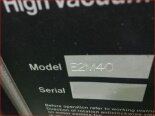

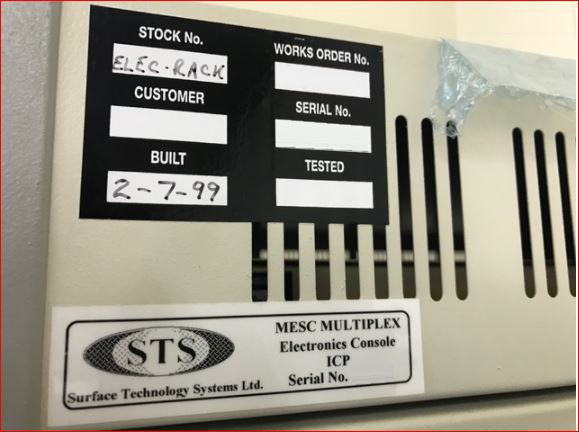

Used STS / CPX MESC Multiplex #9185203 for sale

URL successfully copied!

Tap to zoom

ID: 9185203

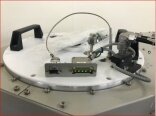

Wafer Size: 6"

Vintage: 1998

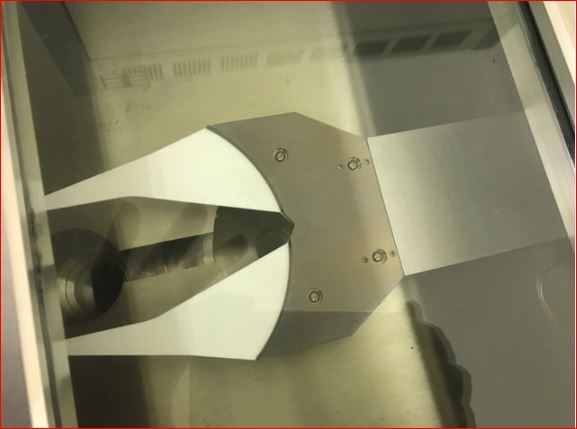

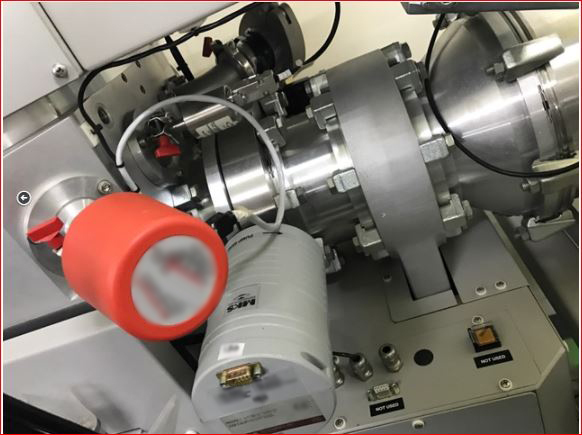

Plasma etcher, 6″

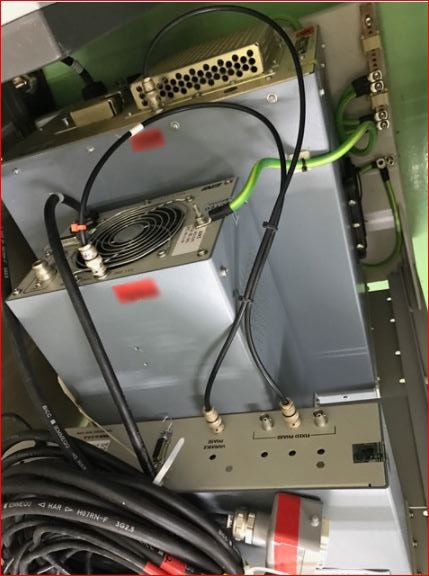

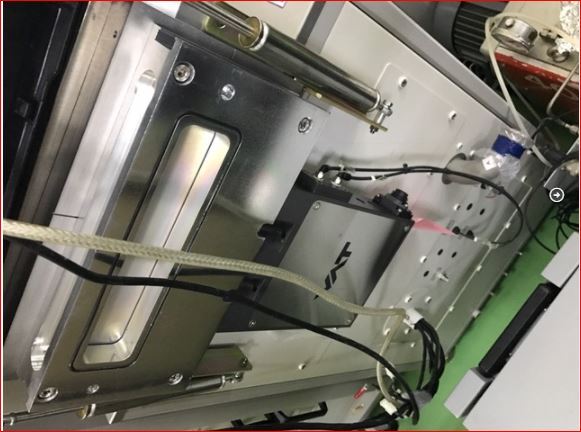

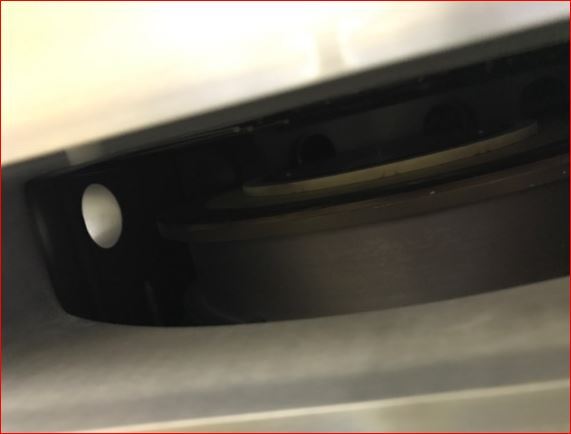

Loadlock system

Al Chamber

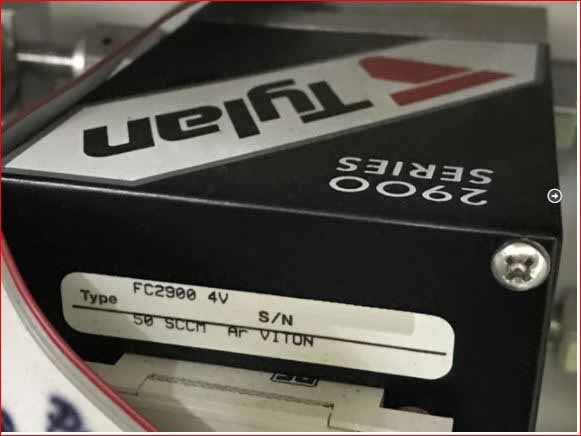

Dual chlorine gas and BCL3

Injection of gas mixtures: N2, O2, SF6, (C4F8), CF4, BCl3, Ar, Cl2 and HBr

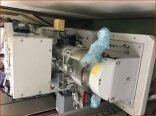

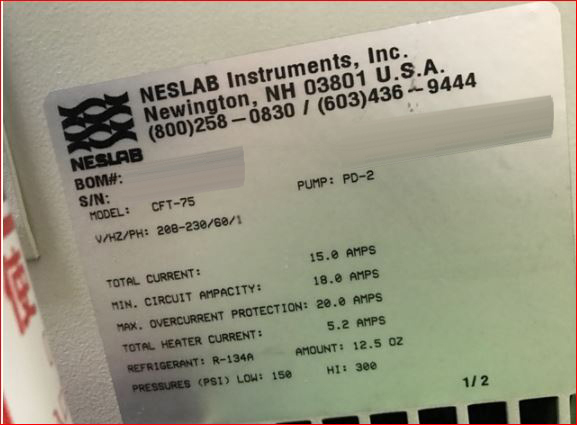

Pumps:

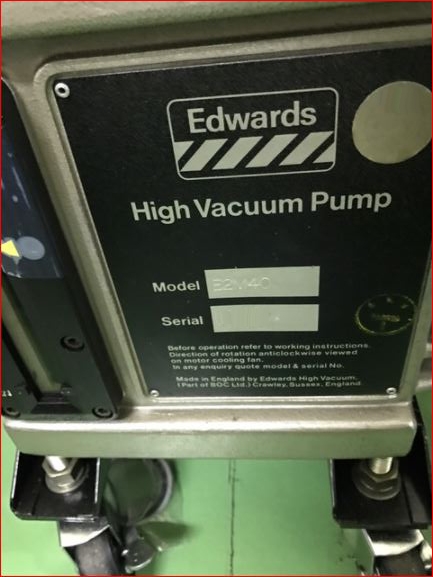

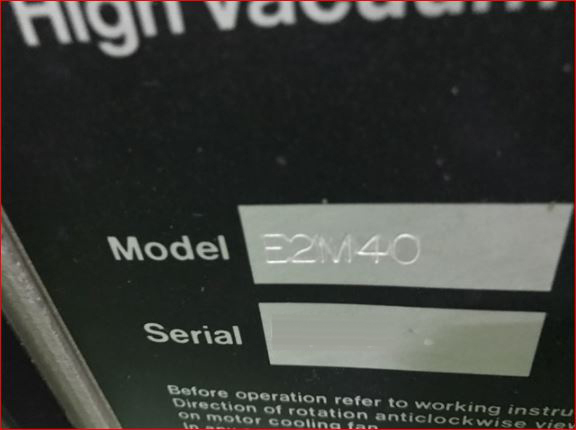

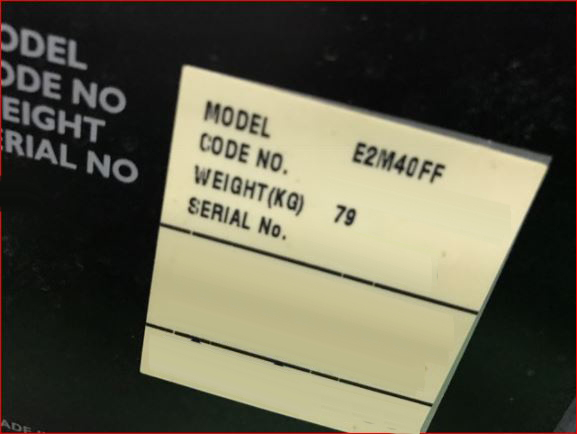

Roughing pump

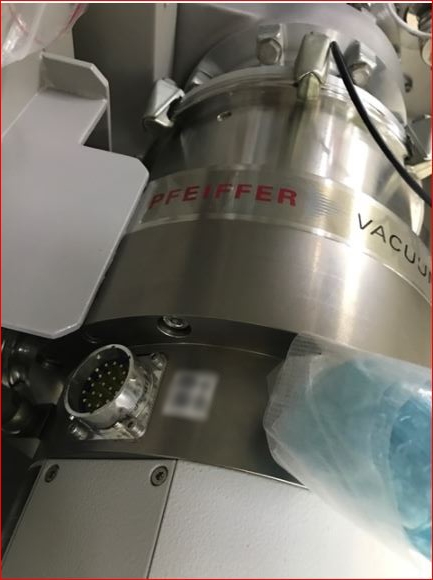

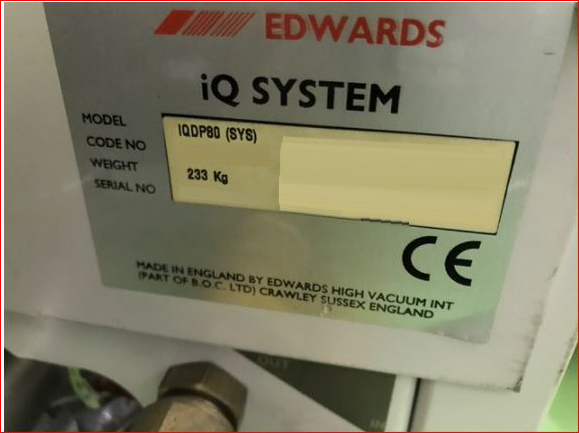

Diffusion pump

Turbo molecular pump

Pumping system: MP, DP & TMP

Inductively coupled plasma: RF1 kW

RF Generator: 13.56 MHz / 0 to 300 W

1998 vintage.

STS / CPX MESC Multiplex is a state-of-the-art etcher and asher. It is designed for the manufacturing of sophisticated electronic devices like microcircuits, microelectromechanical systems (MEMS) and microelectronics packages. STS MESC Multiplex is based on an electrochemical etching process with a sophisticated patented two-stage, multi-level (STS) logic that allows precise control of the etching process for rare-earth-free etching of multiple, simultaneous micron-scale aluminum, copper and ferrous electrodes. This makes the etcher highly efficient and precise over a broad range of materials. CPX MESC Multiplex is a compact system and requires only a minimal amount of wafer surface to begin etching. Its power and size make it perfect for small-scale, laboratory-based and research applications. MESC Multiplex features a modern and intuitive interface and is extremely easy to use. The entire etching process can be monitored and controlled, allowing the user to adjust parameters such as etching speed and current, etching protection time, etching zone and cooling fan speed. The machine is capable of etching shapes and patterns with little to no surface defects, low-voltage output and extremely wide wafer coverage. A separate motor allows for accurate placement of various smart masks, chips and other such delicate, sensitive electronic parts. STS / CPX MESC Multiplex is equipped with a front-panel display, keypad and joystick for ease of operation. All parameters are easily accessible and adjustable as needed. Overall, STS MESC Multiplex provides a quite efficient and precise etching system for all sorts of microelectronics applications, especially those with tight space restraints. With its various settings, capabilities and ease of operation, it is the perfect system to meet a wide range of etch requirements.

There are no reviews yet