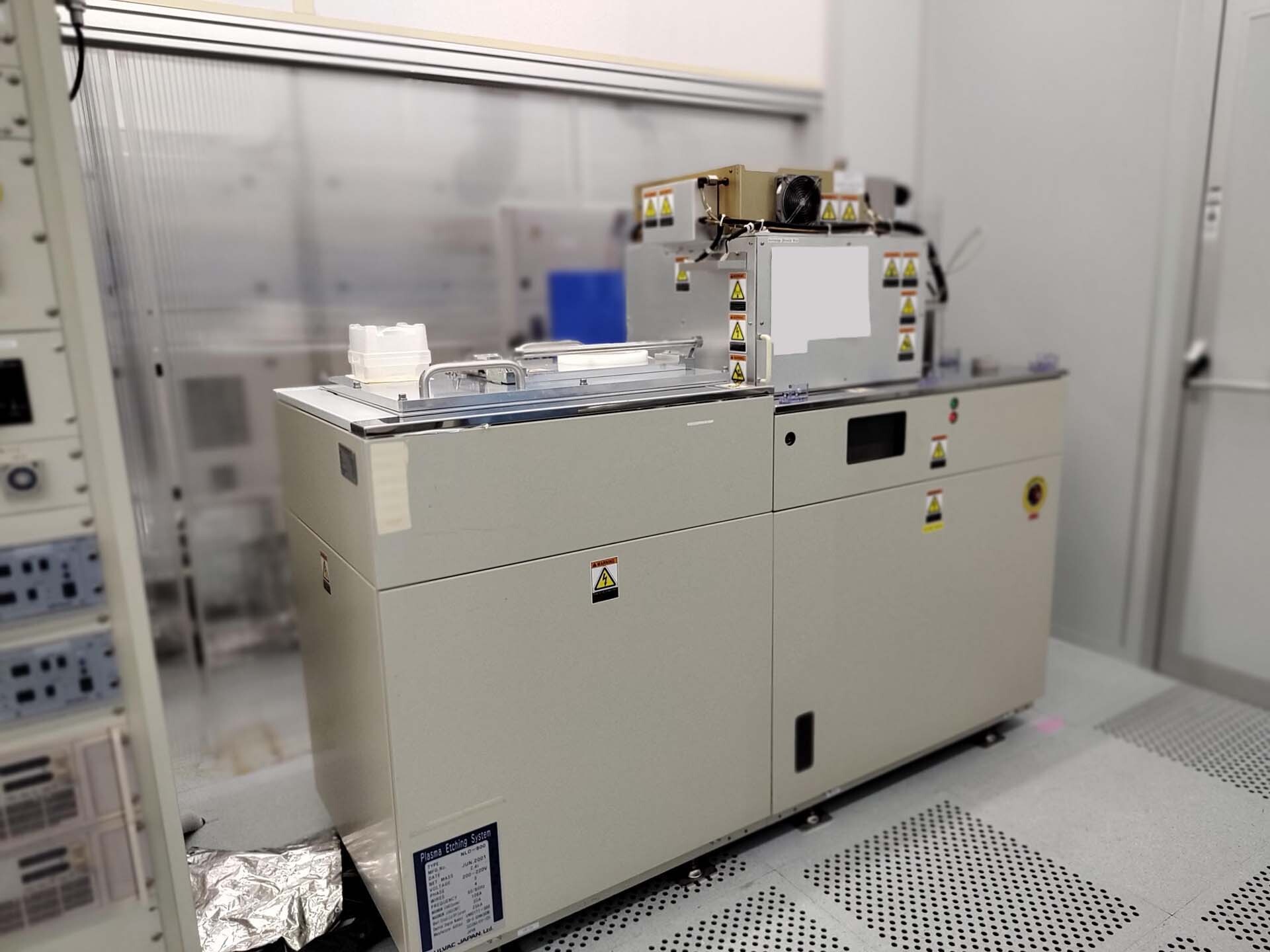

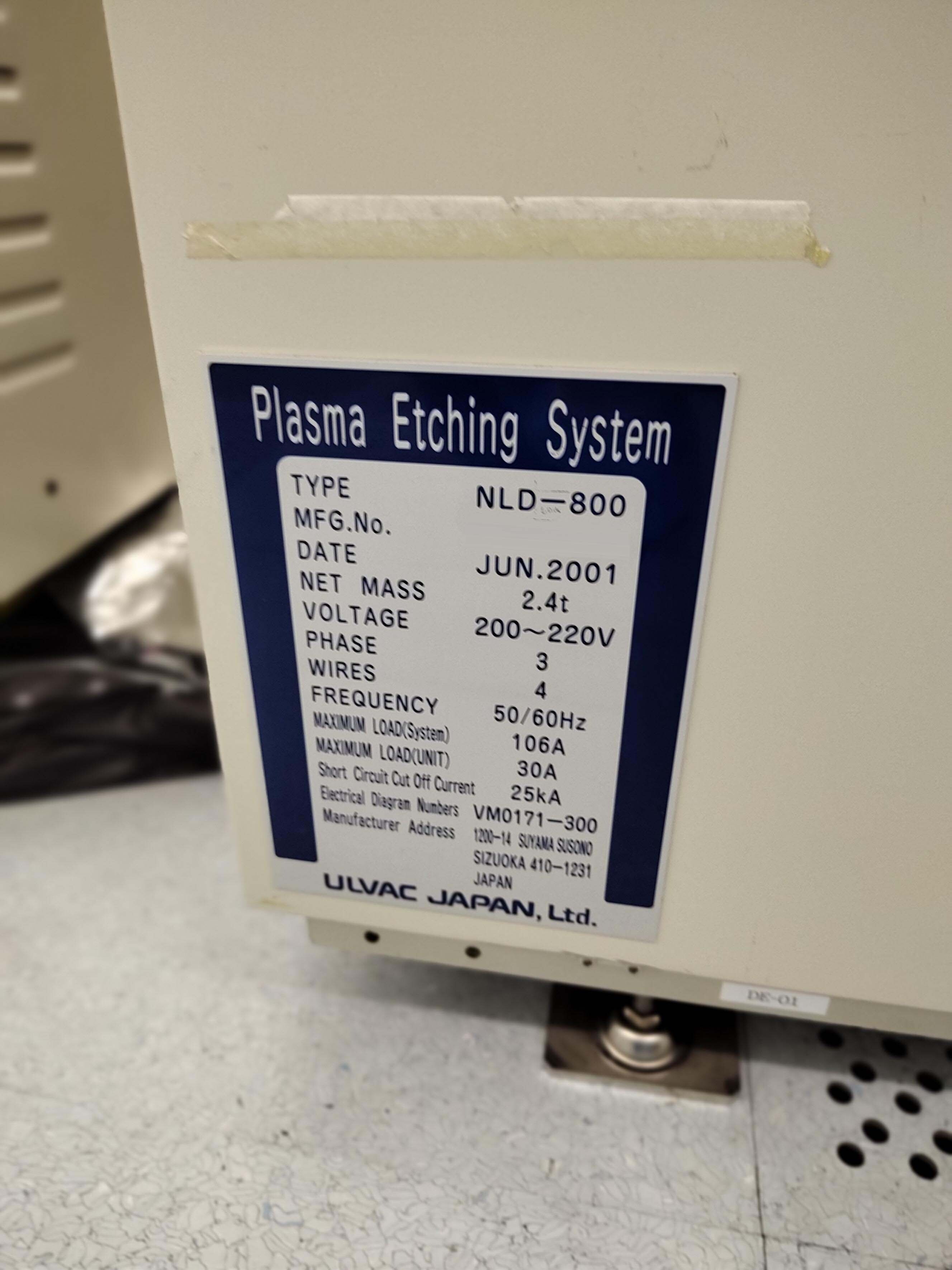

Used ULVAC NLD-800 #293610229 for sale

URL successfully copied!

Tap to zoom

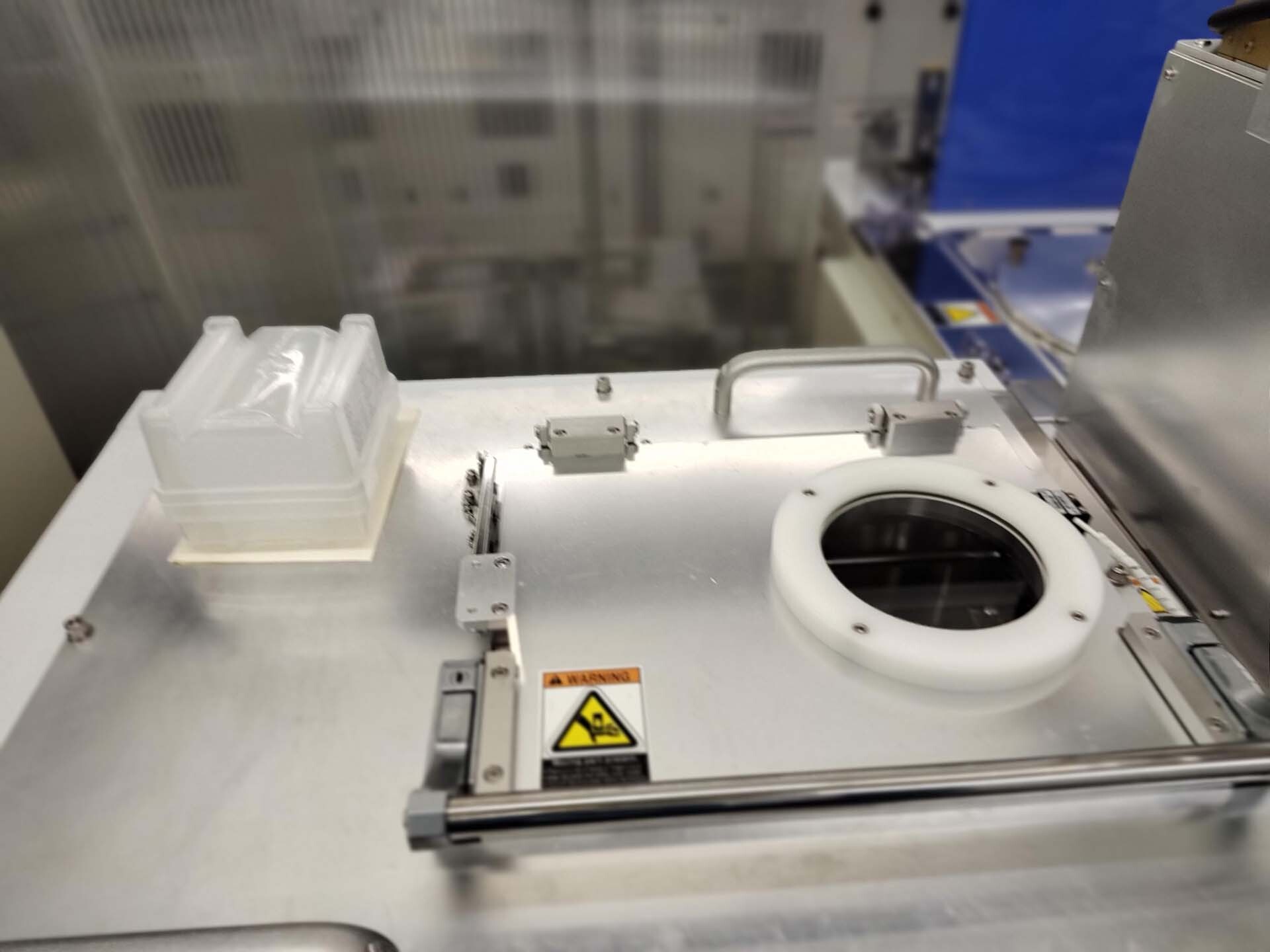

ULVAC NLD-800 Asher / Etcher is a high performance etching and ashing device ideal for the processing of wafers and wide range of substrates. With its ultra-precision etching and ashing process and features that enable the go-to etcher unit for a majority of customers, NLD-800 is the perfect solution for extremely tight dimensional tolerances and high rate production. The etcher/asher has a large chamber and is equipped with a radio frequency generator to efficiently transfer electric energy and to precisely control the etching and ashing process. ULVAC NLD-800 is designed to take advantage of the RF generator's high frequency and high power capabilities to provide a homogeneous, highly repeatable and very controllable etching and ashing process. It has an array of control parameters such as the number of processes, platen temperature, frequency, power and chemical concentration that can be programmed to ensure the best results for each application. NLD-800 is designed to conveniently process substrates up to 6.0" in diameter without any modification. Standard accessories such as clamping systems, movable baskets and holders, and a dome supporting platform for isolation plates have been provided to uniformly process substrates. Substrates can be easily loaded and unloaded with the use of a batch loader system. ULVAC NLD-800 is also equipped with various safety measures such as a cover interlock switch and plasma resistance ionizers that prevent the chamber from being opened before its inner pressure is normal. Also, with a low mass stainless steel cover and an optimized evacuation system, the discharge of process chemicals can be significantly reduced. The advanced design of the etcher/asher enables an optimal compatibility with a range of chemicals, reducing the chemical consumption and minimizing its impact on the operator and the environment. In addition, advanced diagnostics and preventive maintenance features allow the user to monitor the process conditions and parameters of the system in order to ensure a homogenous and repeatable etch or ash process. NLD-800 is the ideal choice for high precision etching and ashing operations in R&D, contract manufacturing or production environments. With its lightweight design, advanced safety features and RF generator capabilities, ULVAC NLD-800 provides a high degree of control, repeatability and functionality for a wide range of clients.

There are no reviews yet