Used AMAT / APPLIED MATERIALS Centura Ultima HDP CVD #9063643 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9063643

Wafer Size: 8"

Vintage: 2000

Etcher, 8"

(2) Ultima chamber

(1) Ultima plus chamber

Technology :IMD

Wafer Size : 8"

Wafer Shape : SNNF (Semi Notch No Flat)

Software Version : B4.3.14

CHAMBER TYPE AND LOCATION

Ch A : Ultima HDP-CVD

Ch B : Ultima HDP-CVD

Ch C : Ultima + HDP-CVD

Ch E : Multislot Cool Down

Ch F : Orientor

CHAMBER A,B Ultima HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Microwave

CHAMBER C - Ultima + HDP-CVD :

Nozzle : Long/Long Side

Clean Gas Distribution : Baffle

Turbo Pump : Ebara ET1600WS w/ HVA

Wafer Temperature Monitoring : Yes

Top Gas Feed : Without Top O2

Dual Independent He Control : Standard 10/10 TORR

Clean Method : Top Mount

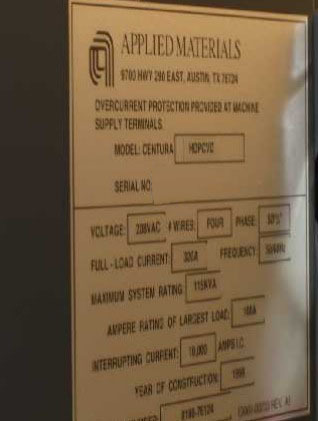

EXISTING ELECTRICAL REQUIREMENTS

Line Frequency : 60Hz

Line Voltage : 200/208V

Line Amperage : 600A Platform

EXISTING SAFETY EQUIPMENT :

EMO type : Turn to release EMO

EMO Guard Ring : Yes

System Labels : English w/Chinese Non-simplified

System Smoke Detector : Controller

EXISTING MAINFRAME :

Mainframe Type : Ultima HDP w/Multislot

Frame Type : Standard Frame

System Placement : Through the Wall

Mainframe Skins : No

Mainframe Exhaust Duct : No

Mainframe Facilities Connection : Back

Robot Type : HP Robot

Robot Blade : Ceramic

Loadlock Cassette : Narrow Body

Narrow body Loadlocks : Cassette Present Sensor

Loadlock Wafer Mapping : Basic

N2 Purge Type : STEC 4400MC 10 Ra Max

EXISTING GAS DELIVERY :

Gas Panel Surface Finish : Standard Gas Panel

MFC Type : STEC 4400MC 10 Ra Max

Valves : Fujikin 5 Ra Max

Filters : Pall Ni 10 Ra Max

Transducers : MKS w/ Display

Regulators : Veriflo

System Cabinet Exhaust : Top

Gas Panel Gas/Flow Direction Labels : Yes

APC Seriplex Cover : Yes

Gas Panel Doors : Solid

Gas Pallet Configuration :

Chamber A, B, C

Gas Stick/Process Gas/MFC size/Regulator/Transducer

#1 SiF4 100 Y Y

#2 O2 400 Y Y

#3 SiH4 200 Y Y

#4 Ar 300 Y Y

#5 SiH4 20 Y Y

#6 Ar 50 Y Y

#7 NF3 2000 Y Y

#8 Ar 2000 Y Y

REMOTES :

RF Generator Rack - Ultima Gen. Rack

ASTEX 80S09mW (3)

Quantity : Two

Ultima Stand-Alone RF Generator Rack : Yes

Generator Rack Cooling - RF Gen Rack Manifold with Quick Disconnect Ultima Gen Rack H20 Connection - Barbed Brass

Existing Heat Exchanger : SMC Thermo

Umbilicals :

System Controller Signal Cable Length : 55ft

RF Gen Rack Cable Length : 50ft

Ultima Stand-Alone Generator Rack : 98 ft

HX Hose Length : 50ft

HX Cable Length : 50ft

Pump Cable : 50ft

Ultima Microwave Generator Cable Length : 50 ft

Ultima WTM Cable Length : 32.8 ft (10m)

Vacuum Pumps, Exhaust Scrubber not included in sale

Currently crated and stored

System Can be inspected

1999-2000 vintage.

AMAT / APPLIED MATERIALS Centura Ultima HDP CVD (High-Density Plasma Chemical Vapor Deposition) reactor is a modular, low-cost, vertical furnace designed for high-volume, high-throughput production of cutting-edge thin-film materials. The reactor features an innovative patented design that uses high densities of plasma over a large volume, enabling faster deposition rates and higher yield rates. The technology also offers low parasitics and improved uniformity of deposition, making it an excellent choice for use in applications such as solar cells, flat panel displays, optical coatings, and advanced semiconductor devices. AMAT Centura Ultima HDP CVD reactor uses RF-driven high-density plasma (HDP) to drive reactions at low temperatures, making it energy-efficient and ideal for producing high-performance thin-film coatings. The technology also eliminates many of the costly material handling and cleaning steps traditionally associated with CVD processes, minimizing costs and boosting overall yields. The equipment is highly configurable, allowing for a wide range of plasma sources and materials—including metal and dielectric targets, dielectric compounds, and gas targets—to be used in a selectable sequence. At the heart of APPLIED MATERIALS Centura Ultima HDP CVD reactor is the sub-module, or work-space, which is a fully enclosed chamber with a single plasma source and an integrated gas care system. This gas care unit ensures that the continuous flow of gases used in the deposition process is always at optimal levels for accurate results. A centrally-mounted target holder ensures that the substrate to be coated is rotated by the plasma without any obstruction for optimal uniformity in the deposition process. The high-density plasma, coupled with uniform deposition, ensures that the temperature of the substrate remains low and uniform, preserving the material's properties while ensuring a high-quality, precisely-patterned deposition across the surface. The machine's advanced control software provides an intuitive user interface, allowing for precise control over process parameters and allows for targeted optimization of the deposition process. Centura Ultima HDP CVD reactor is an excellent choice for any production line involving cutting-edge thin-film deposition. Thanks to its innovative and cost-effective design, high-throughput production is enabled at low cost and minimal overhead. This makes the tool an attractive choice for industrial manufacturers looking to realize the full potential of thin-film deposition and improved device performance.

There are no reviews yet