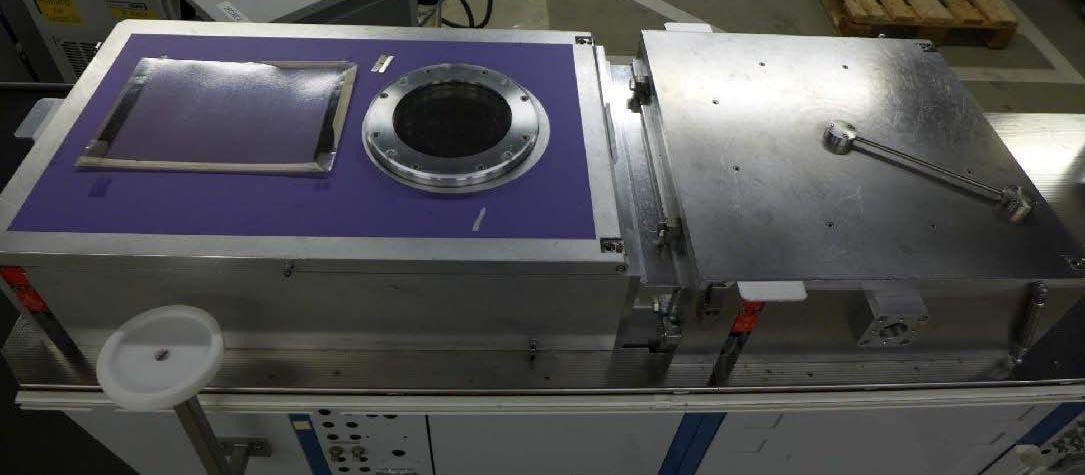

Used OXFORD Plasmalab 133 #9090813 for sale

URL successfully copied!

Tap to zoom

ID: 9090813

Vintage: 2004

RIE (CL) Dry etchers

CL: Configured for chlorine based corrosive chemistry

Set up for GaN etch

Platen: 330 mm

RF Power: 600 W, 13.56 MHz

Water cooled electrode: 10 C-80 C

End point detection: Verity optical emission spectroscopy (200-800 nm)

Windows PC

Gas pod with (6) lines including following MFCs:

Ar: 100 sccm

CL: 100 sccm

BCL3: 100 sccm

N2O: 100 sccm

2004 vintage.

OXFORD Plasmalab 133 etcher is a dedicated plasma etch and asher equipment designed for use in a variety of research and production applications. The system utilizes multiple chambers and technologies to enable a variety of etching and surface preparation processes. As a versatile, multi-purpose etching unit, Plasmalab 133 can be used for a wide range of substrate types, including but not limited to Silicon, III-V, and metals. The machine is built on an air-cooled chamber design that features an integrated RF generator that supports both RF sputtering and ion etching. A high power, direct RF generator provides up to 1 kW of power output for sputtering applications and up to 500 W of power output for ion etching applications. A dual frequency RF generator also supports dual frequency plasma operation, allowing the user to switch between high frequency and low frequency sources for optimized etching results with a single tool. OXFORD Plasmalab 133 features sophisticated process control technology, including a real-time pressure gauge that is integrated into the vacuum chamber, allowing for precise pressure control during plasma processing. An inert gas valve and flow meter is also provided, allowing for precise control of the process gas composition and pressure. The on-board gas control asset allows for a wide variety of process gases, such as oxygen, nitrogen, and argon, to be used during the etching process. The model also includes an integrated motorized sample holder that allows for easy sample loading and unloading. The holder is equipped with a manual Z-axis, allowing the sample to be moved up and down for fine adjustment of the etch parameters. Finally, Plasmalab 133 comes with an integrated controller that provides precise control of the process parameters to ensure repeatable and reliable etching results. In summary, OXFORD Plasmalab 133 etcher is a multi-purpose, versatile equipment designed for reliable etching and surface preparation applications. With a variety of chambers and process control technologies, the system can be used to etch a wide range of materials, including Silicon, III-V, and metals. The integrated on-board gas control unit, real-time pressure gauge, dual frequency RF generator, and motorized sample holder provide precise control for etching results, allowing for repeatable etching process optimization.

There are no reviews yet