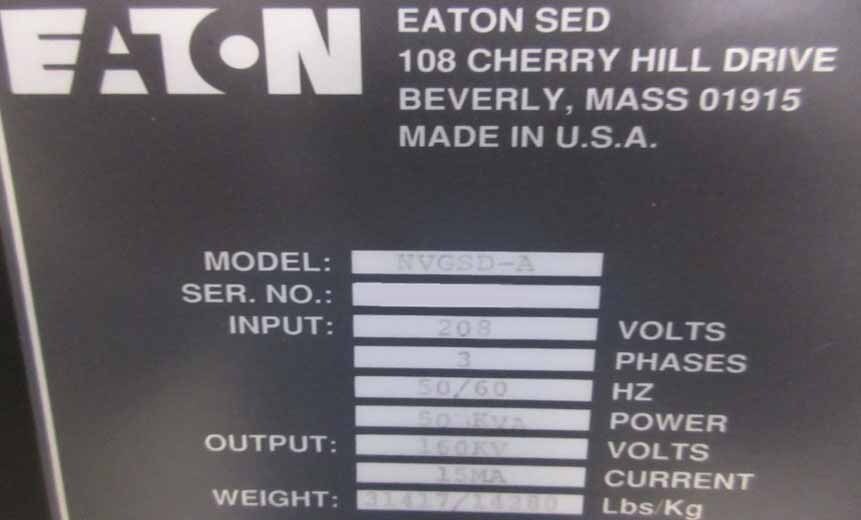

Used EATON NOVA / AXCELIS NV GSD A 160 #293610571 for sale

URL successfully copied!

Tap to zoom

ID: 293610571

Wafer Size: 6"

Implanter, 6"

Bernas source type

SEIKO SEIKI STP-2000C Turbo pump

(2) EBARA 40X20 Dry pumps

Compressor: CTI 8200 / CTI 8510

NESLAB HX-150 Disk chiller

E-Shower gun

Rotary motor: Belt drive

Flat finder

Without coating disk

Secondly sun

Beamline

Post-Accel

Bias aperature

Cyro pump:

CTI Torr-08

CTI Torr-10

Gas type:

Gas 1: AR/SDS (HP, SDS, External)

Gas 2: ASH3/SDS (HP, SDS, External)

Gas 3: PH3/SDS (HP, SDS, External)

Gas 4: BF3/SDS (HP, SDS, External).

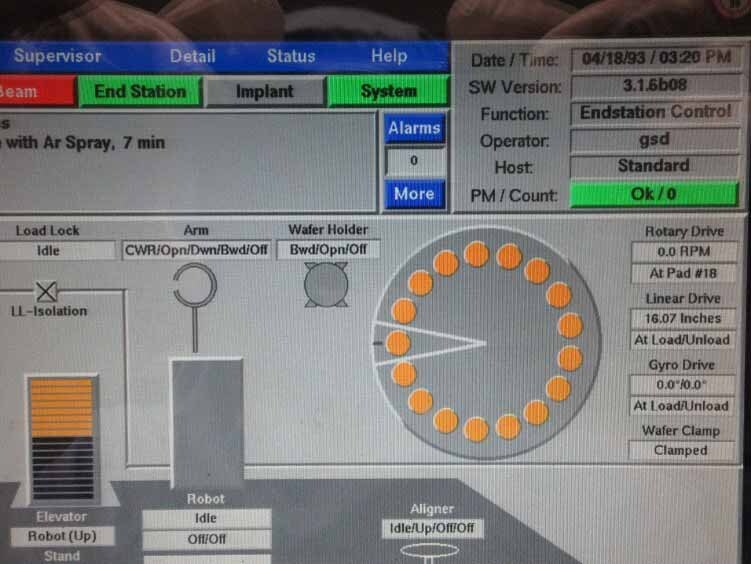

EATON NOVA / AXCELIS NV GSD A 160 is a state-of-the-art ion implanter and monitor designed to meet the most advanced requirements of semiconductor fabrication processes. It is the most comprehensive implanter equipment available in the industry and provides numerous advantages when compared to other systems. The system offers a high-speed 16 bit analog ion current measurement which yields high-resolution imaging and allows for precise ion implantation and Optimized Implant Perimeters (OIP). AXCELIS NV-GSD-A-160 is equipped with an adjustable high-voltage platform and a 1.87 meter long rectangular substrate holder with 2 scalable beam axes, allowing for an accurate dual-axis implantation. EATON NOVA NV GSD-A-160 also offers a complete set of diagnostic tools and measuring instruments to evaluate the process performance. NV GSD A 160 has three main features: a high-resolution imaging unit, a high-voltage platform and a two-axis implantation machine. The imaging tool is comprised of a 100 micron resolution CCD chip and advanced corner-steering optics which allow for the most detailed ion implantation previews. It also offers an OIP capability which can be used for accurately controlling dose and energy distributions. The high-voltage platform is capable of operating up to 50 kilo volts and provides a good degree of control when using larger ion beams. The two-axis implantation asset allows for the implantation of four axes of ions at once, with each set of four axes comprising the x, y, z and theta axes. It also comes with full motion control and process monitoring, providing total control over the implantation process. Finally, NV-GSD-A-160 also offers a wide range of diagnostic and monitoring options. It is equipped with a Guardian Model which monitors all aspects of the hardware and software performance, as well as an Ion Implant Diagnostics (IID) tool, which can be used to determine the ion beam configuration and energy levels. The equipment also offers a comprehensive set of measurement Instruments and tools for analyzing the implantation process. Overall, AXCELIS NV GSD A 160 is the ideal tool for conducting advanced semiconductor fabrication processes. With a high-resolution imaging system, adjustable high-voltage platform, two-axis implantation unit, and comprehensive set of diagnostic tools, it provides all of the features needed for complex implants. By offering a total control approach, EATON NOVA / AXCELIS NV-GSD-A-160 can help give your manufacturing operations a significant advantage.

There are no reviews yet