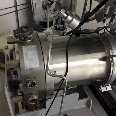

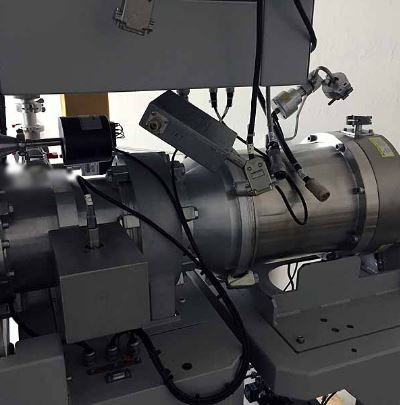

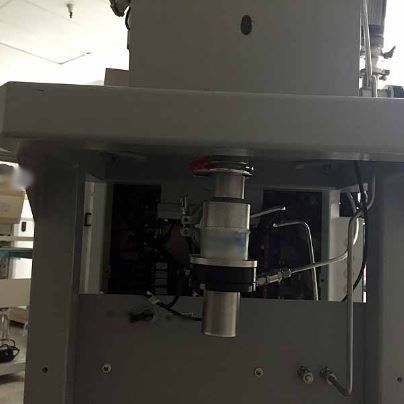

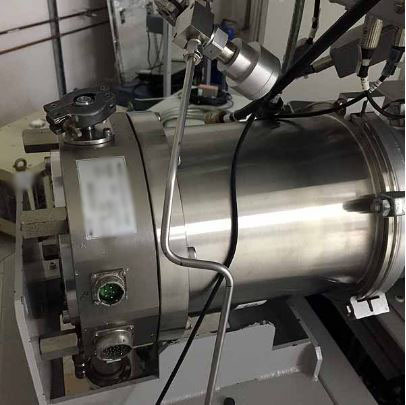

Used STS / CPX Multiplex #9145667 for sale

URL successfully copied!

Tap to zoom

ID: 9145667

Vintage: 1997

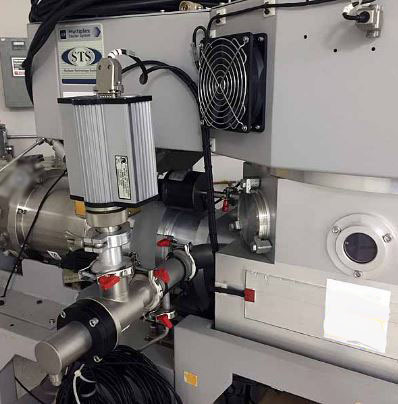

ICP Etcher

(1) Chamber: Poly / Oxide

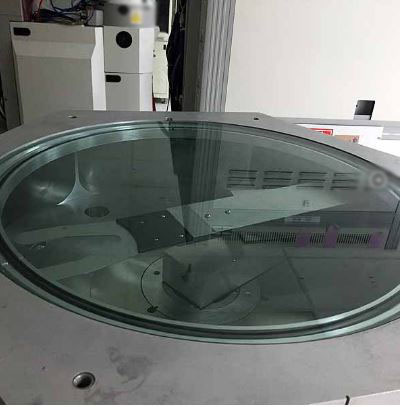

(1) Transfer chamber

(1) Vacuum cassette loadlock

(2) Process kit

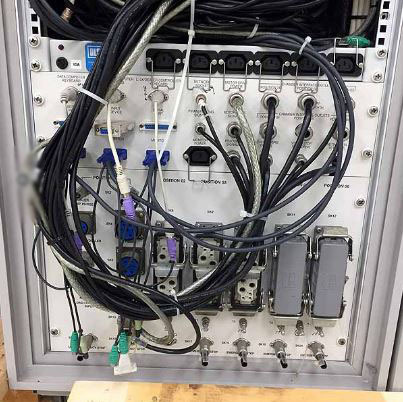

Manometer: LEYBOLD 100mPa / MKS10mBar

ESC Chuck

RF Gen source: ENI (ACG-10B)

Bias: ENI (ACG-10B)

RF Match: Auto match

Transfer: Cluster

Load lock: Vacuum cassette elevator remote

Gasbox MFC: N2/200, O2/50, N2/50, N2/100, N2/300, N2/100, N2/50, N2/50

Process gas: SF6, O2, Ar, CF4, C3F8, CHF3, Cl2, C2H4

Drypump

Chiller: NESLAB CFT-75

1997 vintage.

A STS / CPX Multiplex etcher/asher is a diffusion furnace with integrated inputs and outputs that allow for multiple process steps to be done in one unit. This type of furnace offers a single equipment that can handle a variety of processes, from etching and ashing to epitaxial deposition. STS Multiplex etcher/asher is a robust, reliable and efficient tool that can be used to produce complex structures and devices. CPX Multiplex etcher/asher is composed of several connected, independent modules that function in unison to perform various etching and ashing processes. Each module contains a wafer transfer system, process chamber, exhaust unit and a gas delivery machine. The wafer transfer tool is responsible for loading and unloading of wafers into their respective process chambers. Process chambers are built with alloy bodies, insulation liners and heated elements which are used to heat gases and promote deposition. The exhaust asset is designed to collect and filter out residual particles, volatile organics and process gases from the process chambers to ensure a safe and compliant work environment. Finally, the gas delivery model is responsible for the introduction of process gases and precursors into the process chambers for the various etching and ashing processes. Multiplex etcher/asher can be operated at temperatures between 200-350°C and offers superior control over all process parameters, such as gas flows, temperature, pressure, and power. The temperature and pressure can be adjusted by controlling the temperature of the chamber, as well as the pressure of the process gas. Additionally, each process chamber is equipped with an inlet and outlet port to allow for the introduction of reactive gases and the exhaust of spent gases. Also, the multiplexing capabilities of STS / CPX Multiplex etcher/asher allow it to perform multiple process steps within the same unit, which are controlled via the machine controller. The controller can also be used to program automatic recipes for various processes, allowing for repeatable, consistent results with minimal downtime. STS Multiplex capabilities of CPX Multiplex etcher/asher provide tremendous flexibilities and cost savings. The multiple processes it can complete within the same unit make it very versatile and cost-effective for various production scenarios. It can help to reduce both wafer handling time and cycle times, which saves the user both time and money. This makes Multiplex etcher/asher an excellent choice for businesses who are looking for a reliable, cost-effective diffusion furnace.

There are no reviews yet