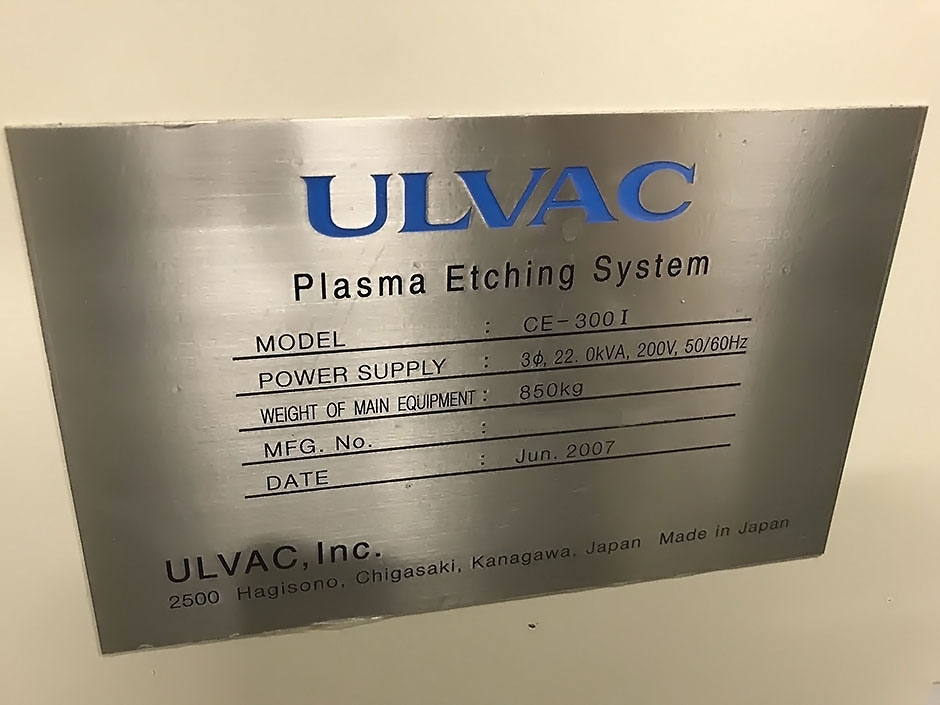

Used ULVAC CE-300I #9206958 for sale

URL successfully copied!

Tap to zoom

ID: 9206958

Wafer Size: 3"

Vintage: 2007

ICP Etcher, 3"

Load-lock type: ISM

Load-lock chamber

Sample size: 75 mm

Process reliability / Accuracy:

RF Discharge source: Inductive coupled plasma

RF Frequency: 13.56 MHz

Discharge impedance: Auto control

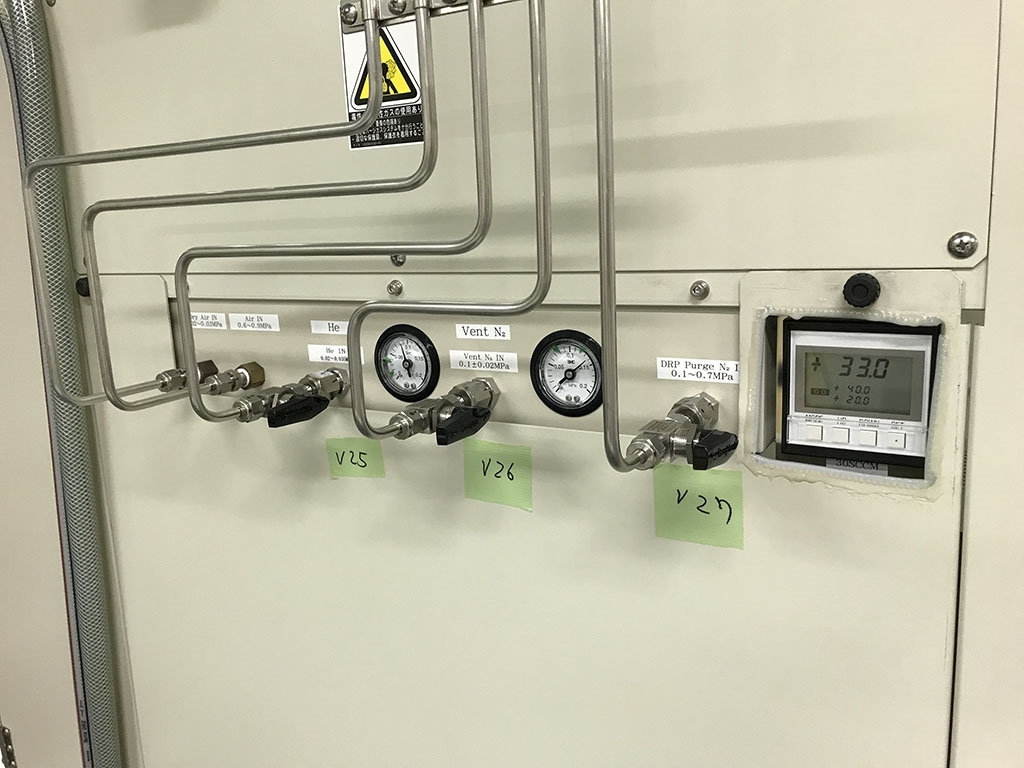

Purge gas: N2

Temperature control: Water circulator / He gas

Wafer hold type: Electrostatic chuck

Target materials: Mo, TiN, NbN, Si

QUARTZ Wafer tray

UBE RID-2 UV Ozone cleaner

THERMO ELECTRON NESLAB Merlin M75 chiller

Power supply: 208-230 V, Single phase, 10.1 A

UBE INDUSTRIES UBE RID Exhaust gas treatment device

Gases: O2, Chlorine gas, acid gas

ULVAC Abatement pump

Gases: O2, N2

RF Power:

ICP Assembly upper electrode: 1000 W

RF Biased lower electrode: 300 W

Load lock gases: SF6, CF4, C4F8, O2

Process / Gases: Pressurized air, He, N, Ar, O, SF6, CF4, B(OH)3, Cl

Plasma concentration: 1 x 1011 cm³

Etching operation pressure: 0.07 ~ 10 Pa

Etching rate: 200 nm ~ 500 nm/min

Uniformity: ±5% or less

Substrate temperature control: Electrostatic chuck

Manual included

Power supply: 200 V, 3-Phase, 22.0 kVA

2007 vintage.

ULVAC CE-300I is an etcher/asher specifically designed for semiconductor applications. The equipment is equipped with an advanced capacitively-coupled inductively-loaded (CCIL) plasma source that offers a higher etch rate than conventional RF systems. The system is designed to be easy to use and to provide a cost-effective, efficient etch process. The CCIL plasma source also provides an extremely repeatable etch profile with very minimal undercut compared to other plasma sources. The unit features a 350 mm x 350 mm process chamber, allowing larger substrates to be processed at once. The machine also features internal topside cooling of the substrate which helps to reduce the critical temperatures encountered during semiconductor processing. CE-300I also provides precision temperature control of both the chamber and the substrates, via multiple thermocouples located throughout the tool. This ensures that the etch process is consistently repeatable and reliable. ULVAC CE-300I features a unique touch-screen interface for ease of use. This interface allows the user to quickly access asset information, monitor the process parameters and adjust process settings as necessary. This also allows remote monitoring of the model, allowing users to keep an eye on the etch process from any location. The equipment also features a recipe mode that allows users to save and re-use previously-used processes for increased efficiency and consistency. CE-300I features a unique gas delivery system with up to four servo-controlled bulk gas controllers that provide precise gas flow control for maximum process uniformity. The unit also utilizes a high-precision mass flow controller for even more precise gas delivery. The gas cabinet also features a vacuum chuck machine, allowing for even base pressure control during the process. In addition to the etch process, ULVAC CE-300I also features an optional ionized metal-assisted chemical etch (IMAGE) mode for more precise etching of small features. IMAGE mode provides a more directional and controlled etch process, enabling users to etch features smaller than 50 nm. Overall, CE-300I is an advanced, compact etcher/asher with powerful features that can provide a cost-effective, economical etch process. Its unique CCIL plasma source and touch-screen interface provide superior uniformity and repeatability compared to traditional RF systems. The tool also features precision temperature and gas flow control and an optional IMAGE mode for advanced etching applications.

There are no reviews yet