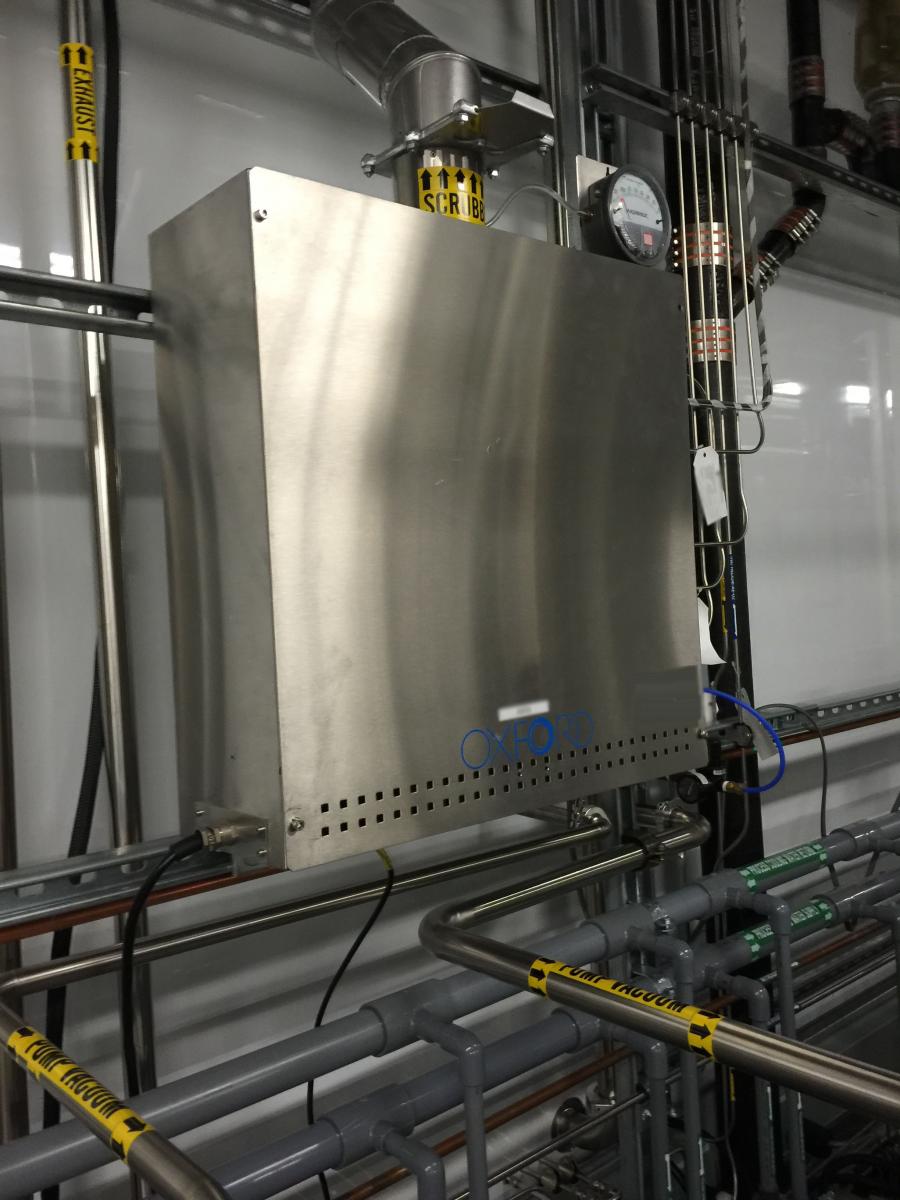

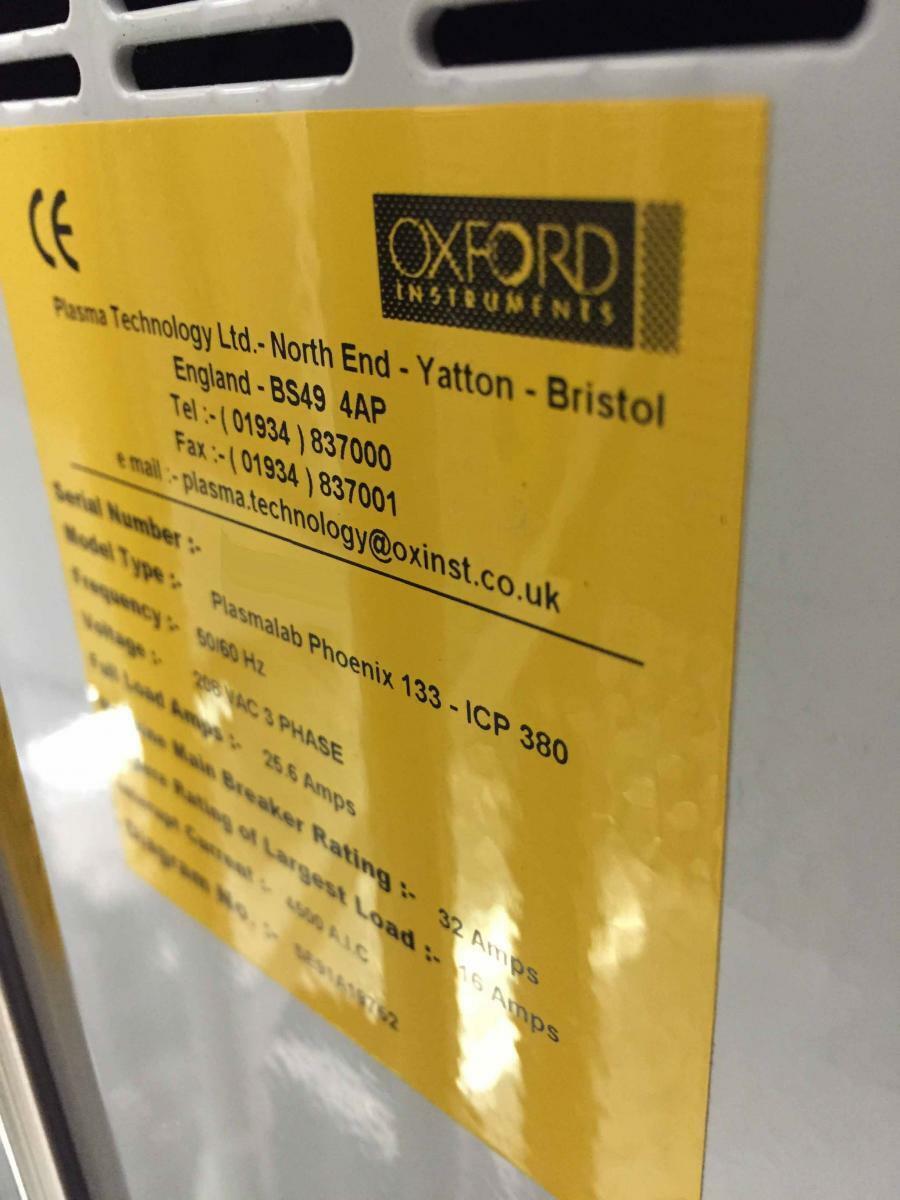

Used OXFORD Plasmalab 133 #9151442 for sale

URL successfully copied!

Tap to zoom

ID: 9151442

Reactive Ion Etcher (RIE)

Ion Coupled Plasma Etcher

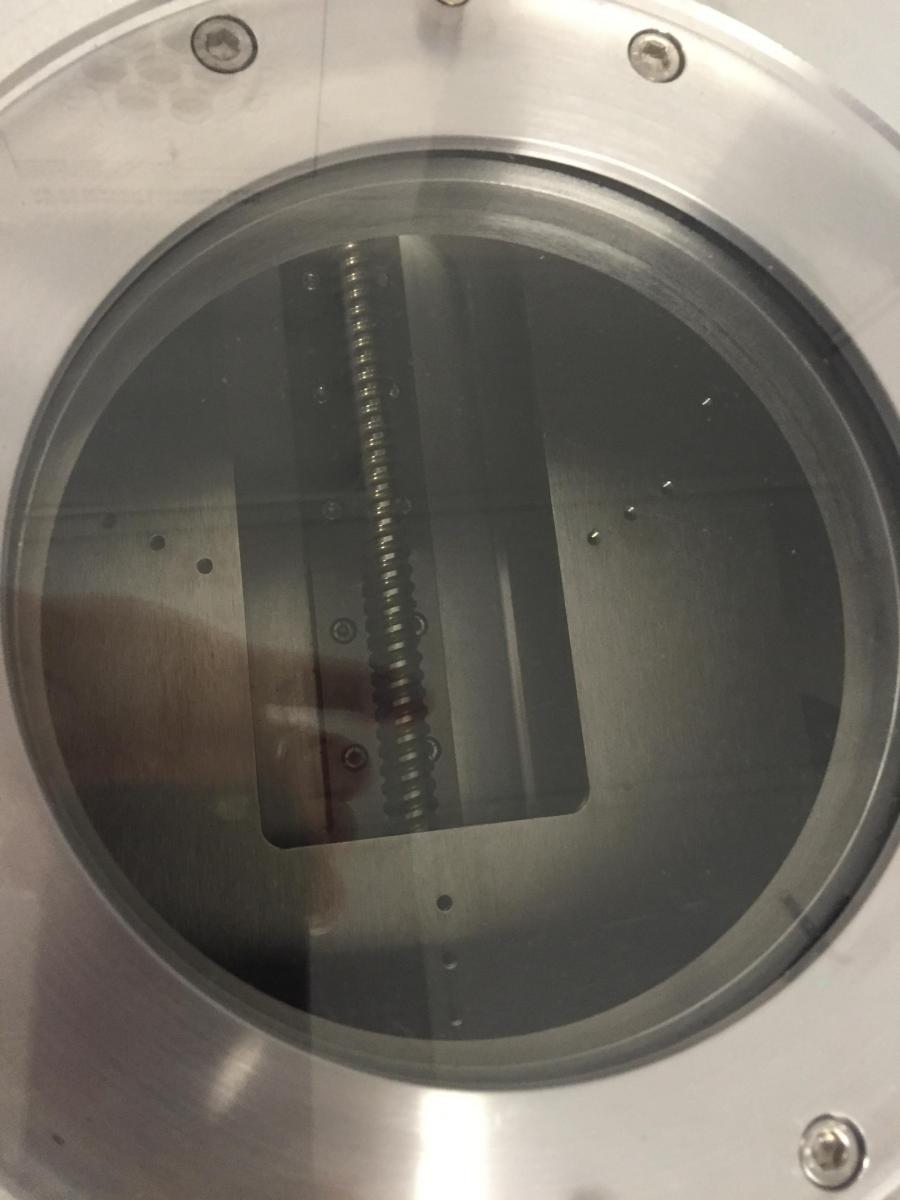

Chamber size: 380

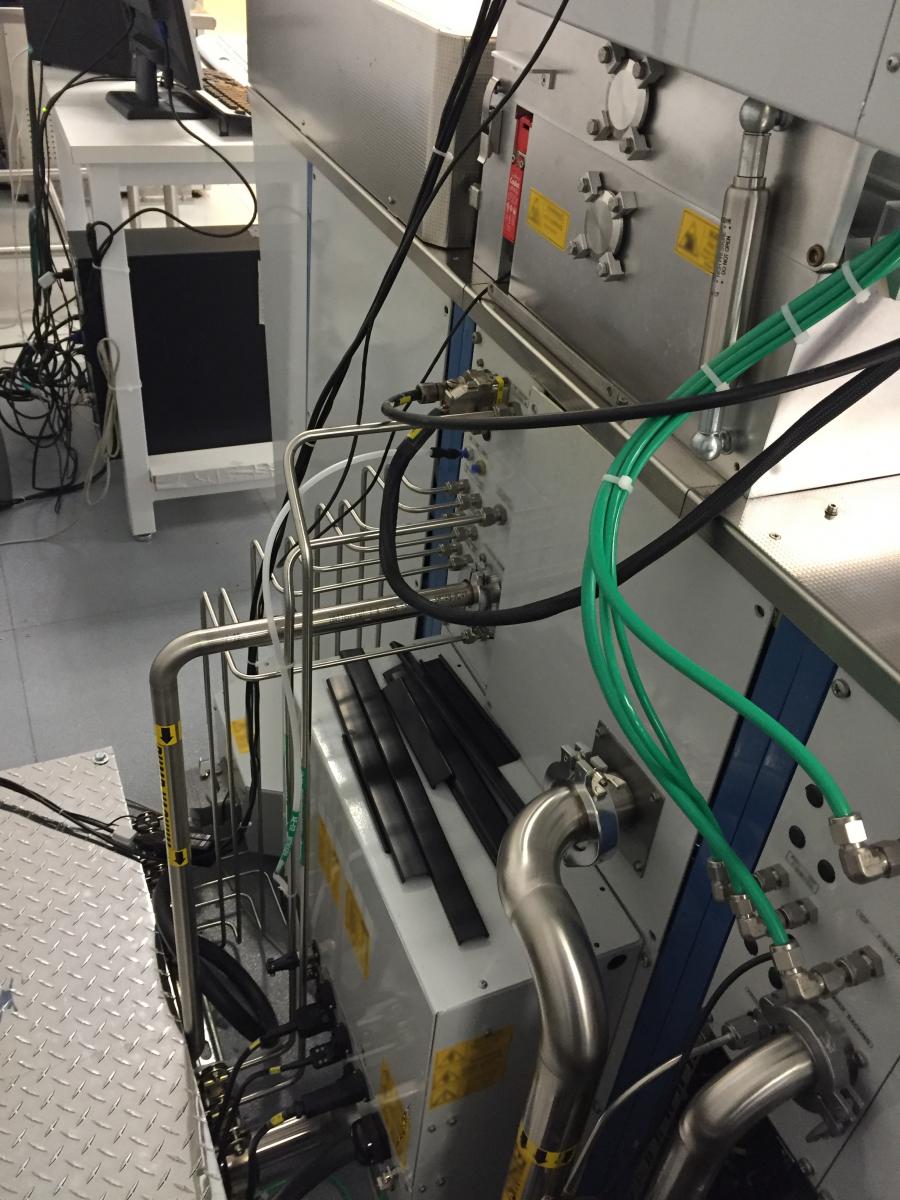

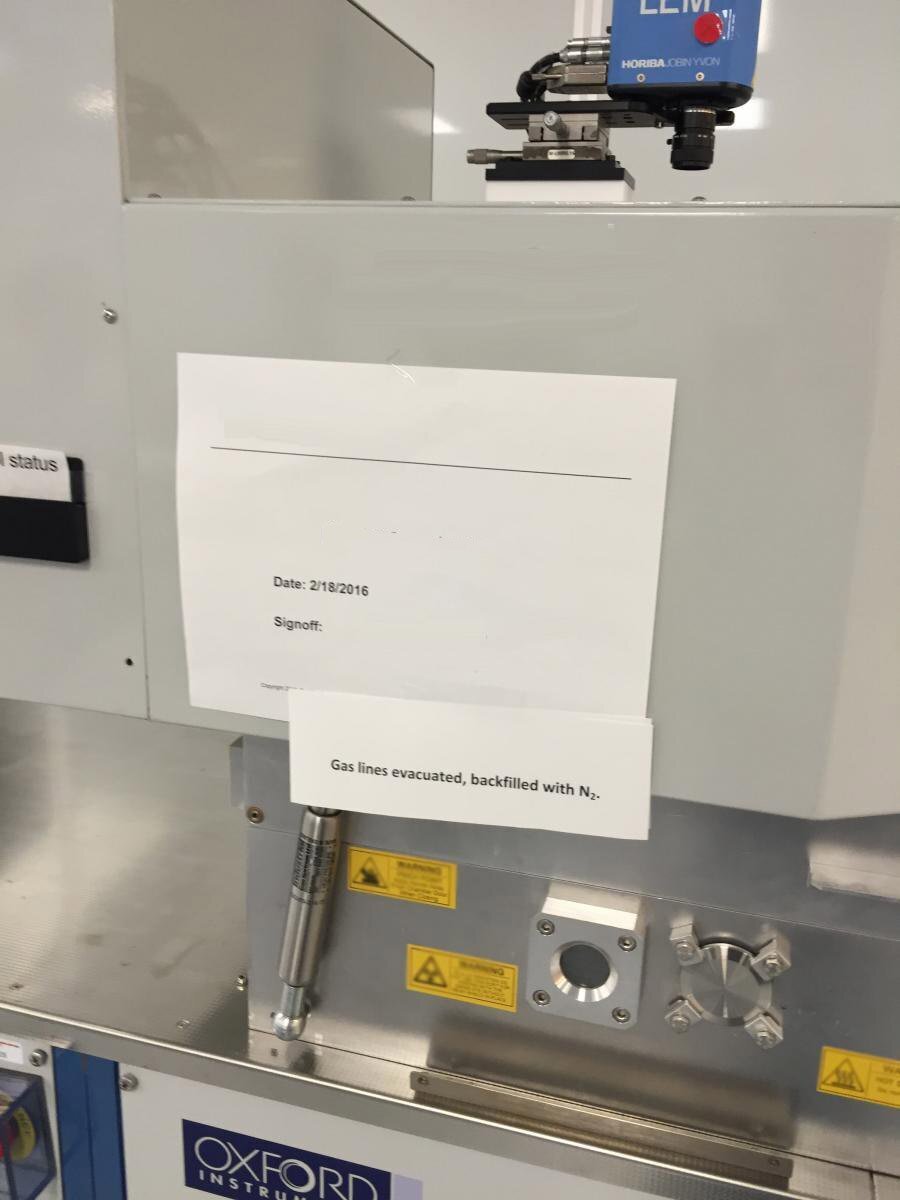

VAT Gate valve with PM5 controller

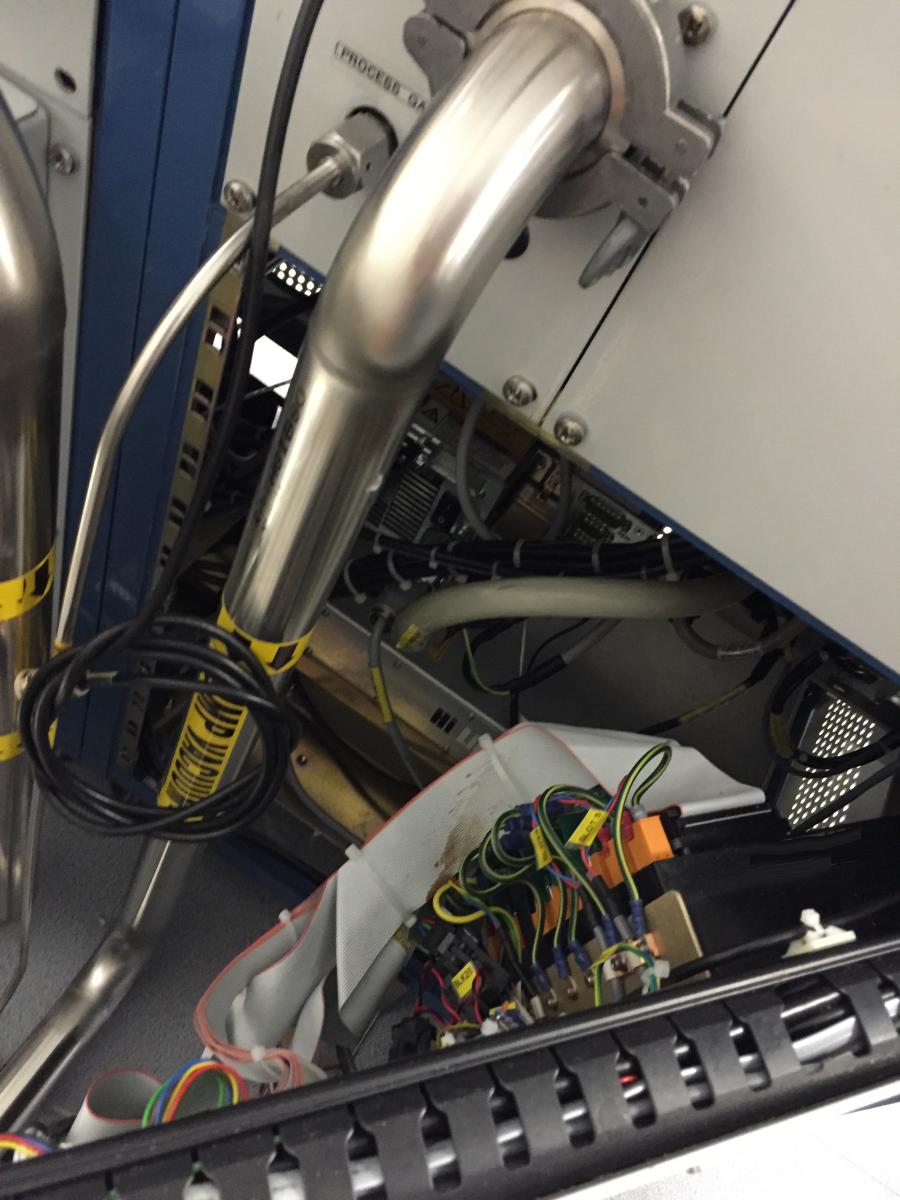

ADVANCED ENERGY RFX600A & HFV 8000 RF Power supplies

ALCATEL / ADIXEN / PFEIFFER 1000M Turbo pump with NT20 Controller

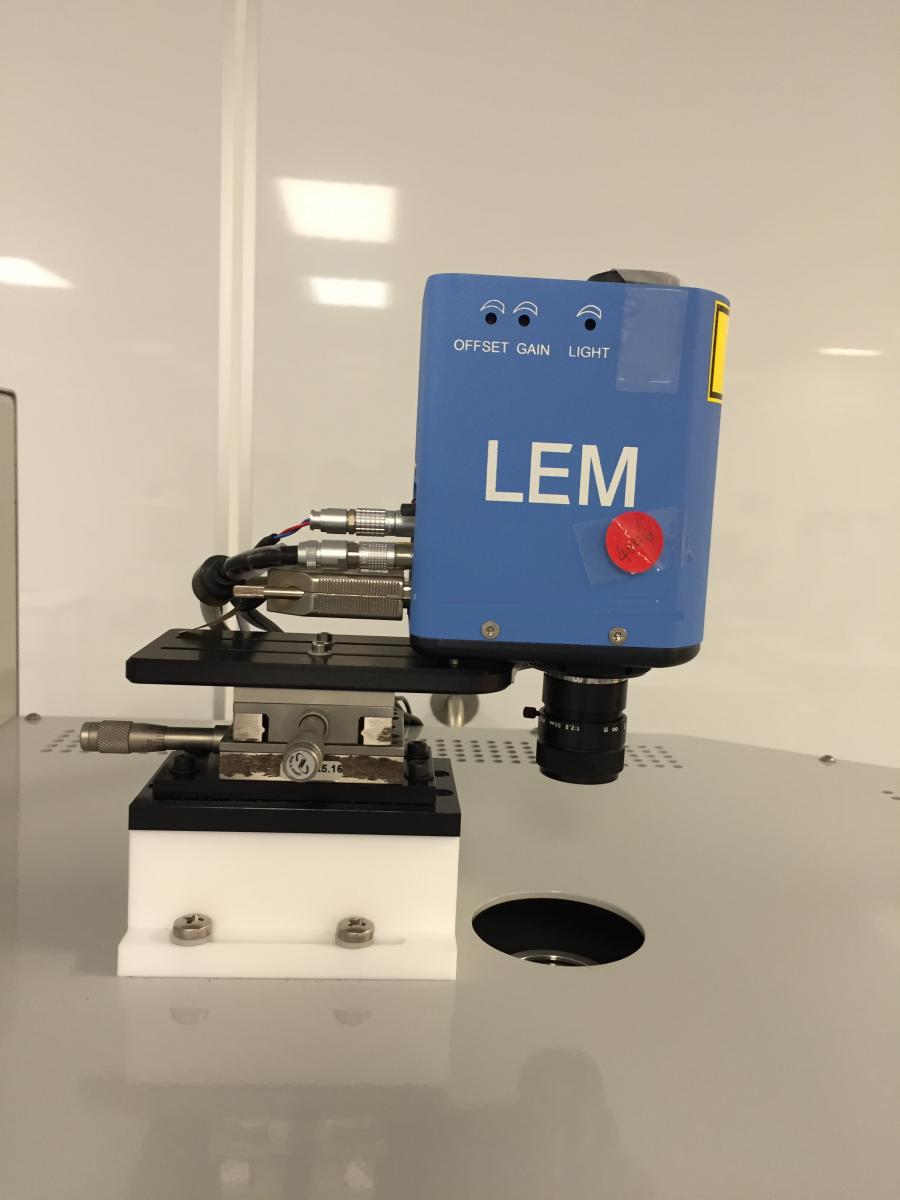

Endpoint detector type: TB-XY-MA16

Match work and tuner

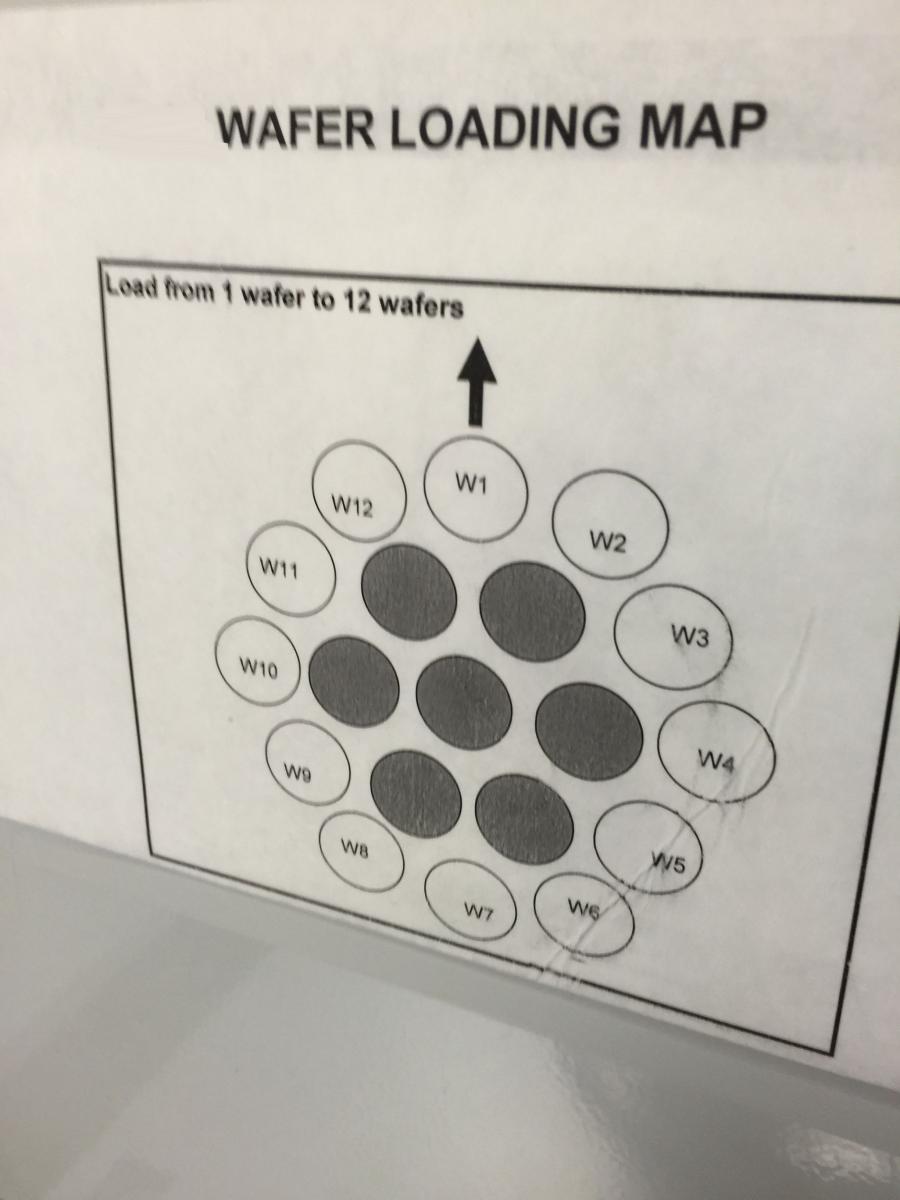

Manual load lock

Ceramic clamp

(8) Mass flow controllers

Power supply: 208 V, 60 Hz.

OXFORD Plasmalab 133 is an etcher and asher equipment produced by OXFORD Instruments. It is a advanced, low-pressure etcher and asher combination platform. This system is designed for semiconductor device processing, including polymers, metals, dielectrics, and ceramics. This unit is an ideal tool for processing thin films, MEMS devices, LEDs, RF modules, and other high-performance devices. Plasmalab 133 includes features and tools that allow users to precisely control etch, deposit, or remove material with ultimate accuracy. The etcher enables users to produce clean and uniform etched layers for creating high-precision electronic devices. The asher provides very fine and high-resolution sputtering deposition of thin film materials. OXFORD Plasmalab 133 features a powerful High Resolution Magnetron sputtering technology, which provides for the uniform deposition of films with superior characteristic adhesion. This machine is also equipped with an anisotropic etching source and a highly-modular process chamber, allowing for the etching and processing of several materials at the same time. It also features advanced automation for complete process control and a user-friendly interface. Plasmalab 133 is capable of processing a wide range of materials, including silicon, aluminum, gallium arsenide, copper, and diamond-like carbon. It is also designed to meet the exacting demands of semiconductor device fabrication and can be used for various applications, such as acceleration of electron emission, bipolar thin-film formation, chemical mechanical planarization, and selective area patterning. This tool offers advanced process control algorithms, allowing users to adjust process parameters and monitor the asset. The Advanced Process Control (APC) feature constantly monitors and evaluates your process parameters and automatically adjusts the corresponding settings to maintain optimal process results. Moreover, the model is designed for operation in harsh environmental conditions and is available with an integrated vacuum and gas supply. In addition, it is equipped with a range of safety features and fire suppression equipment to safeguard your personnel and processes. OXFORD Plasmalab 133 is the perfect etcher and asher combination platform for any engineer looking to maximize precision and accuracy in fabricating high-performance electronic devices. This system is designed to be reliable and efficient, offering an advanced platform for etching and depositing various materials with total accuracy.

There are no reviews yet