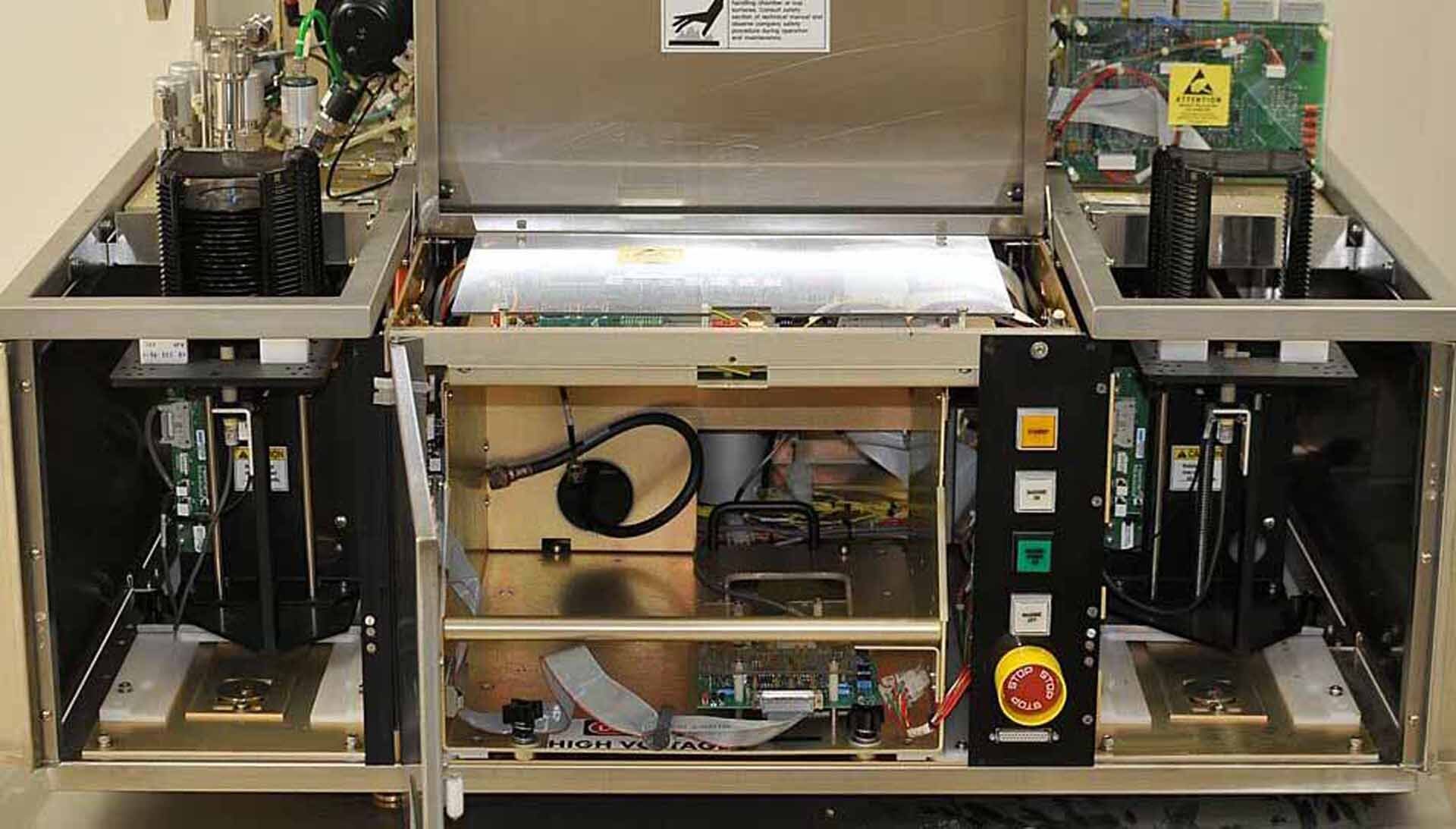

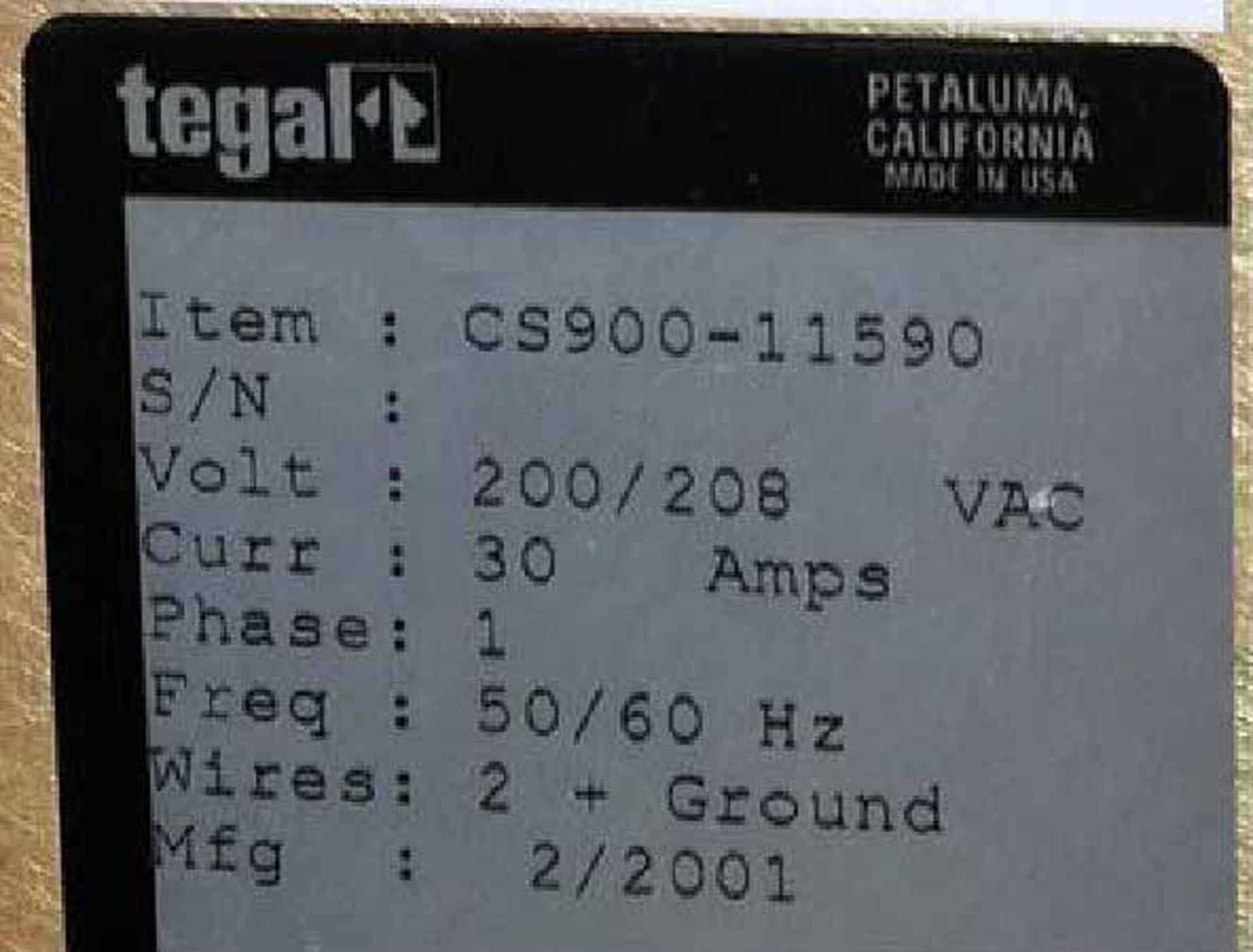

Used TEGAL 901e #9381612 for sale

URL successfully copied!

Tap to zoom

ID: 9381612

Wafer Size: 3"-6"

Vintage: 2001

Plasma etcher, 3"-6", parts machine

P/N: CS900-11590

(4) Gas input lines

P/N: 99-172-003/F IMN-3

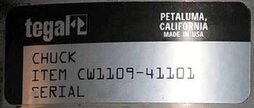

Chuck, P/N: CW1109-41101

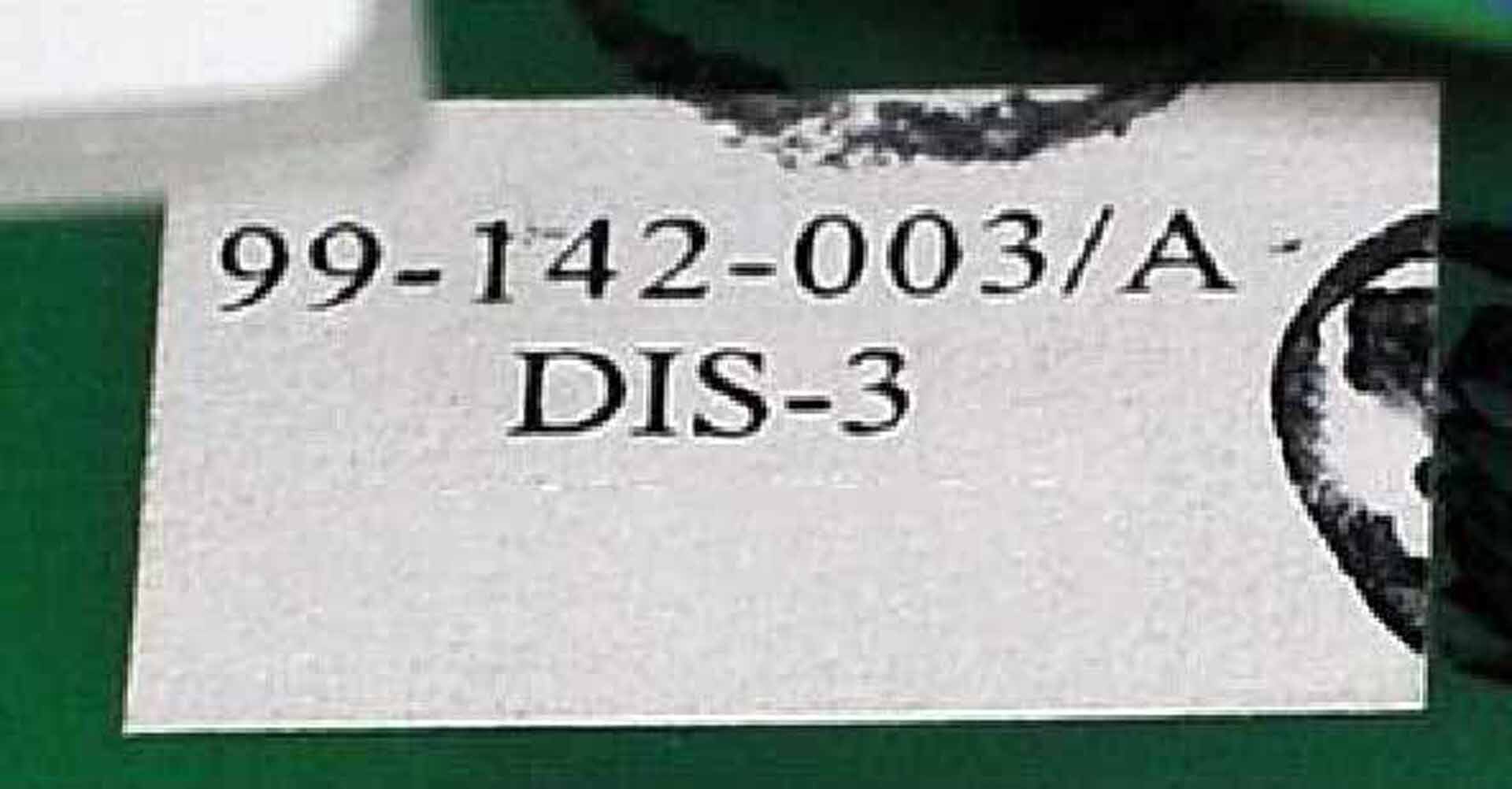

P/N: 99-142-003/A DIS-3

RF Delivery, P/N: CR1124-01002

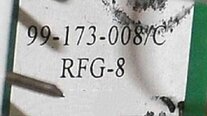

P/N: 99-173-008/C RFG-8

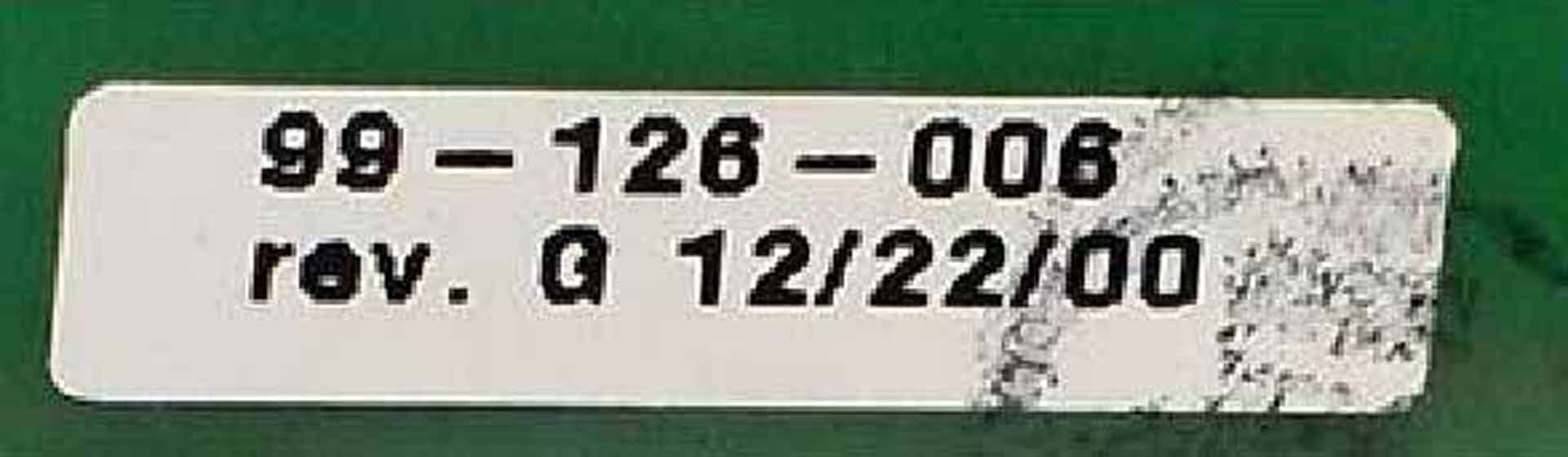

P/N: 99-128-006

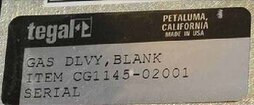

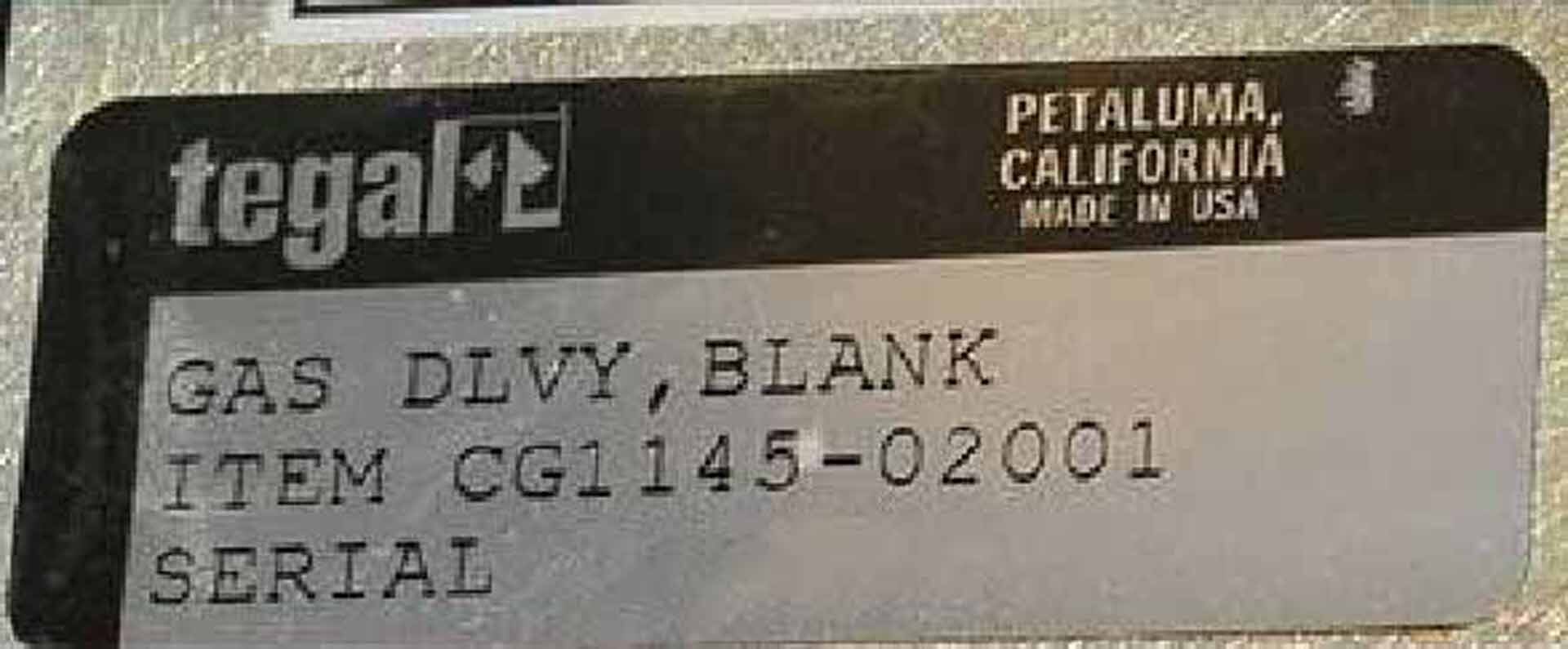

Gas delivery blank, P/N: CG1145-02001

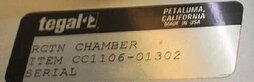

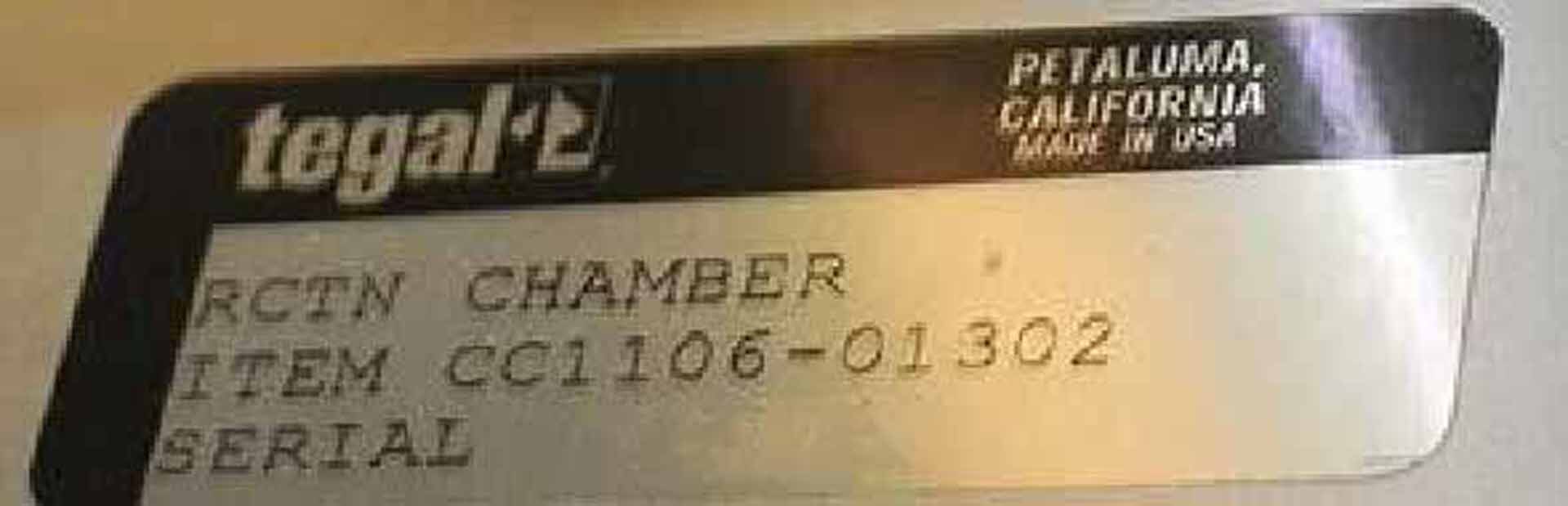

RCTN Chamber, P/N: CC1106-01302

P/N: 39-342-001

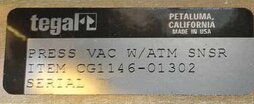

Press vacuum with ATM sensor, P/N: CG1146-01302

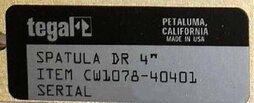

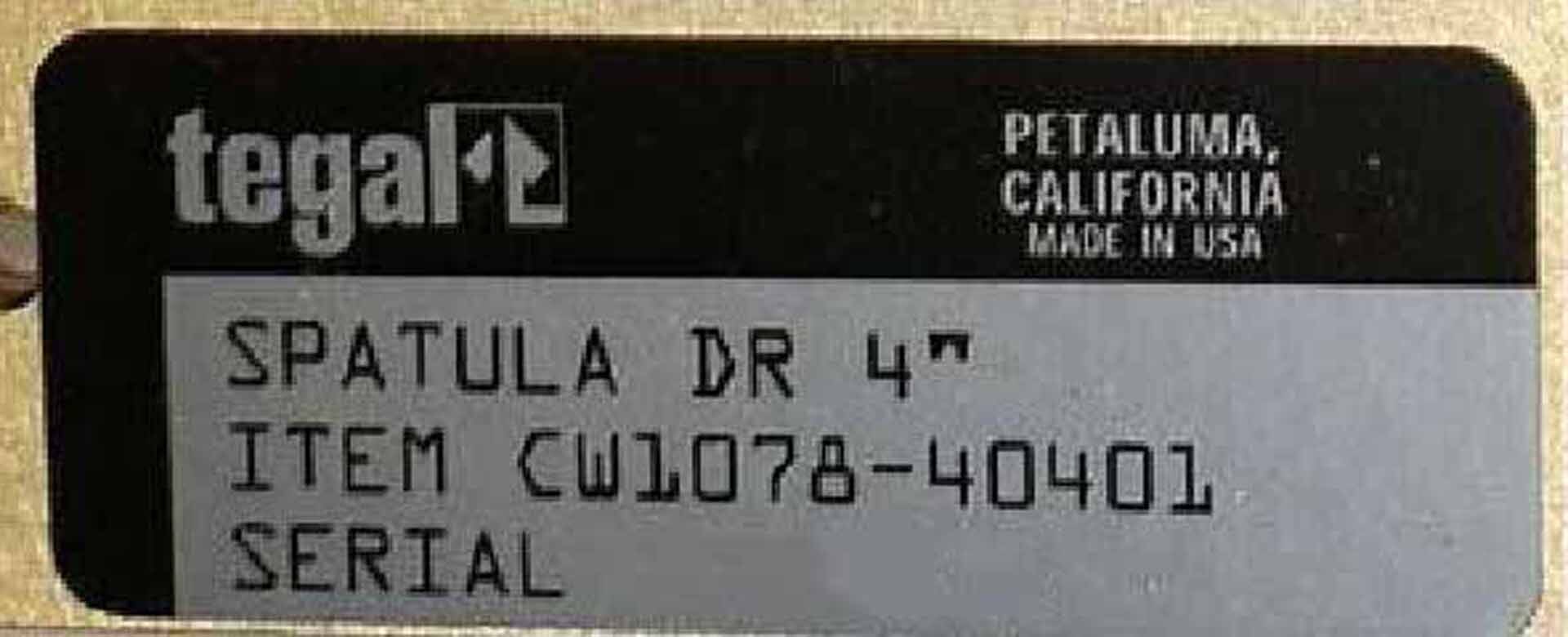

Spatula Dr, 4", P/N: CW1078-40401

P/N: 99-207-004/K MBE-4

P/N: 80-095-278

P/N: 26-041-039C

Missing parts:

Control computer

Capacitance manometer

Mass flow controllers

RF Match unit

Vacuum pump

Manuals

Cords / Cables

Power supply: 200/208 V, Single Phase, 30 A, 50/60 Hz

2001 vintage.

TEGAL 901e is an very powerful etching / ashing equipment designed for superior performance in wafer processing operations. This etcher / asher system is a fully automated, high-throughput unit with a graphical interface and embedded computer that provides process control and analysis capabilities in one modular package. The unit also provides for a variety of process etching and ashing of substrates such as silicon, FR4, germanium, and GaAs. TEGAL 901 E is equipped with a 120-mm loadlock chamber and load port that can hold up to 6 wafers per batch, facilitating quick and efficient wafer processing. Additionally, the chamber offers an extensive range of options including a sublimation heating stage, a sample viewing machine, and a mass flow controller. The sample viewing tool combined with the panoramic imaging ensures precise positioning of the sample during etching and ashing. 901e's plasma source is based on multi-frequency ECR (electron cyclotron resonance) technology. It is capable of generating an RF power output that ranges from low to high, allowing for a wide variety of etching and ashing conditions. The plasma source is also equipped with a rapid cycling mechanism for shorter process cycle times. 901 E is also designed to be safe and energy efficient, making it ideal for use in research, pilot line, and industrial applications. Utilizing the fully automated wafer handling asset and graphical user interface, TEGAL 901e simplifies etching and ashing processes by allowing users to print wafer maps and program sequence automatically. It enables users to precisely control etching parameters including the frequency and power, temperature, pressure, and gas composition. Furthermore, with the machine's software, users can easily monitor process progress and analyze post-process results, ensuring that the results are reliable, repeatable, and consistent. TEGAL 901 E provides our customers a reliable, powerful etching / ashing tool that delivers superior performance in wafer processing and long-term stability during run time. The compact design and intuitive user interface makes wafer processing easier and more efficient. Plus, the model's ability to identify and monitor process parameters allow users to precisely manage process conditions and maintain product quality.

There are no reviews yet