Used TAMARACK 161B #165720 for sale

URL successfully copied!

Tap to zoom

ID: 165720

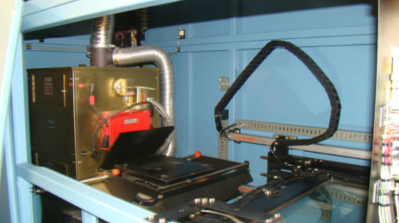

Printed circuit board exposure system

Specifications:

Semi-automatic machine

Used to provide rapid and precise alignment of large PCB panels

Components:

Panel alignment / exposure station

Collimated illuminator

Pneumatic valves

Sequencer

Alignment / exposure station:

Provides the facilities for aligning the P.C.B. panel with respect to the artwork and providing vacuum contact for exposure

Mylar cover frame is hinged toward the rear of the machine to allow raising of the frame for changing the panel and artwork

Collimated illuminator:

Provides a condensed beam of ultra-violet light of uniform intensity for use in exposing the panel

Shutter within the illuminator opens for a preset interval to accomplish the exposure

(2) modes of exposure control are available to operate the shutter: constant time and constant energy

Constant time is set in on the exposure time in seconds

In the constant energy mode, exposure energy in millijoules per centimeter squared (mJ / cm) is set on the exposure energy thumbpot

Light source for the collimated illuminator: high pressure mercury arc lamp mounted in a forced air cooled housing

Housing is designed to contain and withstand lamp explosion

Lamp is positioned near the first focus of an ellipsoidal reflector

(3) Thumbscrews provide the means of moving the lamp along the X, Y, and Z axes in order to obtain the proper lamp position

Ellipsoidal reflector directs the reflected light toward a distant second focus thus avoiding the possibility of lamp damage due to reflection of energy onto critical parts of the lamp

Ultra-violet light from the ellipsoidal reflector is turned twice to reach a second focus located at the lenticular integrator

Dichroic mirrors which turn the ultra-violet light pass most visible light and infra-red energy which are thus dissipated as heat within the lamp house and exhausted out of the system

Lenticular integrator, located at the second focus of the ellipsoidal reflector, collects the ultra-violet energy and directs it toward the collimating mirror in such a manner as to approximate a point source of light

Mirror collimates the light from the integrator so as to form a beam of light exhibiting uniform intensity over its beam width

Shutter which controls panel exposure is located just ahead of the lenticular integrator

An associated panel switch provides the means of holding this shutter open for the purpose of lamp intensity and focus adjustments or placing it under the control of the digital timer or integrating exposure controller during panel exposure

Panel size: 19" x 25"

Pneumatic panel:

Located inside the machine above the side control panel

Panel supplies air pressure and vacuum to all air operated systems through the machine

Solenoid valves are operated on 24V DC and controlled from the sequencer and pushbuttons

Sequencer:

Control of the 161B is accomplished by a Mitsubishi programmable controller located on the pneumatic panel

Manual switch panel is also mounted on the pneumatic panel

Side control panel:

Used to start and stop all functions of the machine

Main power contactor enable

Lamp ignitor

Lamp exhaust temperature, alarm and lamp meter (resettable)

Machine control power

Front control panel:

Timer and integrating exposure control switch are used to pick the mode of exposure

If the machine is used in the time mode, the exposure time in seconds must be set

When constant exposure energy is required, the IEC will measure the quantity of energy at the panel / exposure plane and control the shutter to maintain the same exposure energy independent of light intensity

Bullnose:

Contains a light table to aid alignment of the artwork to the substrate

The start cycle switches must be actuated simultaneously to begin print drawer movement

Top and bottom vacuum switches, gauges, emergency off switch and final cycle switches are also on the bullnose.

TAMARACK 161B is an advanced mask generation and production equipment designed to produce high quality masks with excellent resolution at a rapid rate. This system is capable of producing a variety of different types of masks, ranging from basic device to 3D stereolithography masks. 161B uses the latest technologies and is capable of generating layer definition files, which are used to create the physical layers necessary for the masks. The unit utilizes a powerful optical alignment machine for simple and efficient mask generation as well as advanced imaging algorithms for optimum alignment and mask quality. The tool also incorporates a state-of-the-art electron-beam lithography asset for increased resolution and production speed. TAMARACK 161B is designed for rapid throughput and easy operation, making it ideal for all types of mask-making applications. The model has several key advantages over existing mask production systems, including improved imaging precision and speed, accurate alignment and registration of multiple layers, reduced material costs, and support for multi-level mask production. Through its robust design and integrated capabilities, 161B is capable of meeting the demands of device manufacturers in a wide range of industries. The equipment is capable of performing various tasks, such as photographing, lithographic printing and imaging of all levels of circuitry. In addition, the system offers a fully automated mask generation process by including a CAD (Computer Aided Design) facility, making it easier to develop complex circuits and architectures. TAMARACK 161B's integrated image data management unit allows users to store and retrieve designs with ease and accuracy. The machine is also able to incorporate additional features such as failure analysis, test measurement, and process integration. To keep up with the latest advancements in mask-making technology, 161B regularly receives upgrades and updates. Customers are provided with software updates, regularly scheduled maintenance, and access to dedicated customer service for a hassle-free experience. TAMARACK 161B is a reliable, efficient, and cost-effective mask generation and production tool, making it the ideal asset for all mask production needs.

There are no reviews yet