Used TEGAL 901e #9009940 for sale

URL successfully copied!

Tap to zoom

ID: 9009940

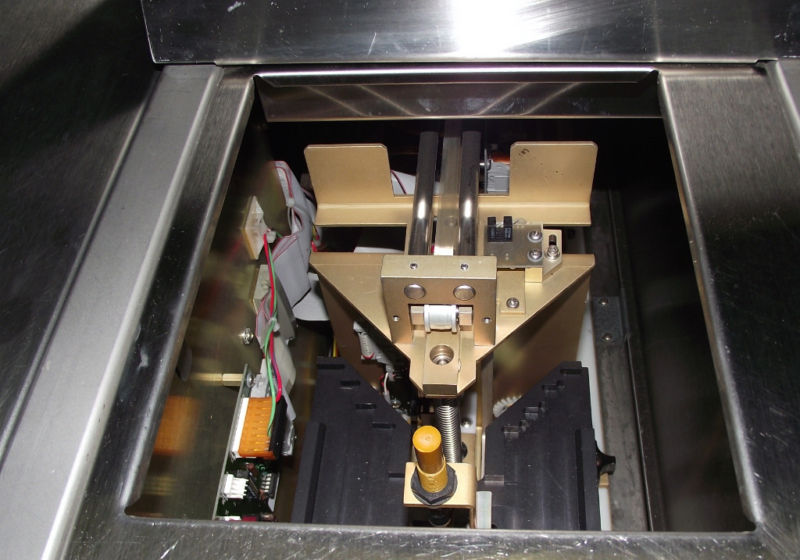

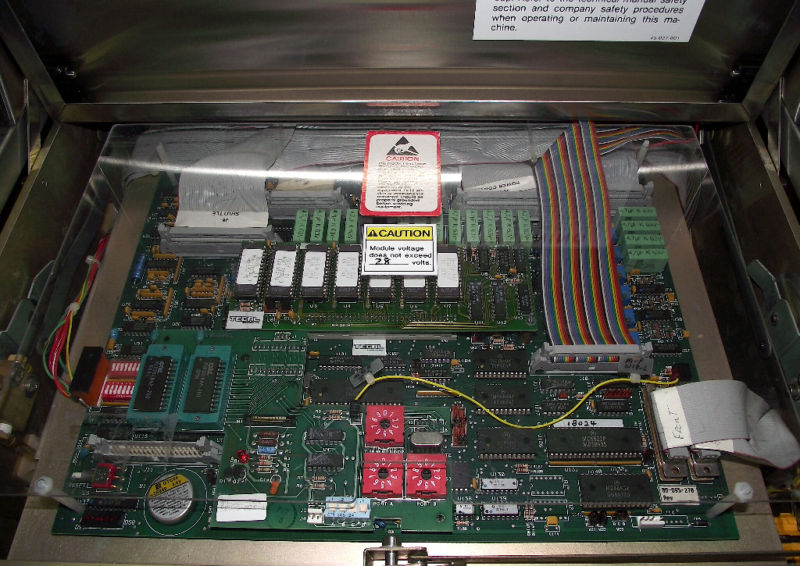

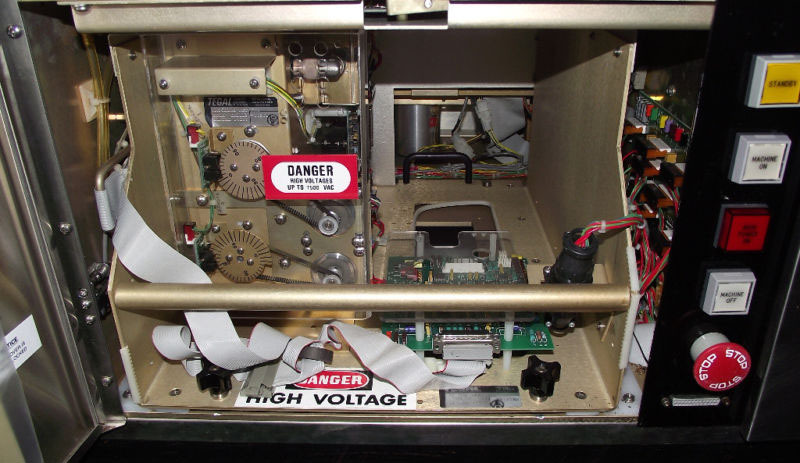

Plasma etcher

Includes:

ENI ACG-10T 1000w 13.56 RF generator, 200-240 V, 1 phase, 60 Hz

Omega RD-46 plotter

Digital VT 420 monitor and keyboard

(3) Plastic boxes of parts

(6) Manuals.

TEGAL 901e is an etcher/asher designed to produce a high level of performance and flexibility while providing reliable, accurate etching and ashing processes. This etcher can be used in combination with compatible substrates such as III-V semiconductor material and MEMS materials. As a low pressure, plasma-assisted device, TEGAL 901 E offers superior processing capabilities in any environment, including high-vacuum, low-pressure RF and low-pressure oxyhydrogen environments. 901e is constructed from a rugged, 100% stainless-steel chamber and includes a safety enclosure with EHD heaters and sensors. This allows for plasma processes over a wide range of temperatures and pressures. The etcher features quartz window viewports, allowing for in-situ observations. An independently controlled and heated shield eliminates contamination and cross-contamination of major etch/ash components. 901 E can be used in both manual and fully automated modes. For manual operation, the user can independently and precisely control the pressure and RF power during etching. Furthermore, the etcher has a four-dimensional sequential feature, which allows the user to set a sequence of etching and ashing parameters and repeat them multiple times with minimal reset time. This feature helps to maximize process repeatability and productivity. The comprehensive diagnostics and control system allows users to display process parameters, monitor and control multiple processing parameters, as well as store, recall and transfer recipes. The system also offers advanced data logging to track process-related history, so users can efficiently diagnose process problems. TEGAL 901e is designed with a variety of methods of wafer handling, from manual wafer loading, to cassette compatible wafer transfer, to isolated load-lock, load chamber and unload chamber. The load-lock chamber, for example, allows for independent atmospheric pressure control for particle-free etching and ashing. Combining all these features, TEGAL 901 E offers versatility and superior performance for etching and ashing processes for both research and production applications. It offers high-throughput, repeatability and reliability in producing high-quality components.

There are no reviews yet