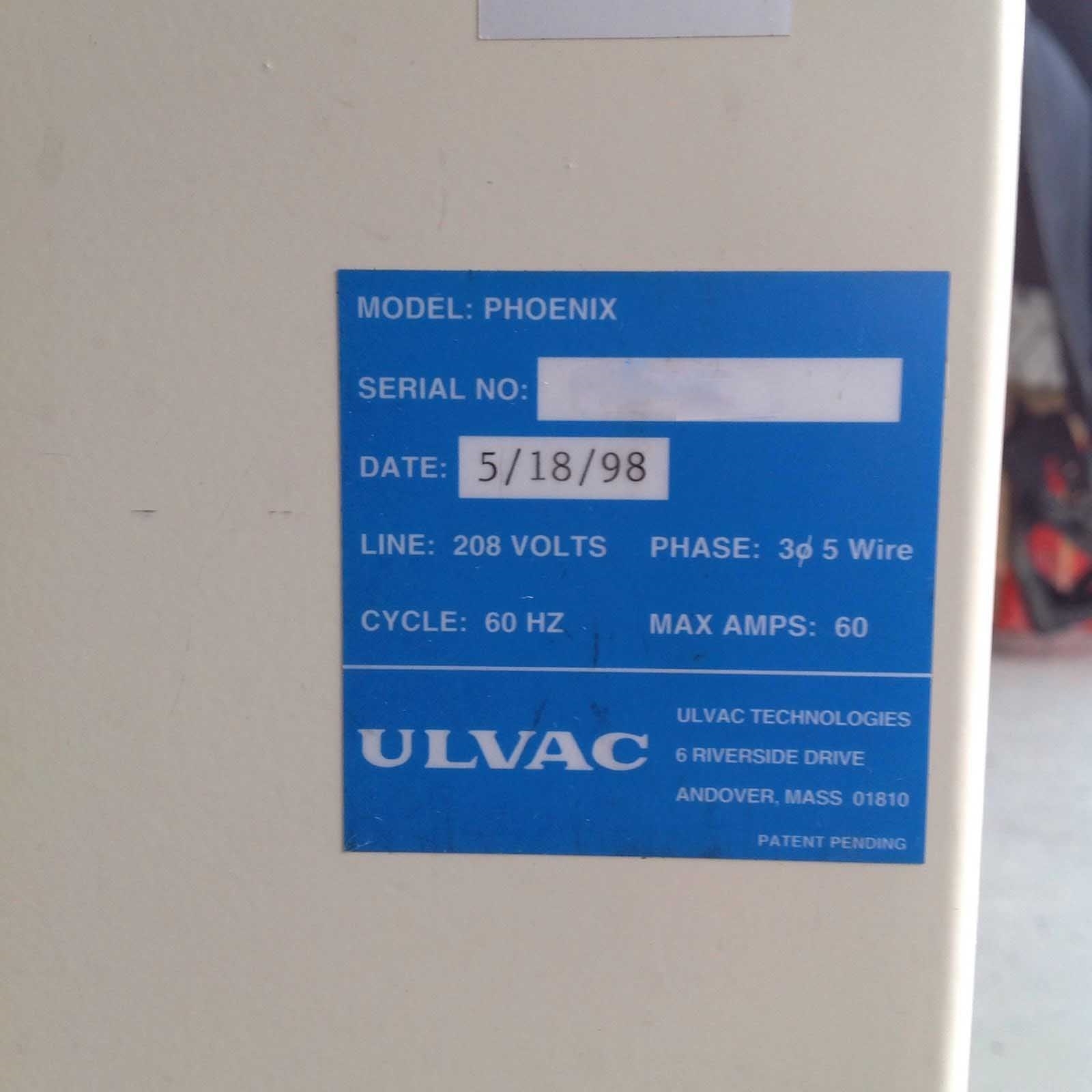

Used ULVAC Phoenix #9164102 for sale

URL successfully copied!

Tap to zoom

ID: 9164102

Vintage: 1998

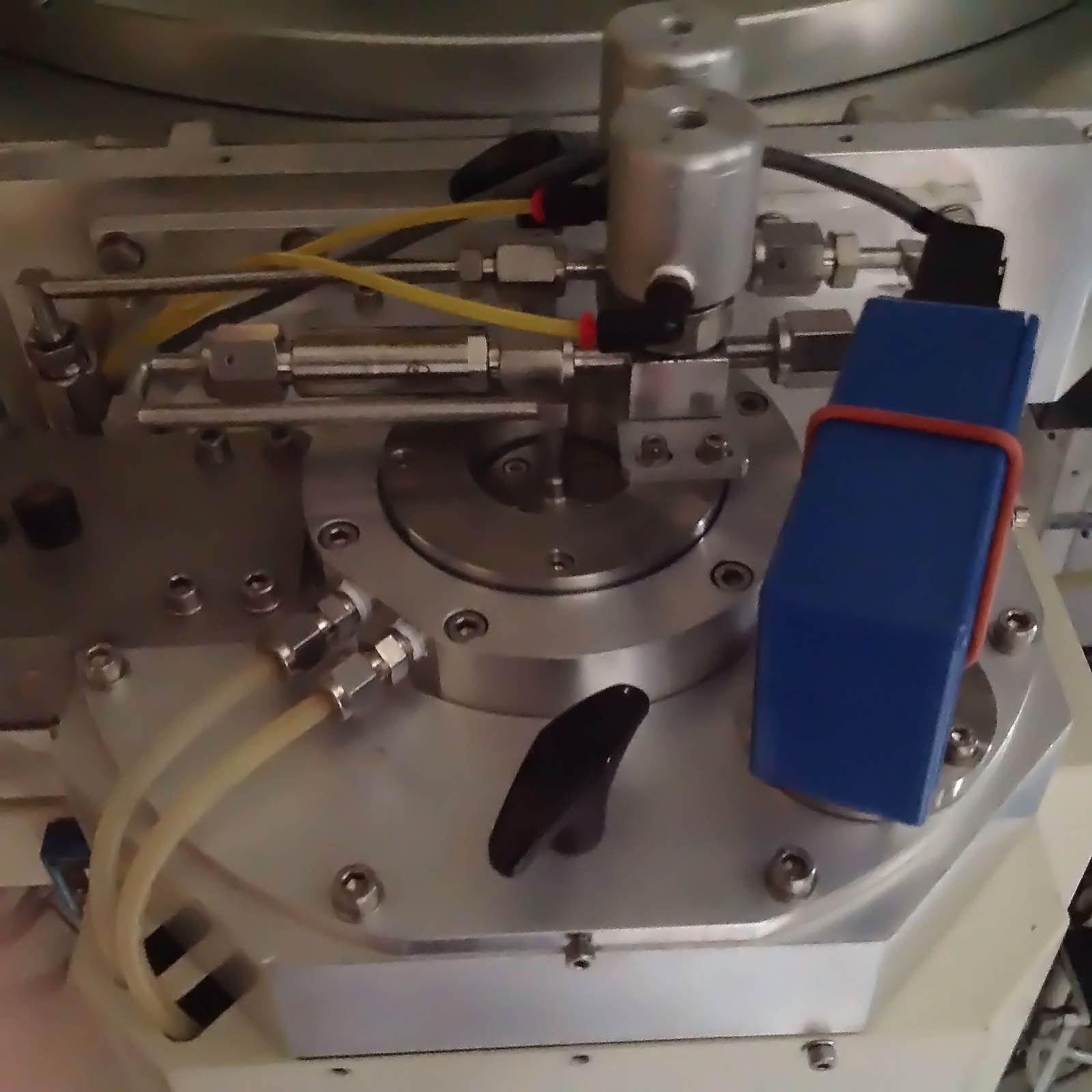

Etcher

Enviro single chamber

Multiple step RF

Microwave plasma asher

Includes:

BROOKS AUTOMATION MTR-5

BROOKS AUTOMATION Board M/N 001-1951-02 revC3

BROOKS AUTOMATION M/N 001-8200-76

BROOKS AUTOMATION M/N 001-2300-47

ASTEX AX2050 2500 W Microwave power generator

ASTEX AX3032

ASTEX AX3030

ASTEX F120047

ASTEX SA2050TBB

ASTEX S402WG2

ASTEX AX3060

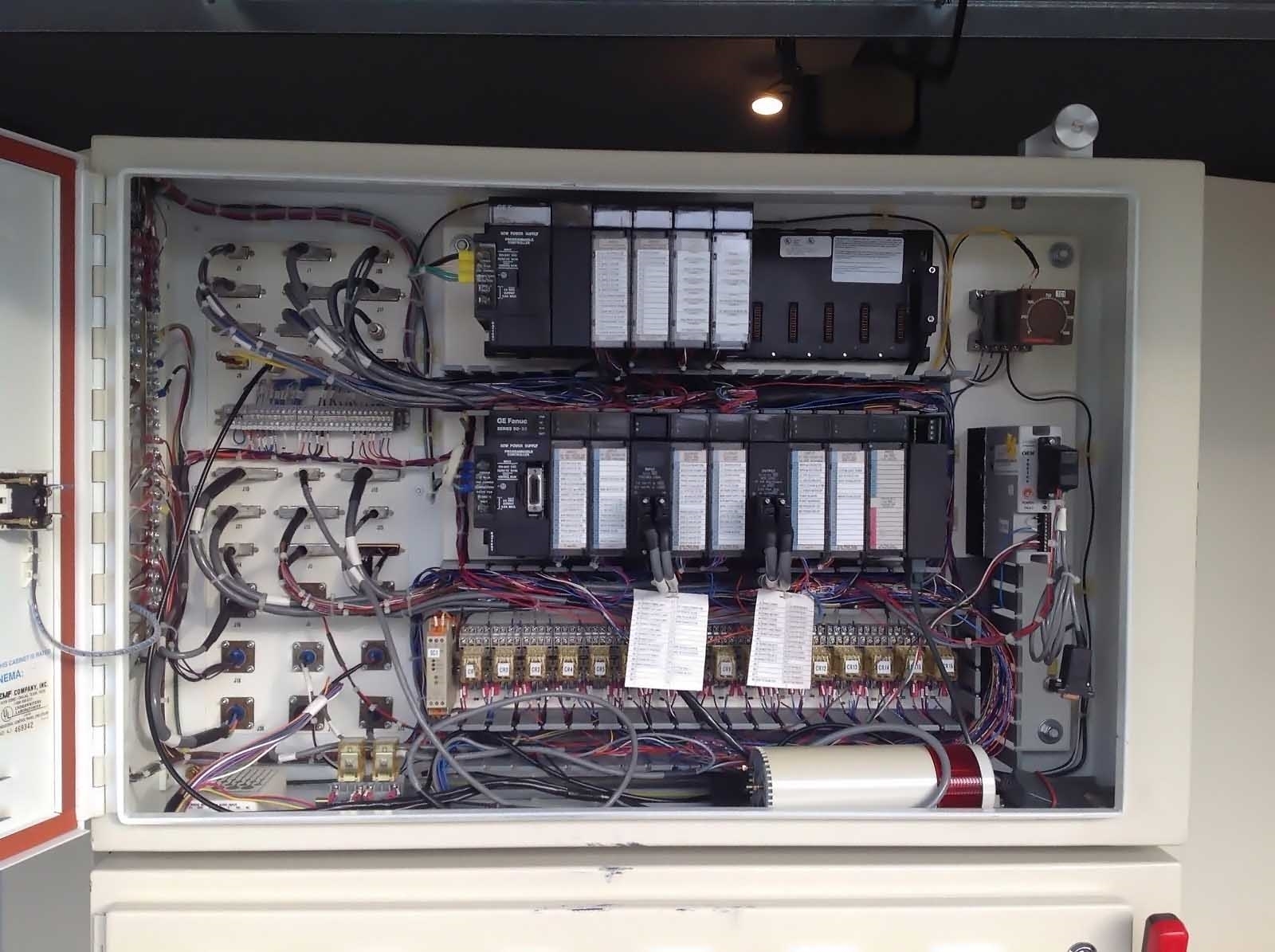

GE FANUC Series 90-30 CPU 341

ENI Automatch M/N MWH-5-01M3

JET Light power supply M/N DC24-8000-30

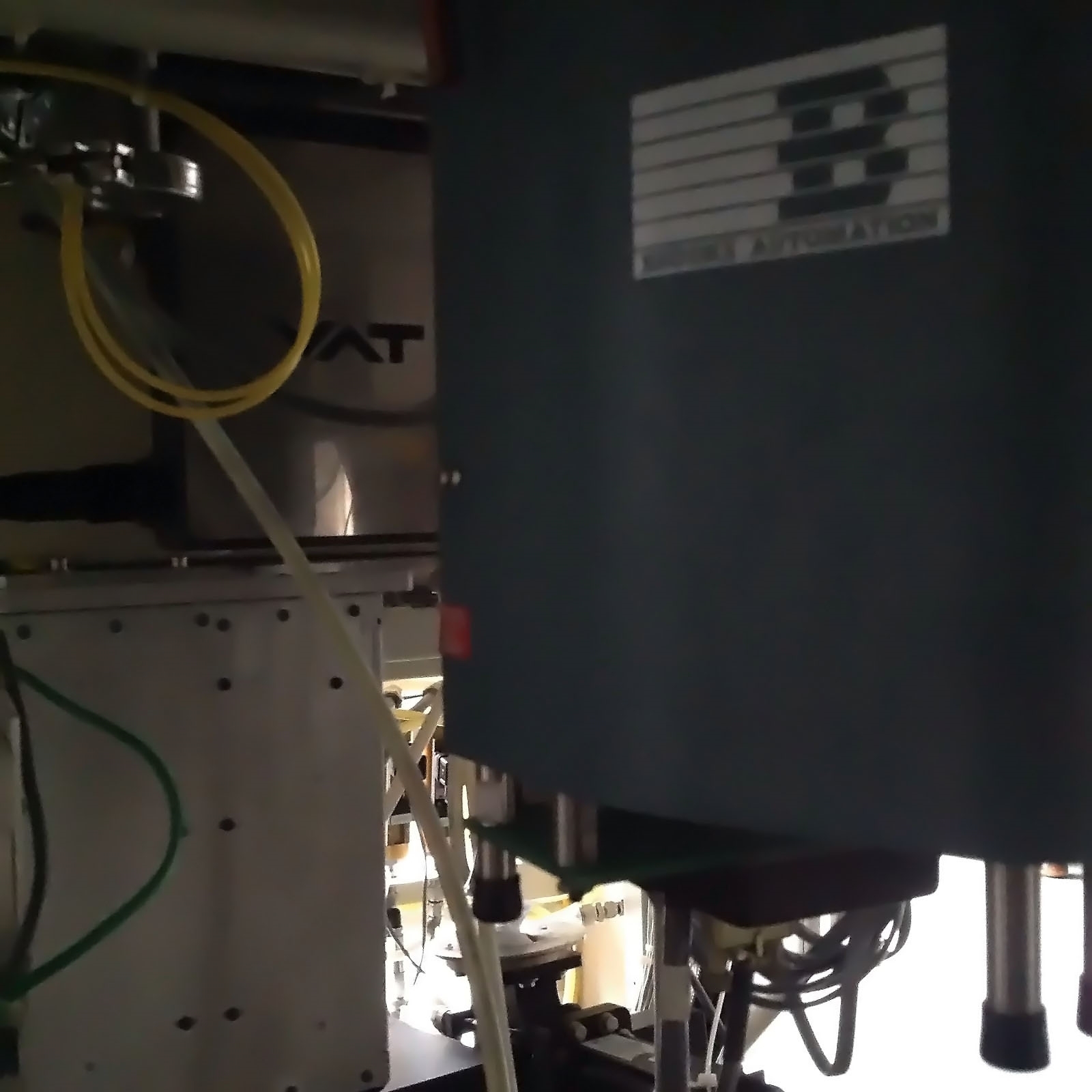

VAT Vacuum gate valve M/N 02010-BA24-1008

VAT Vacuum gate valve M/N 02010-BA24-1009

THK-SC6

MKS Vacuum isolation valve M/N LP2-40-AK-CLVS

MKS BARATRON Pressure transducer M/N 122BA-00010AB

Multiple AERA MFCs FC-7700CD

NUPRO Valves

Gateway computer & wonder ware

Spare parts

Multiple support manuals & documentation

Power: 208 V, Cycles 60 Hz, 30 Phase, 60 A, 5 Wires,

1998 vintage.

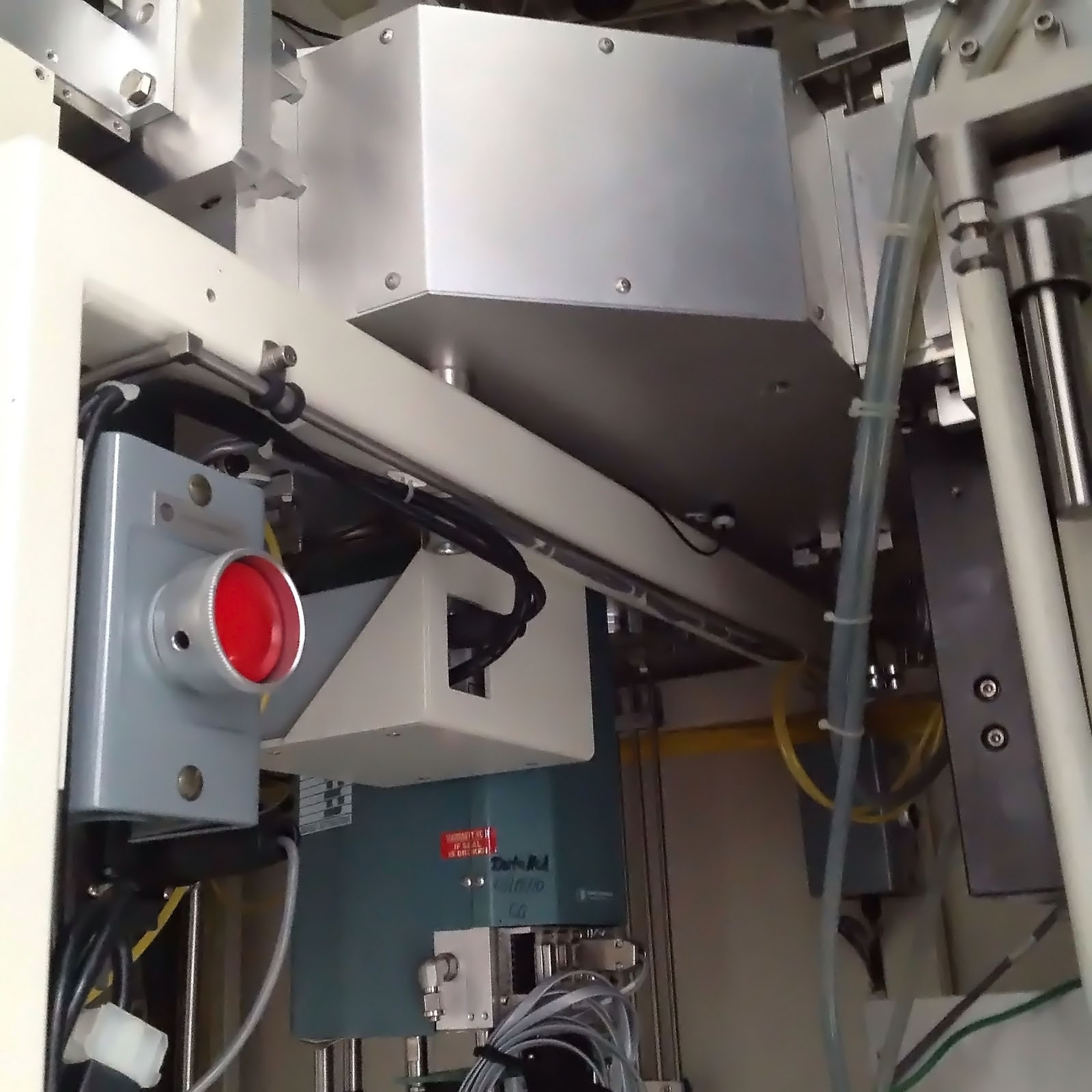

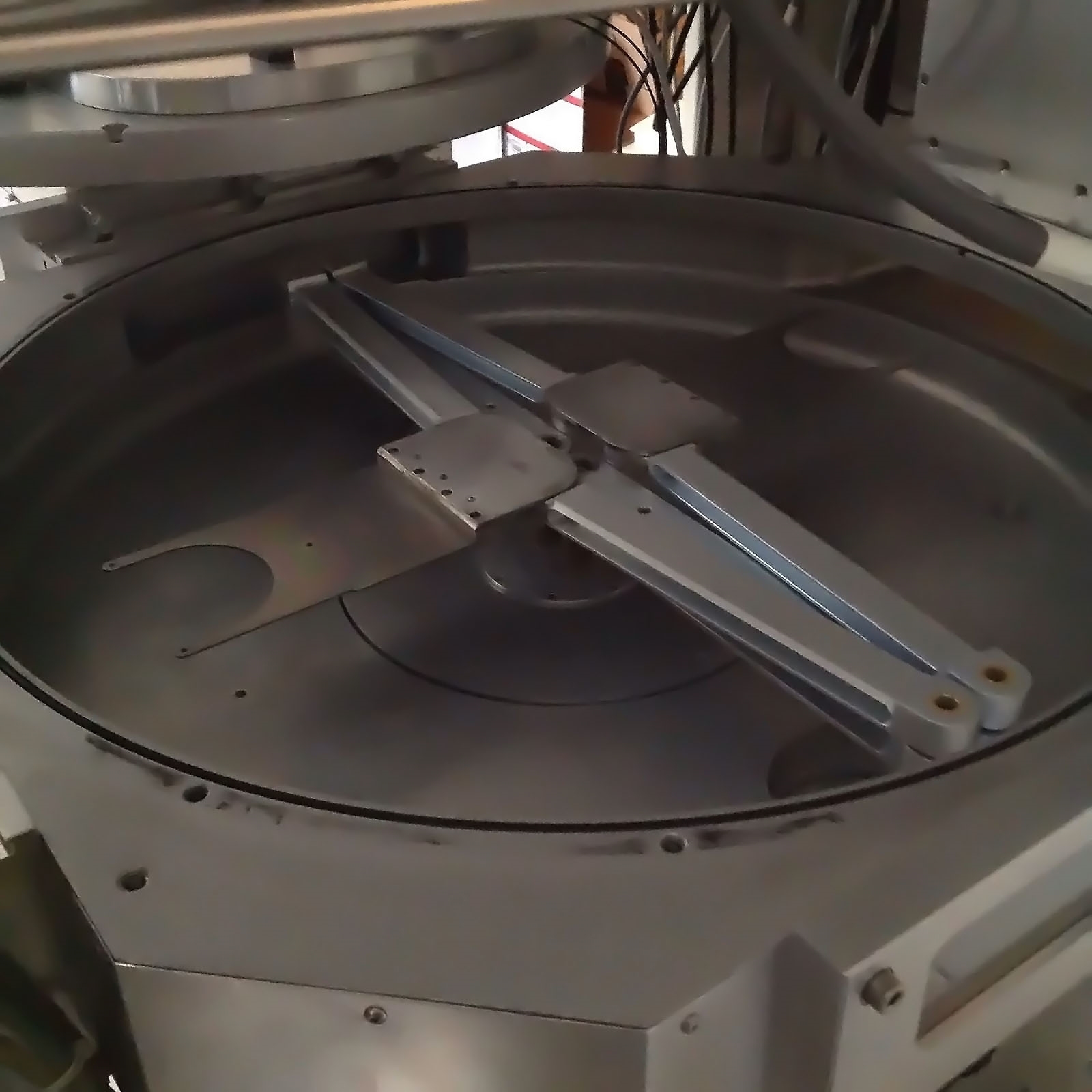

ULVAC Phoenix is an etching / asher equipment developed by ULVAC, Inc. It is designed for high speed and high accuracy etching and ashing of various substrates. The system has an automatic substrate handling unit which permits ultra-high speed, one pass, angular control, over a wide range of materials. Phoenix uses an ion beam to uniformly etch a substrate, and it has two main components: the etching / ashing source, and the control unit. The source is comprised of an ion source, a mechanical motion machine, and a series of lenses to focus the ion beam. The control unit provides the parameters needed to control the etching, ashing, and cleaning process. The control unit is designed to provide a wide range of parameter settings, allowing the user to program the parameters to achieve the desired results for various substrates. Programmable parameters include gas flow, source beam power, etching and ashing angles, and material layer rate. The adjustable parameters provide the flexibility for a wide variety of materials and processes. In addition, ULVAC Phoenix is designed to meet international standards of safety, including anti-static protection, ergonomically designed control panels, and a sophisticated safety tool. Phoenix is one of the most powerful and reliable etchers / ashers available. It utilizes high speed etching and ashing, sensitive control systems, and advanced safety features to provide the user with an efficient and effective solution for etching and ashing substrates. Additionally, its flexible programming capabilities enable a wide range of applications and processes, enabling users to achieve optimum performance for their etching / ashing needs.

There are no reviews yet