Used TEGAL 6500 #9238618 for sale

URL successfully copied!

Tap to zoom

ID: 9238618

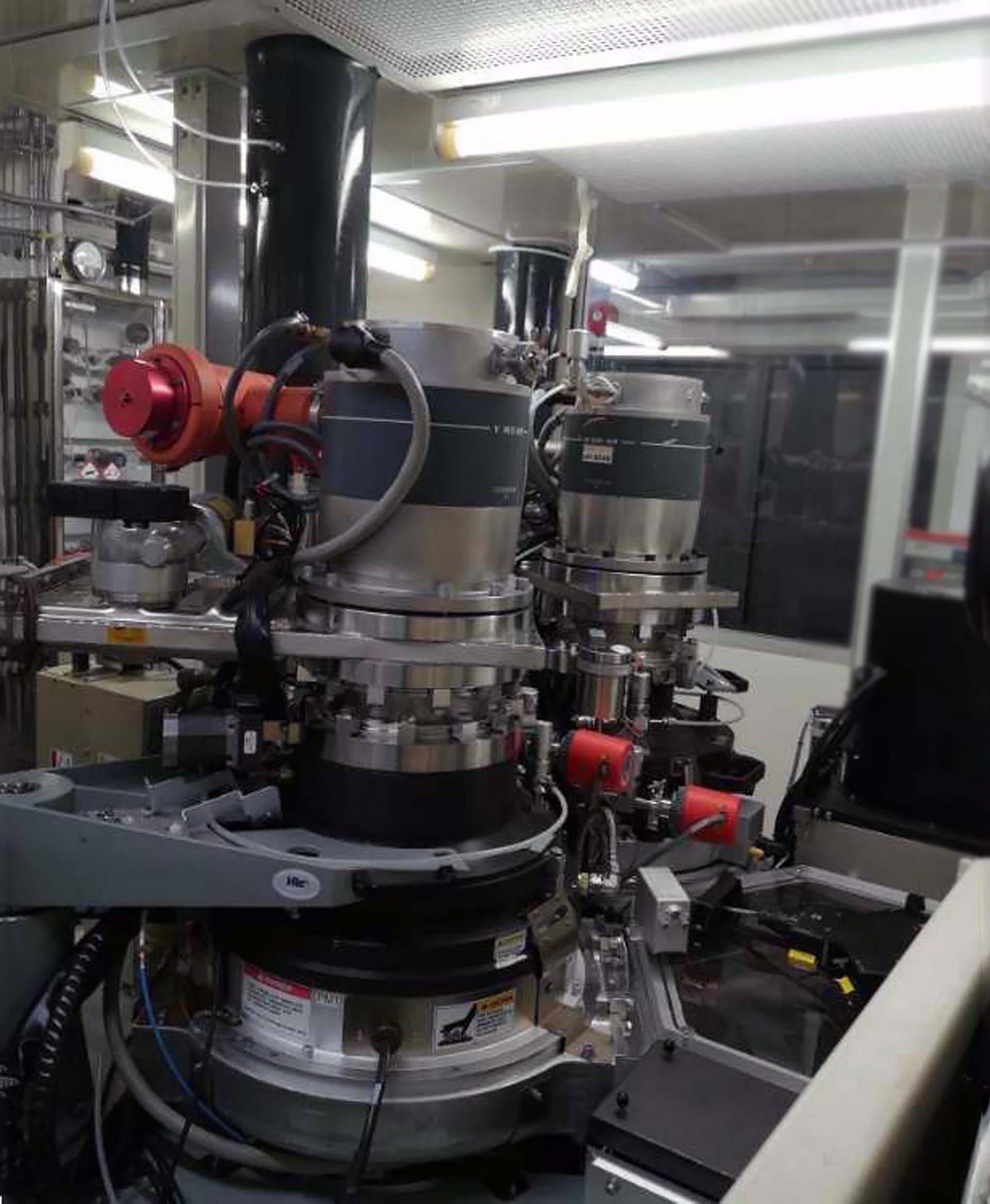

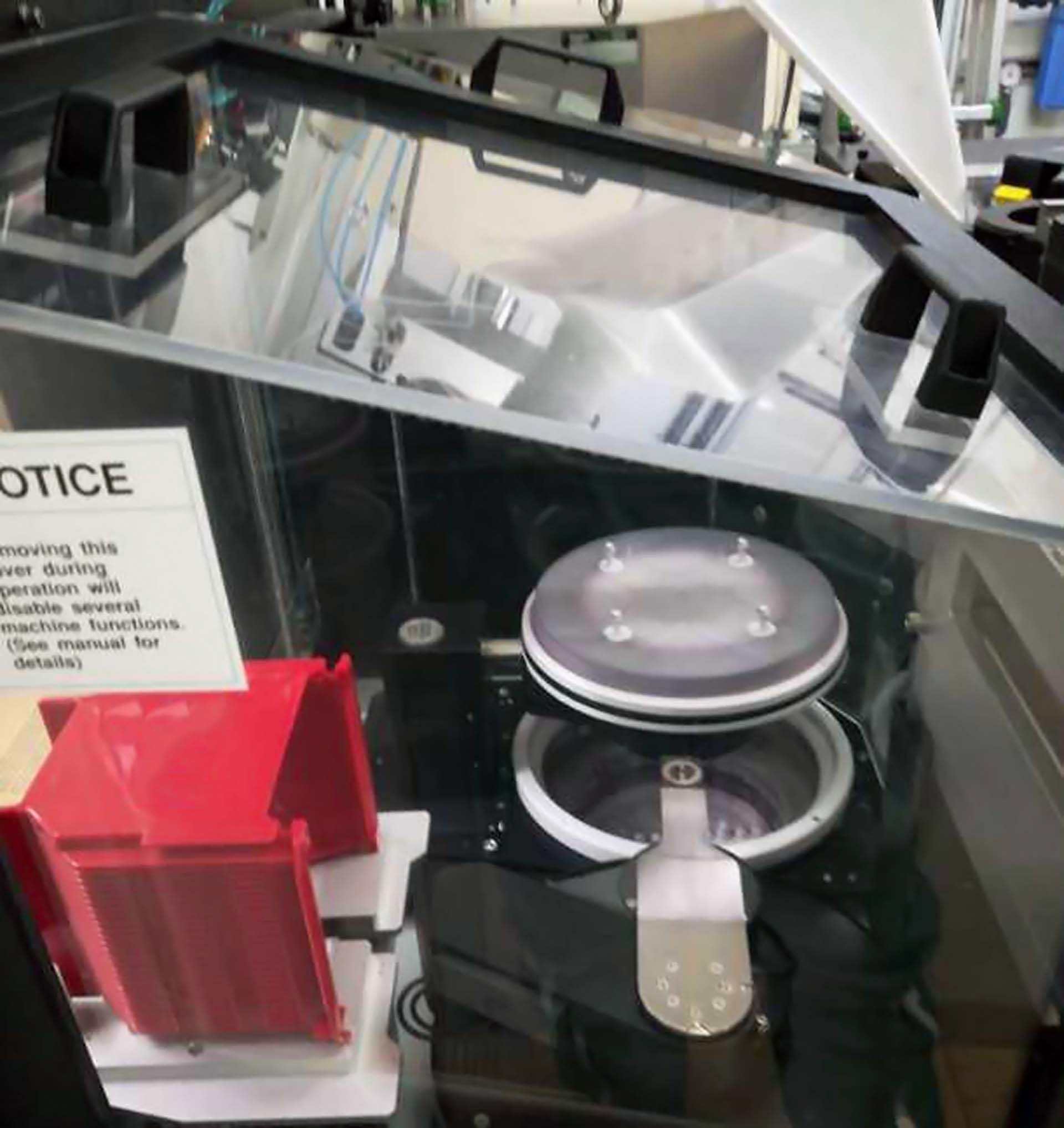

System, 6"

Etch chamber

Passivation chamber, 6” for metal etch AlSi / AlSiCu

PM1-Non-functional

PM2

PM3-Stripper

PM4-Rinser

PM5-Aligner

CM1-Cassette module 1

CM2-Cassette module 2

TM1-Primary robot

TM2-Secondary robot-atmosphere

Chiller

RF Generator

Monitor.

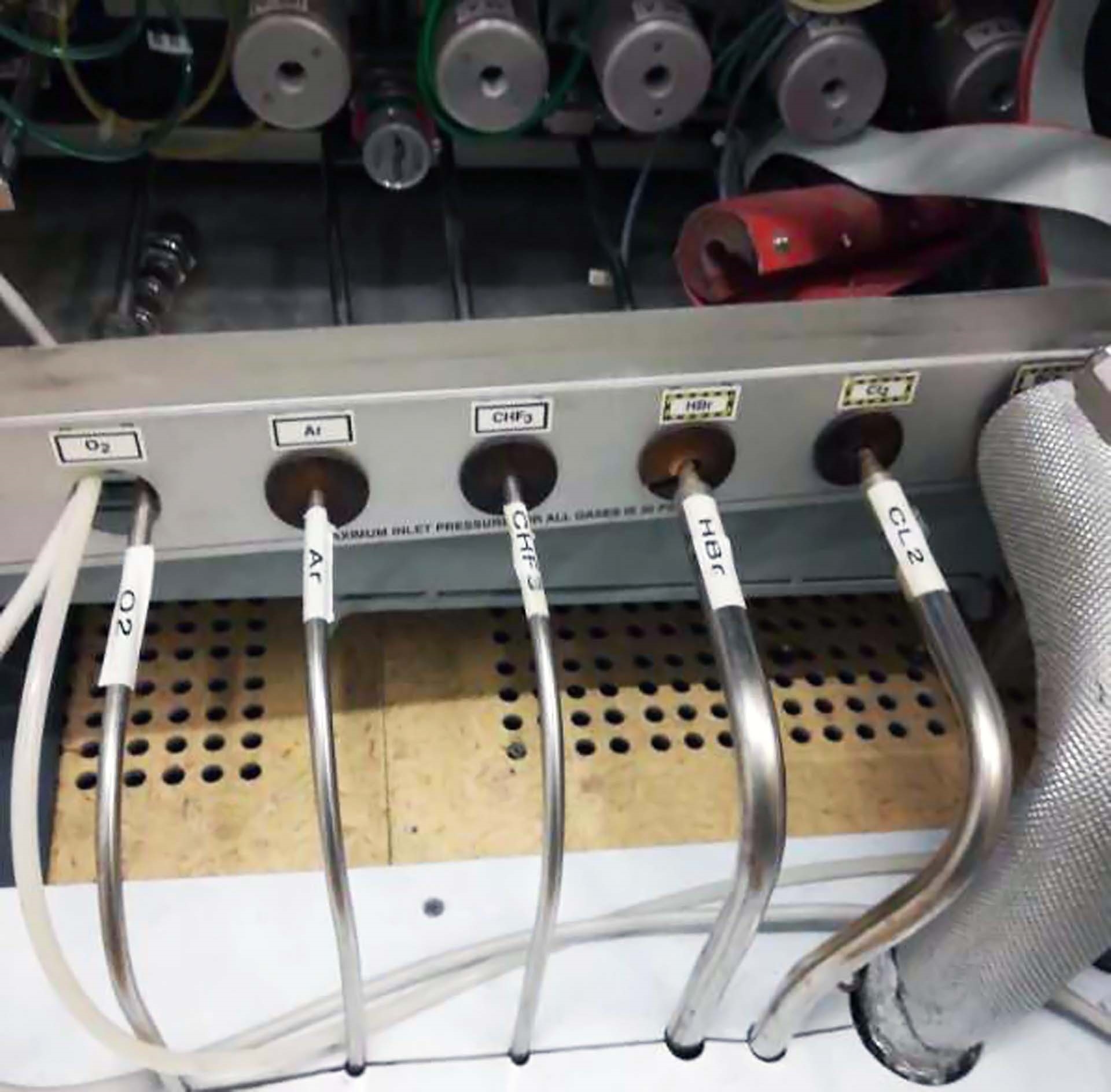

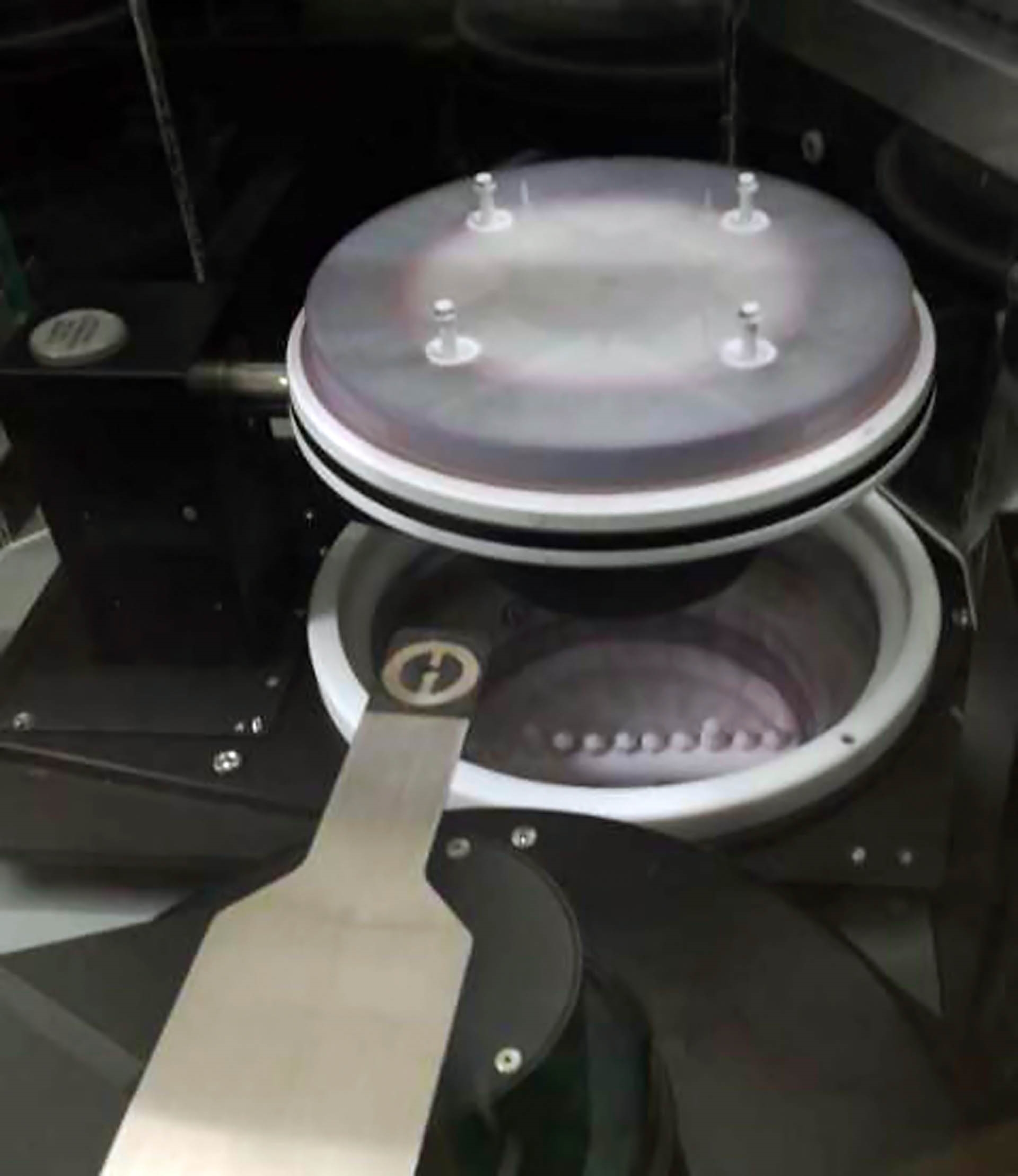

TEGAL 6500 is a microfabrication tool used for etching and ashing in a wide range of materials. The equipment is extremely versatile, with a wide range of applications including doping, deposition, material removal and etching. Its standard heating system allows it to process a wide range of materials, including metals, silicon, oxides, polymers and ceramics. 6500 features a 13-zone reactor, which is composed of a hydraulic octagonal crystal chamber (28.5 cm in diameter) and six magnetically-suspended, out of plane, evenly-distributed extraction channels. This electro-magnetic design gives the unit great flexibility when selecting and defining etching and ashing parameters. The 13-zone reactor enables TEGAL 6500 to reach up to a total of 18 zones of usable process area, while its uniform distribution of gas flow over the whole process area gives even etching and ashing on all surfaces. The standard lift height of 6500 is 20mm, exceeding current industry standards. The Machine also features a wide range of Auxiliary Options. These can be configured for specific applications, such as reactive ion etching, and they can be used to improve specific etching mechanisms or to optimize process throughput. These include an Ion Source, Remote Plasma Source, Plasma Hot-Spot Identification and Compensation Tool, and an Advanced Deposition Function. The Ion Source can be used to achieve high fidelity and vertical etching of materials like silicon and germanium alloys. The Remote Plasma Source can be used to achieve a homogeneous etching for high aspect ratio structures. The Plasma Hot-Spot Identification and Compensation Asset refer to a model used to detect and suppress hot spots which can damage surface features. The Advanced Deposition Function can be used to create conductive or insulating metal layers. TEGAL 6500 is designed with an advanced management equipment which provides remote access and real-time monitoring for all its functions via its dedicated control panel. This allows for enhanced safety and process control, as well as, convenient maintenance of the system. All relevant unit parameters can be populated from its integrated library, and it has the added capability to save and recall recipes for easy reuse. 6500 is an extremely handy and versatile tool, which offers a wide range of options for research and development, prototyping, and production. Its advanced process management, coupled with its wide range of options make it well suited for a variety of processes in both laboratory and manufacturing settings. Its wide variety of options and its affordability make it an excellent choice for a variety of processes and applications.

There are no reviews yet