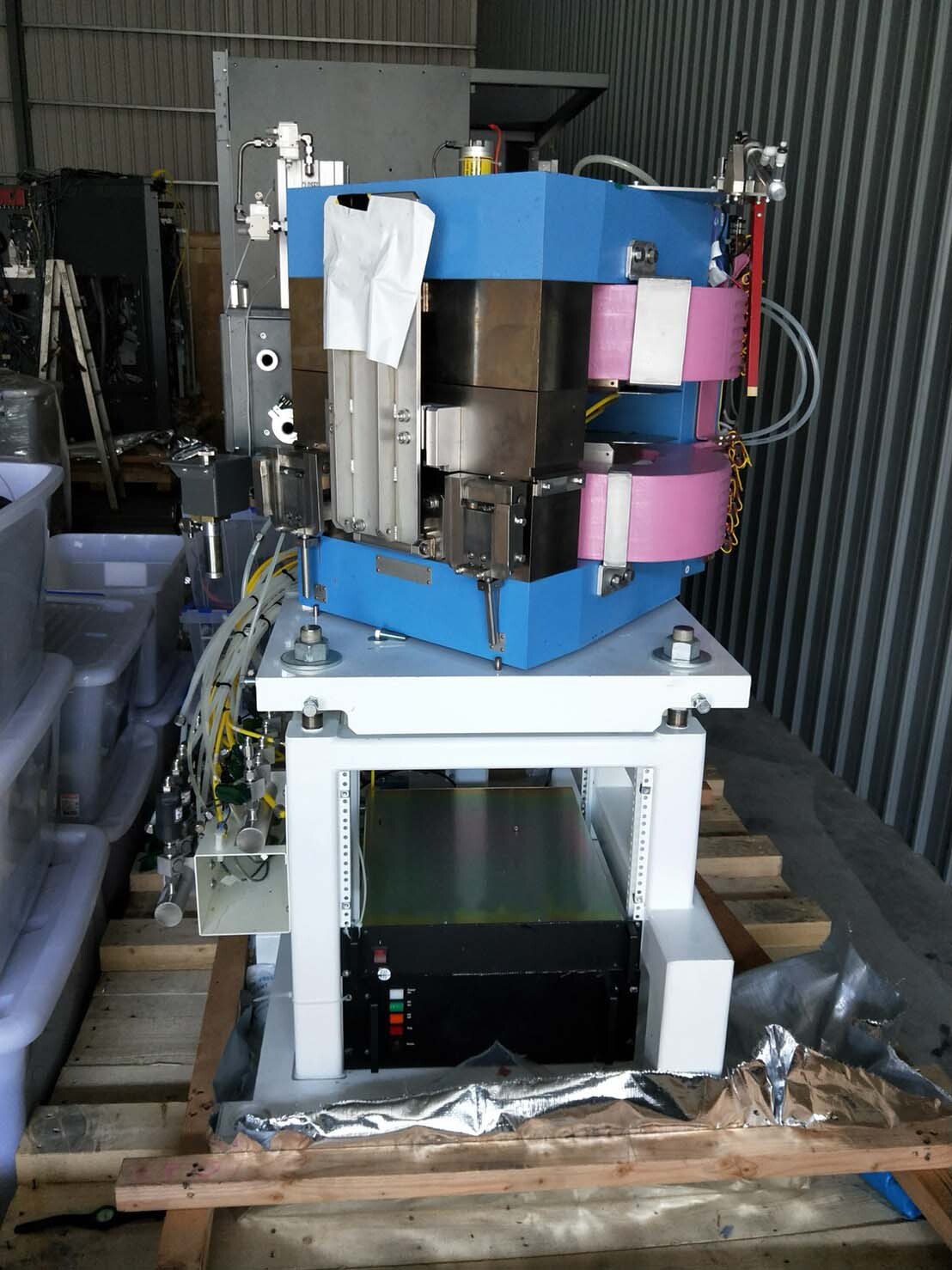

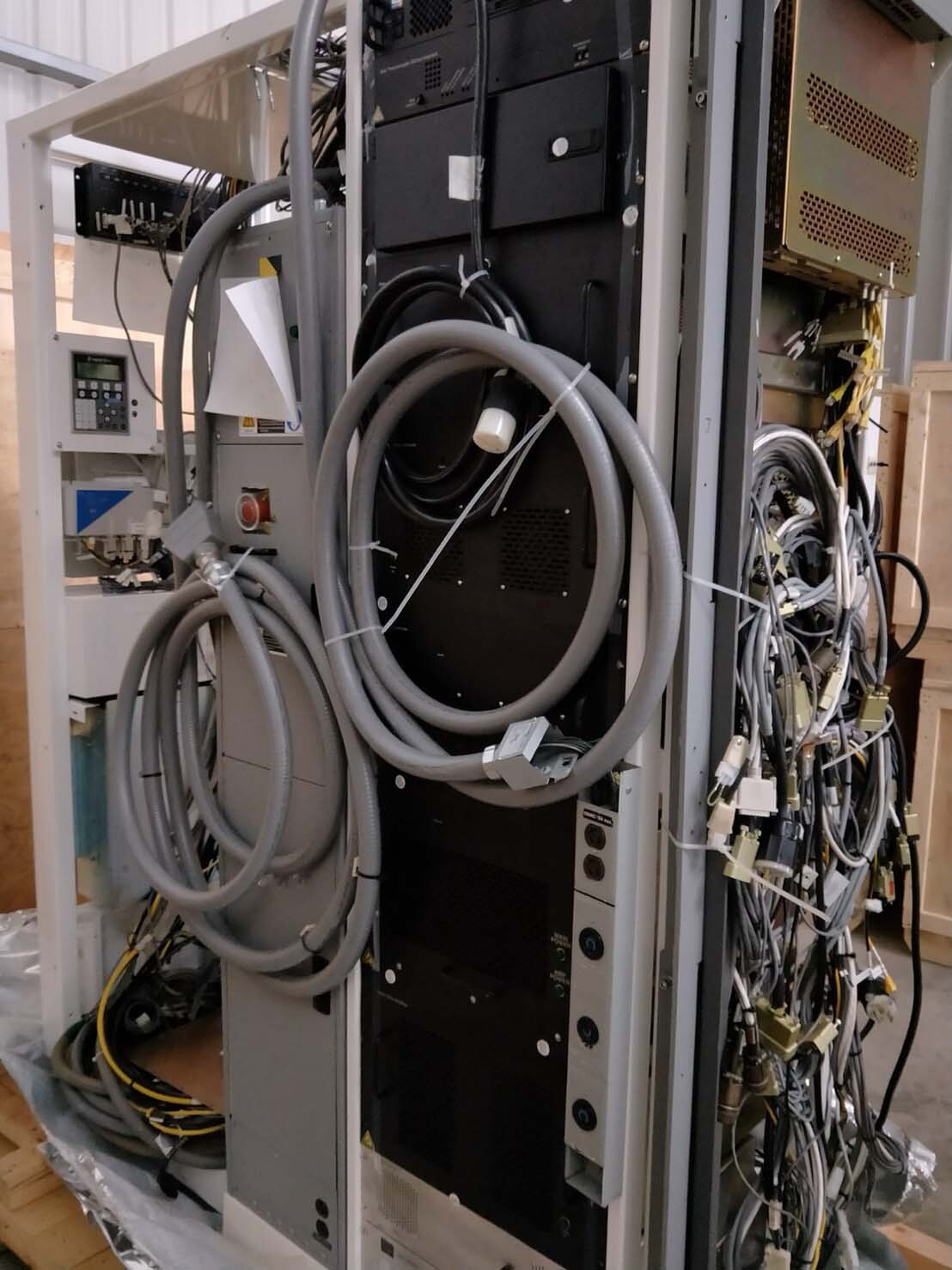

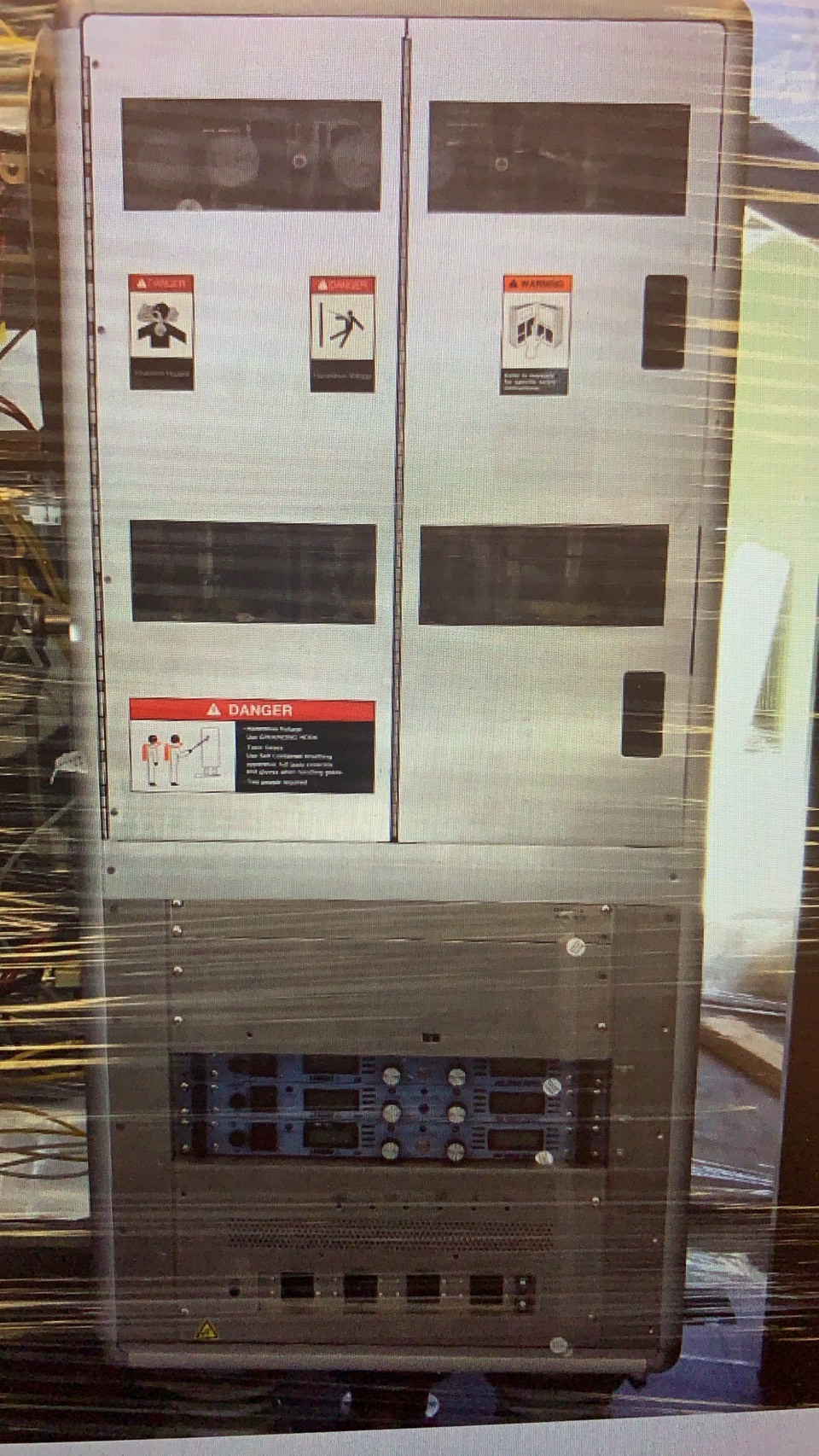

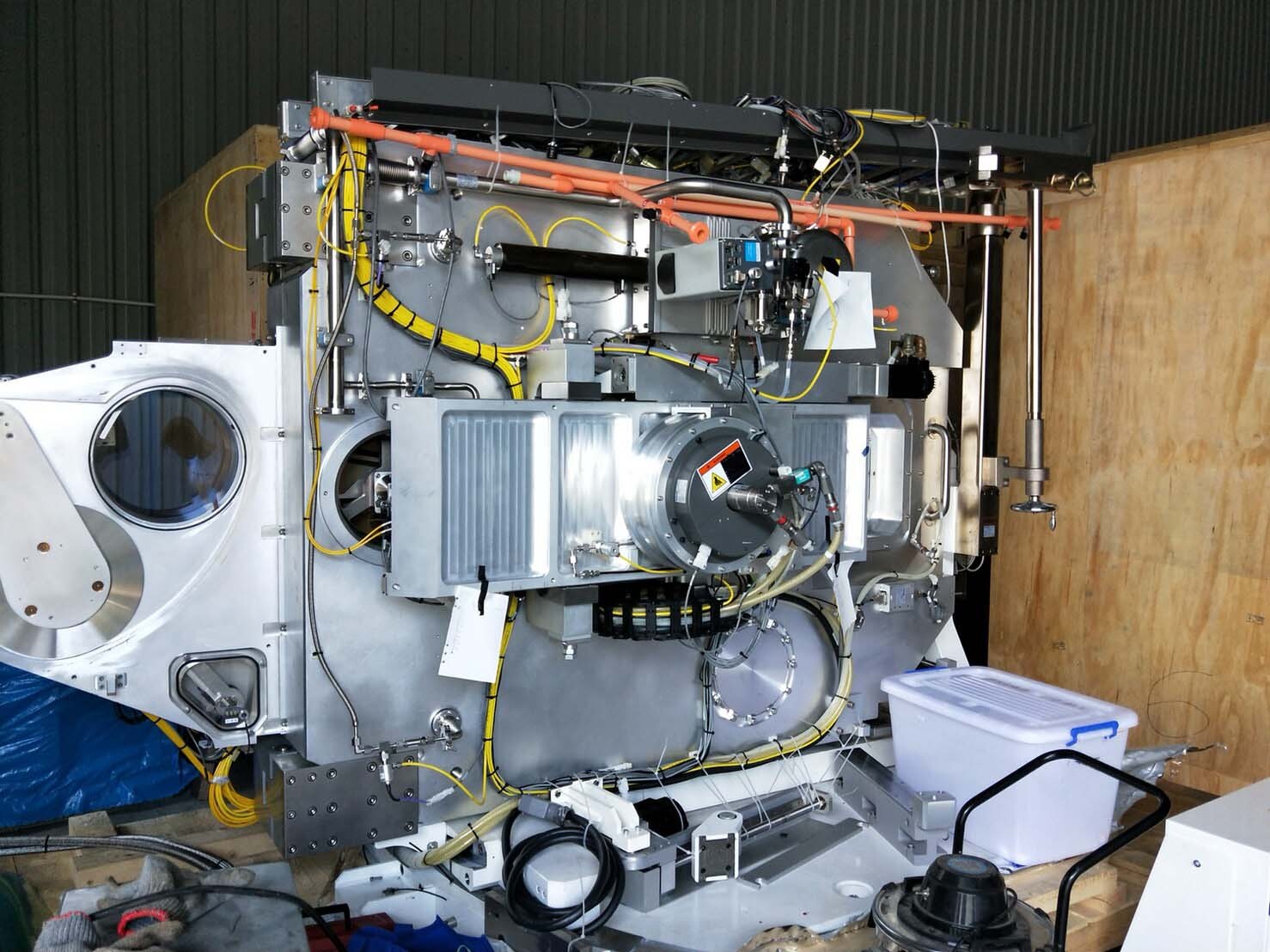

Used EATON NOVA / AXCELIS HC3 #9411352 for sale

URL successfully copied!

Tap to zoom

ID: 9411352

Ion implanter

YASKAWA Robot

YASKAWA XU-ACL4140 Robot track

Disk type: Variable Speed Drive (VSD)

Wafer transfer type: In-Air

Dry transformer

HYT

Vacuum ARM: CAM Arm

(3) CTI-CRYOGENICS 250 F (On-board) Cryo pumps

(2) CTI-CRYOGENICS 9600 Compressors

Shower type: P-Shower 11020020

Cell type: V6

BROOKS AUTOMATİON Fixload load port

Spare parts:

Part number / Description

1187286 / Disk TC DI Cryo interlock

11053210 / Cell controller V6

11049380 / Scan controller

11054580 / Wafer transfer controller

11054560 / Load lock controller

1195730 / Rotary drive controller

11028010 / Rotary drive amplifier

XU-BCD3111 / YASKAWA Robot driver box

XU-CN0821 / YASKAWA Robot controller box

11050220 / Power dose controller

11017920 / Gas box controller

110000950 / Source controller

1214110 / Filament PSU

1214120 / Arc PSU

1214130 / Cathode PSU

1188151 / Terminal beam line DI

1163967 / Ground electronic DI

1163960 / Ground electronic DI

1195140 / Disk VAC DI

1188310 / Electrode manipulator DI

1214460 / Plasma filament PSU

11020020 / Plasma controller

110098500 / 100101530 / Rotary driver brake controller

2100276 / Source magnet PSU

1188375 / Terminal electronic DI

2200176 / Decal PSU

2200173 / HV PSU Extraction suppression

2200173 / HV PSU Decal suppression

11054570 / Gyro controller

11034940/ 2200175 / AMU PSU (Power ten)

2200187 / Extraction PSU

1196510 / Gyro ball screw assembly

1196610 / V43

1908930 / Air interface

1908940 / Air interface

110001490 / Wafer holder assembly

11030960 / CAM Arm assembly

110002530 / V3 Assembly

11047650 / V7

2014 vintage.

EATON NOVA / AXCELIS HC3 Ultra is a highly sophisticated ion implanter and monitor equipment designed to meet the demands of modern ion implantation applications. This tool features a high-current ion source that can accelerate ions up to 50 KeV, a multi-stage demountable vacuum chamber, an automated patterning system, and a robust control package. AXCELIS HC3 Ultra is particularly beneficial for forming high-quality layers in active microelectronics, dielectrics, and substrates. EATON NOVA HC3 Ultra uses an electrostatic immersion lens unit to ensure that a consistent beam of ions is directed towards the target area. This machine also enables the user to precisely adjust the shape of the ion beam, as well as its size and spread. Moreover, HC3 Ultra contains a multi-stage demountable vacuum chamber which helps to maintain a stable process environment for ion implantation. EATON NOVA / AXCELIS HC3 Ultra also features an advanced user-friendly interface. Its intuitive graphical user interface enables users to fully monitor the tool and adjust parameters such as the ion source current (up to 50 KeV) to control the process. The software also aids users in adjusting the beam shape and energy spread of the ions. Furthermore, users have the ability to select and switch between implant programs, as well as store custom gas mixtures. AXCELIS HC3 Ultra contains a number of other innovative features. For instance, its automated patterning asset enables users to pattern substrates with pre-selected implantation energies and doses. It also features a unique shift register that permits users to conduct enhanced layer-by-layer implantation processes. EATON NOVA HC3 Ultra is an ideal ion implanter and monitor for those engaged in advanced implantation processes. Its high-current ion source, multi-stage demountable vacuum chamber, automated patterning model, and user-friendly interface make it the optimal tool for achieving fast and accurate implantation results. Moreover, its unique shift register and adjustable beam shape and spread characteristics provide users with a wide range of options for patterning and creating high-quality layers.

There are no reviews yet