and other accessories for added precision. This durable and reliable diffusion furnace also offers several safety features, such as a pressure tool, double-walled chamber piping, and heavy-duty door hinges. The asset has a max operating temperature of up to 1400°C, and its heating elements are made of an advanced alloy that can endure extreme temperatures. A modern control panel allows users to precisely manage all of the furnace's settings and operations. Overall, SEMITHERM VTP 1500LH is an advanced diffusion furnace that is perfect for large-scale semiconductor production. Its multiple zone temperature control, integrated temperature sensors, and low-temperature soaking capabilities give users unparalleled accuracy and reproducibility. The model also has several user-friendly features such as the articulated and manual lift systems, automated fan-shutter equipment, lehr, and more. Finally, its high-quality heating elements and safety features make VTP 1500LH a dependable and long-lasting diffusion furnace.

There are no reviews yet