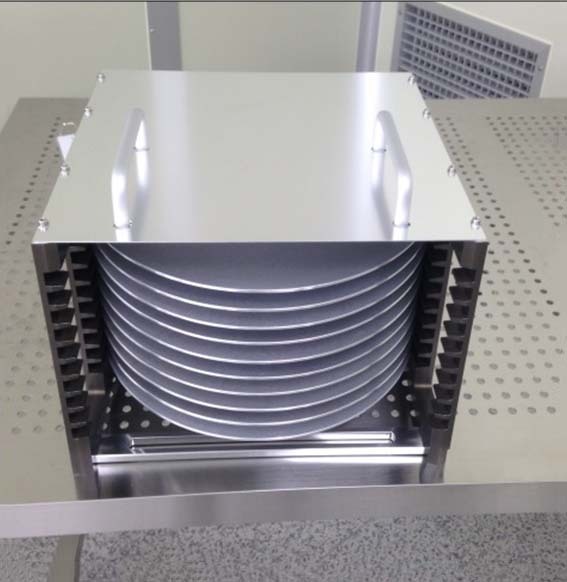

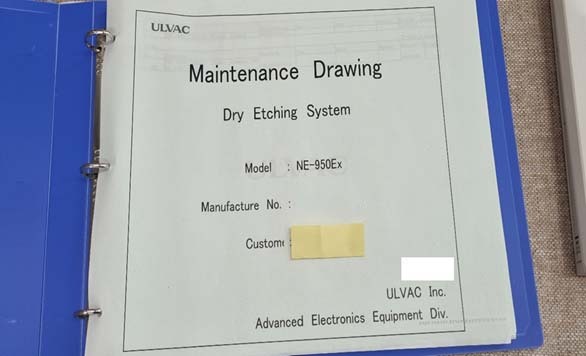

Used ULVAC NE-950EXk #9410744 for sale

URL successfully copied!

Tap to zoom

ID: 9410744

Dry etcher

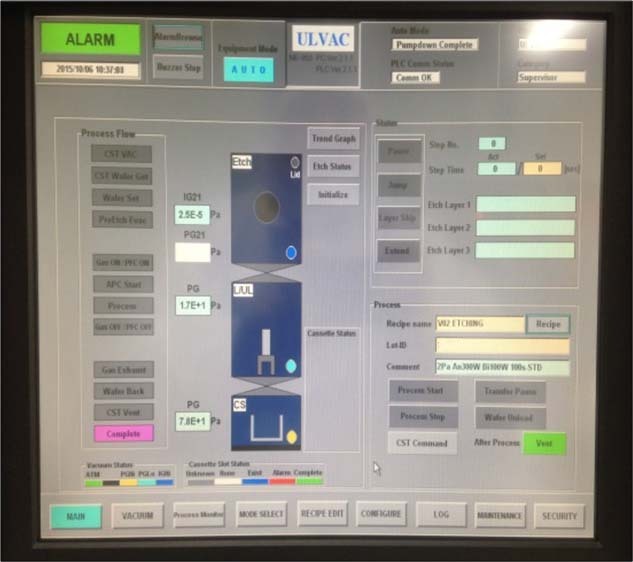

Power supply: AX 3000 III Antenna and bias

Matching box:

AMVG-2000-GA Antenna

AMVG-1000-125M-FV Bias

ULVAC HR60 Dry pump

TMP: 2203LMTG(UI)

NUTEK MFC FCST1005LUC-4J2-F1000-N2

Gases:

Gas line / Flow

Ar / 100 SCCM

D2 / 100 SCCM

CF4 / 400 SCCM

SF6 / 200 SCCM

CL2 / 200 SCCM

BCL3 / 200 SCCM

BCL3 / 50 SCCM

N2 / Gas line purge

TPR280 Prirani gauge

IKR251 Cold cathode gauge

FSTC-CS003L-EC Chiller

65048-JHHC-AEX1 Vacuum throttle valve

649A21T21CAVR PFC Unit He cooling

HITACHI RS550 UPS power supply.

ULVAC NE-950EXk is an etcher/asser with a high-vacuum chamber capable of plasma processing in an area 200mm x 200mm. It creates a plasma process of hydrogen or oxygen with high accuracy for precise etching/etching or surface activation. NE-950EXk is equipped with a power generating source, a process gas mixing source, a pumping source, a temperature controlling source and a temperature monitoring source. ULVAC NE-950EXk is also equipped with a low-temperature vacuum pump, which makes it ideal for etching and surface modification of organic substrates. Its plasma processing system offers an effective depth of approximately 10um, allowing for precise control of the thin film surface. NE-950EXk also offers a wide range of process parameters for etching and surface treatment, such as the time and current for etching, the temperature for surface activation, and gas flow rate. In addition, ULVAC NE-950EXk can be operated in a manual or semi-automated mode. The manual mode allows for basic control of the parameters, while the semi-automated mode allows for setting customized process parameters and automatic compensation for irregularly shaped substrates. The driver also offers data storage and software update capabilities, further providing ease-of-use when performing etching and surface treatment. Furthermore, a 1000-point vector generator is included to allow for setting up of the etching process, while simultaneous cooling can be used to ensure the best possible substrate quality. NE-950EXk's high-vacuum chamber also ensures that the etching/surface treatment processes are conducted in a clean environment. Overall, ULVAC NE-950EXk is an etcher/asser that provides precise etching/surface activation on multiple substrates with a wide range of process parameters. It has a high-vacuum chamber for a clean processing environment and can be operated in both manual and semi-automated modes. Moreover, vector generators provide additional accuracy, while cooling systems help maintain the best quality substrates during etching.

There are no reviews yet