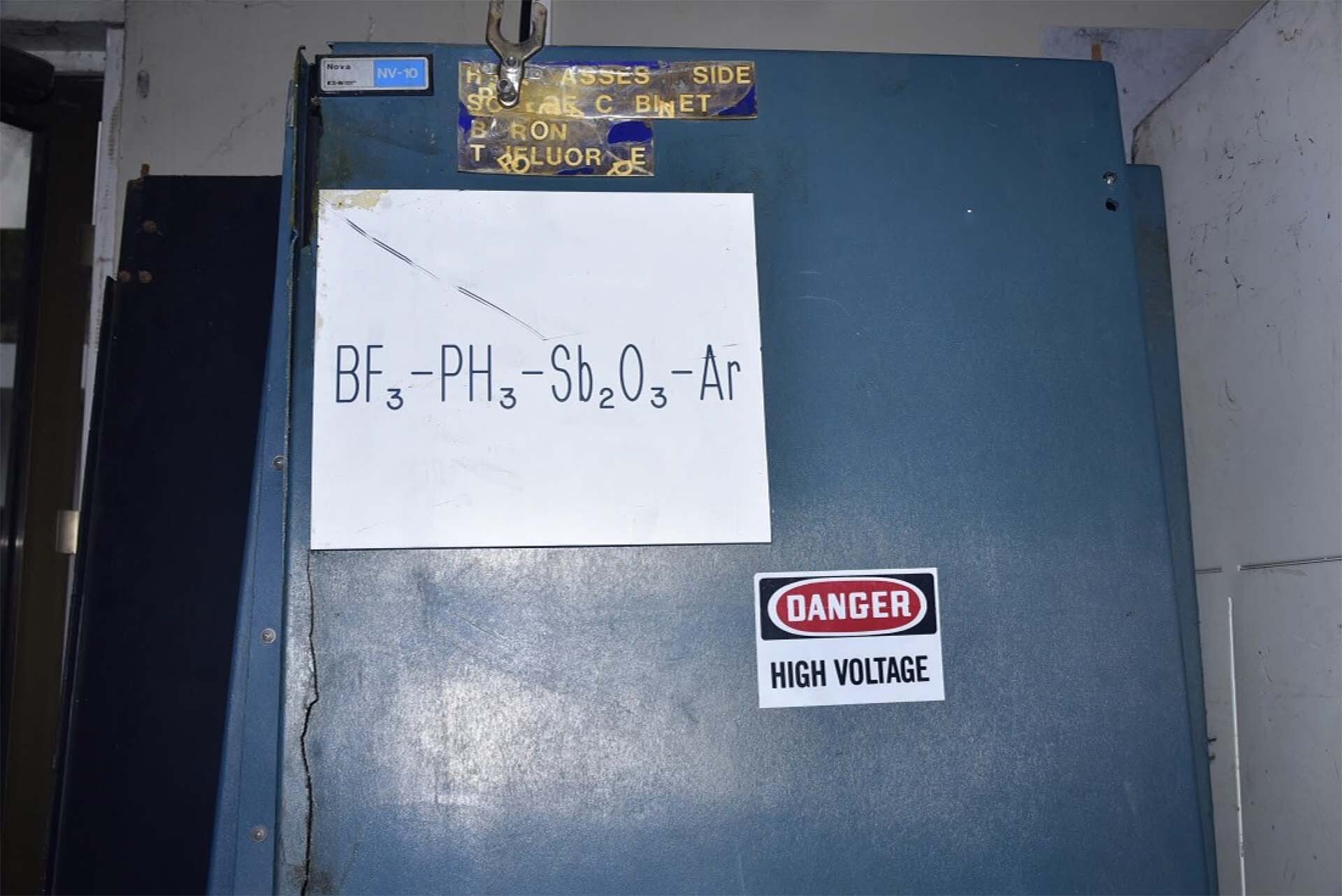

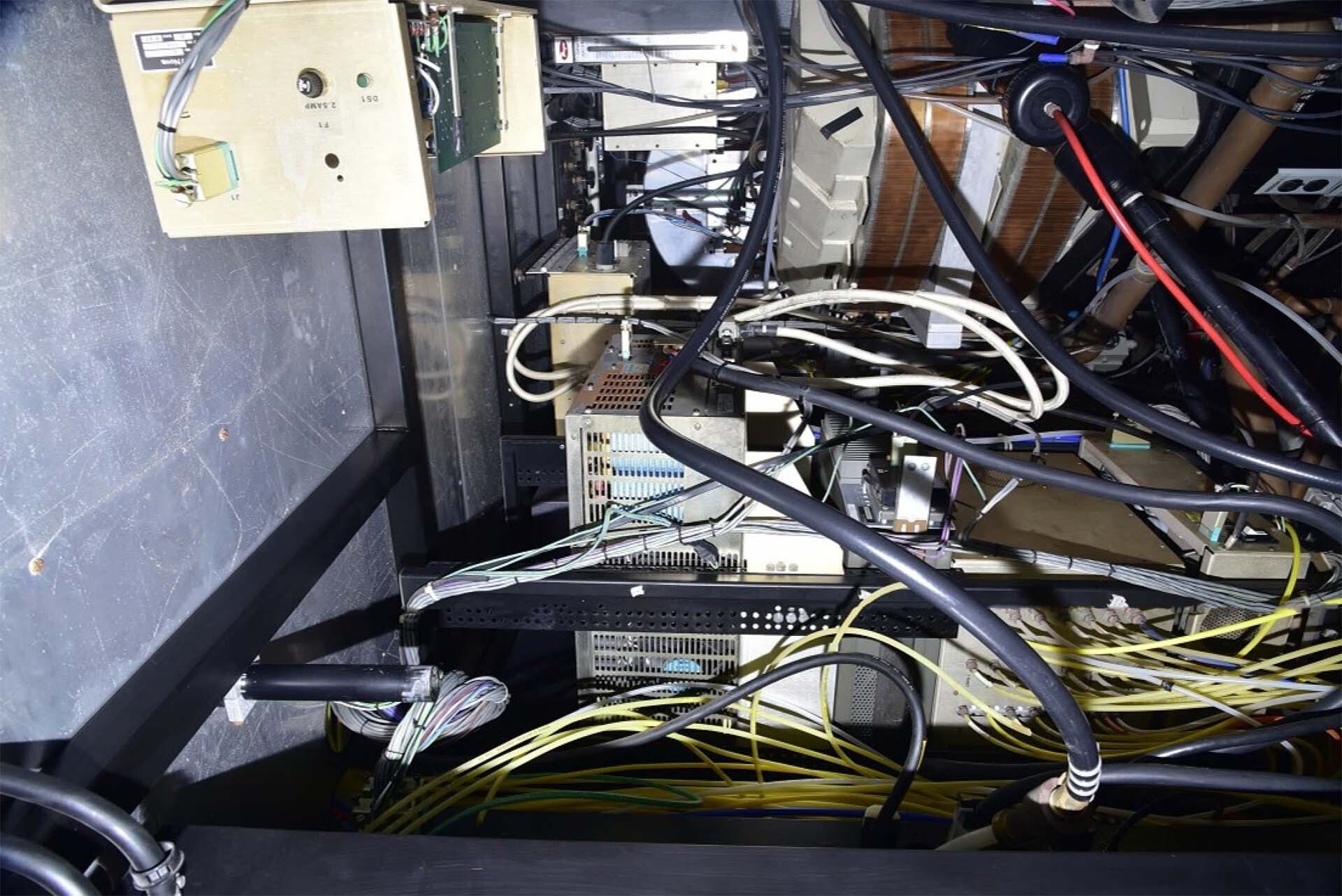

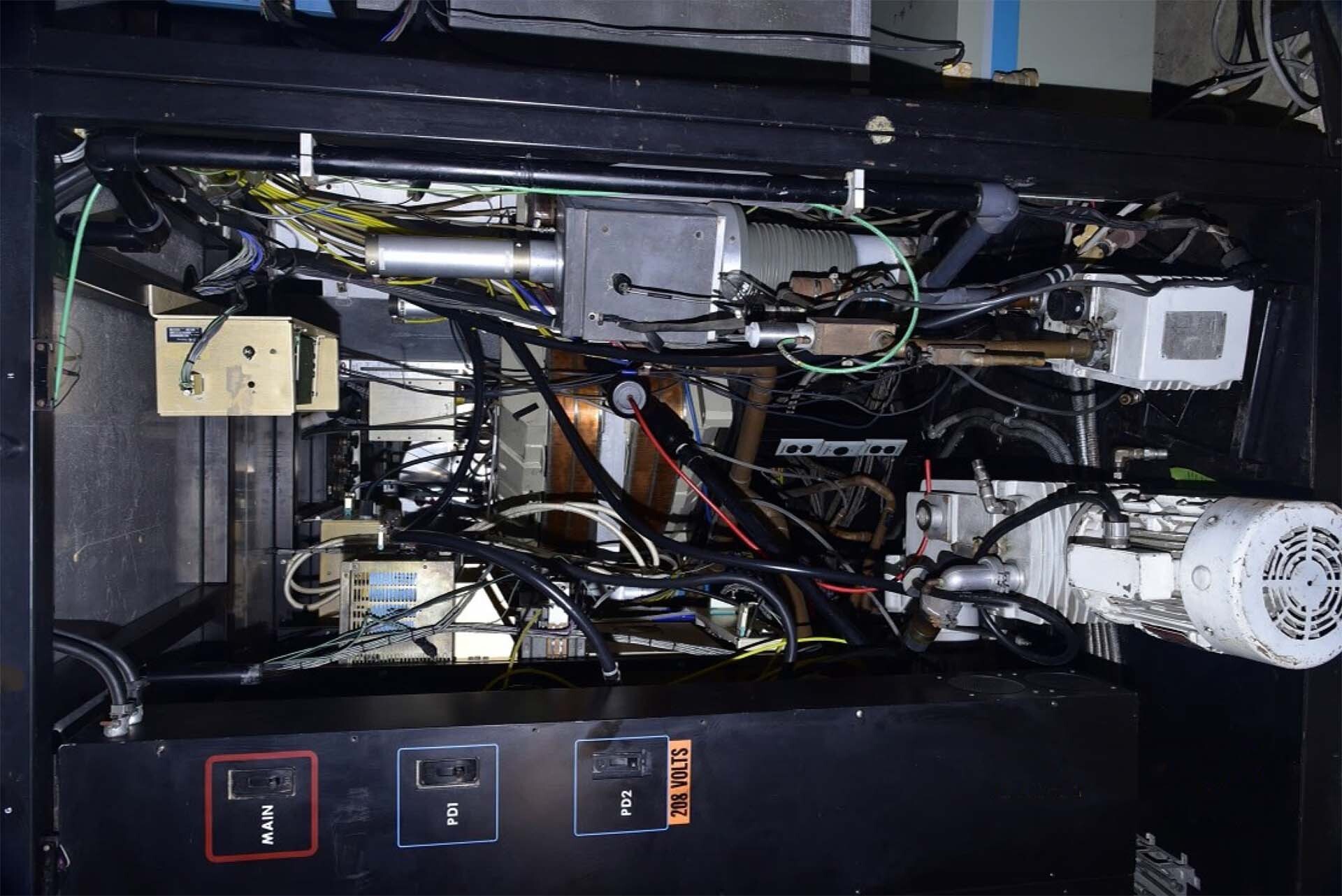

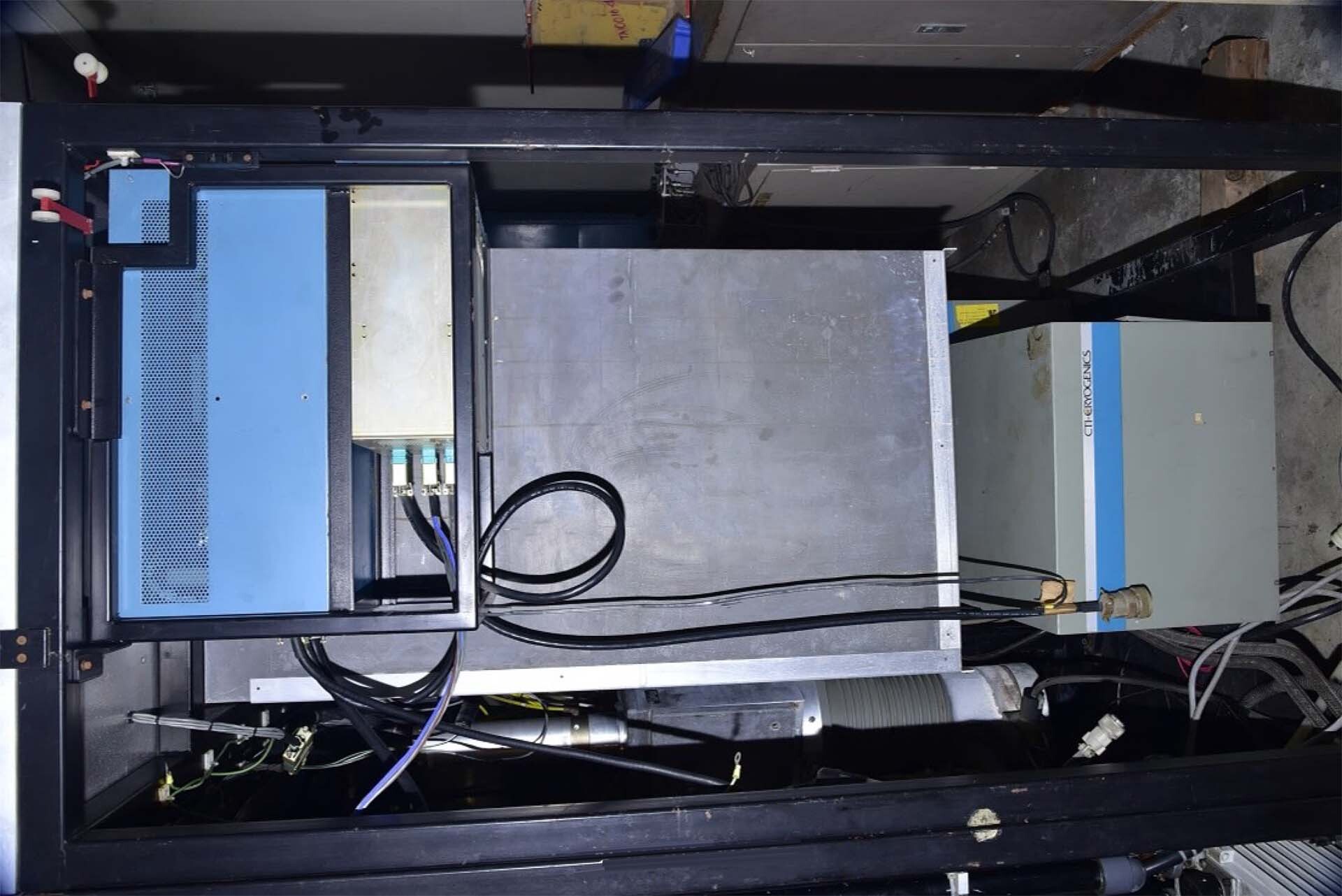

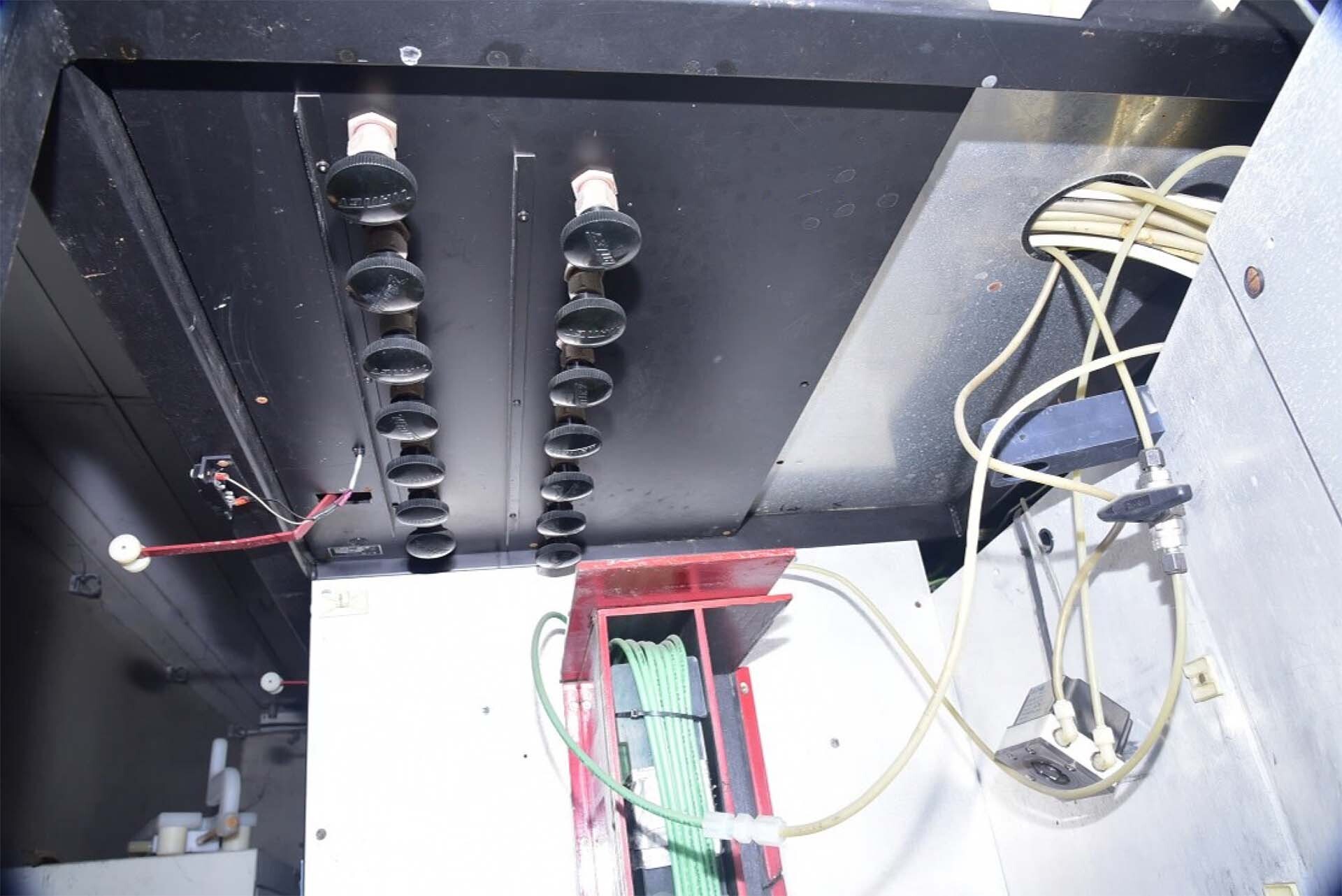

Used EATON NOVA / AXCELIS NV 10-80 #9412142 for sale

URL successfully copied!

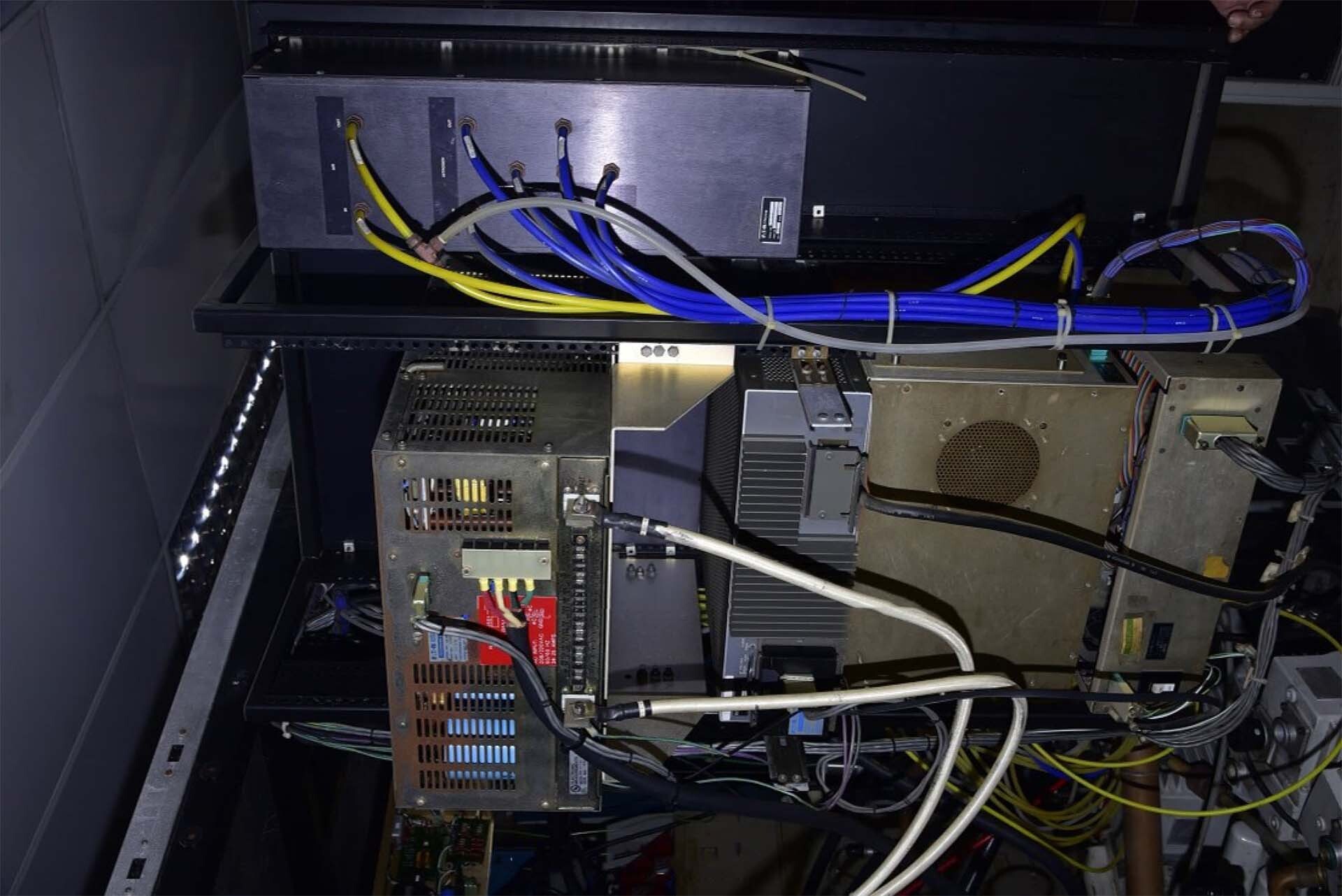

Tap to zoom

ID: 9412142

Wafer Size: 6"

Vintage: 1986

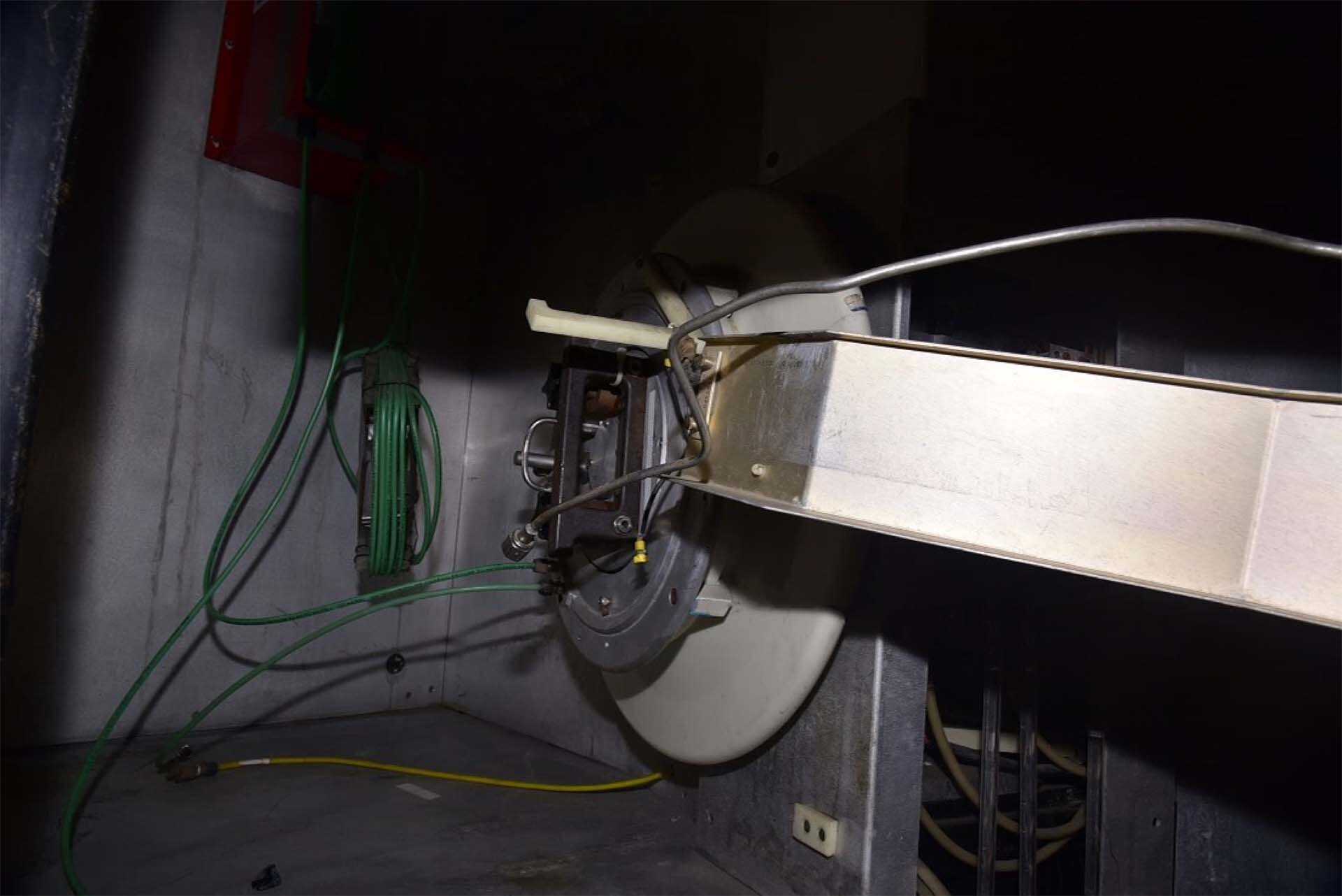

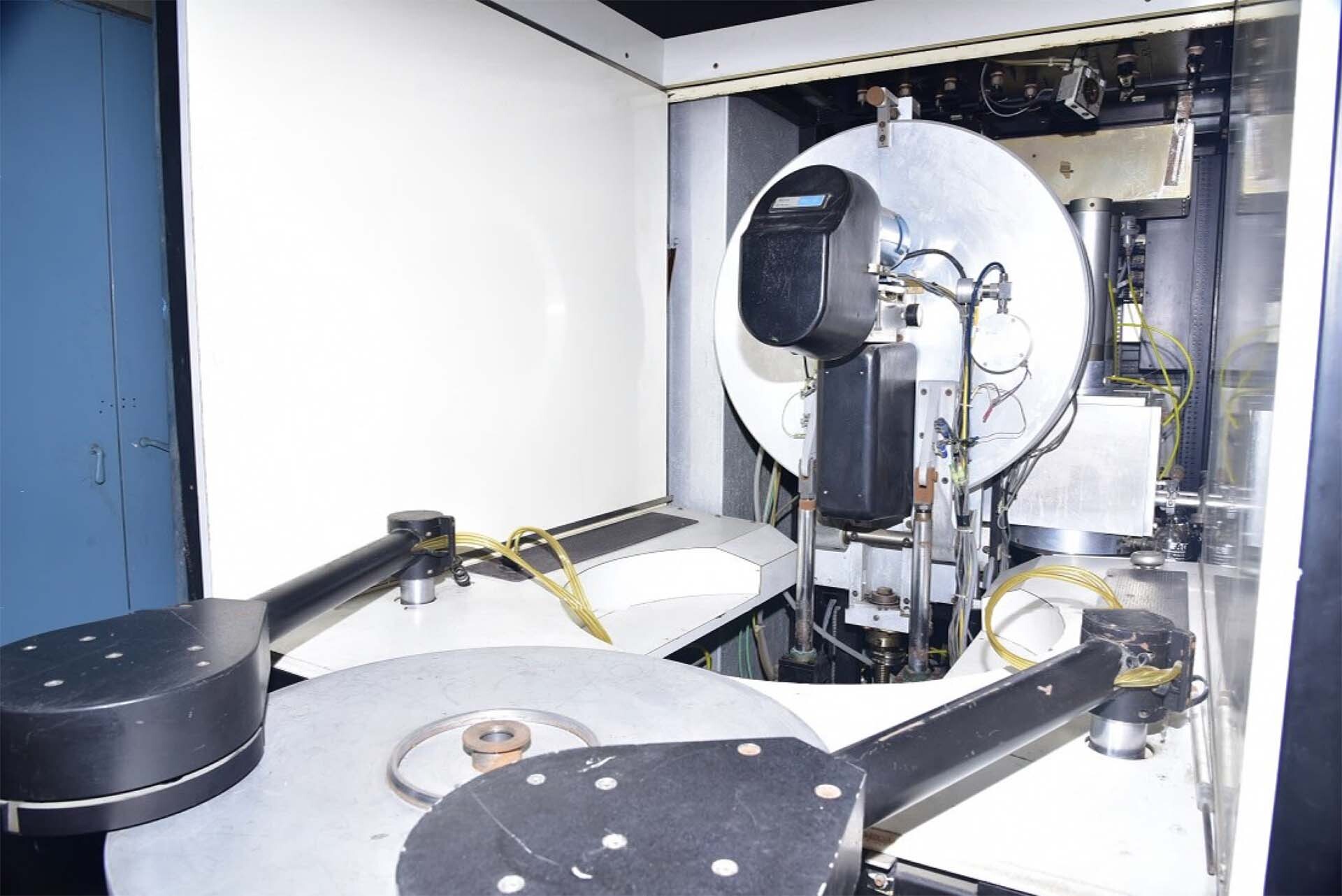

Ion implanter, 6"

(4) Sources

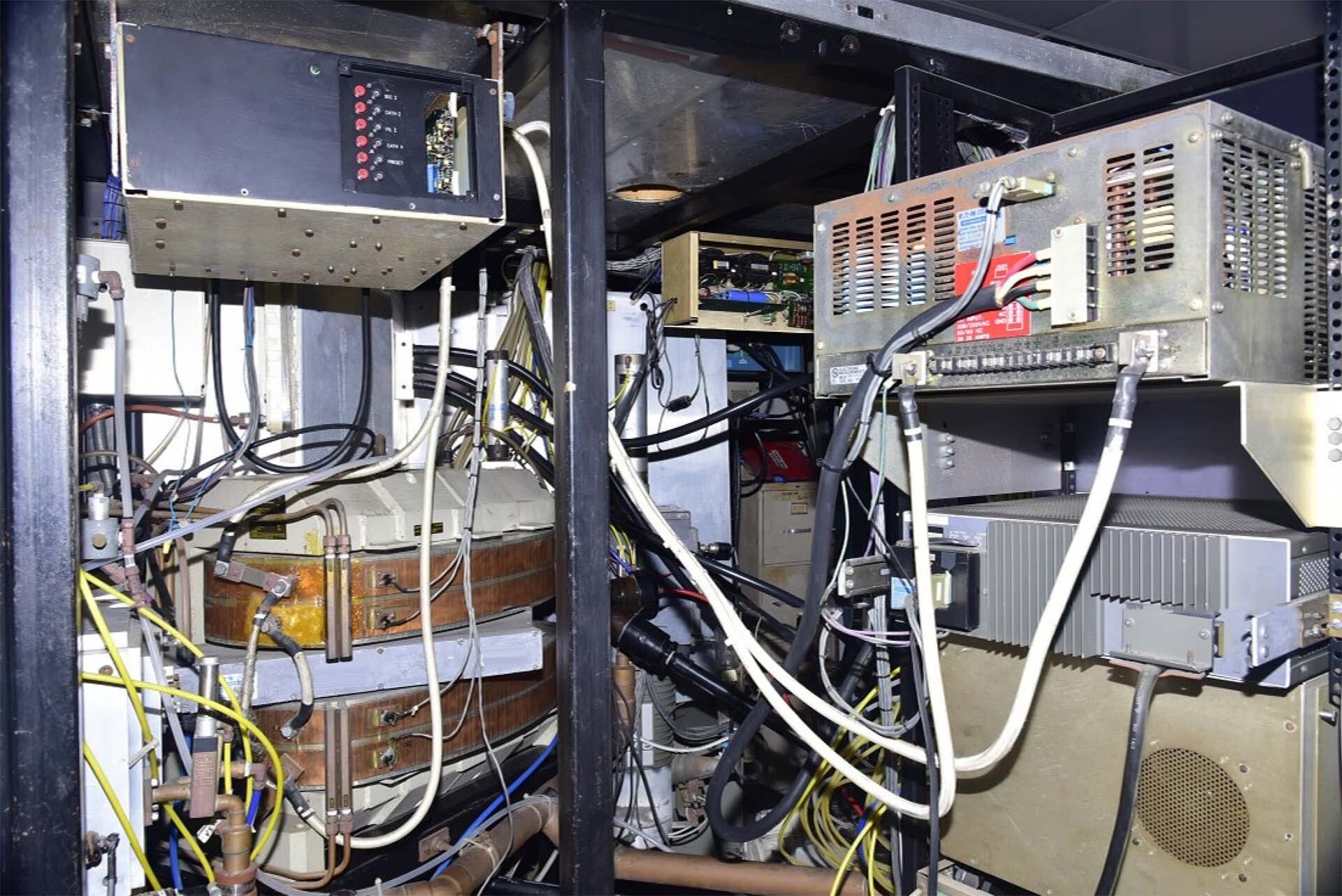

Ion beam energy: 20~80keV

Dose range: 5.0E12 - 5.0E15 atoms / cm²

Minimum beam current: 10µA

Wafer temperature: 100°C

X-Ray emission: ≤0.6μ Sievert / hr (60μ rem / hr)

Charge control technology: Secondary Electron Flood (SEF)

Mechanical throughput:

Batch size: 10 wafers

Throughput: 100 WPH

Maximum implant time: 120 sec

Dose control:

Bare Si Wafers: ≤3.0%

Photoresist wafers: ≤4.0%

Beam current for 80kev:

Energy(keV) / B11(mA) / AS75(mA) / P31(mA)

20 / 0.5 / 0.2 / 0.3

40 / 1 / 1.5 / 1

80 / 2 / 3 / 2.5

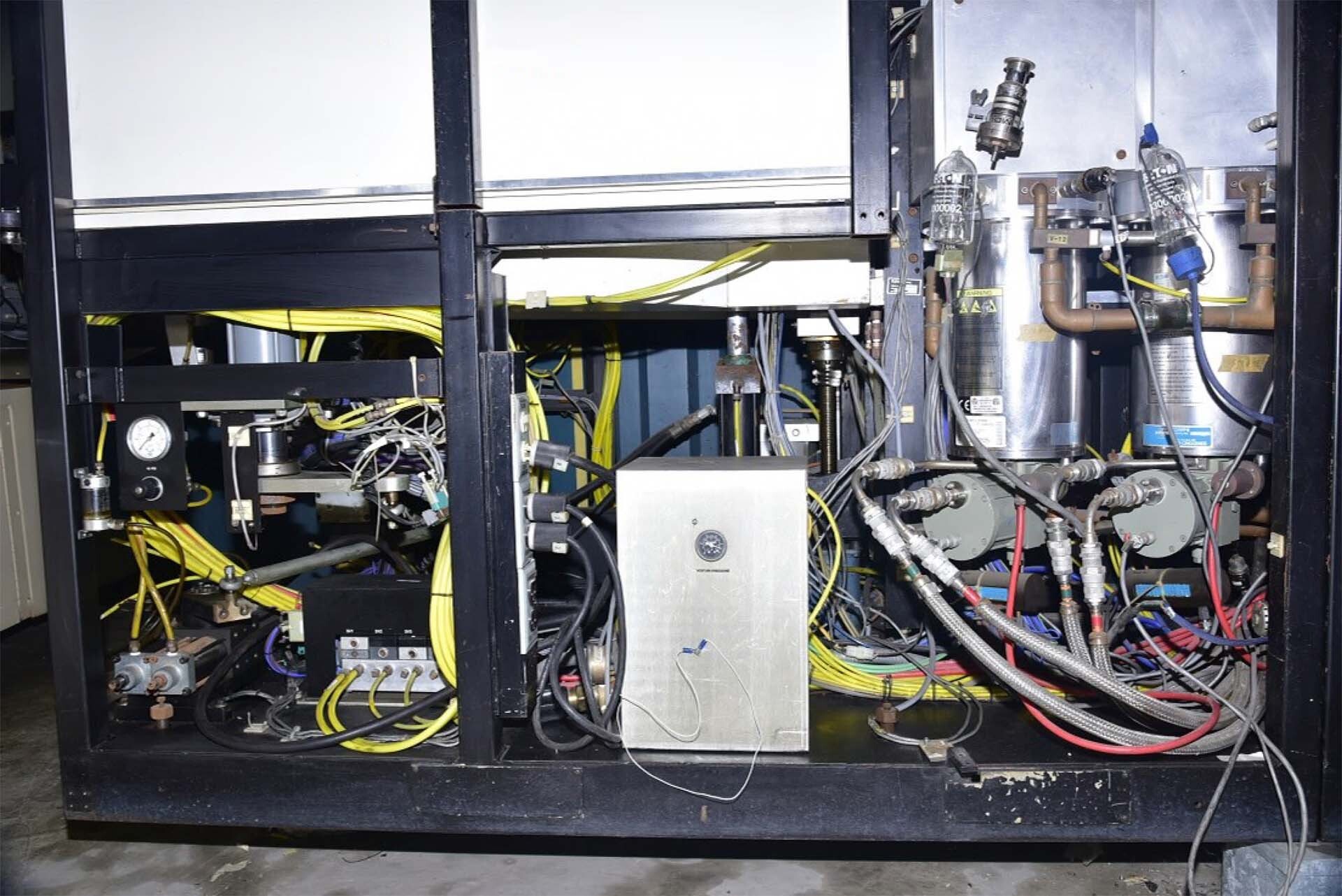

Vacuum performance:

Subsystem / Pump / Base pressure (Torr)

Source / Diffusion pump / ≤5.0E-06

Beamline / Resolving housing / Cryo Torr8 / ≤5.0E-06

Resolving housing / Process chamber / Cryo Torr8 / ≤5.0E-06

1986 vintage.

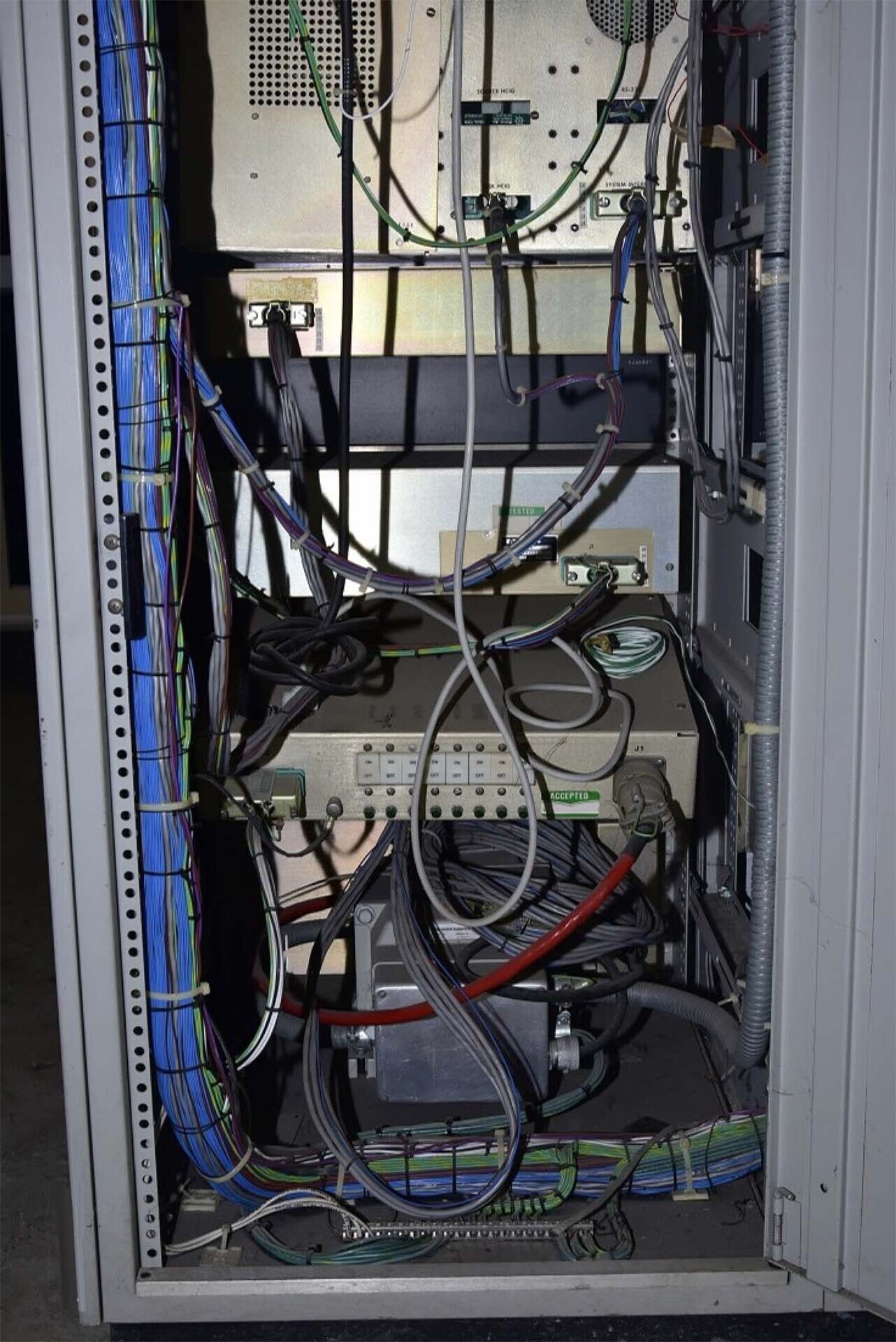

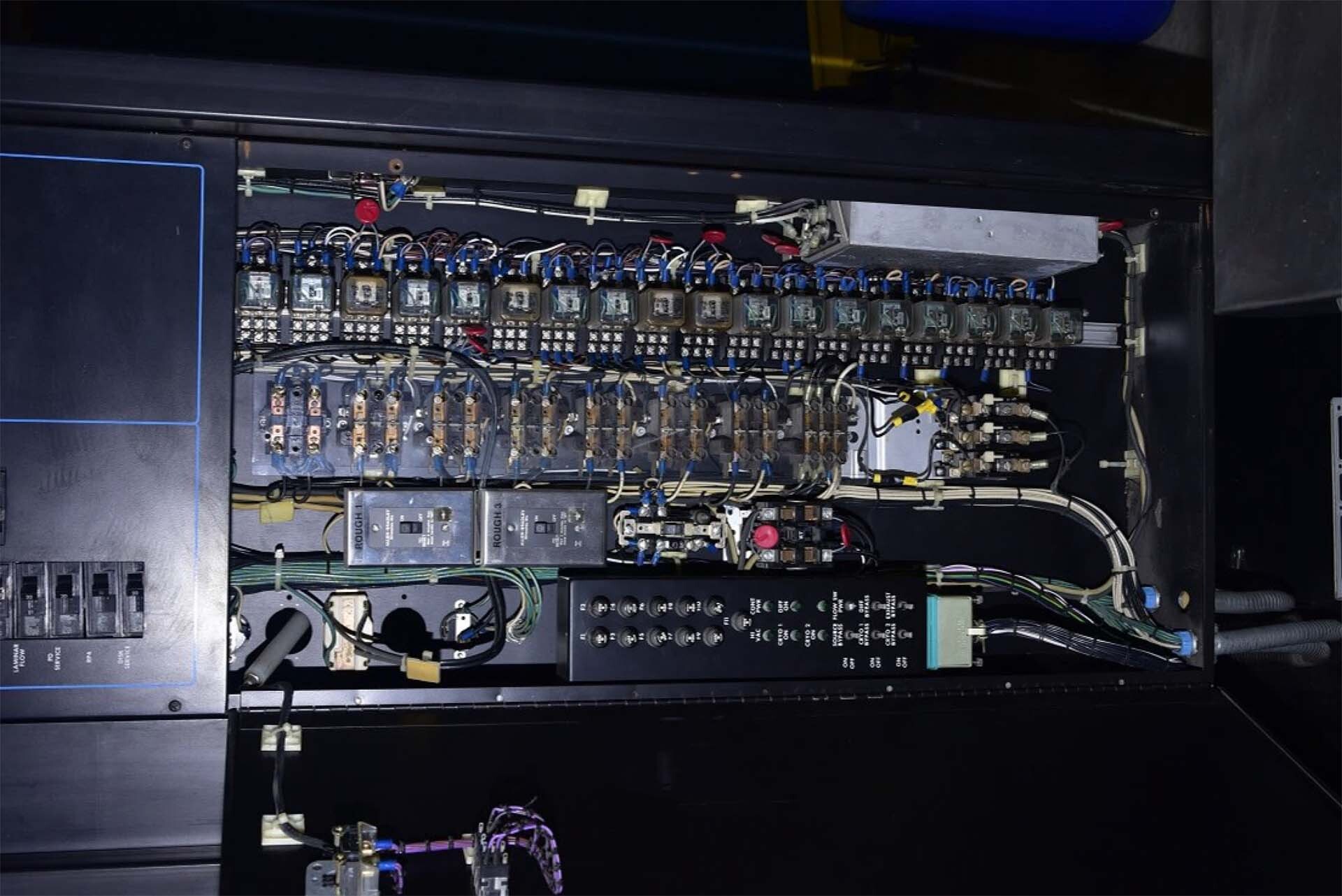

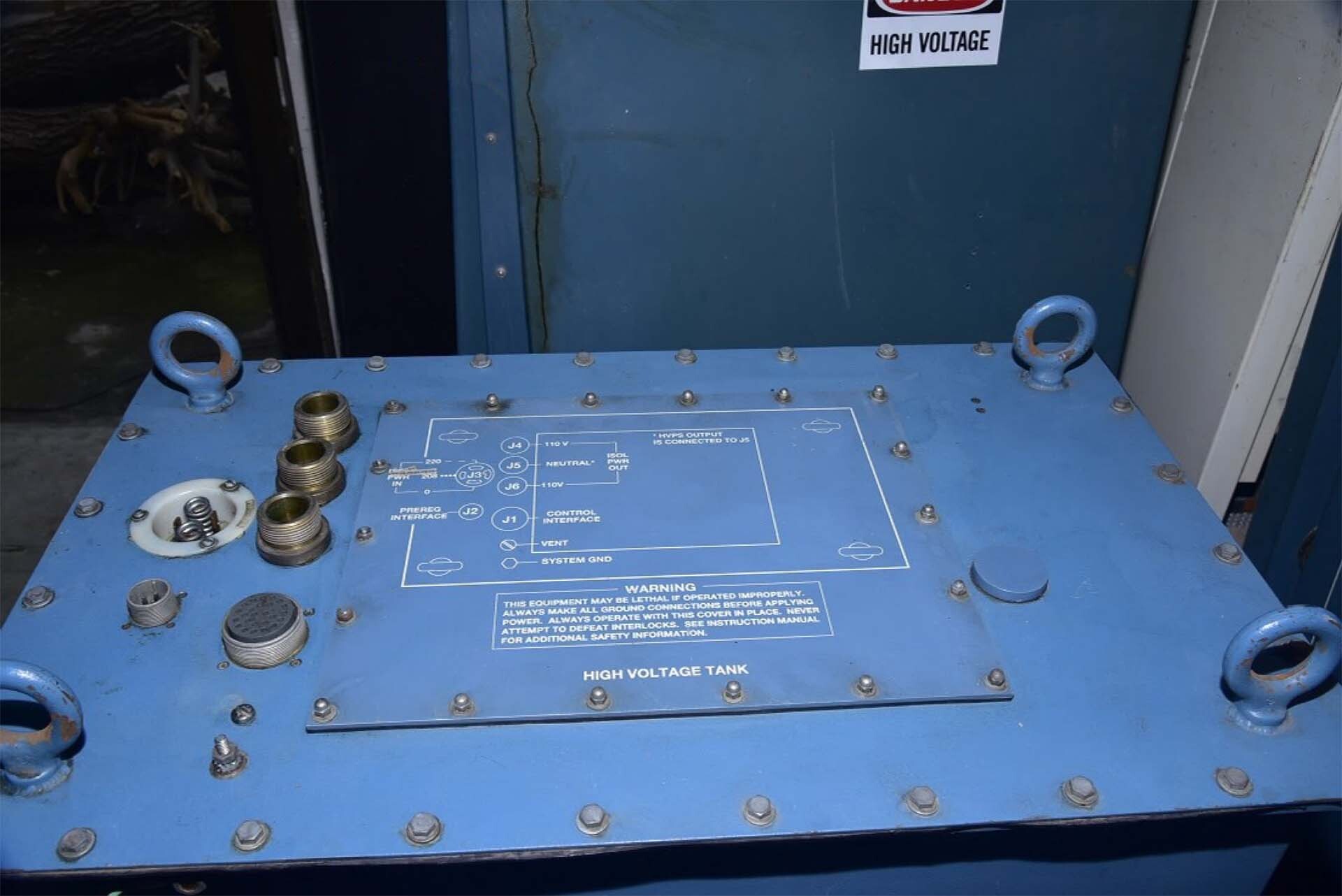

EATON NOVA / AXCELIS NV 10-80 is an advanced ion implanter and monitor used in the semiconductor industry to configure integrated circuits and other microelectronic components. It enables precise adjustments to the surface and internal micro-structure of materials to create sub-micron features in industrial processes. This equipment is ideal for those looking for highly reliable, low-cost, and reliable improvement of material performance in manufacturing. AXCELIS NV 10-80 operates using a high voltage plasma chamber and a programmable multiwire array. The plasma pressure and flow rate is precisely controlled using the built-in array and the concentration of the required ion species is monitored by the on-site Gaussian trap equipment. The precisely controlled output energy of beam is distributed to the target surface which allows for extensive control over the implantation process. The advanced monitoring system of EATON NOVA NV 1080 enables the user to maintain a consistent quality of implantation even when processing intricate components. The real-time diagnostic capabilities of the unit provide detailed characterization of beam parameters and associated defects. This allows for almost immediate failure non-conformance detection and process correction and for the targeted implantation of specific materials. Onshore Overlap monitoring is available for simultaneous monitoring of the overlap of two beam sites in the same plane, which aids operators with rapid diagnoses and dynamically modified overlaps. The machine is designed with flexibility and ergonomics in mind and features a standard operating console, three separate operating tables and a modular positioning machine. It comes equipped with a PC-based control tool, capable of automating a wide range of process monitoring and control tasks. Other features include a precision Lithium cluster ion source, programmable ion type, ion beam current and dose range and an easy-to-use data entry and analysis asset. For maximum safety and convenience, EATON NOVA NV 10-80 is certified for CE and UL safety standards. Its construction and operation are extremely reliable and safe, making it an ideal choice for precision processing. Ensuring maximum process performance in all applications, the machine offers reliable results from its advanced control model and produces consistent high-quality implantation.

There are no reviews yet