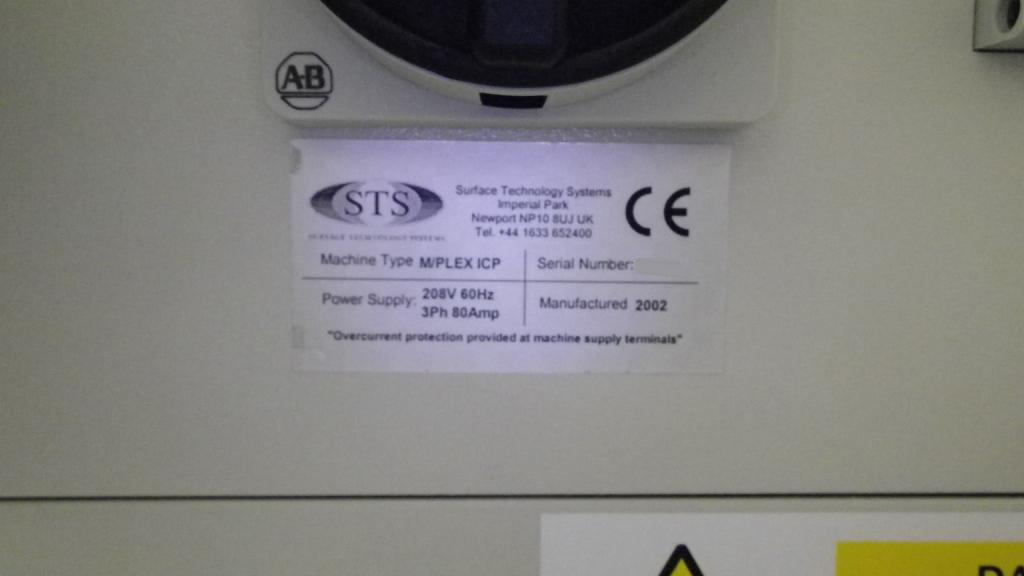

Used STS / CPX Multiplex #9162410 for sale

URL successfully copied!

Tap to zoom

ID: 9162410

Wafer Size: 4"

Vintage: 2002

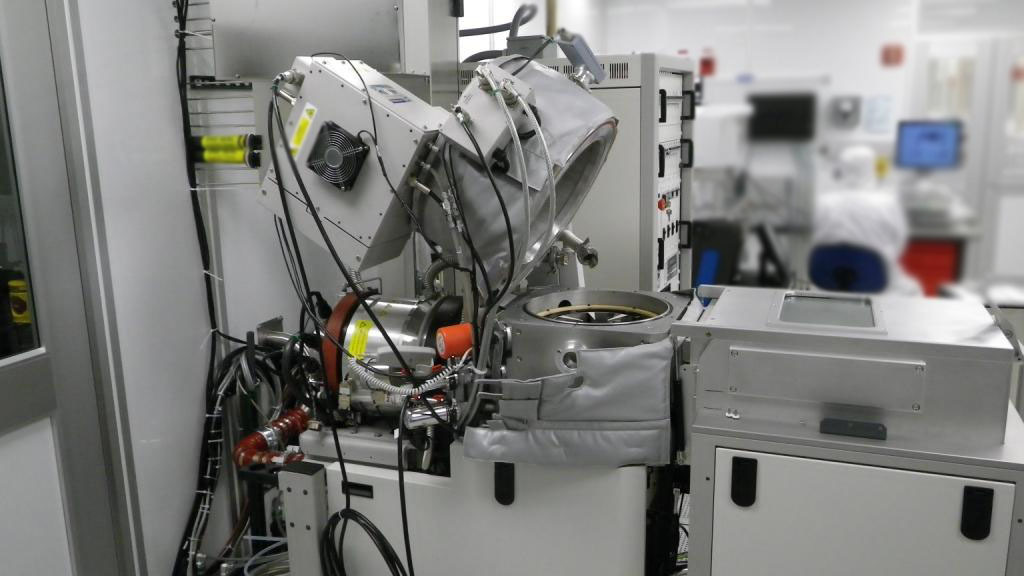

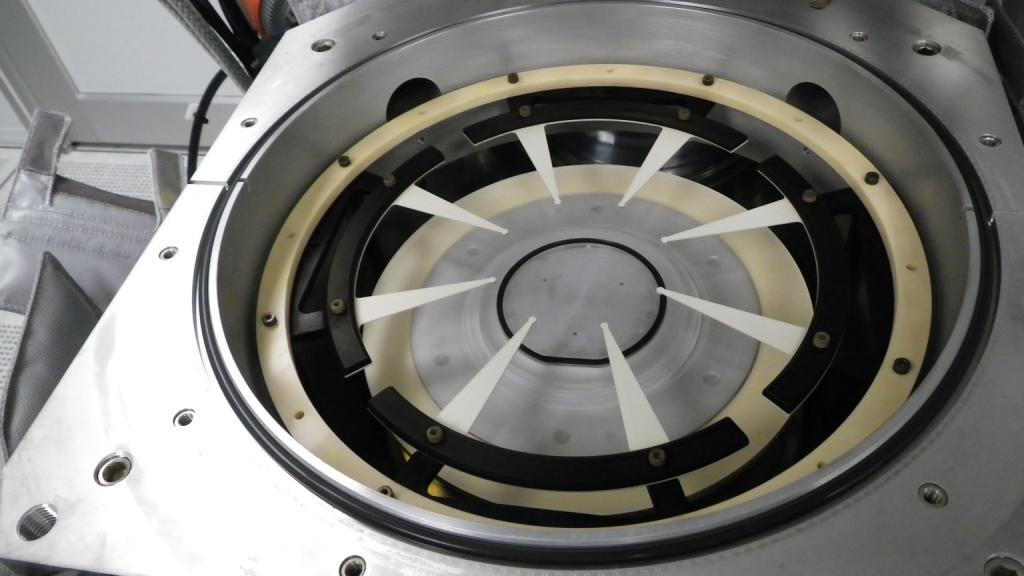

ICP AOE system, 4"

Load lock

Previously used for oxide, pyrex, quartz etching

Process gases plumbed: C3F8, C4F8, SF6, CF4, Cl2, C2H4, O2, H2, Ar, He

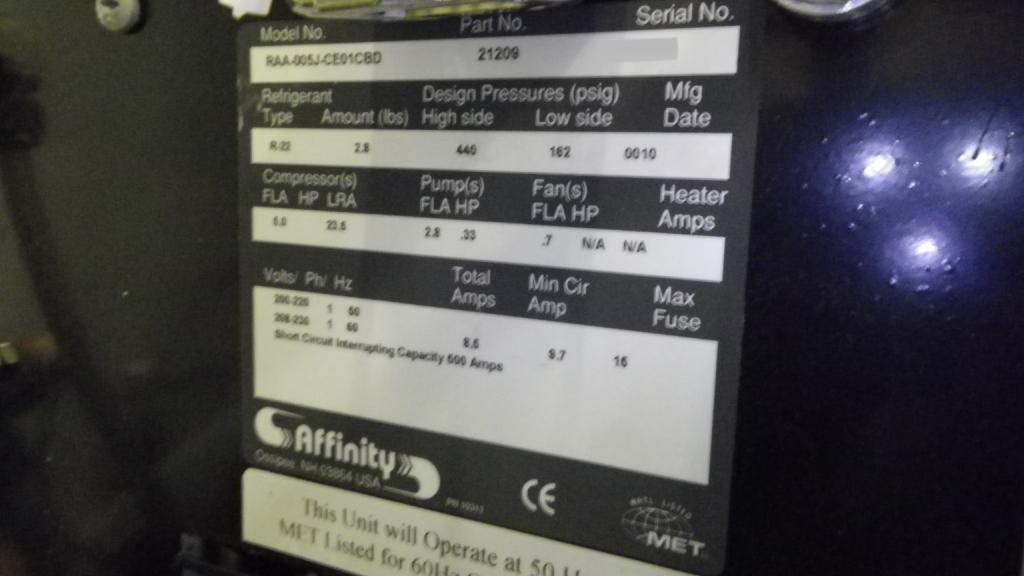

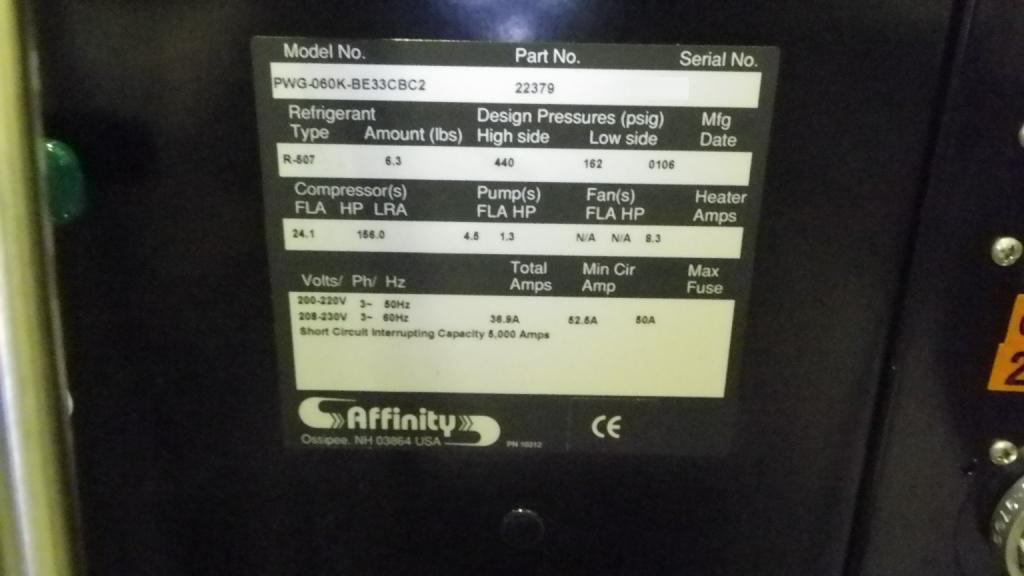

(2) Affinity chillers

Chiller 1: RAA-005J-CE01CBD

Chiller 2: PWG-060K-BE33CBC2

Chuck: Mechanical clamp

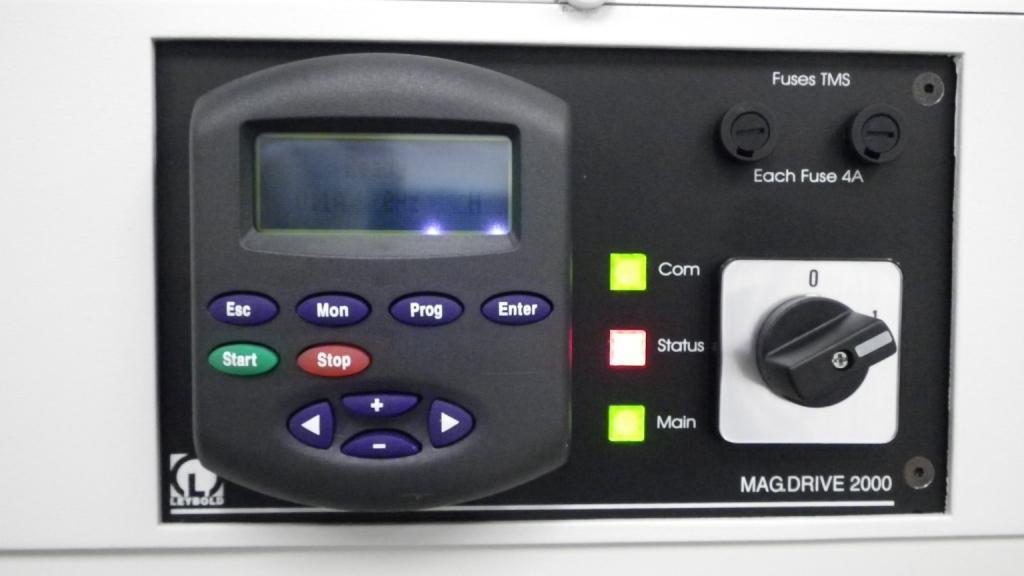

LEYBOLD MAG 2000 CT turbo pump

MAG drive 2000 turbo controller

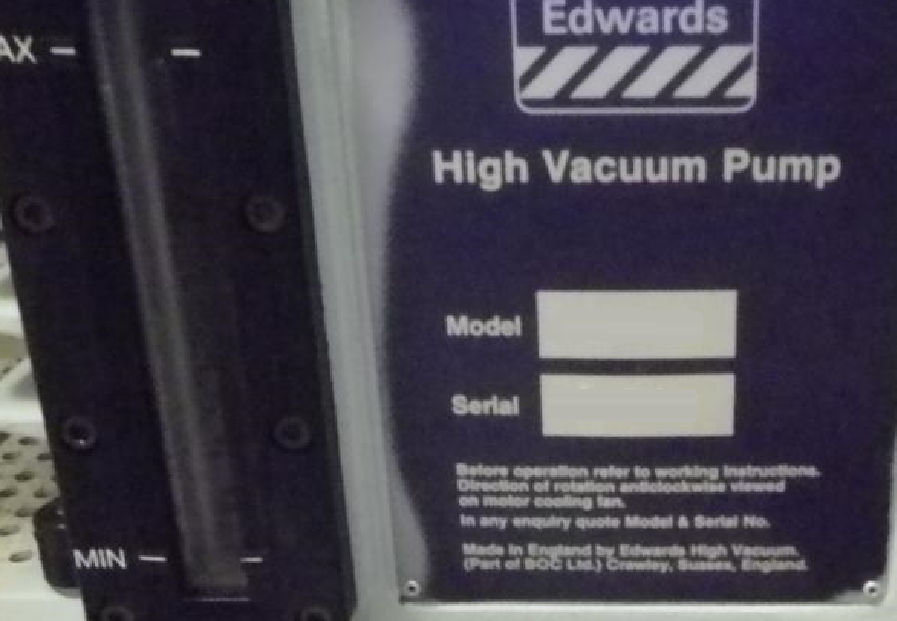

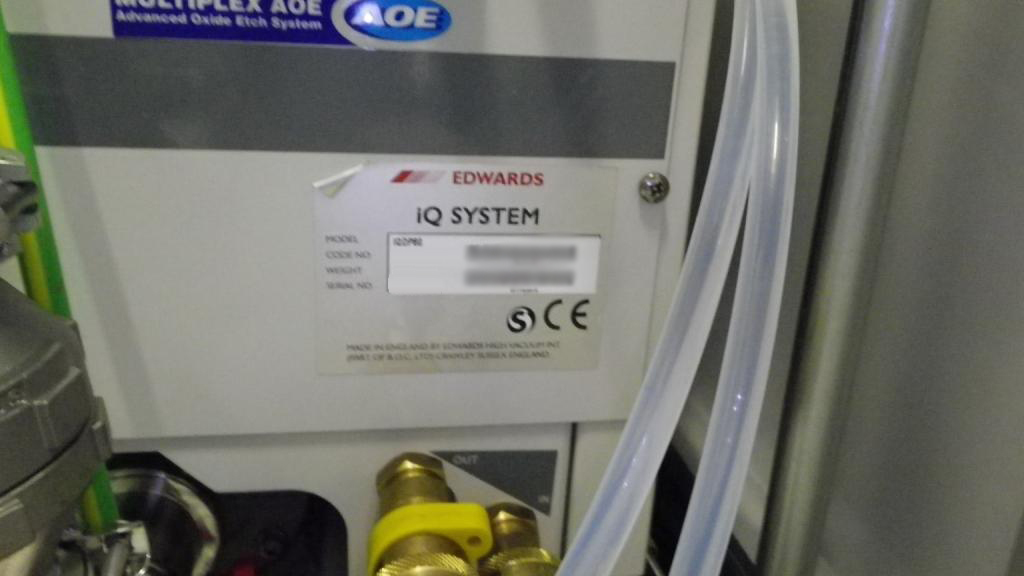

EDWARDS IQDP80 Dry pump

EDWARDS D40BCS Oil pump

MILLIPORE CDLD 1112E HE cooling manometer

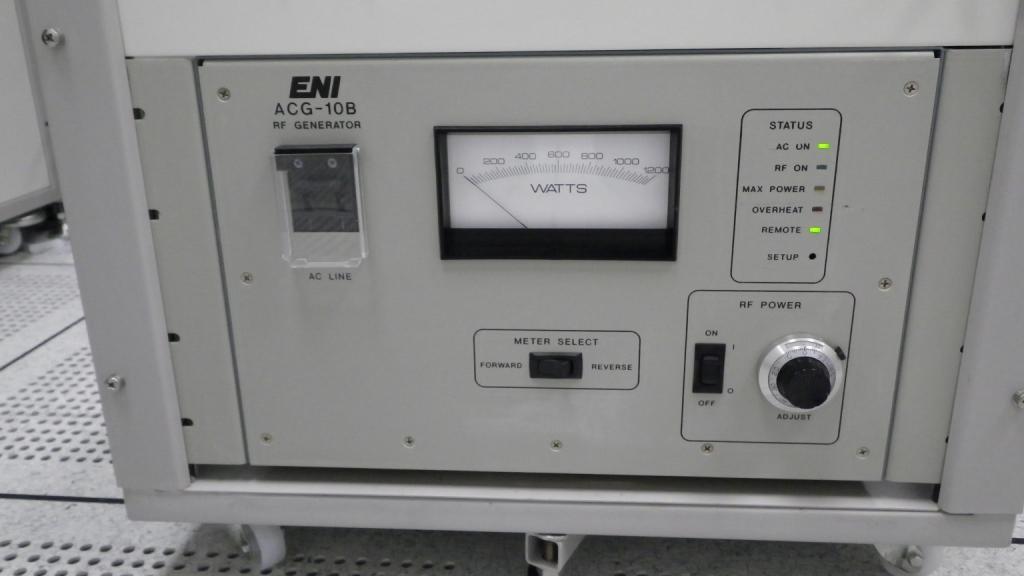

ENI ACG-10B RF generator

AE RFG 3001 RF generator

Finger and ceramic ring has broken

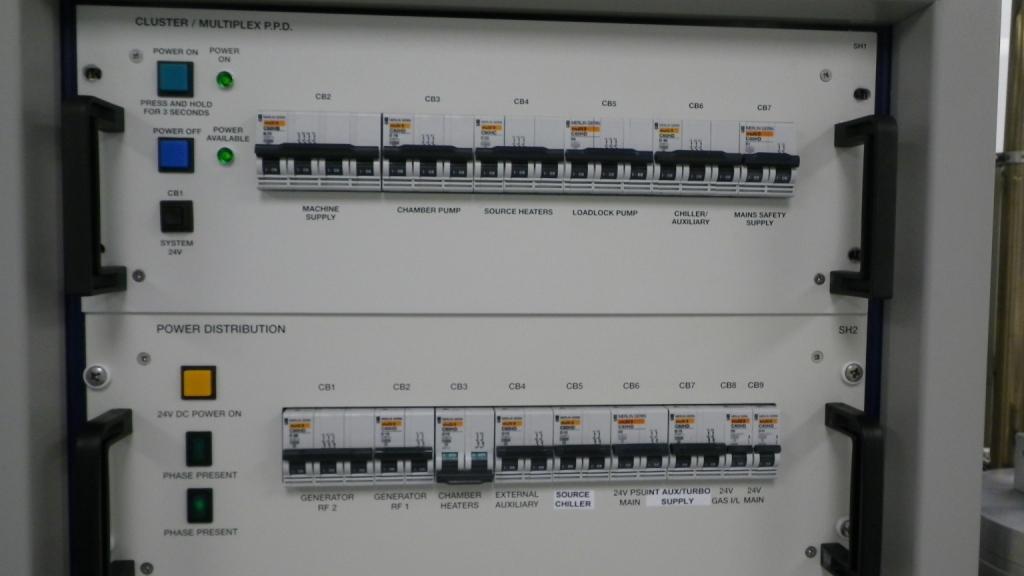

208 V, 60 Hz, 3 phase, 80 A

Missing part:

Gas box

2002 vintage.

STS / CPX Multiplex etcher/asher is an automated equipment for etching and ashing of wafers. It is designed to asher and etch up to eight wafers simultaneously in one operation for high productivity, throughput and cost-effectiveness. STS is built with a stainless steel chamber to provide a stable environment and ensure longer operational life. It has a high-temperature furnace that is capable of reaching temperatures up to 1300°C, and is ideal for etching and ashing silicon and other materials. The system also has increased capabilities for adjusting process parameters, such as temperature, process time, and gas flow rate. The ashing/etching process can be preset for each recipe and monitored during runtime. CPX has advanced process controls, including automated time-sequencing, temperature ramp profiling, and process set-point management. This allows the user to precisely control process parameters such as flow rate, temperature set-point, and cycle time. The ability to program a variety of thermal and temperature profiles for both etching and ashing makes it one of the most versatile etching/ashing systems available. STS / CPX utilizes an advanced monitoring unit for controlling both ashing and etching processes. This includes real-time sensing of chamber pressure, display of the wafer states, automatic calibration & adjustment of pressure for optimal ashing/etching performance, and direct control access for the etching/ashing process. Providing maximum temperature uniformity, the machine also has a unique design of the wafer handling tool that ensures good temperature homogeneity throughout all the wafers in the chamber. This asset is equipped with computer-controlled lift/positioning for the wafers, and optional manual lift/positioning. Overall, STS Multiplex etcher/asher is an excellent choice for high-efficiency, high-throughput wafer etching and ashing. With its advanced process controls, precise parameters, and uniform temperatures, it is ideal for efficient and reliable production.

There are no reviews yet