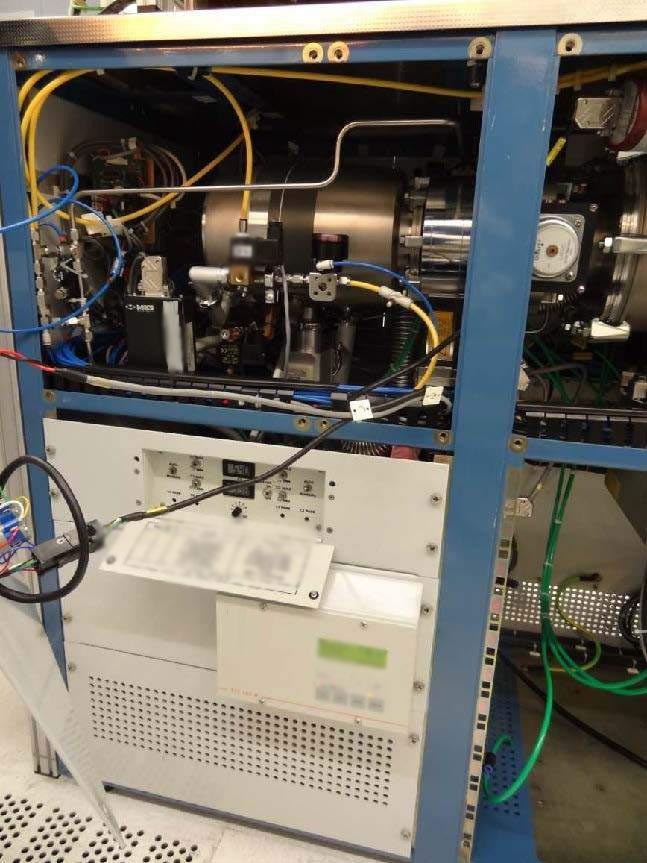

Used OXFORD Plasmalab 133 #9090816 for sale

URL successfully copied!

Tap to zoom

ID: 9090816

Vintage: 2006

RIE (FL) Dry etchers

FL: Configured for fluorine based chemistry

Set up for SiO2 etch

Platen: 330 mm

RF Power: 600 W, 13.56 MHz

Load lock with turbo pump

Water cooled electrode: 10 C-80 C

Windows PC

Gas pod with (6) lines including following MFCs:

Ar: 100 sccm

N2: 200 sccm

CHF3: 200 sccm

NF3: 200 sccm

N2O: 200 sccm

Not included:

Pump

Chiller

2006 vintage.

OXFORD Plasmalab 133 is a high performance etch and asher equipment, capable of producing intricate patterns on materials used in the fabrication of semiconductor devices. Designed for chemical etching and chemical-assisted ion etching (CAI) applications, it is capable of handling a wide range of parameters. Its robust and user-friendly computer control allows for multiple steps etching and ashing processes with very tight control and repeatability. Plasmalab 133 combines pressure-controls and other advanced etching technologies in a single modular package. Its built-in high-power RF generator, suitable for both etching and ashing, delivers optimum process performance at different pressure levels. OXFORD Plasmalab 133 can handle all common etch and ashing techniques, including standard wet etch, dry etch, plasma-enhanced chemical vapor deposition (PECVD), reactive ion etch (RIE), and ion beam etch (IBE). The system is fully automated and can accommodate substrates up to 200mm in diameter, making it well-suited for batch processing applications. Plasmalab 133 is an ultra-precise etcher and asher. Its integration of advanced process control and sensing technologies, combined with its ability to accurately measure etch characteristics like temperature, pressure, and power, provides the means for automated high-precision etching and ashing. It is capable of creating vias, trenching, and other intricate features that require tight control. Additionally, the unit has an integrated video viewing, enabling operators to monitor etching processes from the edges of the vacuum chamber, allowing for fast adjustments when needed. The machine's included SOP software provides powerful process development and control flexibility. The software allows set-up of multiple recipes for different etch parameters and gas flows. Additionally, the software is internet-enabled, allowing for flexible and remote process control. OXFORD Plasmalab 133 is an advanced, high-end etching and ashing tool, designed for both manual and automated operation. It is a complete etching and ashing solution, delivering fast process times, high accuracy, and precise control of etch characteristics.

There are no reviews yet