Used PLASMATHERM / UNAXIS Versaline #9311006 for sale

URL successfully copied!

Tap to zoom

ID: 9311006

Wafer Size: 4"

Vintage: 2003

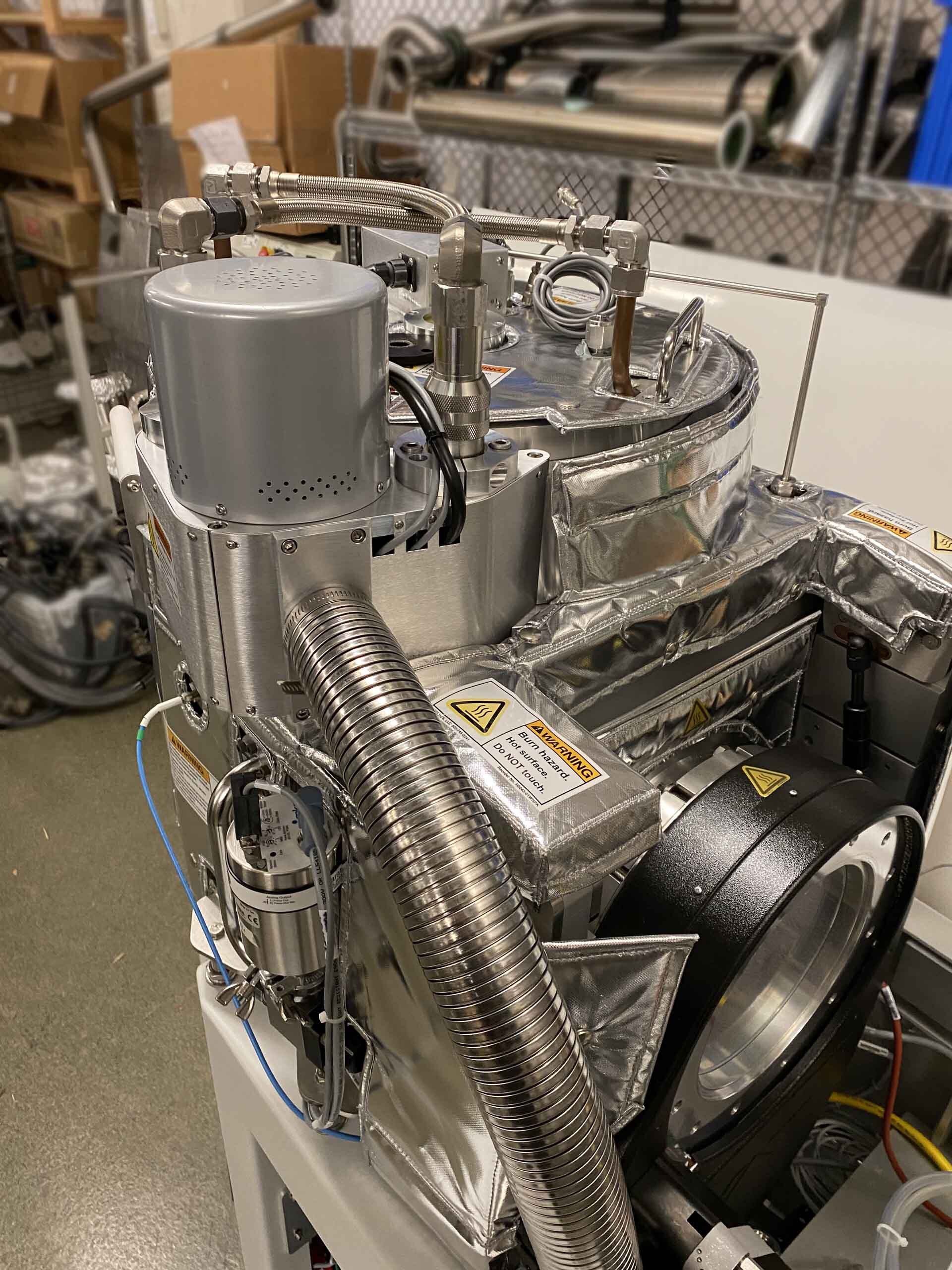

ICP Etcher, 4"

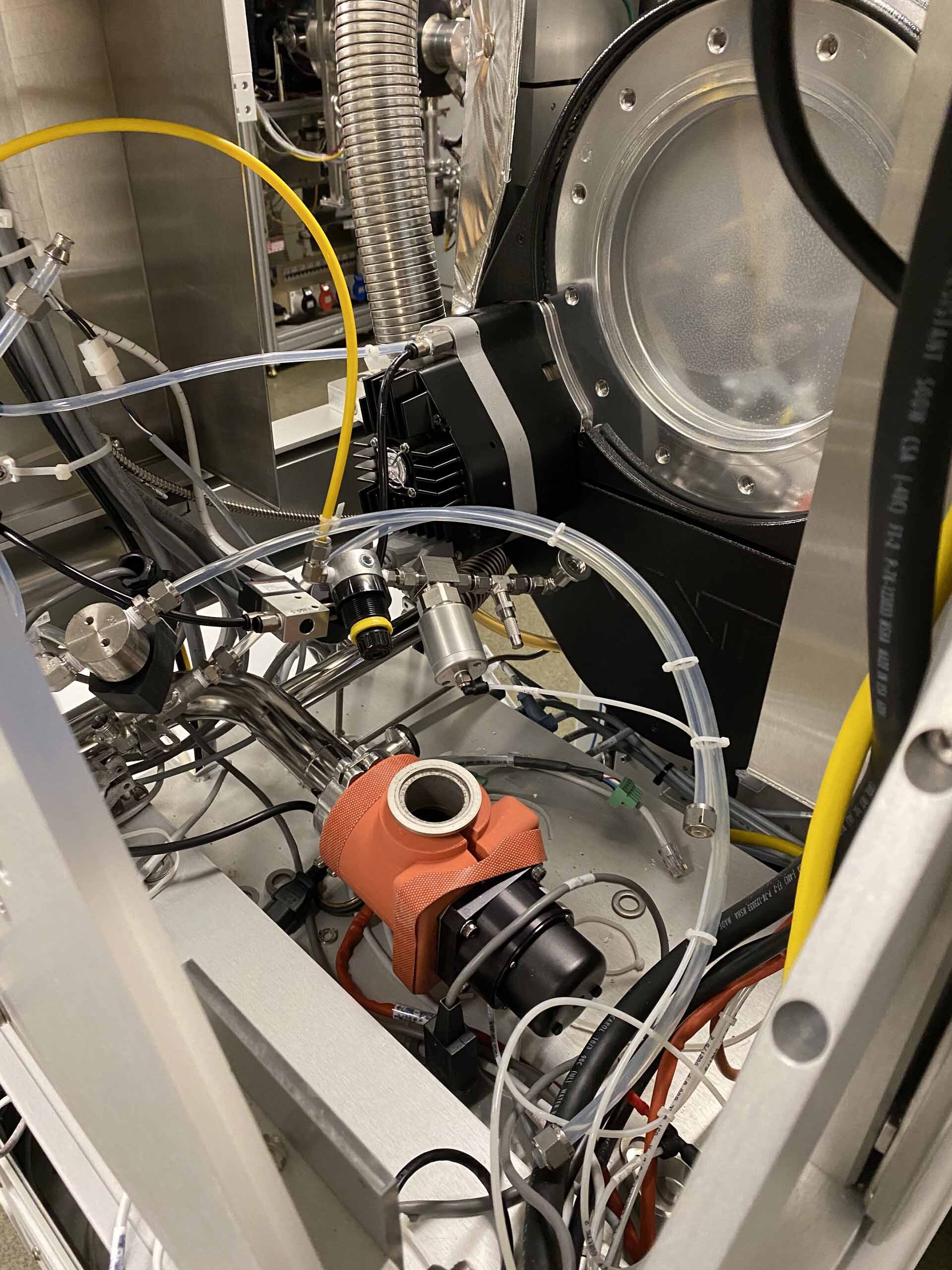

Loadlock

PM1 Chamber

Wafers type: Ceramic mechanical clamp

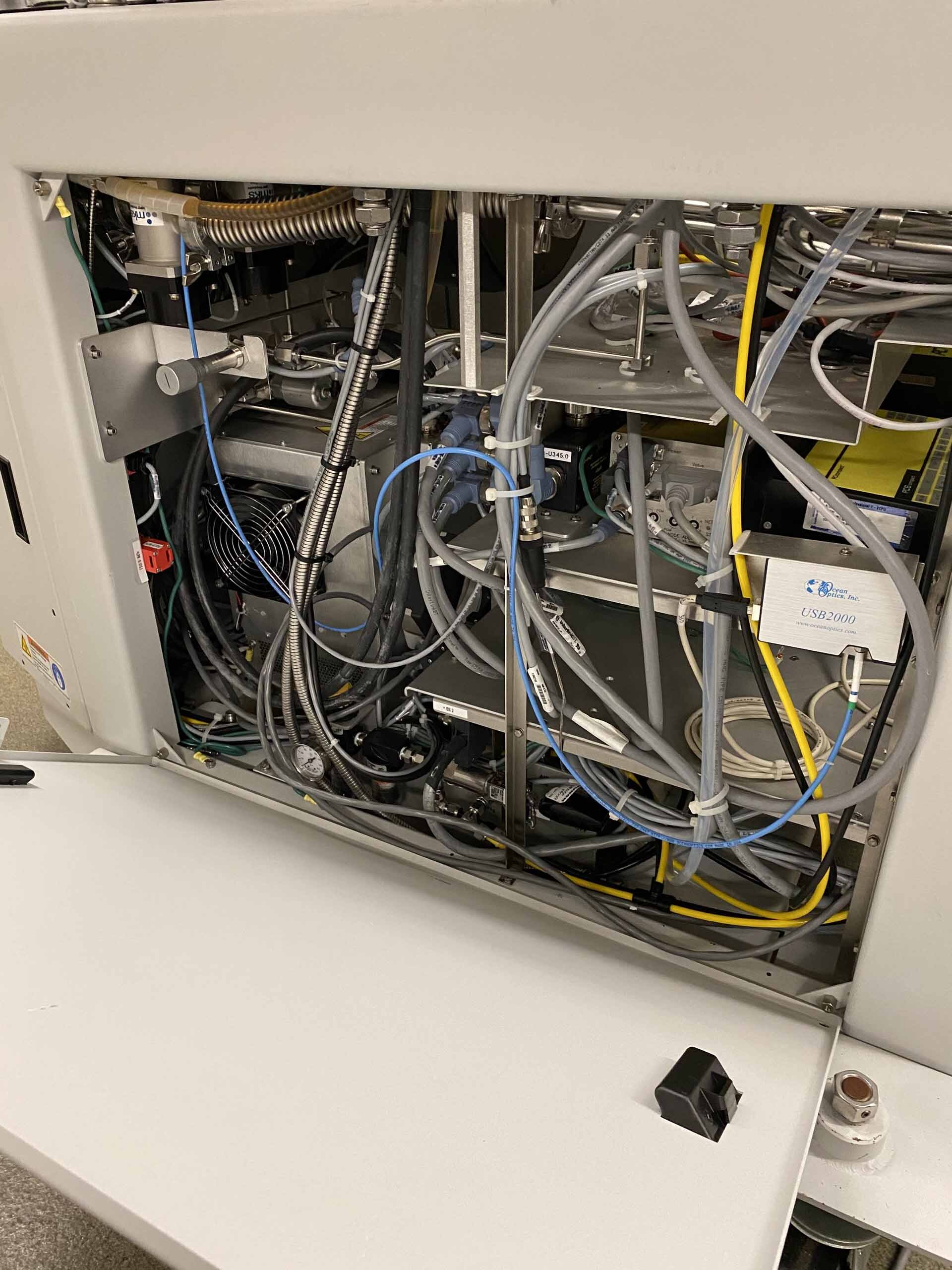

MX-400 Sidewinder wafer hander

SpectraWorks Optical endpointer

Gases: CF4, O2, N2, Ar, He, Cl2, BCl3, HBr

Heater:

JULABO Thermal H5S

JULABO Thermal H20S

Removed parts:

Turbo pump and turbo controller

Heat wrap for turbo

Roughing and backing pumps

RF Cables

Non-functional parts:

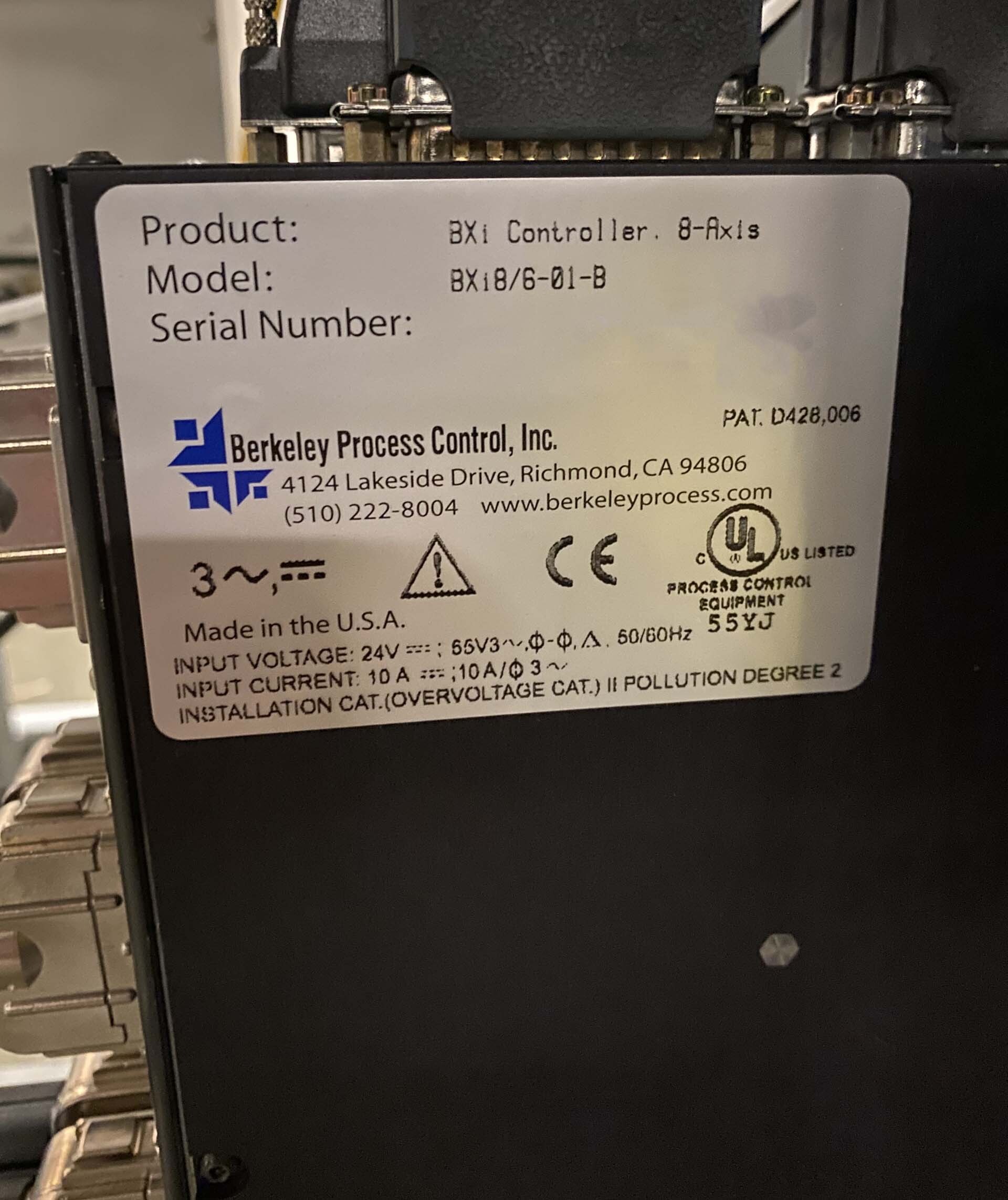

Wafer handler

BERKELEY 8-Axis controller

2003 vintage.

PLASMATHERM / UNAXIS Versaline is a state-of-the-art etcher/asher technology designed to produce high yield and superior surface quality for a variety of materials used in the microelectronics industry. This high-tech etcher/asher uses a proven plasma-based process that can perform etching and ashing operations with precision for all materials, including difficult-to-process metals. Its key features include high rate production, low cost of ownership, versatility, and fast cycle times for etching and ashing movements. UNAXIS Versaline uses radio frequency power to generate high-temperature, high-power plasma. This thermal energy is converted into kinetic energy, which is used to drive the etching and ashing processes. This technique enables PLASMATHERM Versaline to take etching and ashing to a much higher level of accuracy and precision. Versaline etcher/asher also uses unique enhanced plasma technology, which enables precise temperature control and uniform distribution of the plasma into the process gas. This ensures uniform processing of the material with no loss of chambers or materials. PLASMATHERM / UNAXIS Versaline is designed for easy maintenance and it includes a number of cleaning and process monitoring features. It also has a simplified control system, which helps reduce total cost of ownership. Additionally, UNAXIS Versaline system features a low-pressure high-output etching chamber with a sealed lid for improved safety, and a low-cost plasma torch which reduces the cost of operation. PLASMATHERM Versaline is capable of handling various sizes and types of materials. It uses a combination of plasma and magnetic field sources to achieve high resolution surface etches. Versaline can etch in a variety of angles, from straight-sided to angled or curved surfaces. This allows for great flexibility when etching different shapes and sizes of materials. Additionally, PLASMATHERM / UNAXIS Versaline can laminate layers of materials to create multi-layer structures, allowing for precision processes with fine tolerances. UNAXIS Versaline system is ideal for producing batch-size processes with precise results. It is well-suited for high-density assemblies, such as those found in cellular phones, high definition television displays, and other sophisticated electronic products. This highly reliable etcher/asher is suitable for a wide variety of fabrication processes and offers enhanced productivity for both small and large production operations. PLASMATHERM Versaline is also well-suited for rapid prototyping applications because of its fast cycle times and excellent process control.

There are no reviews yet