Used ULVAC NE 5500 #293614742 for sale

URL successfully copied!

Tap to zoom

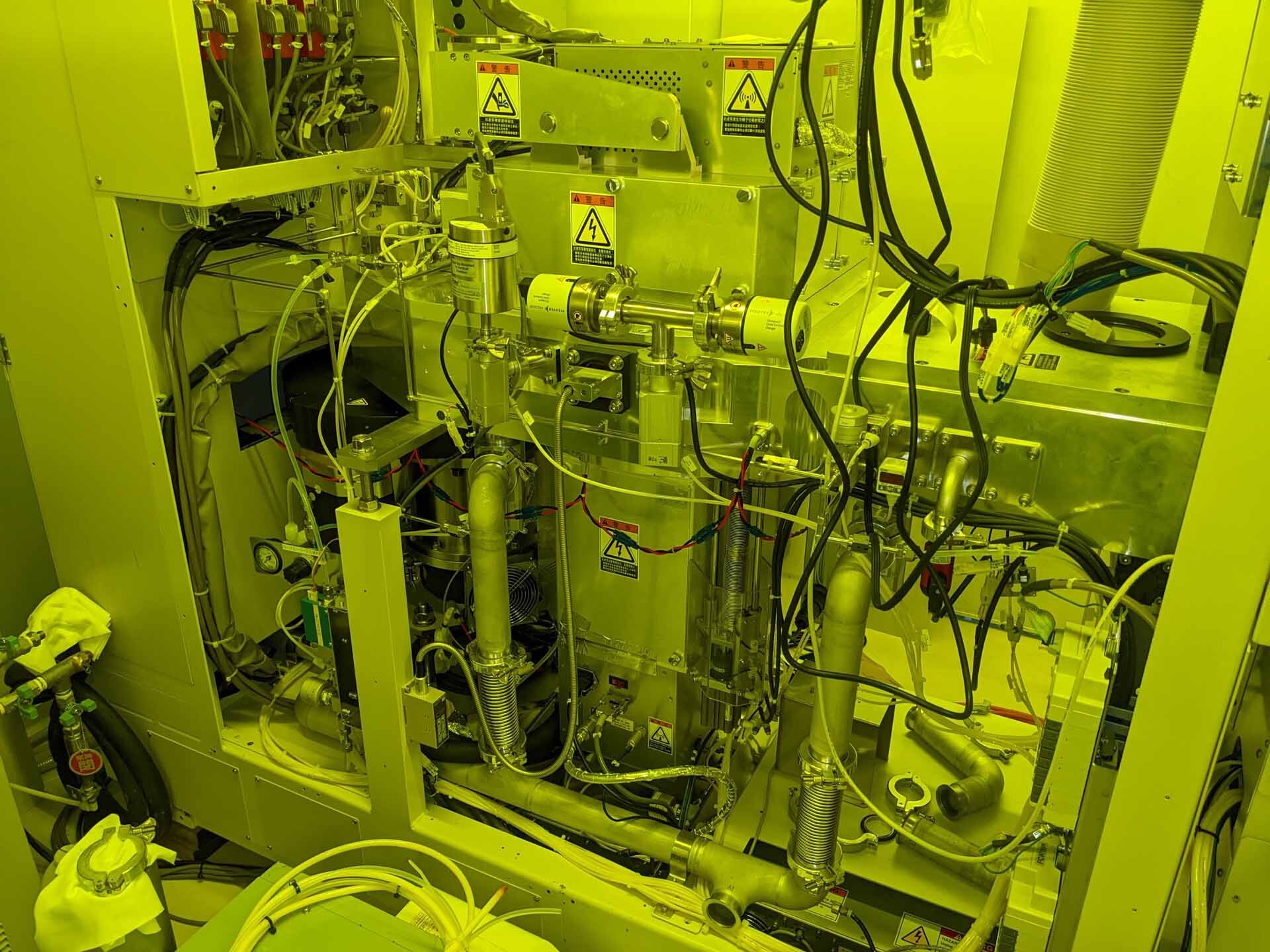

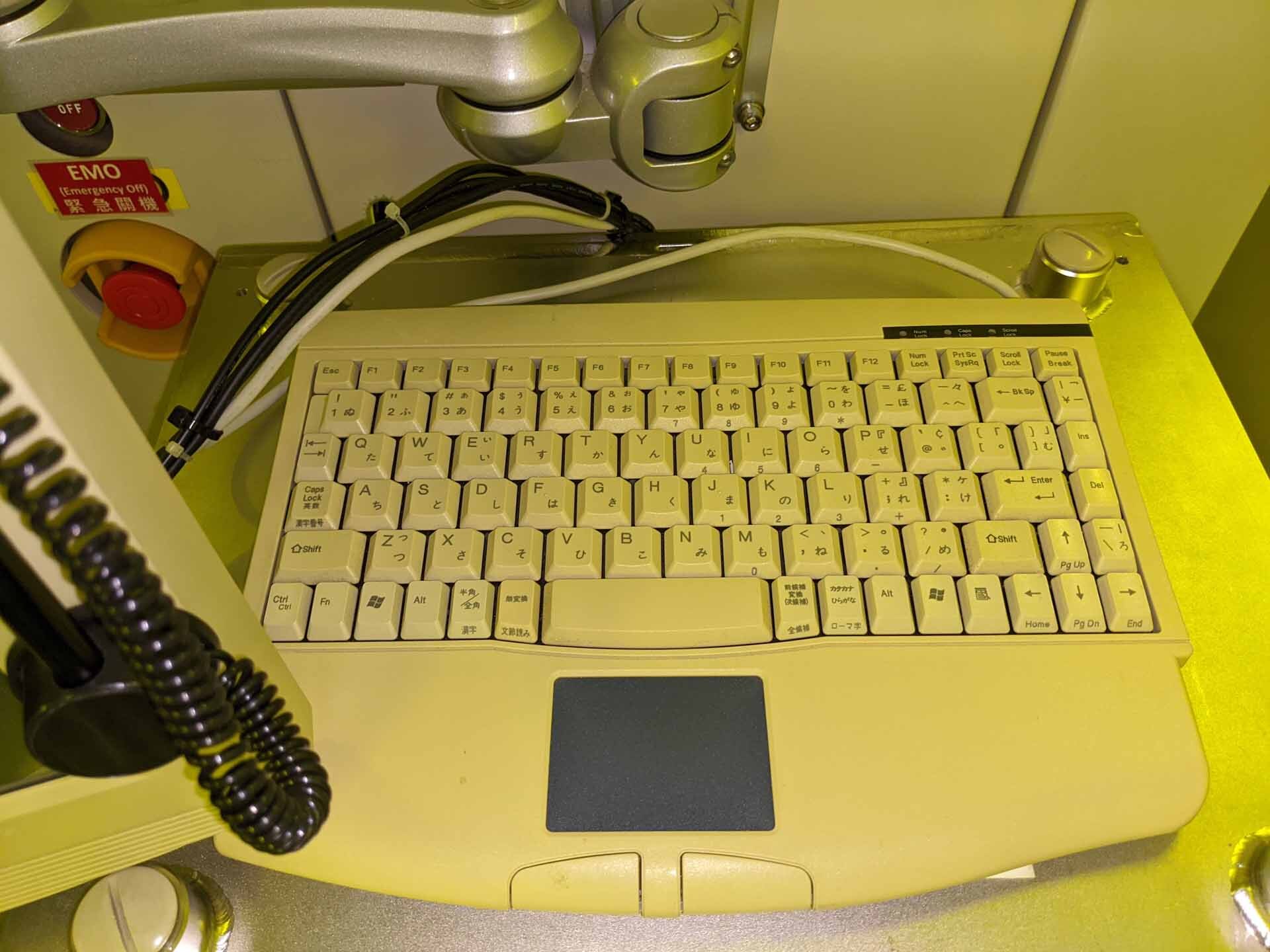

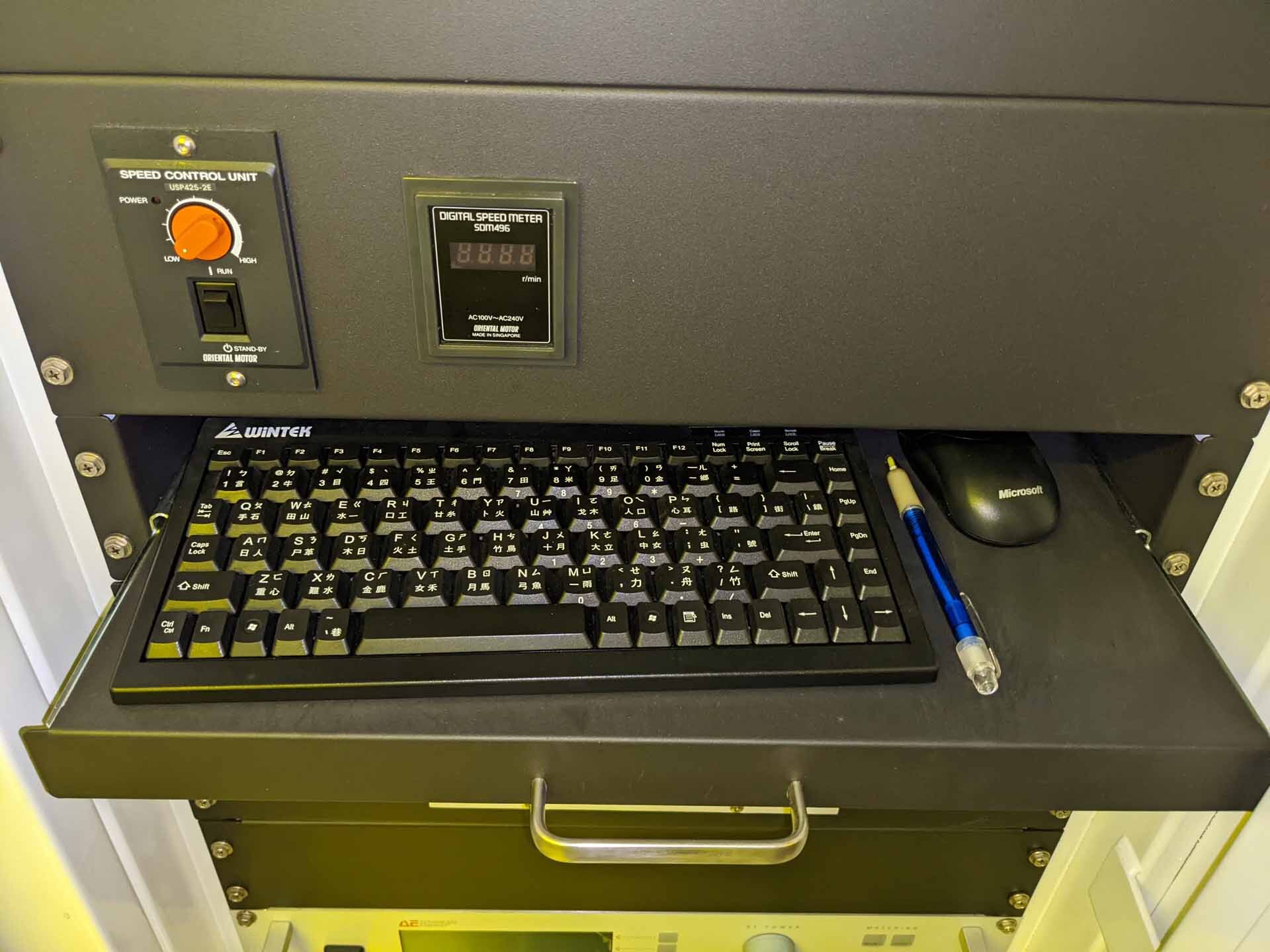

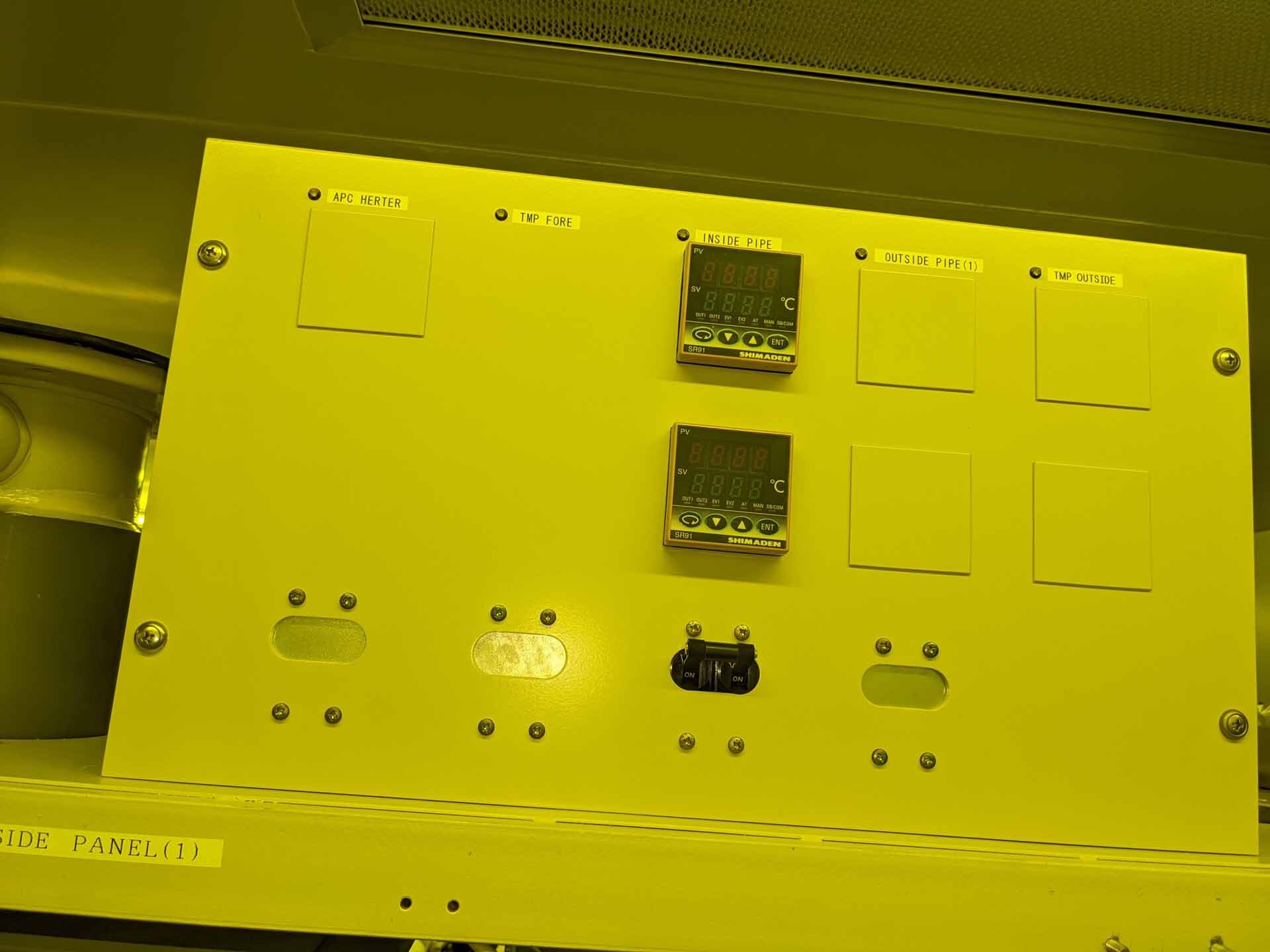

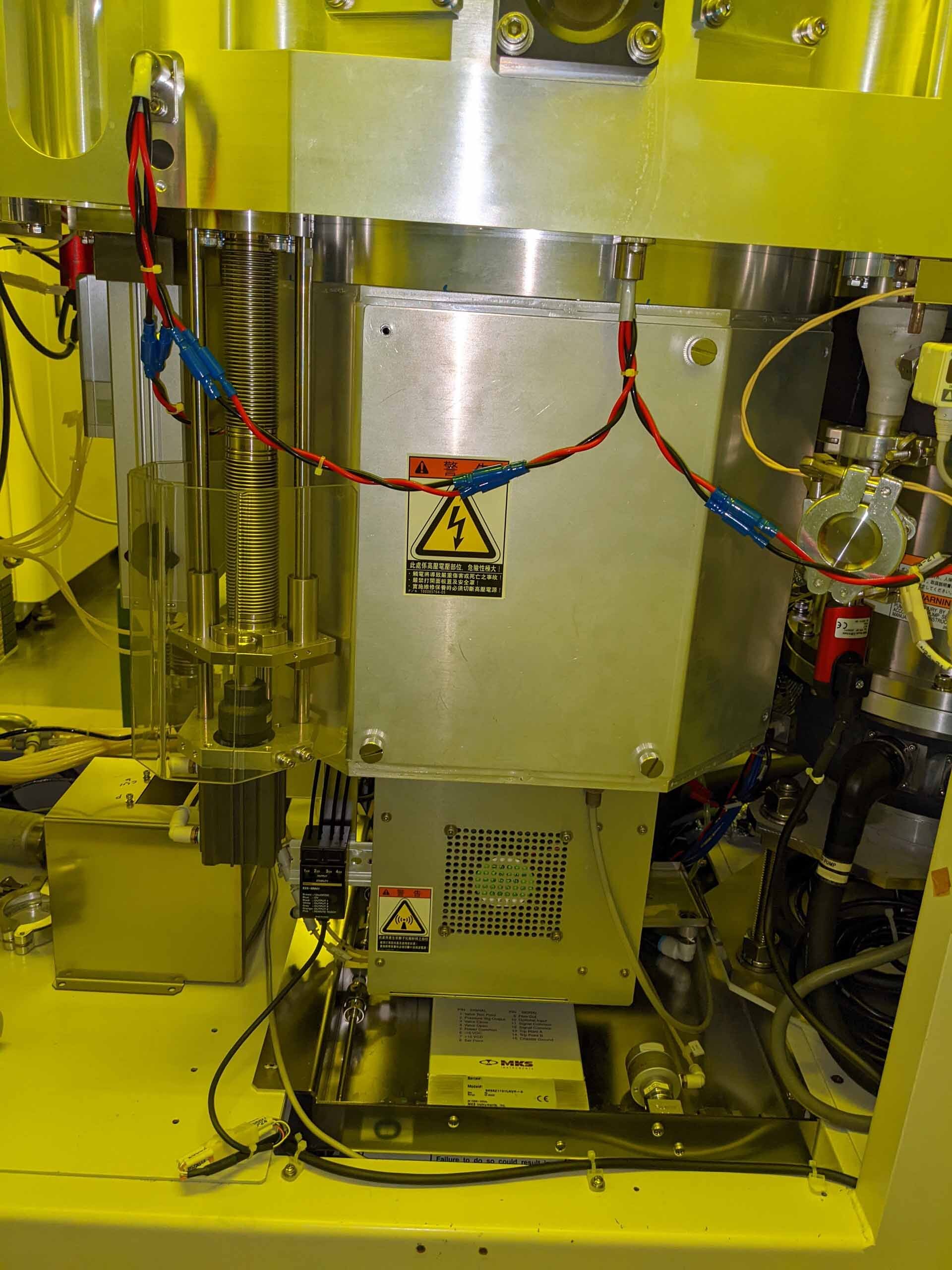

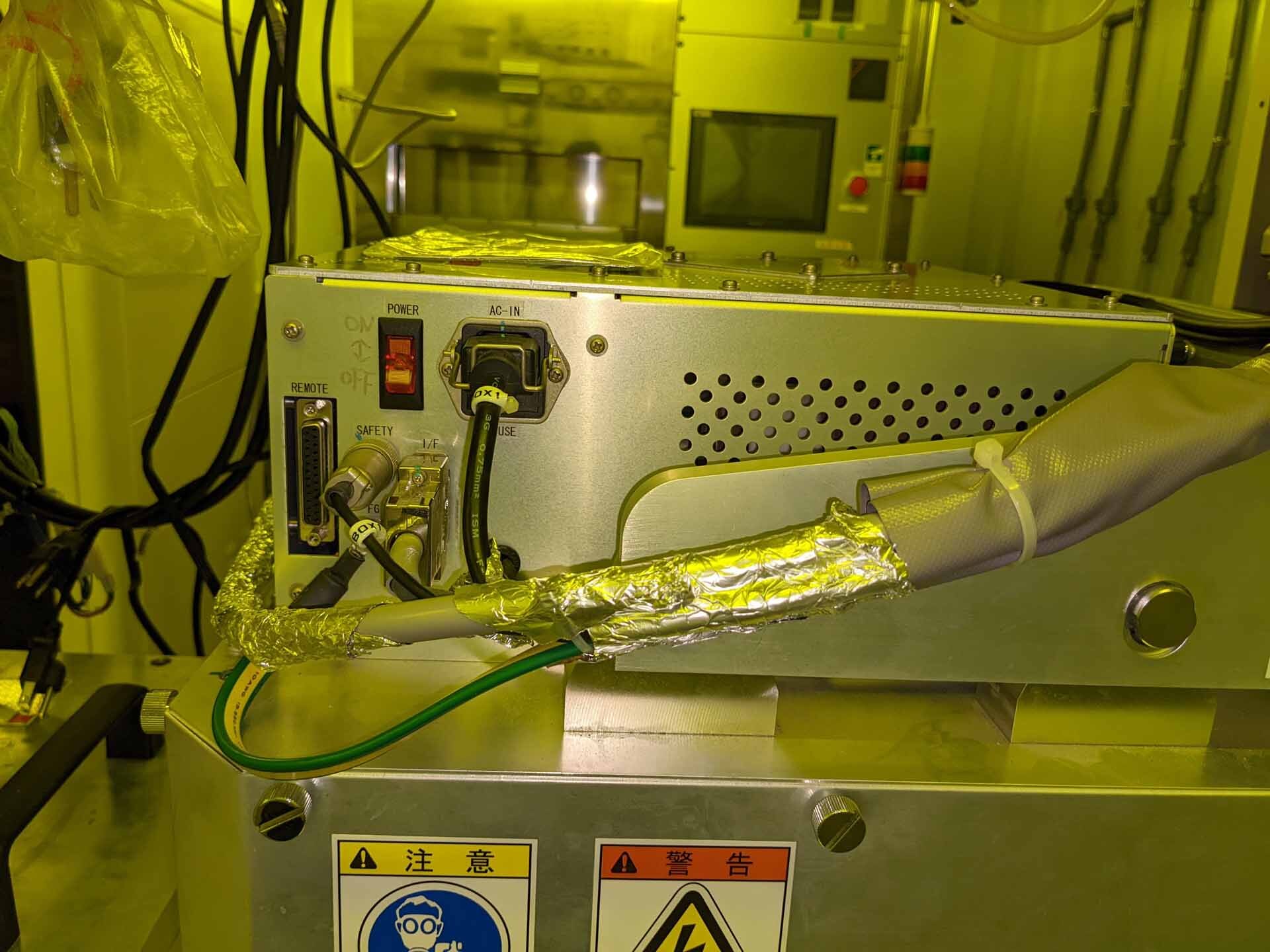

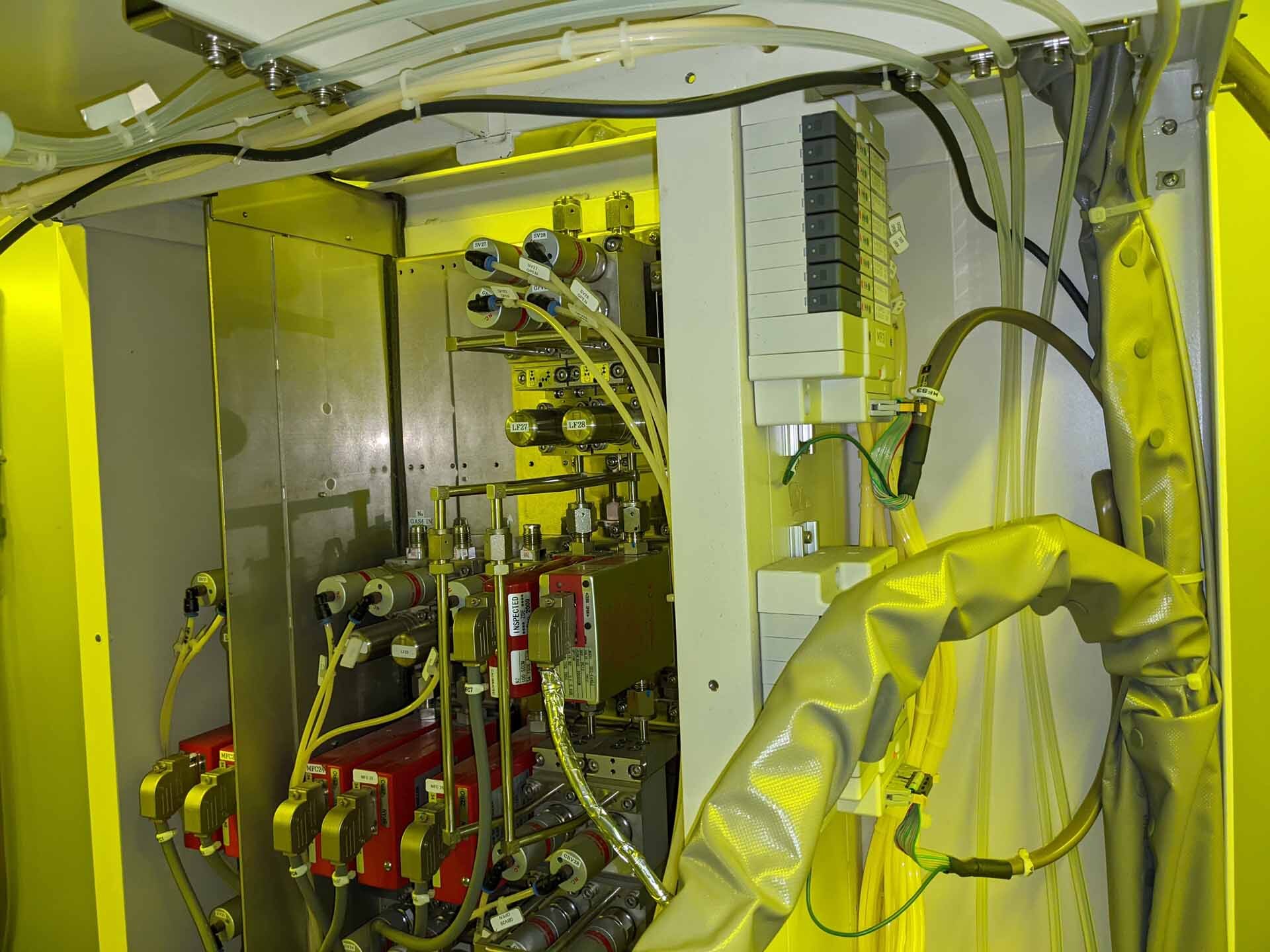

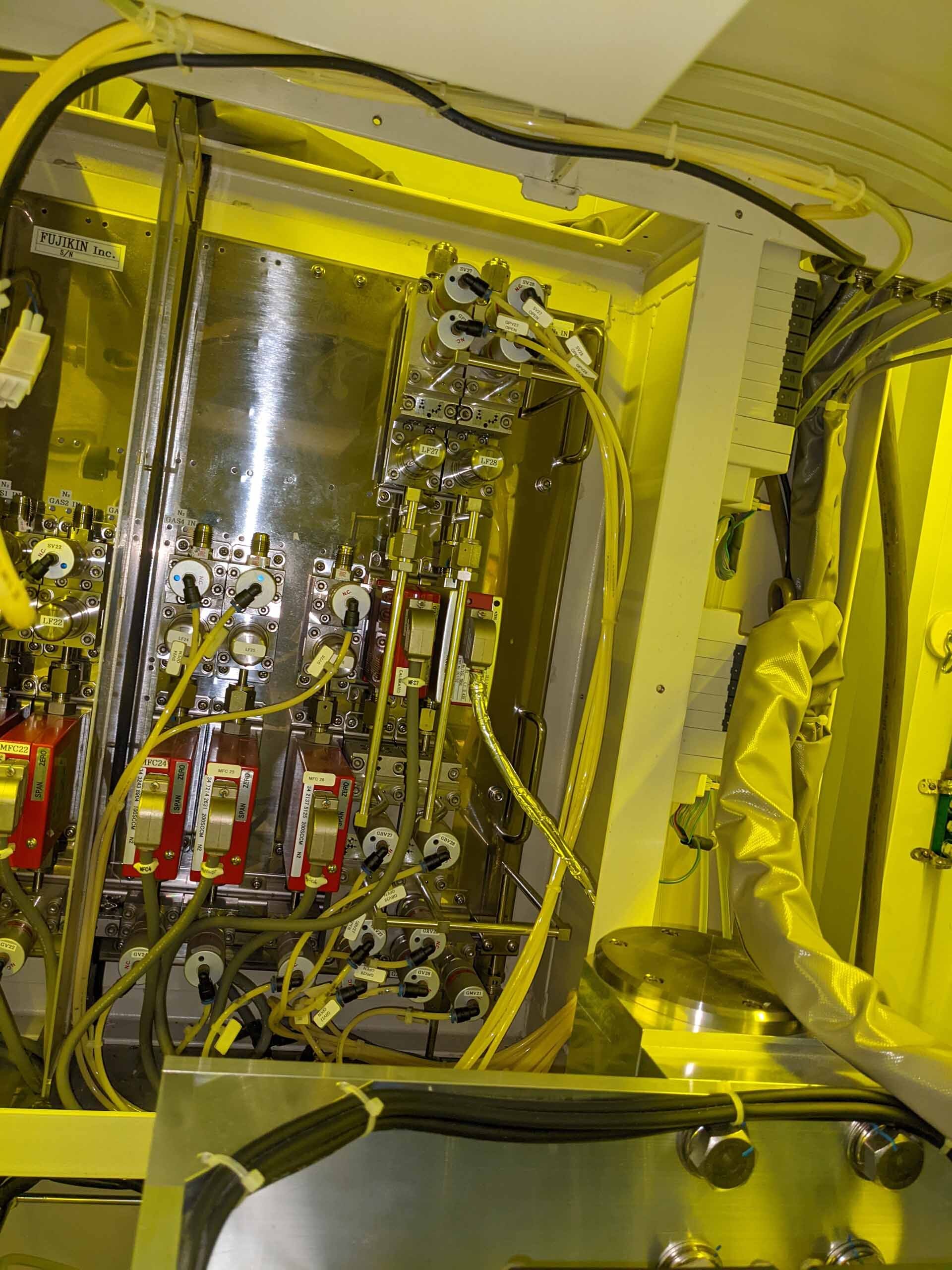

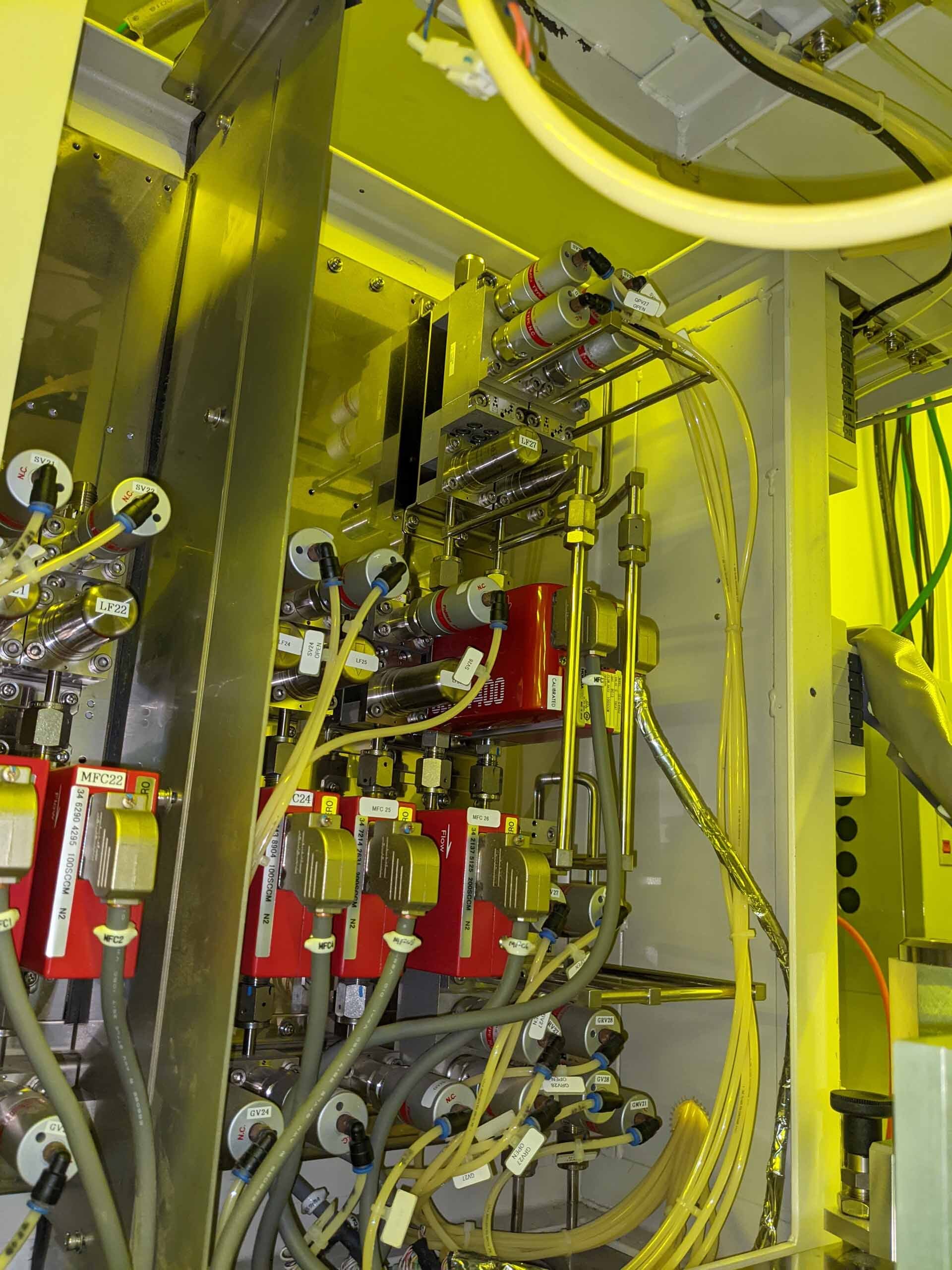

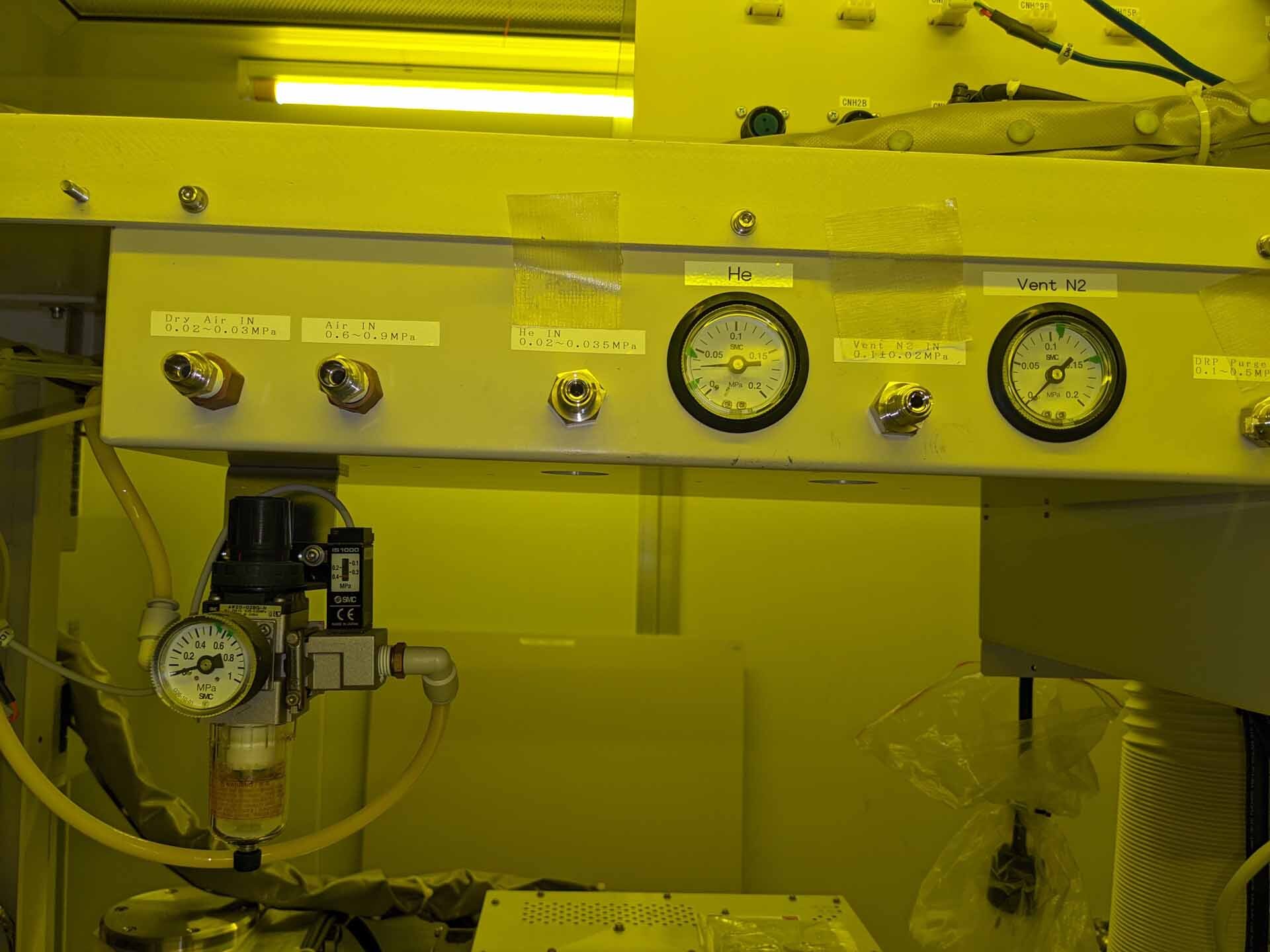

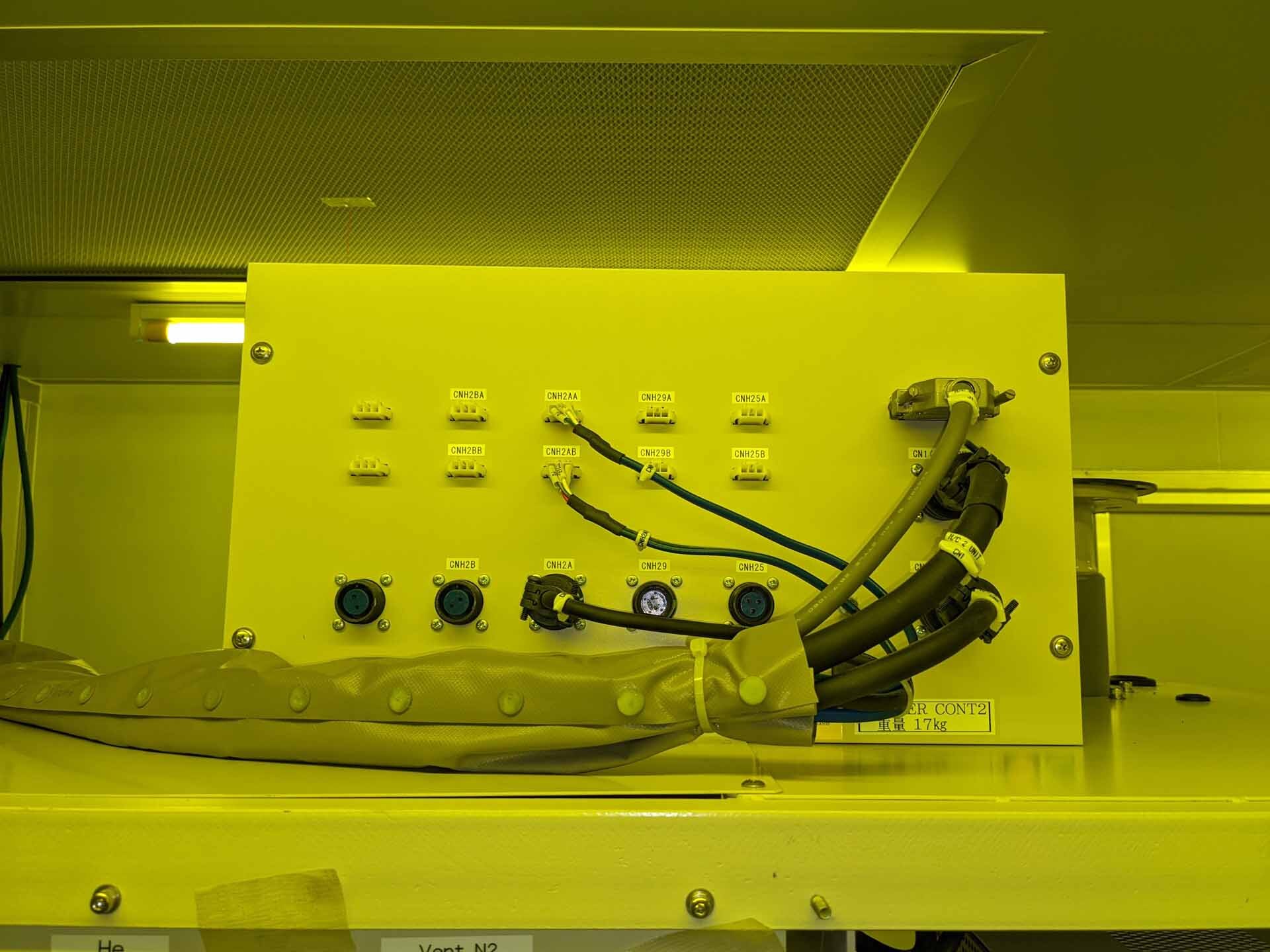

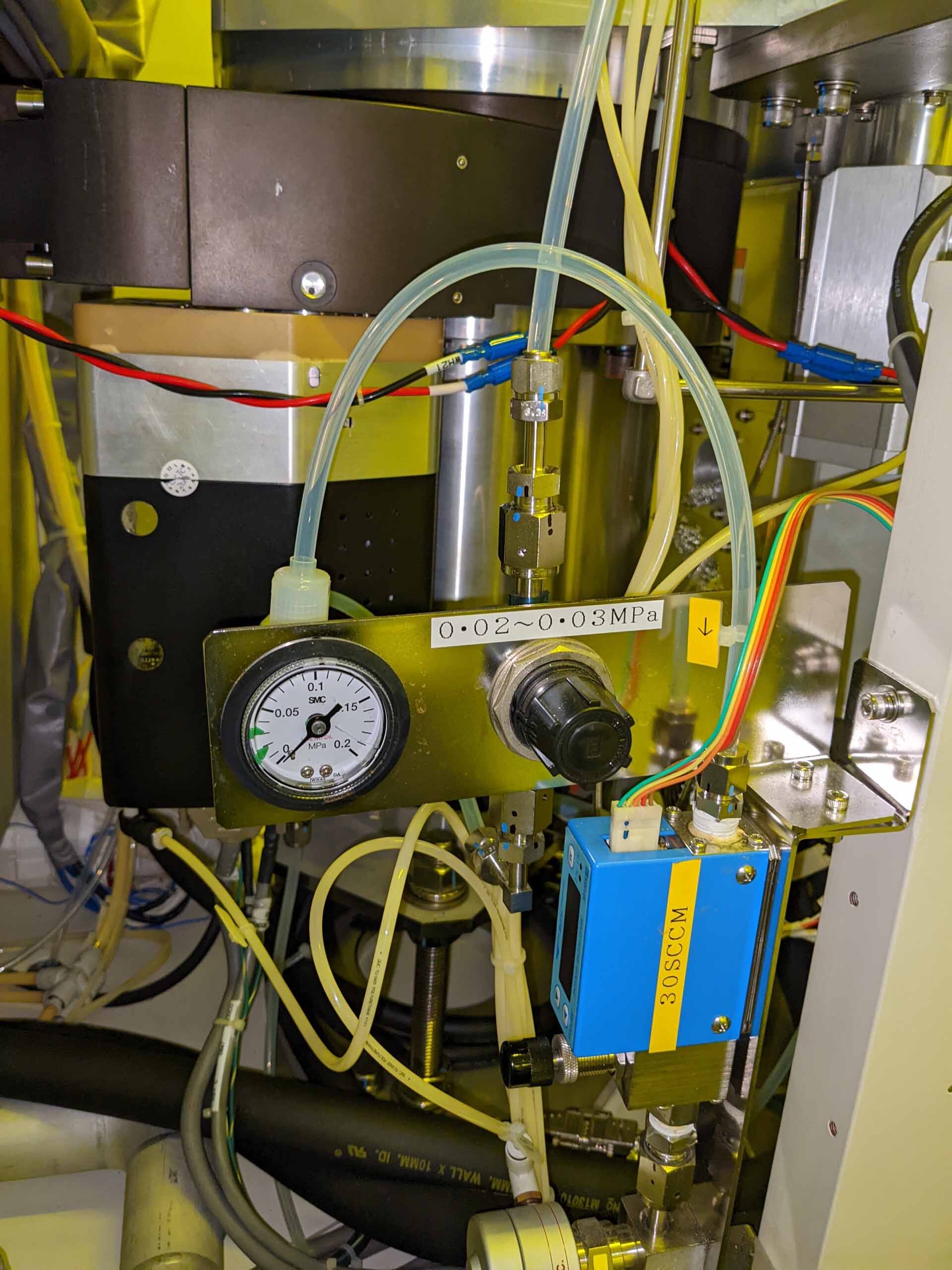

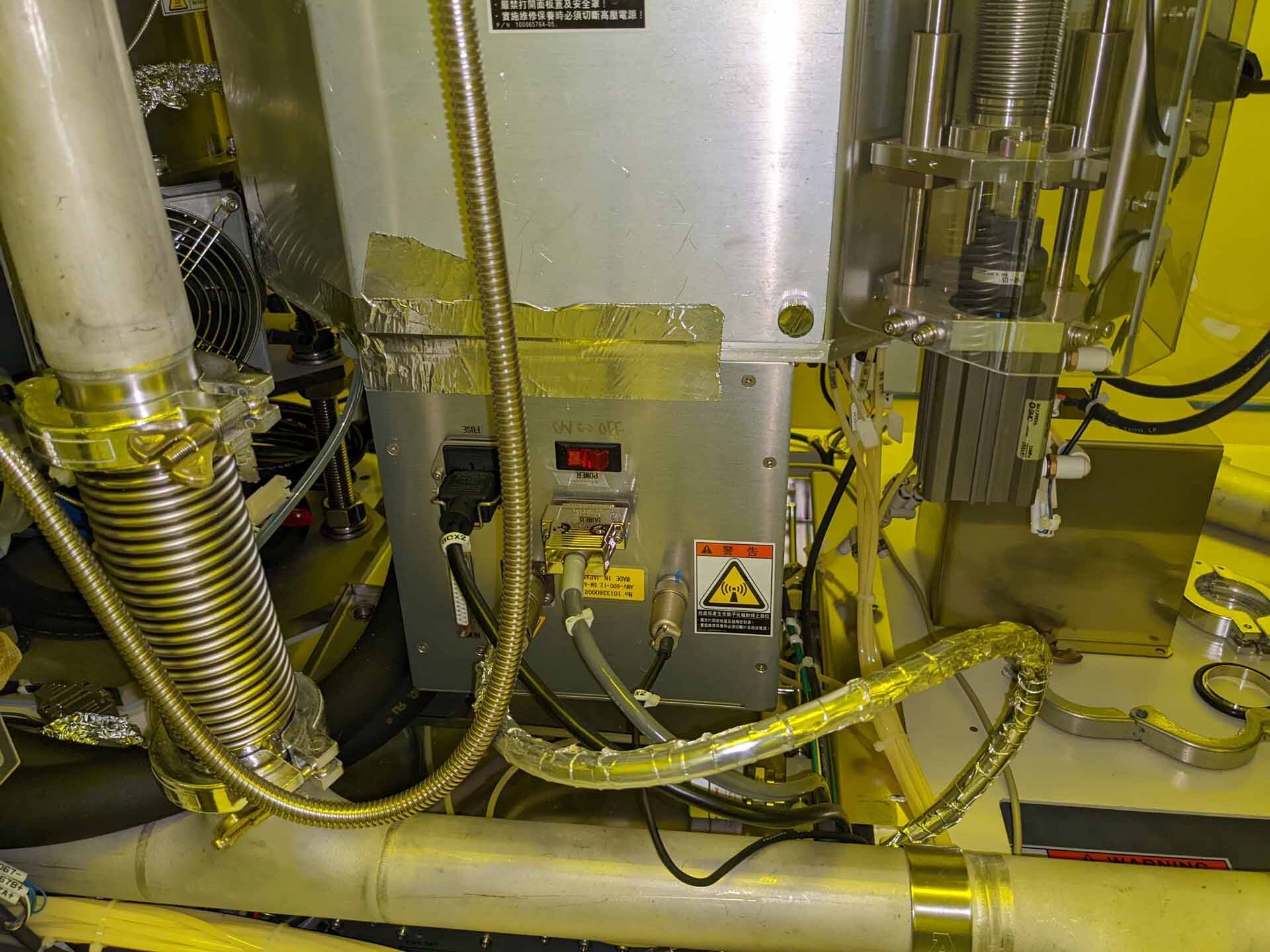

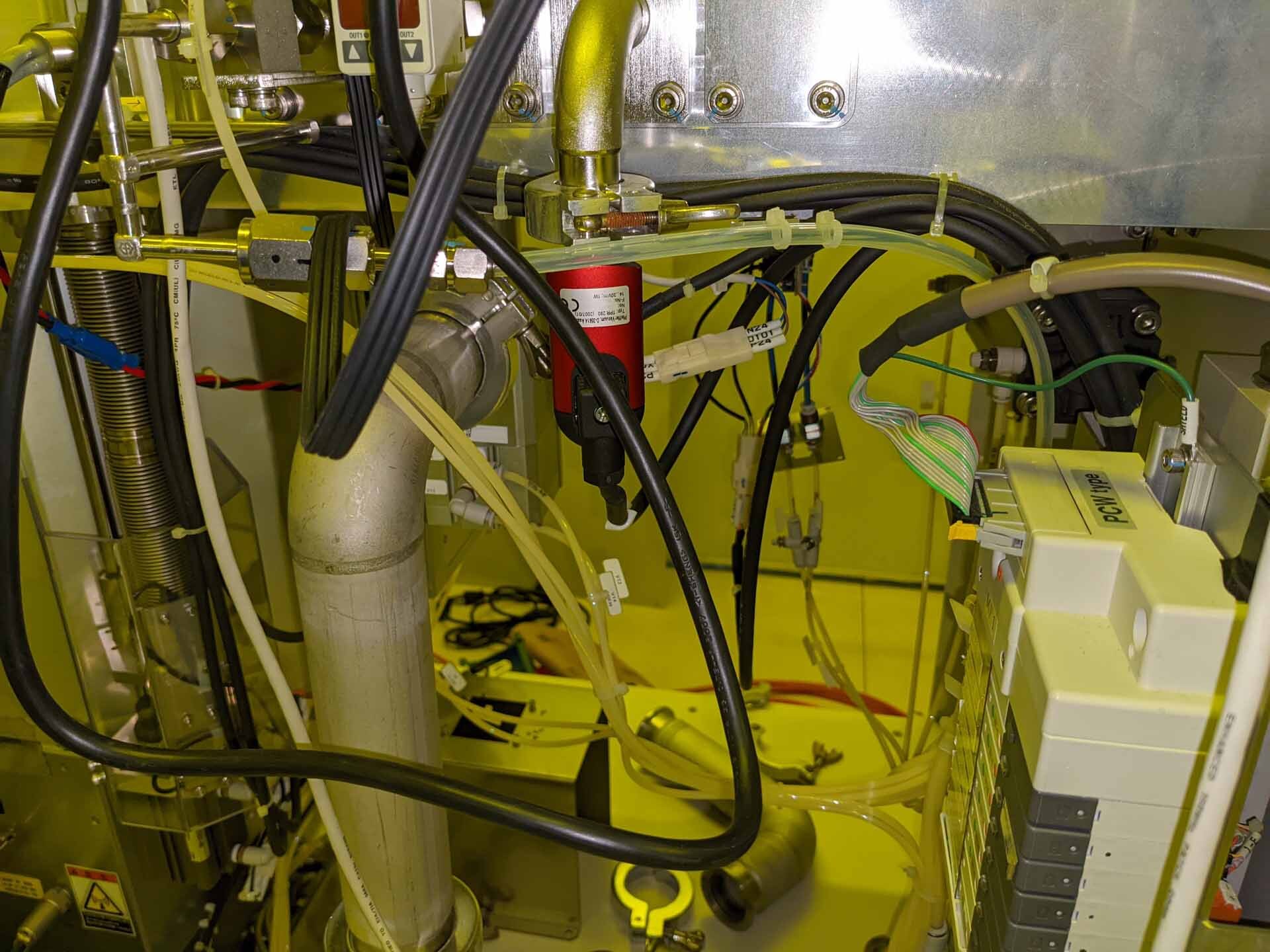

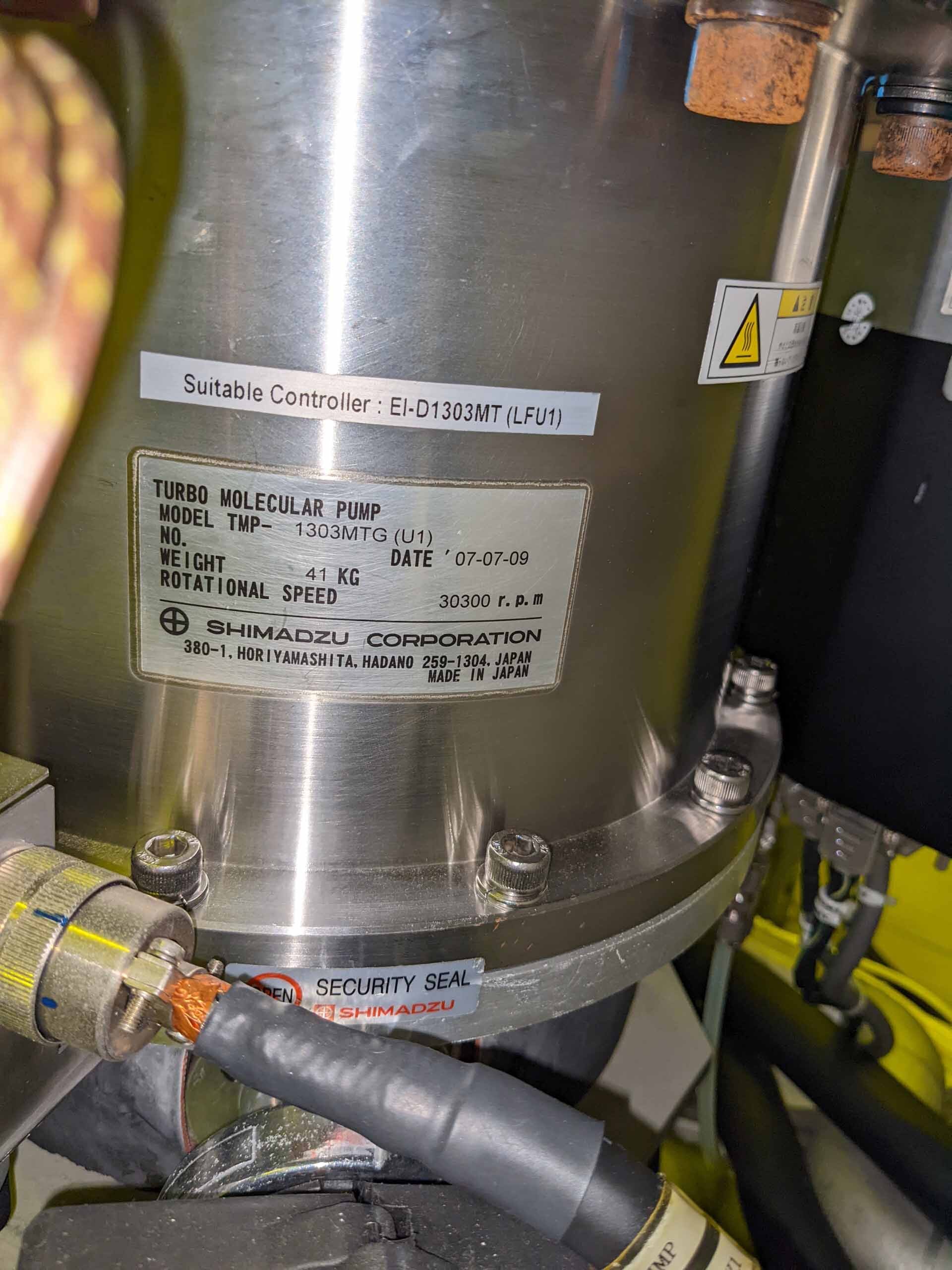

ULVAC NE 5500 is an etcher/asher. It is suitable for precision processing of various materials such as metals, ceramics, and carbon materials. It is a vacuum-type multi-stage oven that can process up to 9 materials at the same time. This advanced etcher/asher offers a wide variety of process control functions, like high-precision upstream and downstream equipment. It has features like auto-controlling etching time and auto-adjustment of temperature. It is also equipped with a multi-zone shutter equipment to maintain the function and the temperature profile control. This etcher/asher has a wide temperature range of between -25 to 350 degrees Celsius, making it suitable for processing of different materials. It can process a number of materials such as SS, Ti, Ti alloys and aluminum of various thicknesses. It also has a full range of services for etching and plasma processes available for servicing for various applications. It has a higher etching accuracy compared to manual and conventional process systems, ULVAC NE5500 also has a wide variety of process functions like auto-inclination of substrate, auto-spinning of substrate, auto-changeable mask, ion source control system, and four-unit interruption. It offers excellent wafer throughput, reducing processing times and ensuring high accuracy and stability. Its excellent control technology and consistent operating machine provide outstanding results for various applications. Furthermore, the incorporation of high-acceleration, low-consumption operation features provides an efficiency and quality of etches and ashers. NE-5500 is also environmentally friendly, with an automatic exhaust and filtration tool, which accurately controls airborne particles to keep the environment safe. It also has integrated safety features in the programmable controller, and the asset design takes into consideration safe operation. Overall, NE5500 etcher/asher is highly durable, precise, and reliable. It has features that provide excellent control, precise operation, and efficient operation. Its multiple applications make it an attractive option for precision processing and etching.

There are no reviews yet