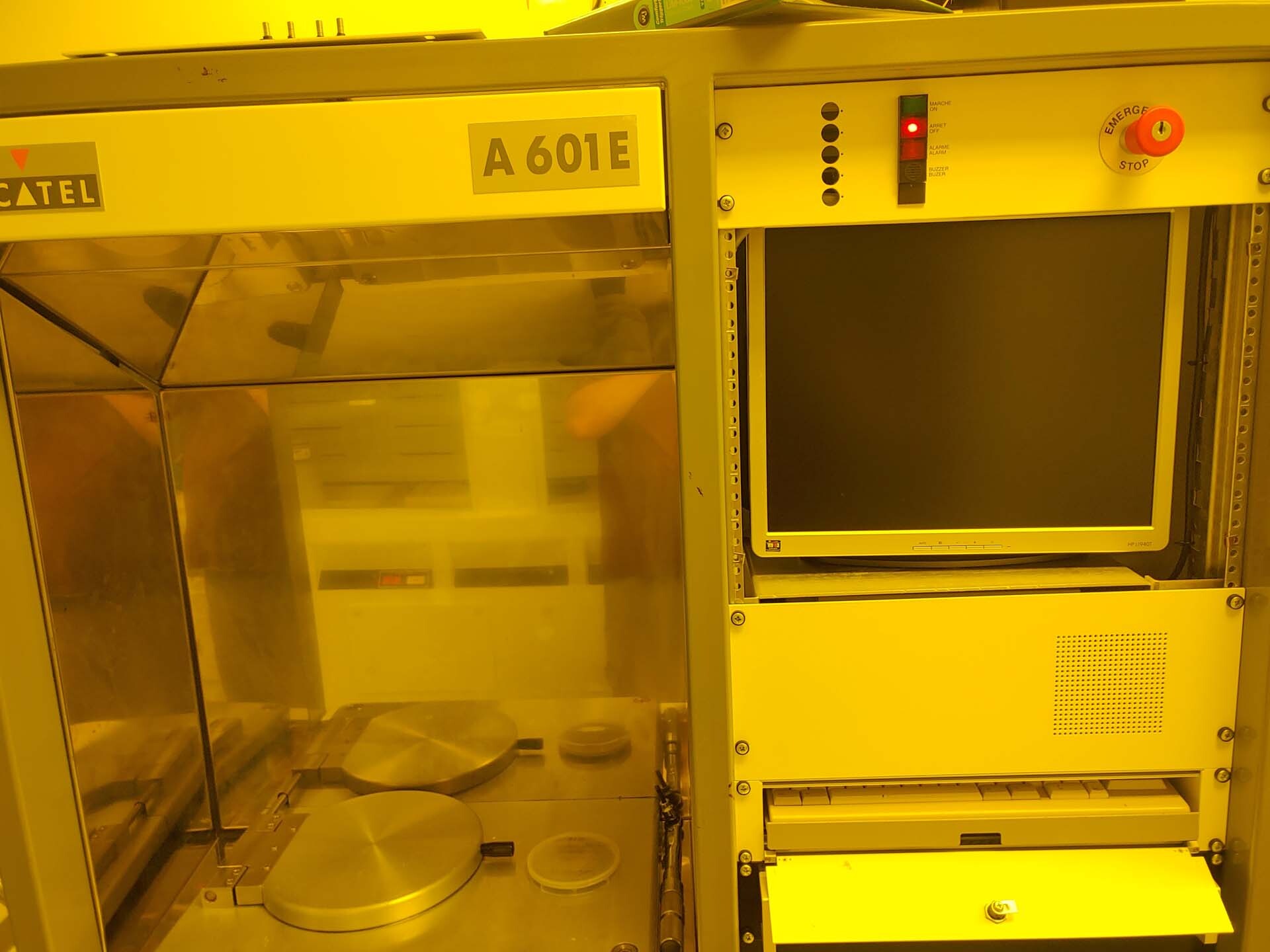

Used ALCATEL / ADIXEN / PFEIFFER A601E #293633801 for sale

URL successfully copied!

Tap to zoom

ID: 293633801

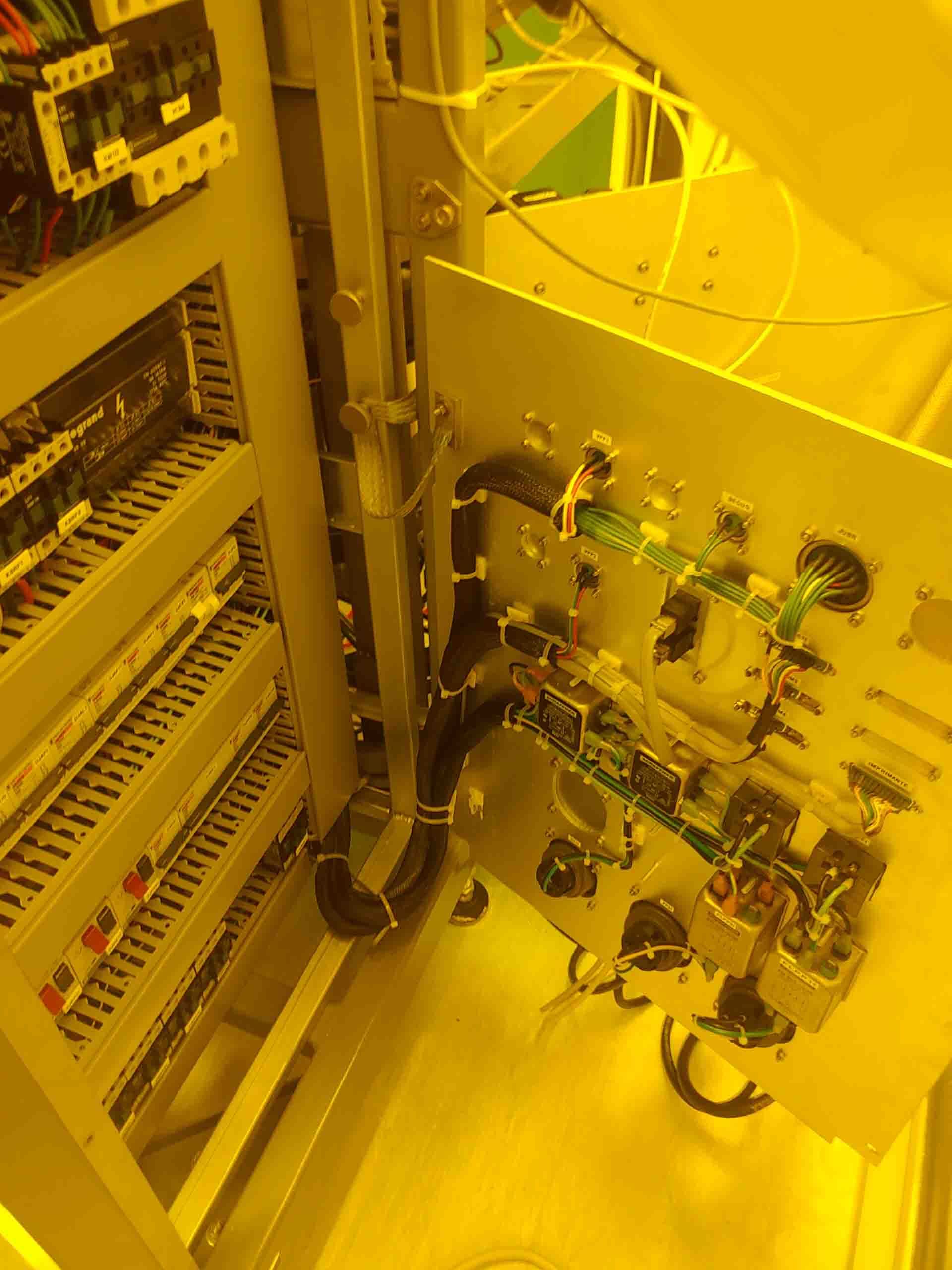

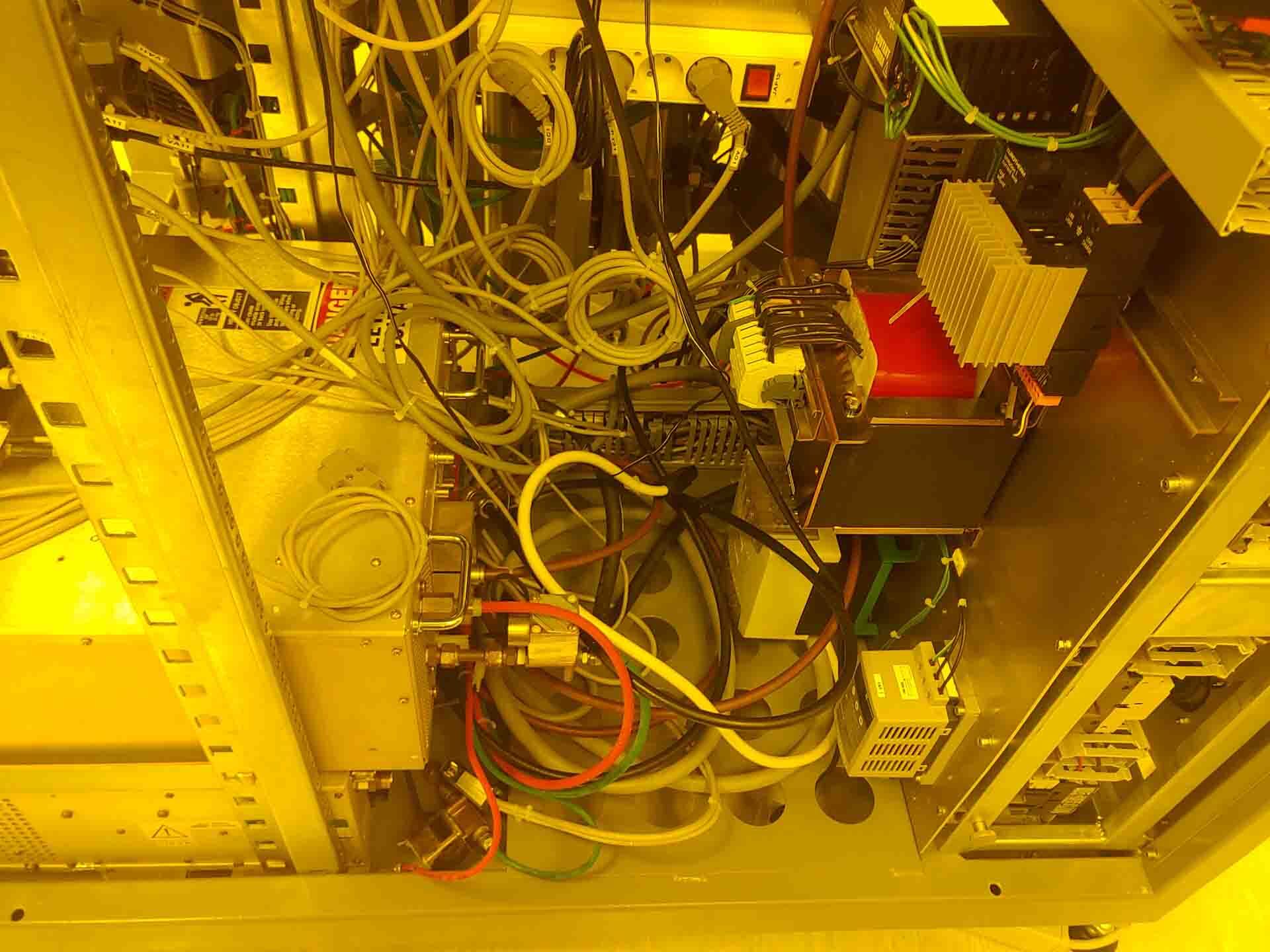

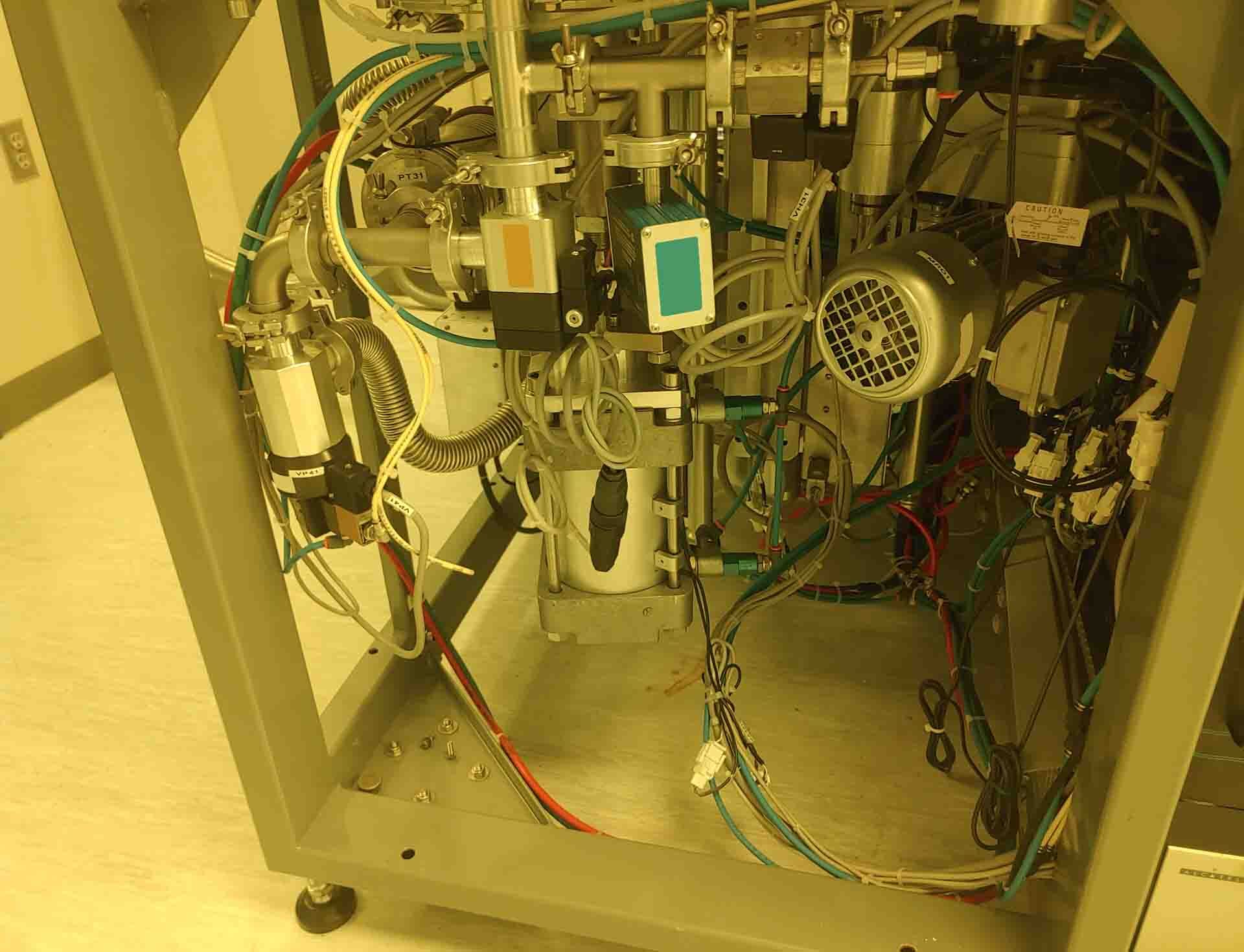

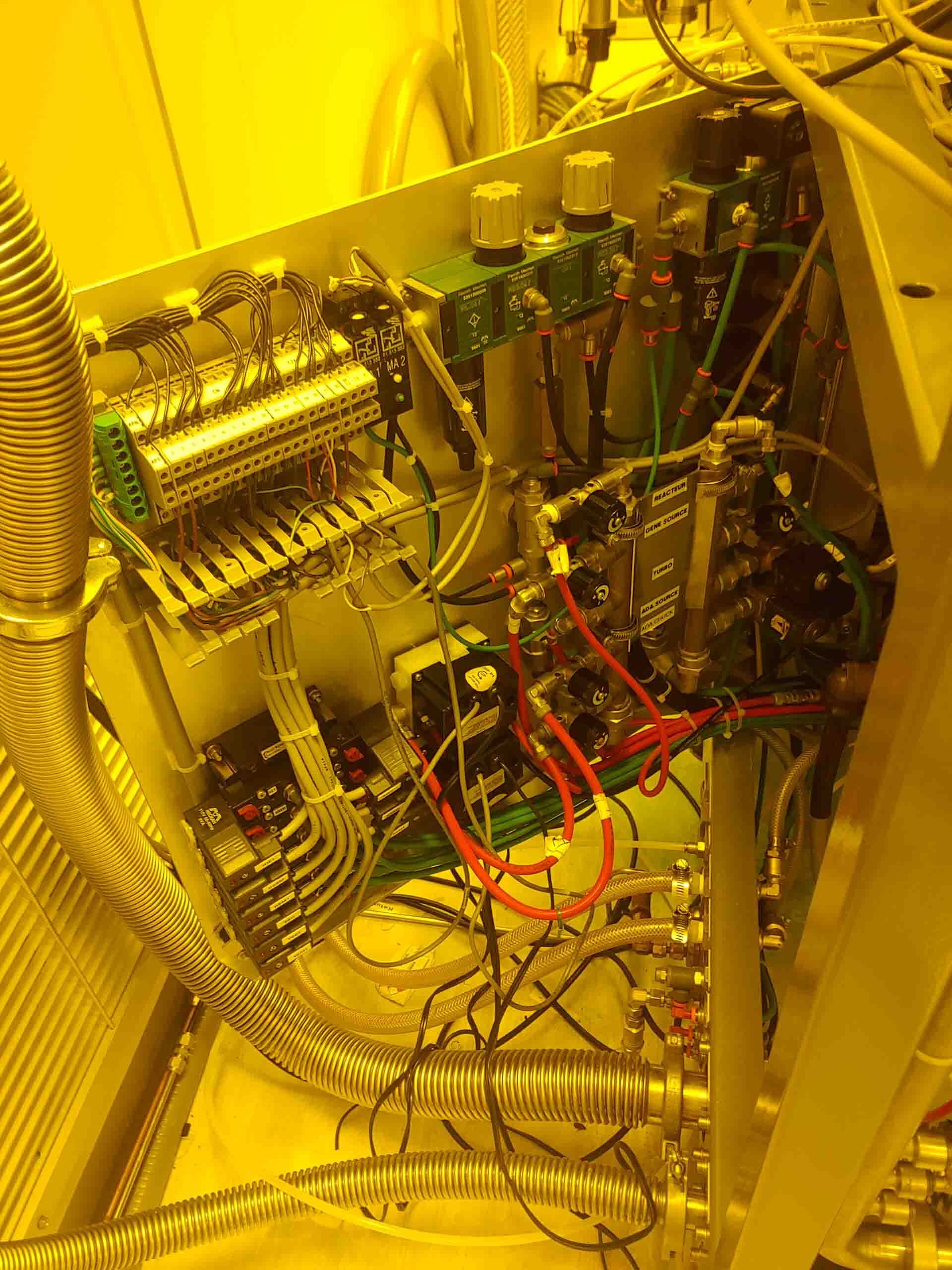

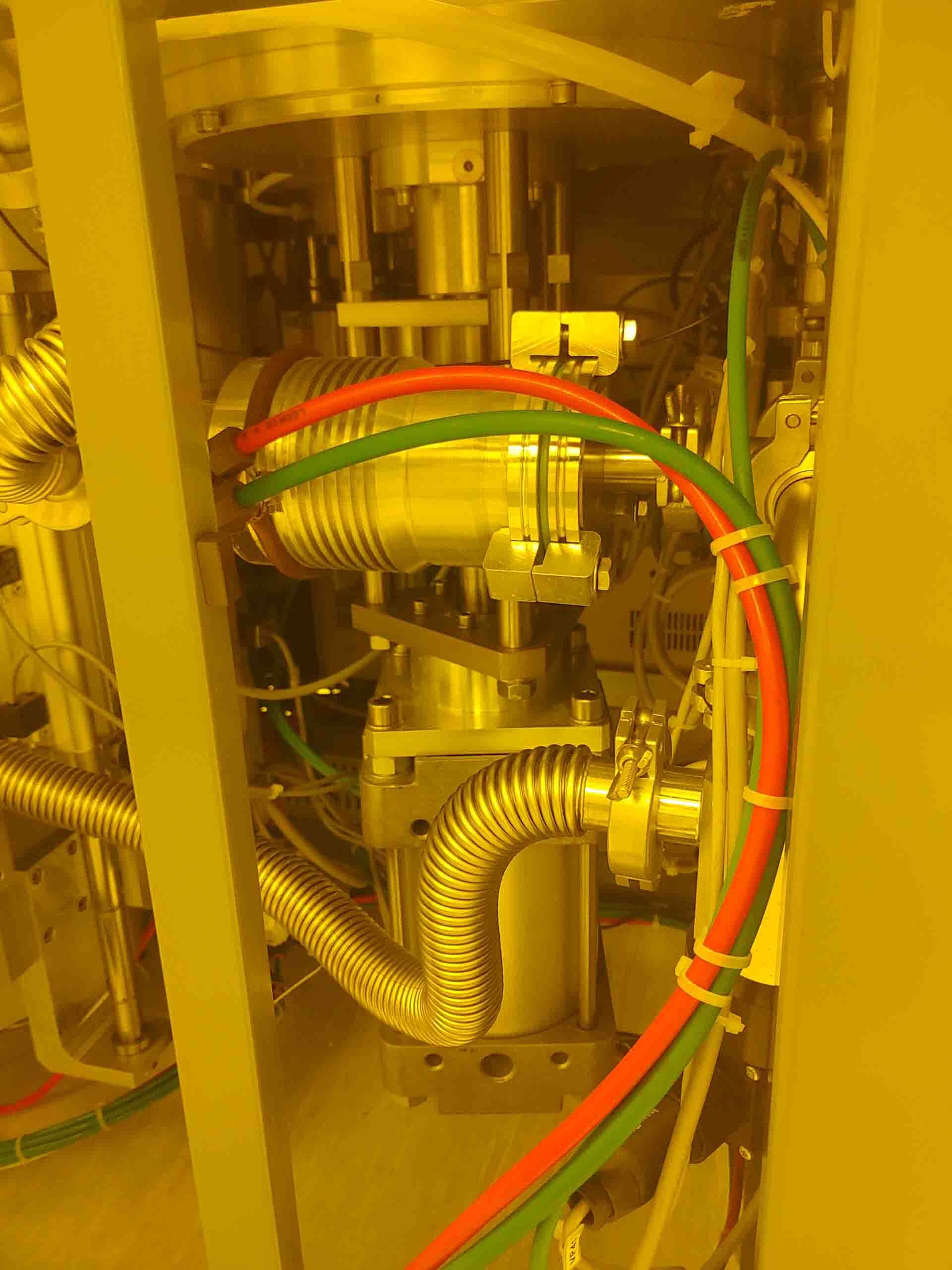

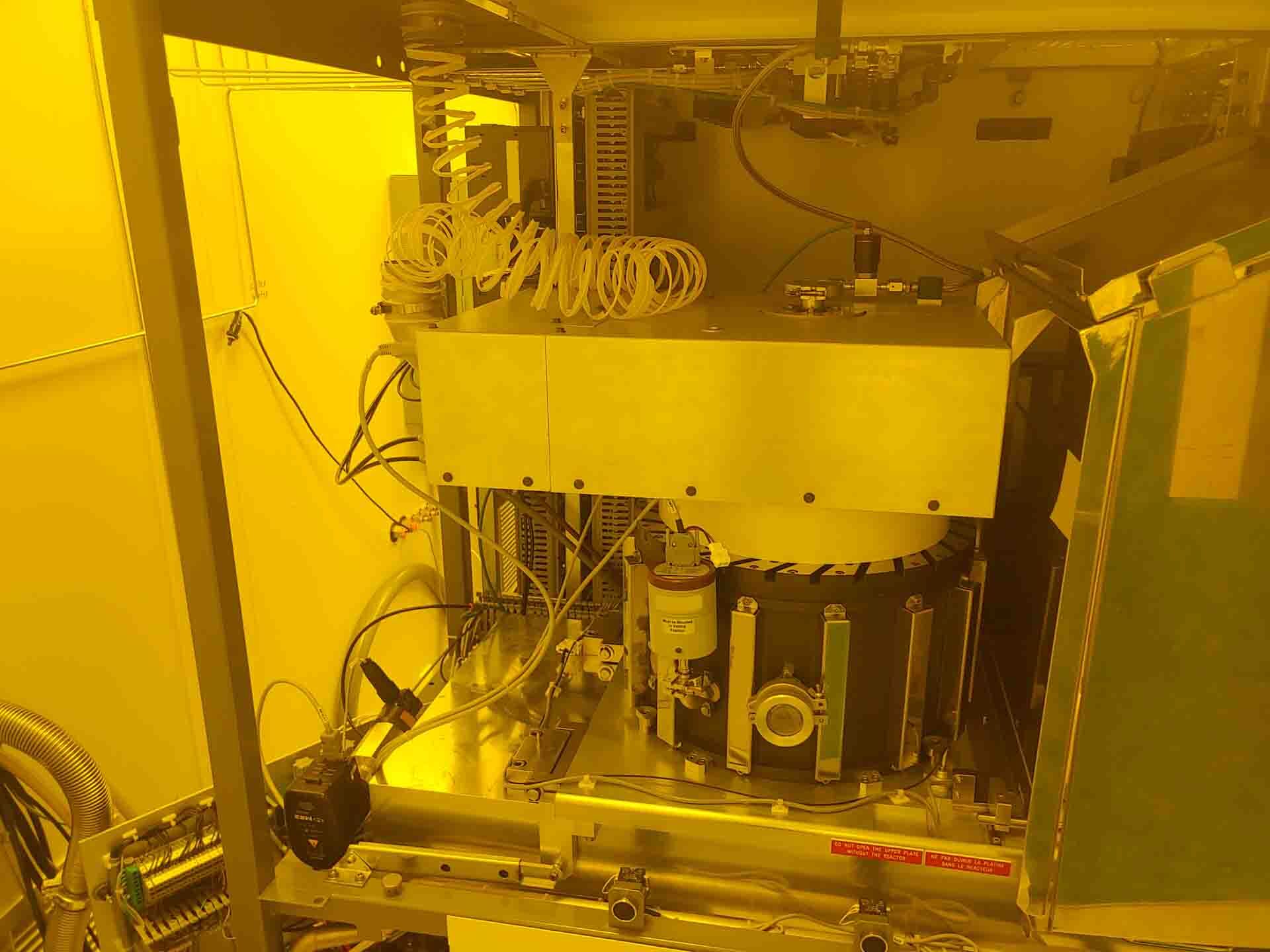

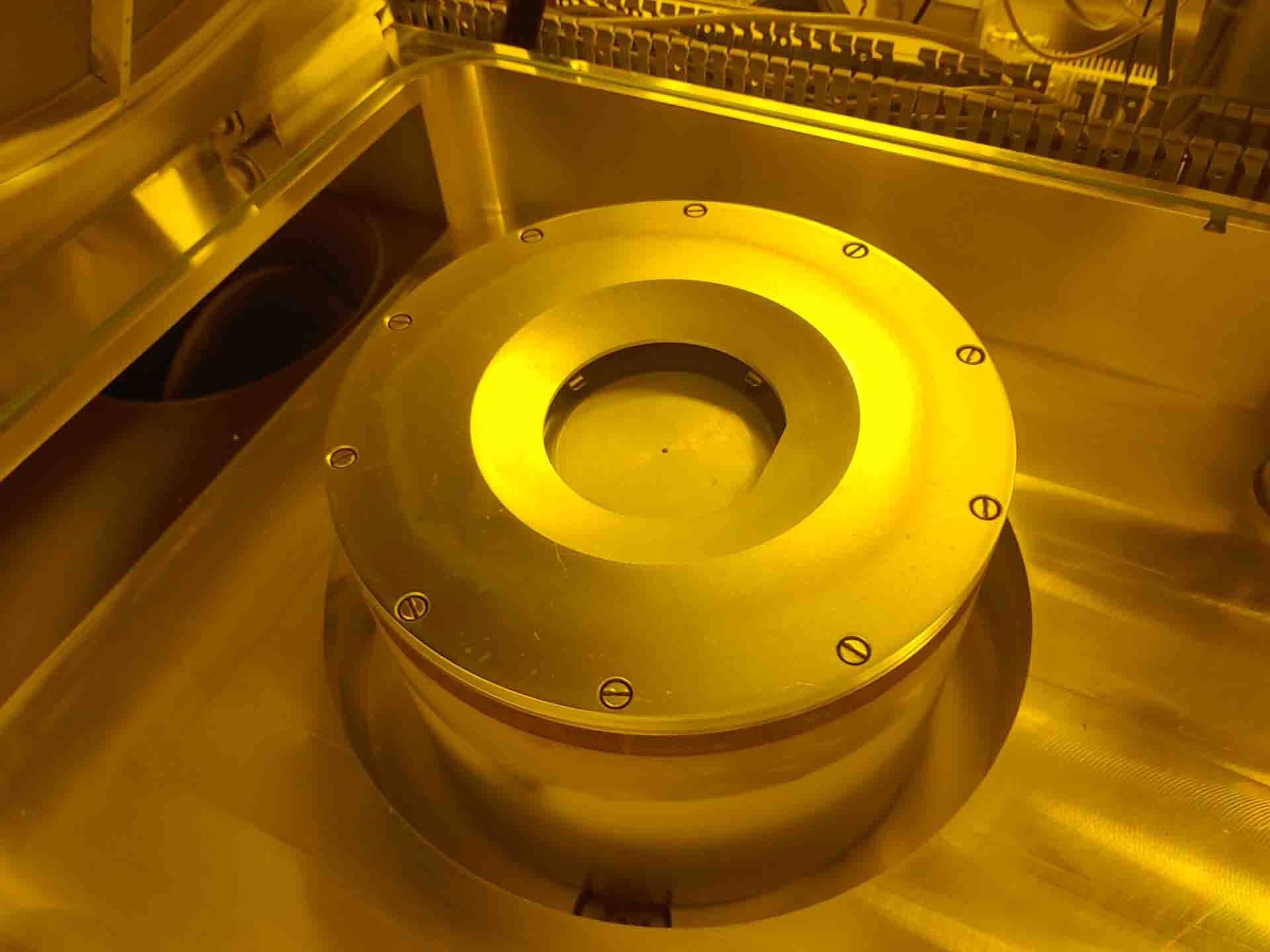

Deep Reactive Ion Etcher (DRIE)

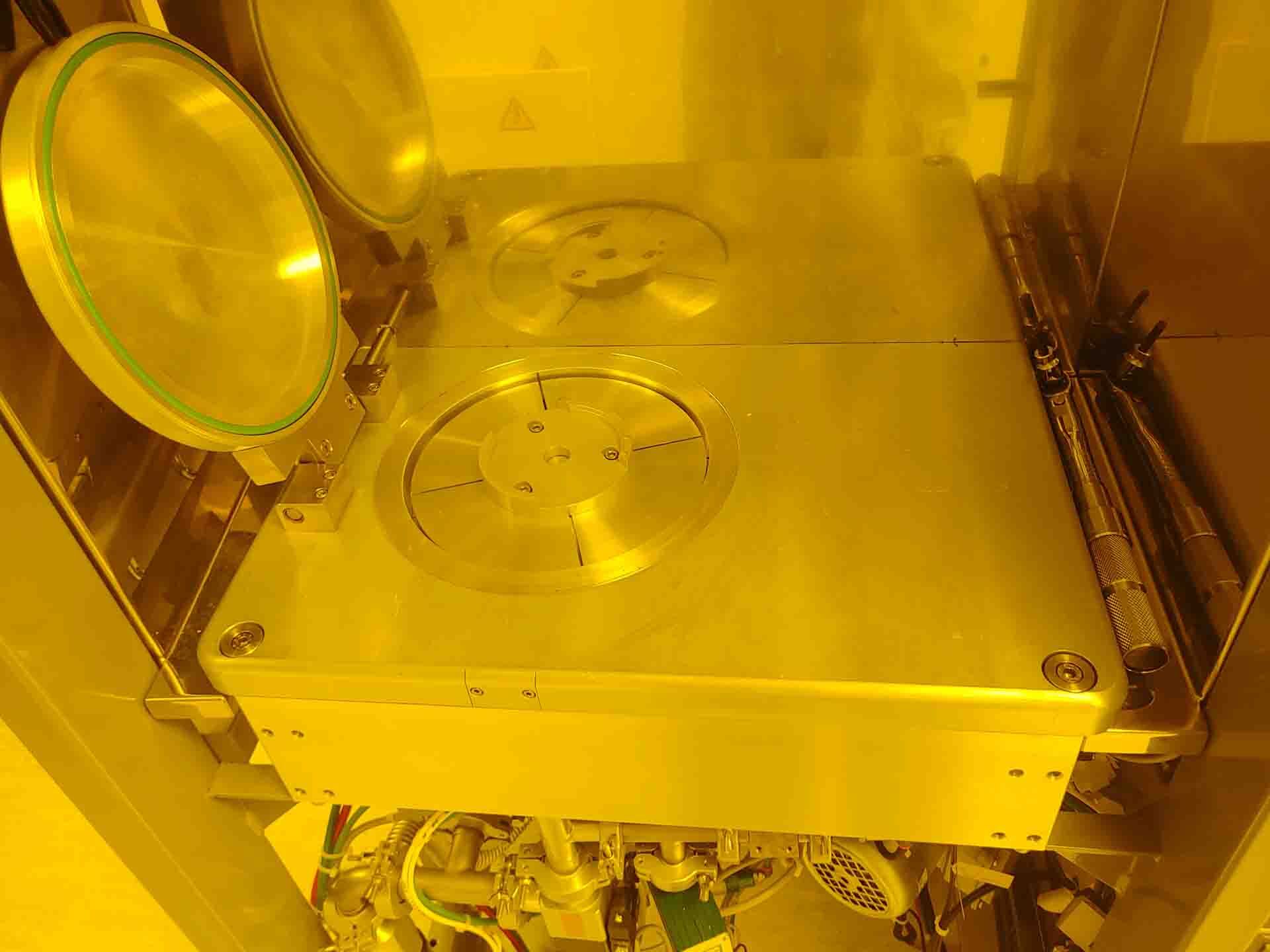

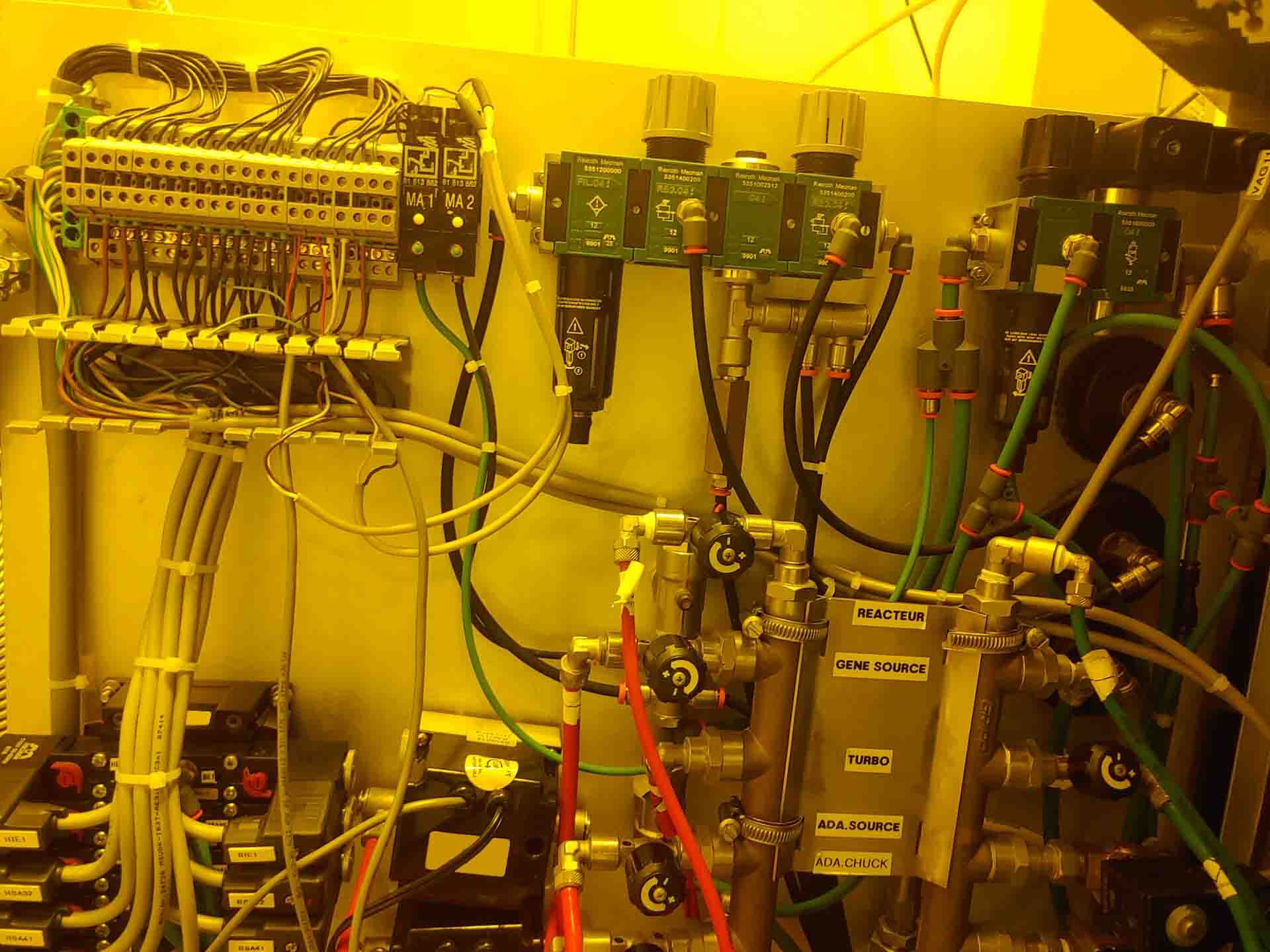

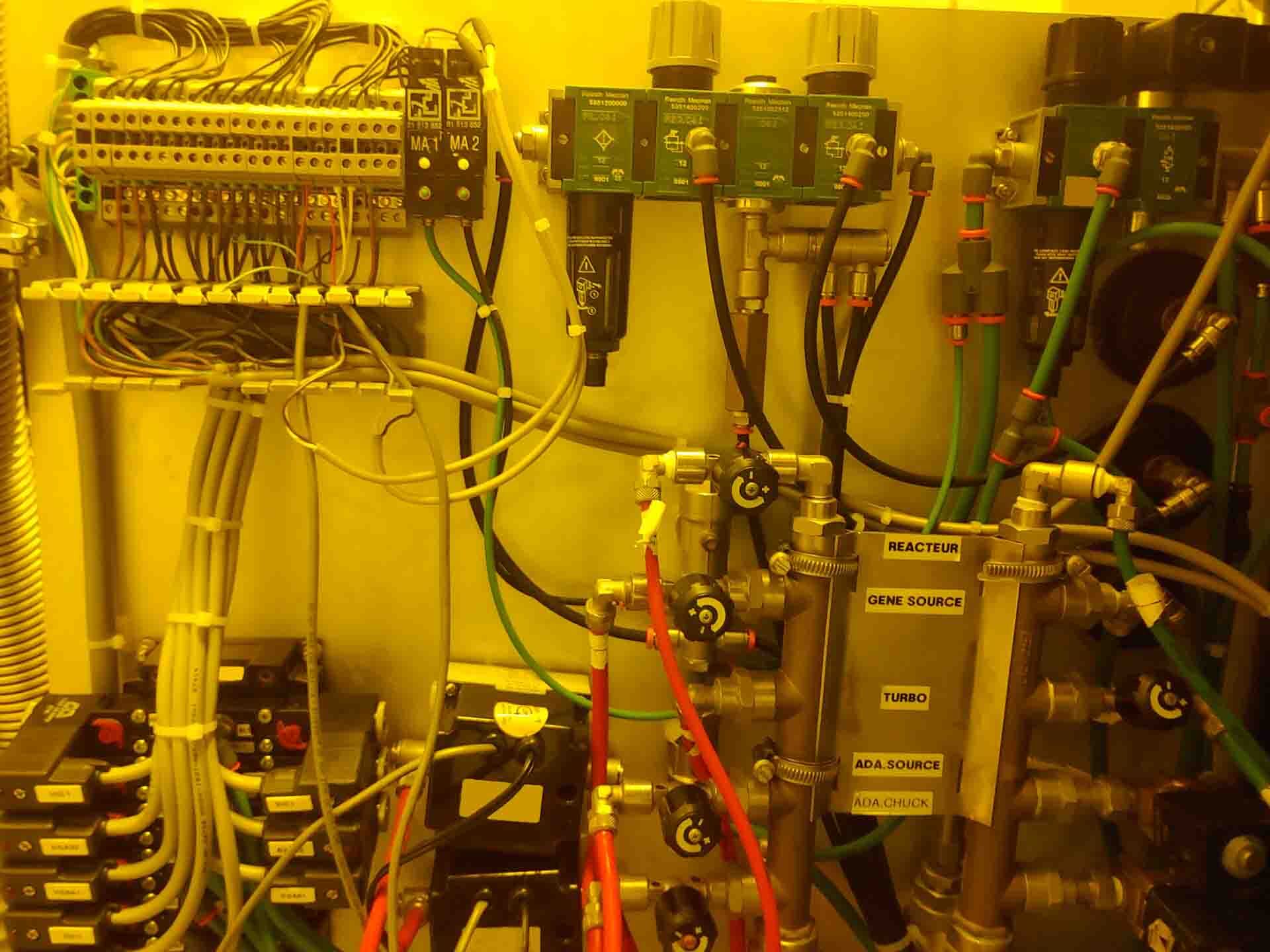

4" wafer chuck with LN2 cooling capability and helium wafer backpressure

Process gas setup: He, SF6, C4F8, O2, Ar, CHF3

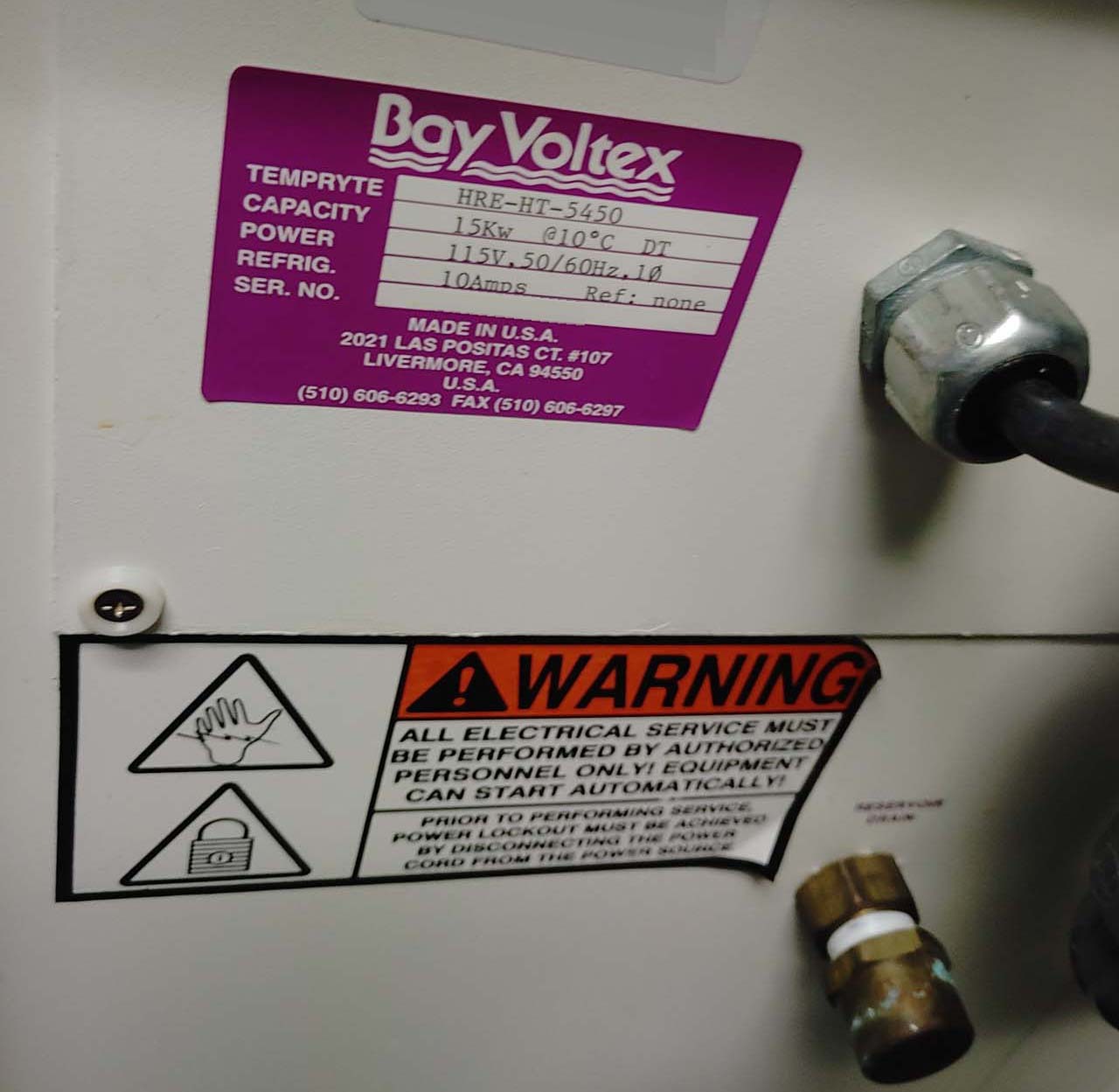

Bay Voltex water chiller

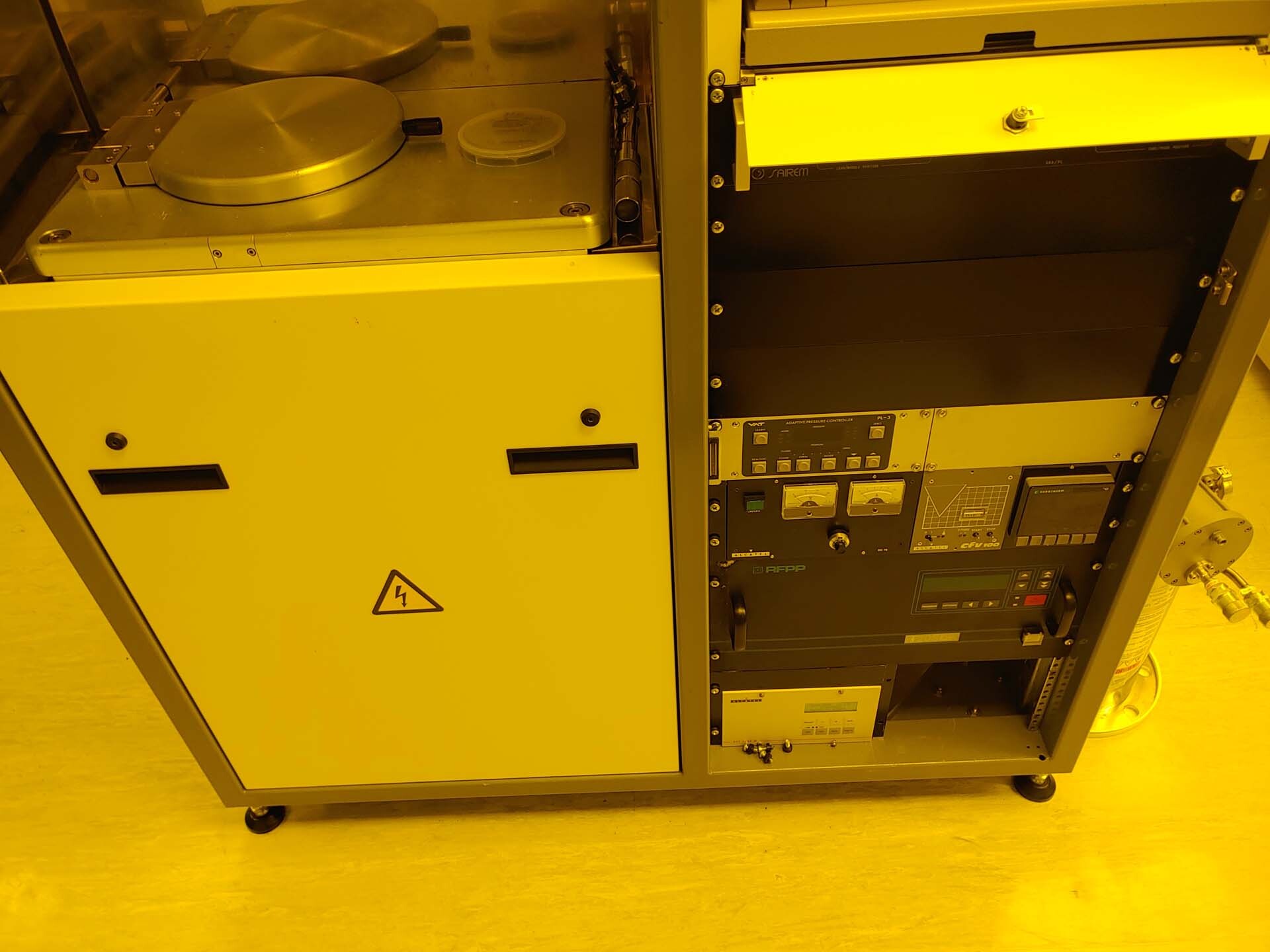

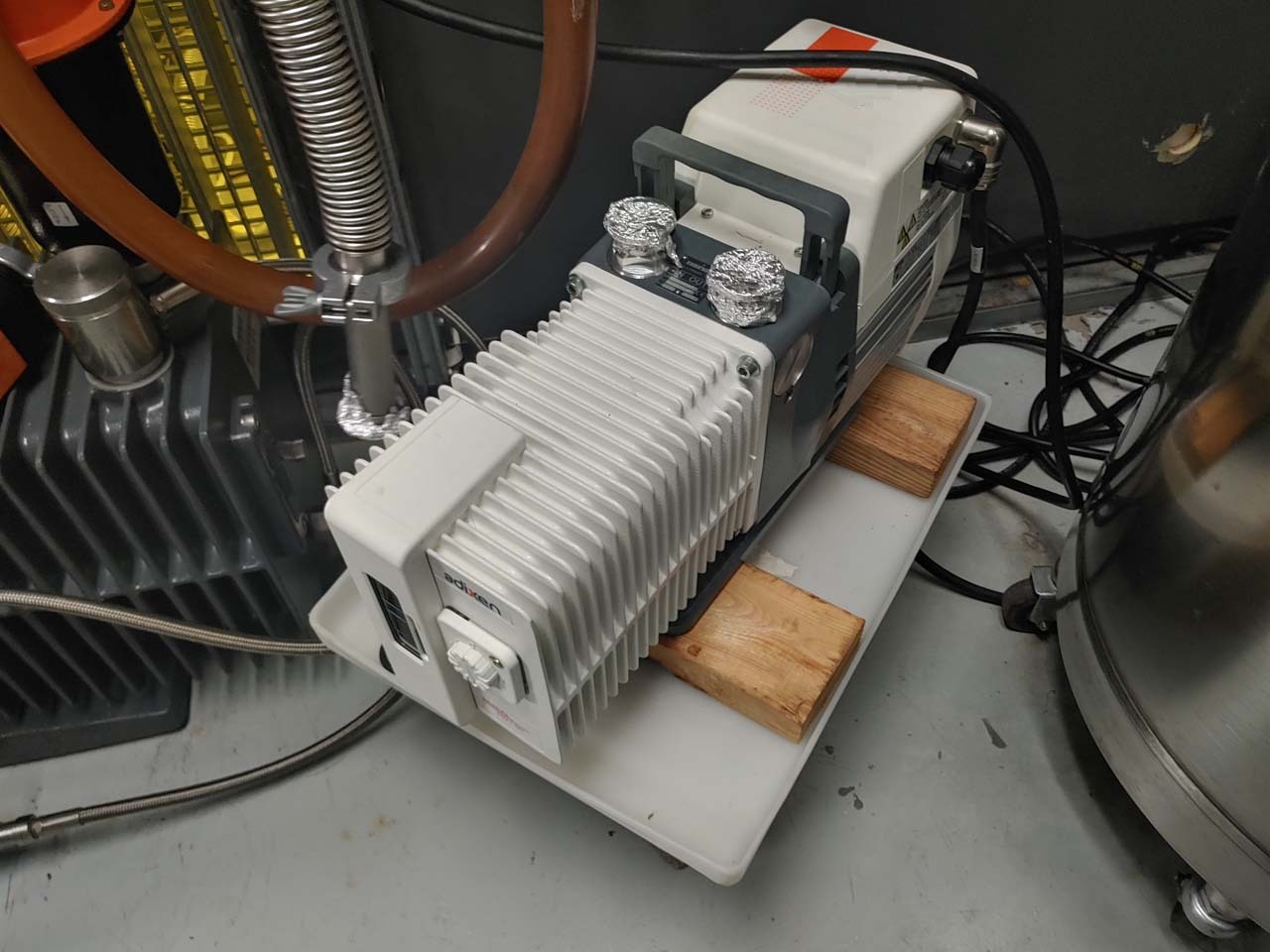

(2) Alcatel roughing pumps

2021SD for loading chamber

2063 C2 for process chamber

Known issues:

LF5 RF power generator will not apply power.

ALCATEL / ADIXEN / PFEIFFER A601E is an etcher/asher, used to rapidly etch and clean deposition surfaces. This tool is especially useful during deposition processes, such as physical vapor deposition (PVD) and chemical vapor deposition (CVD). ADIXEN A601E offers a unique combination of high pressure etching, pre-cleaning, and post cleaning capabilities in a single, integrated platform. ALCATEL A601E is comprised of a main etching chamber and several other components, including a vacuum process chamber, substrate transfer and transfer components, a base etch chamber, an etch pressure monitor and a post-etch chamber. The main etching chamber holds the substrate mount, process chamber and other components. The process chamber, which is usually closed and consists of an inner chamber and outer chamber, holds inert process gas, heated plasma, and a grounded and/or magnetically-coupled body shield. A gas distributor near the top can allow for switching of process gas inside. Substrate transfer and transfer components include a substrate shuttle, which is connected to the process chamber. This can be used to transport substrates or pieces of substrates to and from PFEIFFER A601E; the transfer of the substrates can be done using remote or manual control. The base etch chamber holds and measures the temperature, pressure, voltage, and power of the substrate during the etching process. This can help to prevent damage to the substrate and ensure optimal etching results. An etch pressure monitor is also included; it monitors the pressure inside the main etching chamber and compares it to a predetermined setpoint. In addition, a post-etch chamber is also included. This is used to clean the substrate after the etching process has been completed. Cleaning of the substrate is often done with a high-pressure gas such as nitrogen or argon, allowing for safe disposal of any residue left over from the etching process. A601E etcher / asher is capable of providing high etch rates and clean deposition surfaces in a single, integrated platform. It offers reliable control over pressure, temperature and voltage, making it an ideal choice for etching and pre-cleaning deposition surfaces in PVD and CVD processes. With its powerful performance, high efficiency, and safety features, ALCATEL / ADIXEN / PFEIFFER A601E is an ideal choice for etching and cleaning deposition surfaces.

There are no reviews yet