Used TEL / TOKYO ELECTRON Unity IIe 855DS #197628 for sale

URL successfully copied!

Tap to zoom

ID: 197628

Wafer Size: 8"

Vintage: 2000

Oxide etcher, 8"

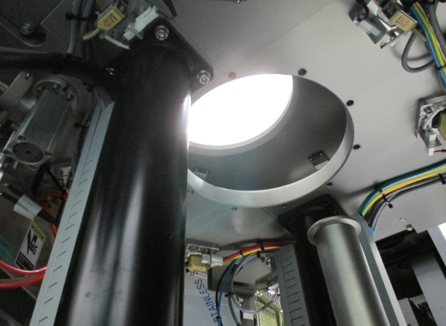

(2) chambers

Mass flow controller

GAS #1 C4F8 50

GAS #2 CH2F2 50

GAS #3 O2 200

GAS #4 CO 300

GAS #5 AR 1SLM

GAS #6 CHF3 100

GAS #7 CF4 100

GAS #8 C4F8 50

Pressure controller

P/V (PC1) VAT 65048-JH52

P/V (PC2) VAT 65048-JH52

Robot

Robot Controller YASKAWA SRC-Ⅱ016

TMP (PC1) EDWARDS STP-A2203W1

TMP Controller (PC1) EDWARDS STP-A2203W1

TMP (PC2) EDWARDS STP-A2203W1

TMP Controller (PC2) EDWARDS STP-A2203W1

Generator (PC1) DAIHEN WAG-30C

Generator (PC2) DAIHEN WAG-30C

Matcher (PC1) DAIHEN CB-13A

Matcher Controller (PC1)

Matcher (PC2) DAIHEN CB-13A

Matcher Controller (PC2)

EPD (PC1)

EPD (PC2)

T/C TMP Controller

HDD DISK (DATA) HDS722580

HDD DISK (S/W) HDS722580

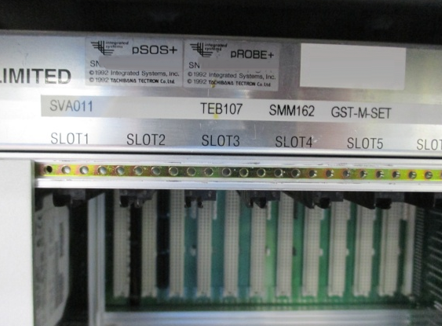

AC Rack (PCB Board)

SVA011: Not attached

TEB107: Not attached

SMM162: Not attached

GST-M-SET: Not attached

TVB0008

TVB0010-1: Not attached

TC(PCB BOARD)

COM

DIO1

DIO2

MAIO

ILK

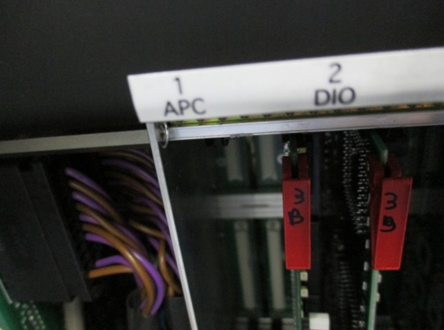

PC1(PCB BOARD)

APC: not attached

DIO

MAIO

COM

TEMP

PC2(PCB BOARD)

APC: not attached

DIO

MAIO

COM

TEMP

Robot controller missing

2000 vintage.

TEL / TOKYO ELECTRON Unity IIe 855DS is a high-end etcher / asher for semiconductor fabrication. It is designed to provide precision etching and ashing processes for the fabrication of semiconductor components, such as interconnect layers, through-silicon vias (TSVs), and MEMS devices. TEL Unity IIe 855DS features a highly precise two-axes cassette-to-cassette transfer equipment and an advanced control system. This enables the etcher / asher to deliver precise and stable etching and ashing processes, with improved uniformity and controllability. The processing chamber is enhanced at higher temperatures compared to standard etcher / ashers, which allows it to reach higher etch rates. TOKYO ELECTRON Unity IIe 855DS also includes unique advanced features, such as versatile gas flow control, advanced process recipes, closed-loop, self-checking protection, auto-abortions, and an advanced end-of-run detection. This ensures a high level of process efficiency, improved quality control, and a reliable etching and ashing experience. Unity IIe 855DS has been designed to process a variety of wafer sizes, up to 8 inch. It is capable of running up to 600 wafers per hour, and ensures short cycle times. This makes the etcher / asher suitable for a wide range of semiconductor production needs. It utilizes advanced process technologies, such as OPC-RI/RIE, strip ashing, etch-stop-etch, and annealing, among others. As for safety and environmental features, TEL / TOKYO ELECTRON Unity IIe 855DS is constructed with certified, ultra-low-leak valves. This ensures an extremely tight seal, and helps to prevent any gas from leaking into the surrounding environment. Additionally, the etcher / asher uses a variety of process gases with low toxicity, and has an integrated safety unit designed to monitor levels of hazardous gases. At a total machine height of just 70 cm, TEL Unity IIe 855DS is compact, making it suitable for a wide range of industry spaces. It is also a highly efficient tool, which ensures lower operating costs. In short, TOKYO ELECTRON Unity IIe 855DS is a precise and efficient etcher / asher for semiconductor fabrication, providing process sophistication, quality control, and reliability. It is known for its high performance, as well as for its environmental safety and low operating costs.

There are no reviews yet