Used ULVAC Phoenix #133356 for sale

URL successfully copied!

Tap to zoom

ID: 133356

Wafer Size: 6" - 8"

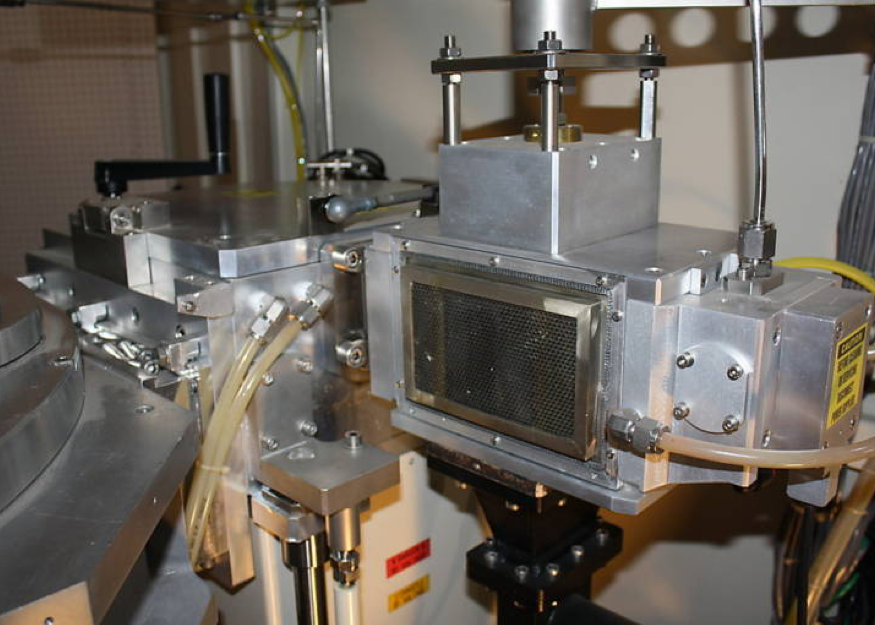

Etcher, 6"-8"

Single chamber

Downstream microwave

Low-damage RIE modes

Load locked

MESC compatible

Multi-step processing capabilities

Windows-based software

Offline recipe selection

SECS/GEM communication standards

Extensive data logging.

ULVAC Phoenix is an etching / ashing equipment developed by ULVAC Technologies Inc. It is an essential tool for the semiconductor industry, as it helps to produce modern integrated circuit designs. The system utilizes thermal oxidation and chemical etching processes to form minute patterns on the surface of a substrate material. This process is essential for creating small, intricate patterns, down to the nanometer range. It is also used to create thin-film circuits, and is one of the most widely used etch/ash equipment in the electronics industry. Phoenix features an ultra-low vacuum (ULV) chamber, with a rotary source that feeds gas or chemicals into the chamber. Parts are loaded into the chamber on a 4-axis robot unit. The robot has a high precision, repeatable accuracy and can accommodate multiple parts of different shapes and sizes. The machine is capable of performing both wet and dry etching. In wet etching, a chemical mixture is injected into the chamber to create desired patterns on the surface of a substrate. Dry etching uses a plasma to achieve selective etching through a process of sputter and/or ions bombardment to create patterns. ULVAC Phoenix supports both single-wafer and wafer cassette loading. It allows for both manual and automated loading, unloading, and transfer to and from the chamber. Once inside the chamber, parts are etched or ashed with a combination of high-vacuum pressure, reactive gases, and heat. Also, different operations within the chamber can be completed quickly and efficiently thanks to a quick cycle time and high-performance rotation accuracy. The tool also offers excellent reliability and repeatability. This ensures a consistent quality of product, resulting in excellent yields and increased production throughput. Furthermore, Phoenix provides industry leading safety, utilizing numerous oxidation and etch processes which are designed to give off minimal by-products. Overall, ULVAC Phoenix is an excellent etching and ashing asset that is ideal for the production of high-quality, intricate sub-micron integrated circuit designs. It boasts an array of features that make it a powerful tool in any production environment.

There are no reviews yet