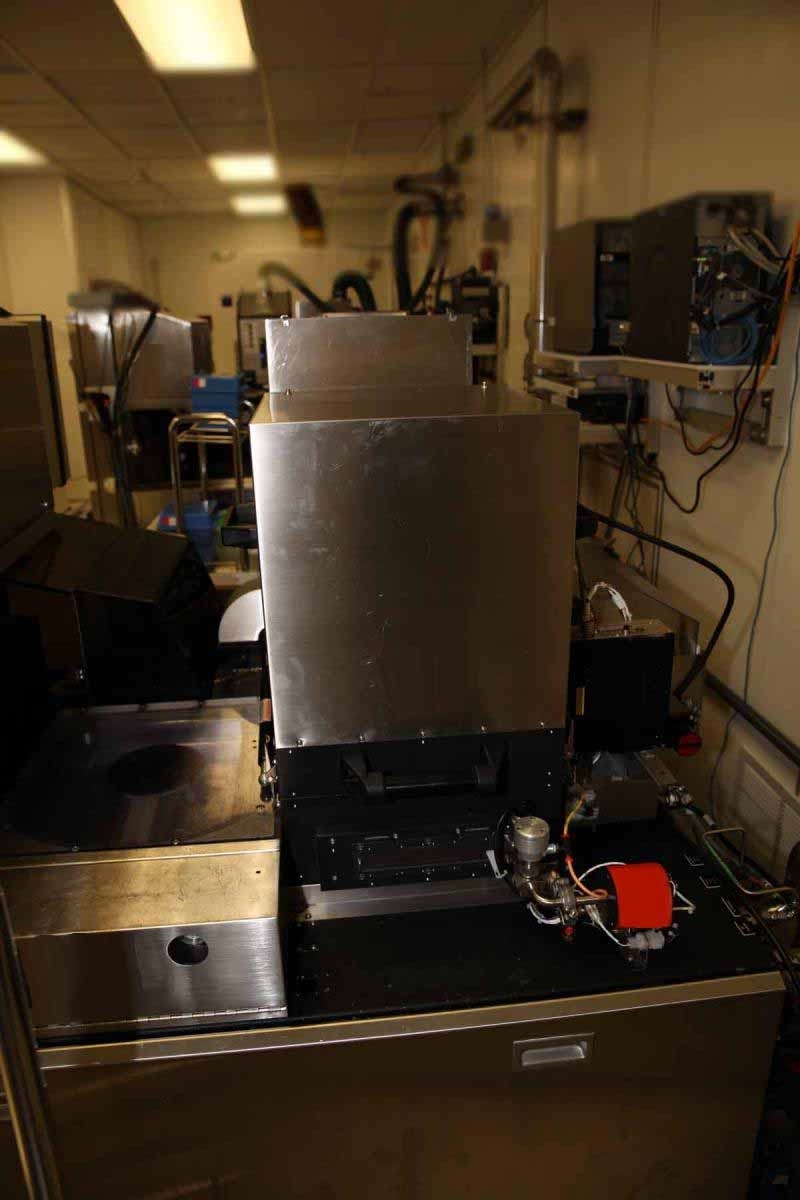

Used LAM RESEARCH Rainbow 4520i #9180717 for sale

URL successfully copied!

Tap to zoom

ID: 9180717

Wafer Size: 6"

Vintage: 2004

Dry etcher, 6"

Clamped chuck

Verity enhanced endpoint detection

Hines indexers

Matching network: LoFat

ISO Matcher: Yes

Top and bottom RF cables: Standard

Chamber process kit parts:

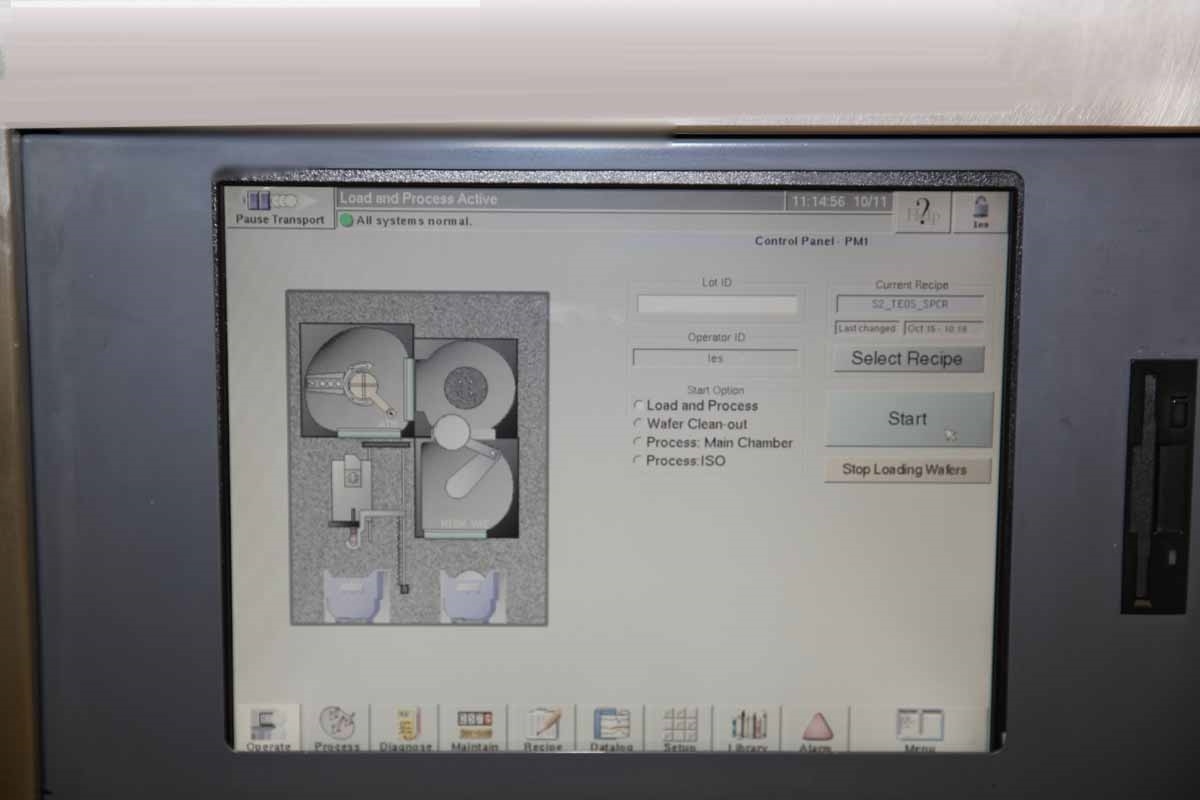

Pick and place wafer transport with non-wafer contact optical alignment

Inductive RF auto tuning: Fast accurate RF tuning for precise control

Active temperature control of upper and lower electrodes

Vacuum load-locked low pressure oxide system

Parallel plate reactor: Proven etch technology

Variable gap spacing: Wide process flexibility

Integrated isotropic-anisotropic etching

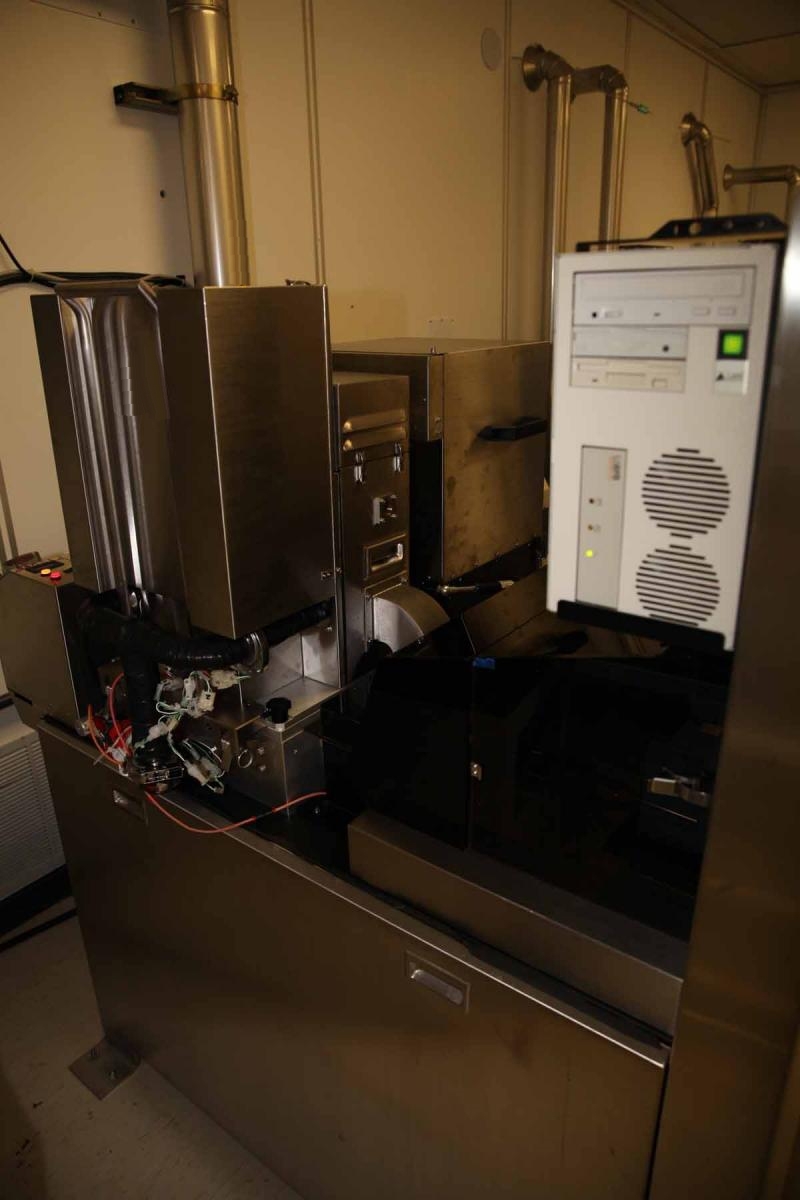

(2) Active chambers

Flat notch orientation

Upper and lower baffles

Electrode clamp ring

Attachment ring

Filler ring lower clamp

Focus ring edge lower

Vespel confinement ring

Bottom wafer clamp

Bell jar

Single wafer

4520i Isotropic etch chamber:

Integrated into entrance load-lock

1250 Watt solid state

Water cooled remote isotropic chamber RF generator

RF Match housing resides at the left side of the isotropic module

(3) MFCs For isotropic chamber

Pressure controller for helium backside wafer cooling

Hinged upper housing of isotropic chamber

Air blower assembly

OEM Specifications / Typical results:

Dry pumps / Chiller not included

Selectivity BPSG/TEOS to poly: >15:1

Thermal oxide etch rate: ≥ 4500A/min

BPSG Etch rate: >7500 A/min

TEOS Etch rate: >5000 A/min

Particles: 0.3μm size

Uniformity: +/- 10% 3

4520 Anisotropic etch chamber:

Single wafer etch: Individual wafer etch

Wafer temperature control:

Reduced loading effects

Profile control with extended over etch

LAM RF Generator rack:

Main RF generator

ISO AE RFG 1250 RF Generator

2004 vintage.

LAM RESEARCH Rainbow 4520i wet etcher/asher is a state-of-the-art plasma etching equipment for a variety of materials including aluminum, copper, silicon, and other hard metals. The system has high repeatability and is designed for high-precision semiconductor applications. With a standard cell, Rainbow 4520i provides uniform, repeatable results throughout the entire etch cycle. The unit features an advanced process control machine, providing real-time control of wafer temperature and pressure, while optimizing etch cycle time and conserving the etchant solution. The tool is equipped with a variable- frequency power source and an advanced electron-cyclotron resonance source (ECR) to obtain uniform, isotropic etching across the wafer surface. The gas and/or vapors are mixed and regulated as required for a particular type of substrate and deposited material. The use of a digital controller allows for precise control of the power levels, temperature, and etch duration. The asset also supports a variety of cooling strategies, providing uniform thermal control of the wafer surface. It includes an advanced impurity control model that helps maintain a high quality etch surface. The impurity control equipment is facilitated by a unique scrubbing system which utilizes a combination of a soft-brush scrubbing and a micro-flux cleaning technique. The unit also includes a range of tools and accessories to meet specific material etching requirements. It is equipped with an array of lift pins and flexible nozzles designed to etch different patterns and sizes. In addition, the machine also supports multiple gases and/or vapors to create various etch surfaces ranging from extremely deep etch to shallow etch. Overall, LAM RESEARCH Rainbow 4520i etching tool is an efficient piece of machinery with various features that provide accurate and repeatable etching results that are second to none. Its advanced features allows it to etch multiple types of materials and its process control asset assists in keeping the etching process uniform and consistent. The flexible nozzles and multiple gases provide a range of etching styles from extremely deep etch to shallow etches. The sophisticated technology of the etching machine makes it one of the best on the market.

There are no reviews yet