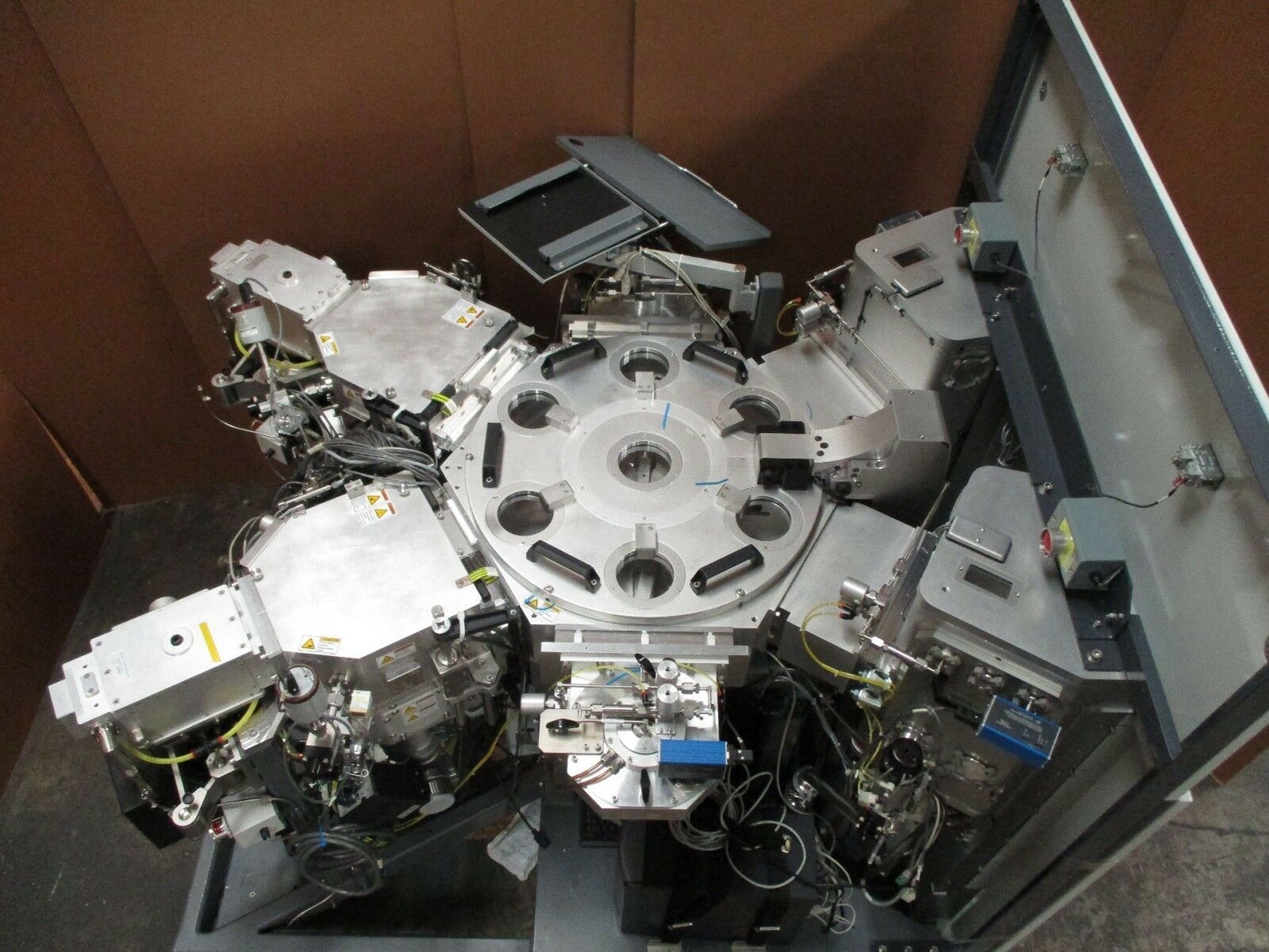

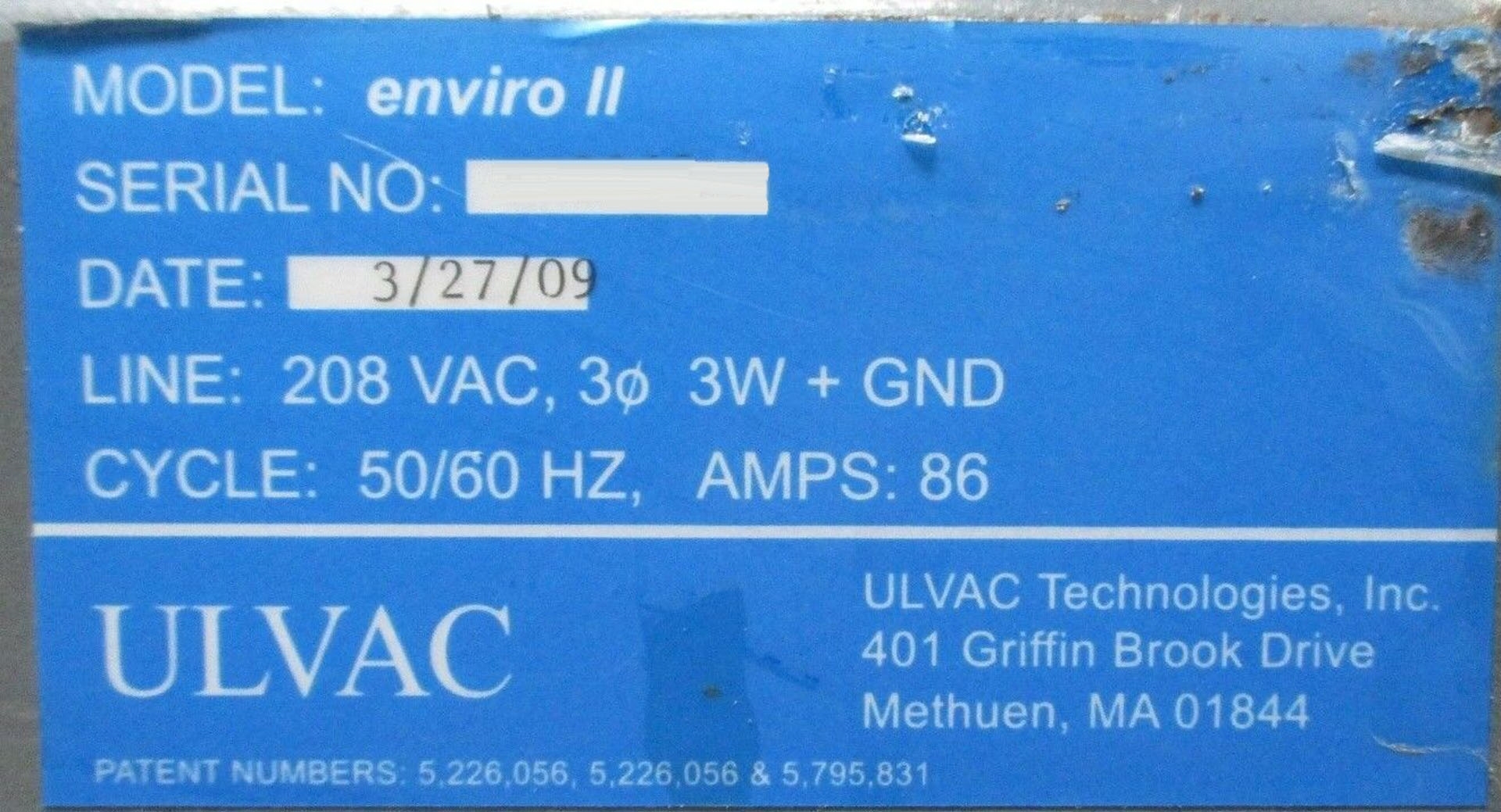

Used ULVAC Enviro II #9258348 for sale

URL successfully copied!

Tap to zoom

ID: 9258348

Wafer Size: 8"

Vintage: 2009

RF Strip system, 8"

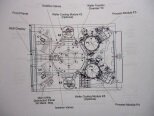

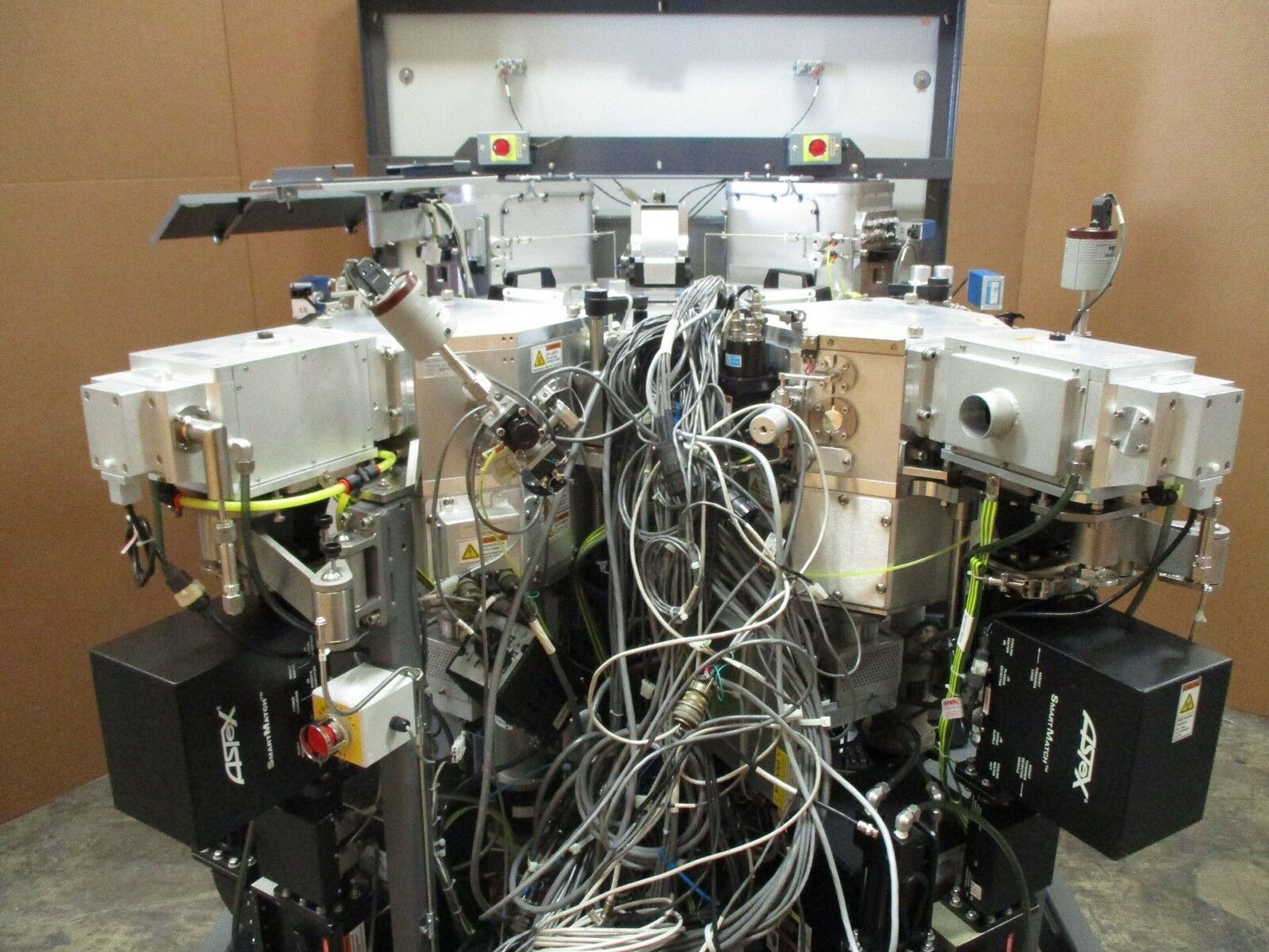

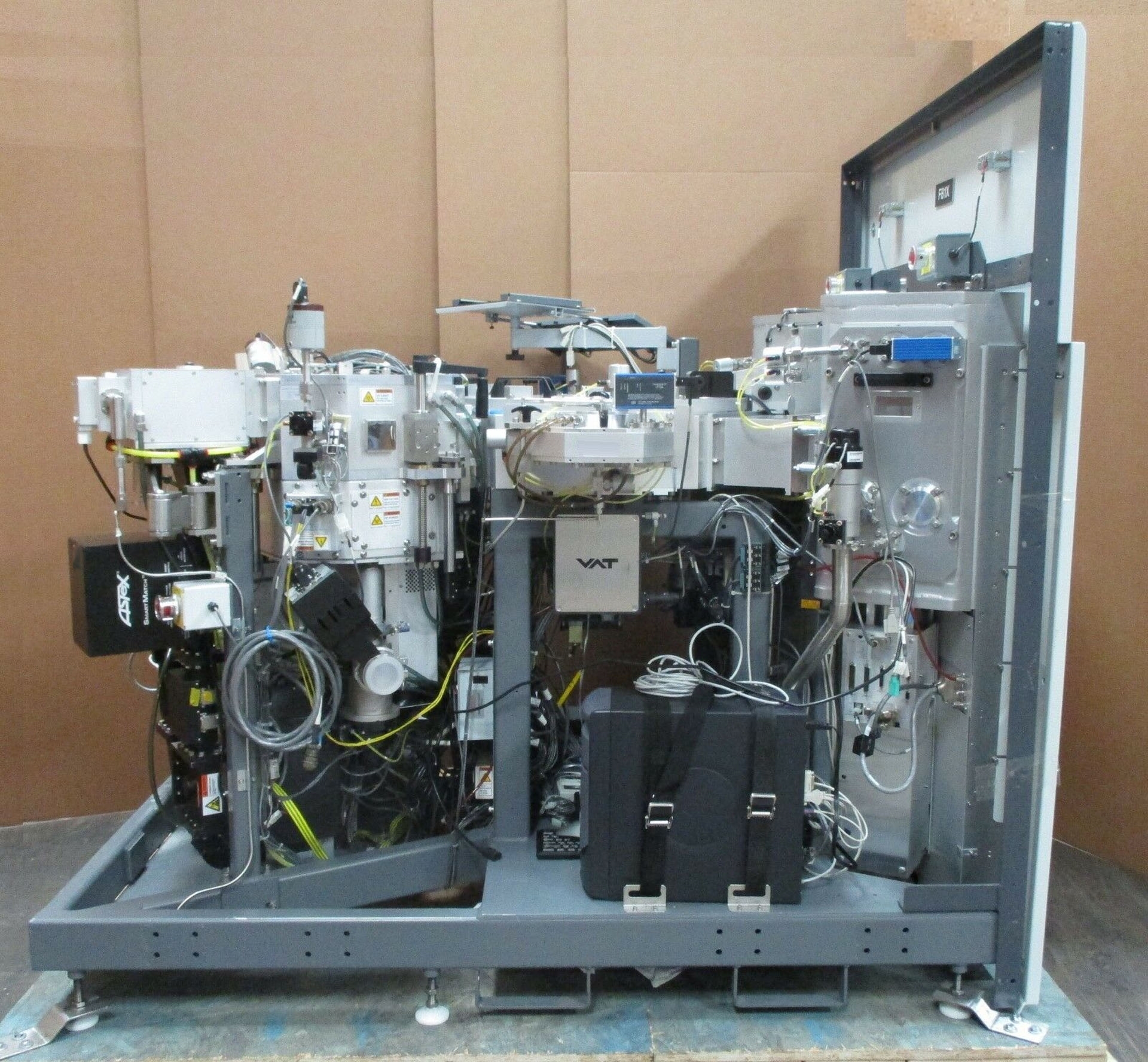

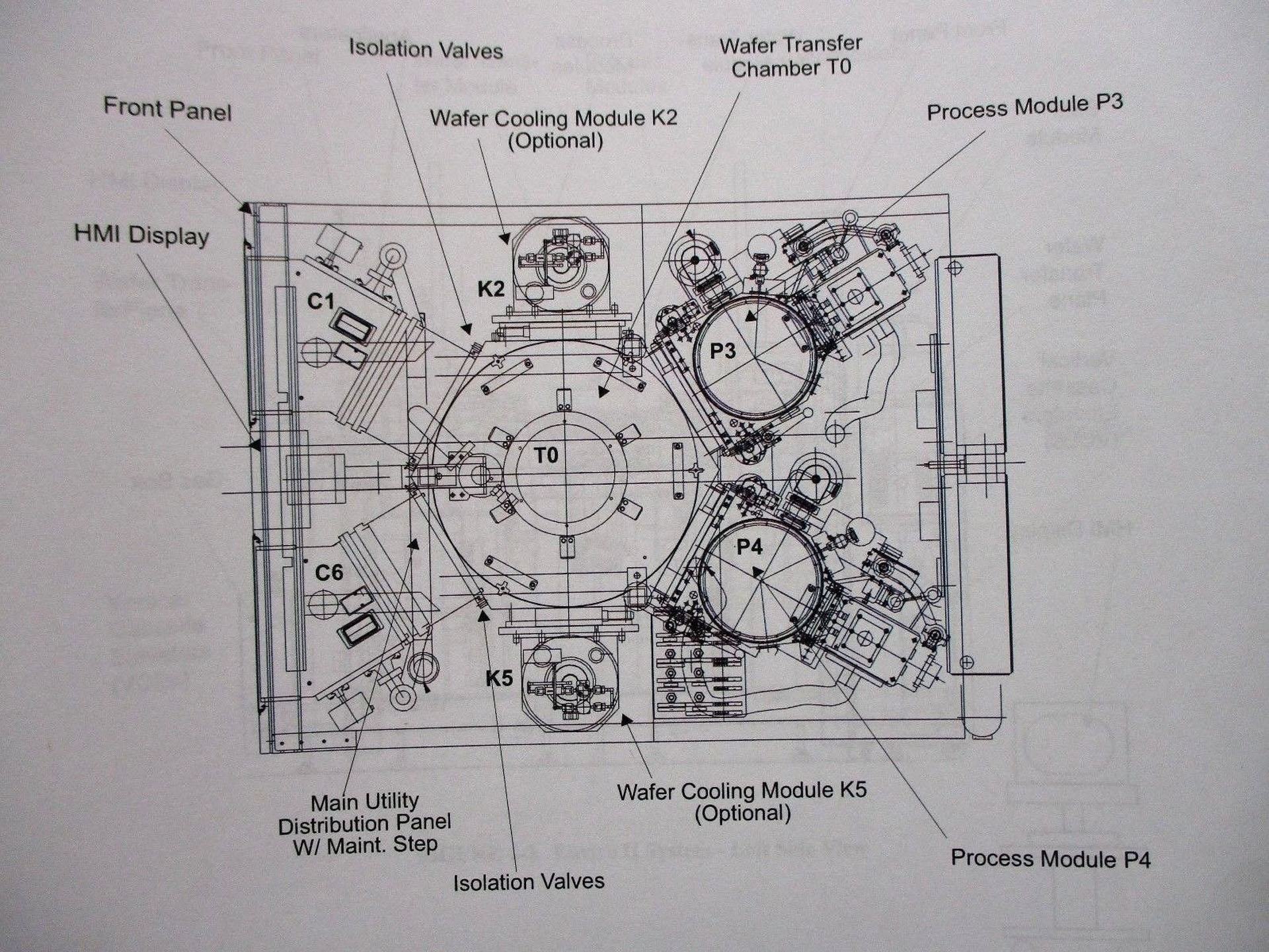

(2) Process chambers

(2) Load lock cassette chambers

Load lock transfer chamber VTS-6

(2) Wafer heating systems

Components included:

ASTEX AX3060-10

ASTEX AX3060-14

(2) ASTEX AX3153, 500 W Load

(2) ASTEX FI20162-1, 3.0 kW Mag Head

ASTEX RF Generator FI20160-1, 3.0 kW Generator

(2) BROOKS AUTOMATION VCE-4 Cassette elevator

BROOKS AUTOMATION Robot VacuTran 5 001-7600-02

DELL Desktop computer

ENI OEM-6B-01M3 RF Generator

ENI OEM-6B-01 RF Generator

ENI MWH-5-06076

ENI MWH-5-01M3

Gateway 2000 desktop computer

(2) MKS Instruments control valve

Power supply: 208 VAC, 3 Phase, 50/60 Hz, 86 A

2009 vintage.

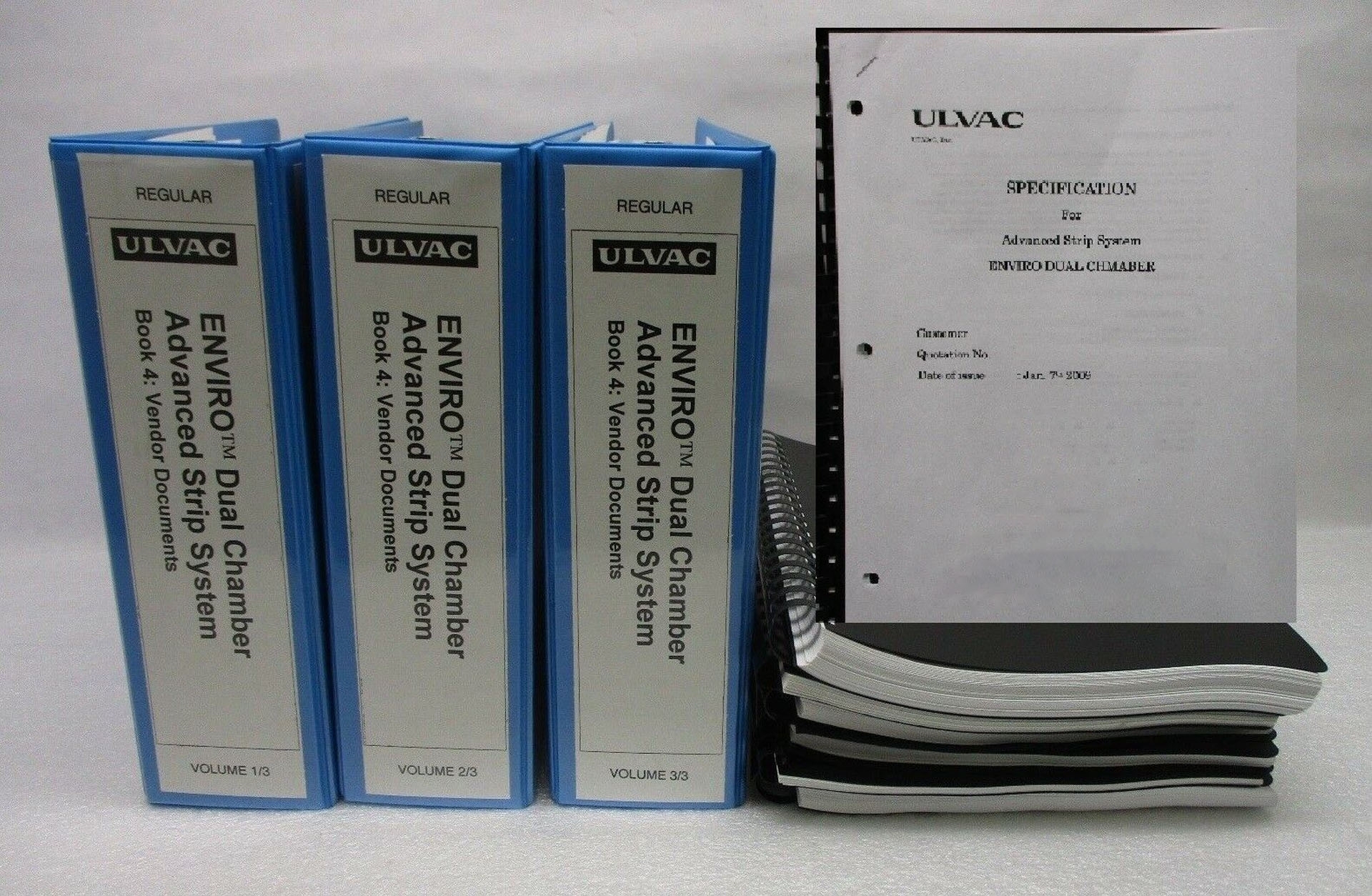

ULVAC Enviro II is a state-of-the-art dry etching and ashing equipment designed to improve the production throughput of chemical vapor deposition (CVD) thin-film production. It is the ideal system for etching and ashing any substrate from semiconductor wafers such as Si, GaSb, InP, SiC and GaN, as well as non-semiconductor materials such as ferrites, glass, quartz and ceramics. Enviro II's source chamber is equipped with three high-quality gas sources such as chlorine (Cl2), boron trichloride (BCl3), and boron trifluoride (BF3). The source chamber is designed to provide high-precision control of gas concentrations, being able to precisely measure up to 300 sccm of Cl2, providing a consistent and highly efficient etch. The chamber is also equipped with two separate stainless steel bases for easy loading and unloading of the wafer carrier. ULVAC Enviro II comes equipped with a unique, innovative feature—the Dual Chamber architecture. This allows the user to simultaneously etch and/or ashing wafers in the Source Chamber and Ashing/Rinsing Chamber. This capacity allows for faster processing and greater productivity. Enviro II has also been designed to maximize safety and reduce environmental impact. It uses ULVAC proprietary single-wall cooling unit, which helps to ensure that the equipment stays cool and runs more efficiently. This reduces power usage and makes ULVAC Enviro II more energy-efficient. Enviro II is also equipped with an air-shower tube machine to prevent contamination from outside sources. The chamber also features a wafer pod under the filter box, which contains the gas precursor and prevents gas flow when not in use. ULVAC Enviro II is the ideal etching and ashing tool for any production environment. Its advanced design and features maximizes productivity while minimizing cost and environmental impact. With its high performance and ease of use, Enviro II is the perfect solution for any etching or ashing application.

There are no reviews yet