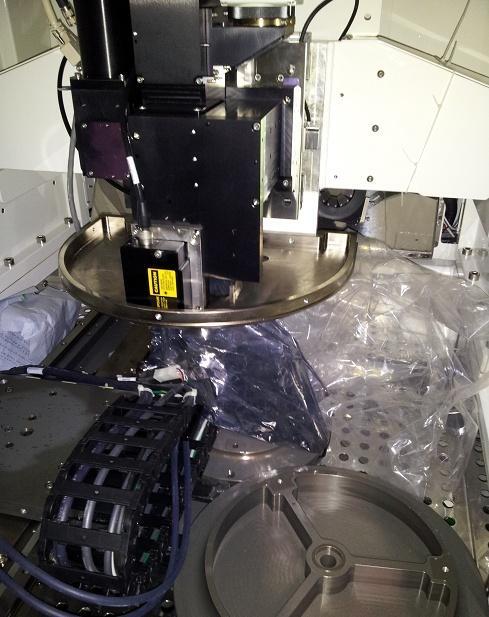

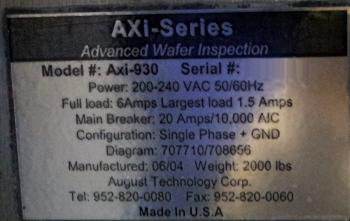

Used RUDOLPH / AUGUST AXI-930 #9107569 for sale

URL successfully copied!

Tap to zoom

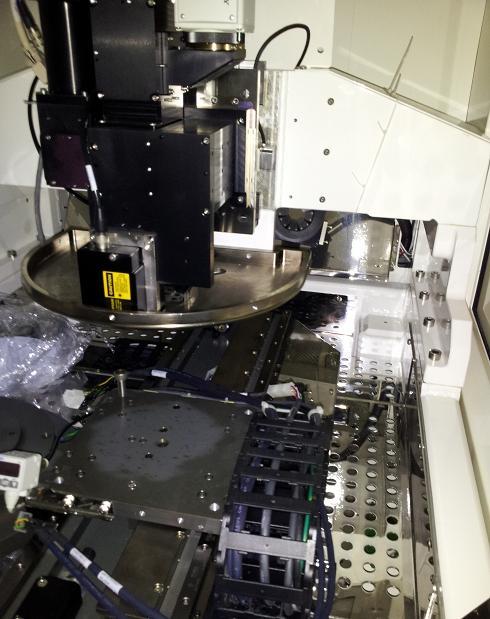

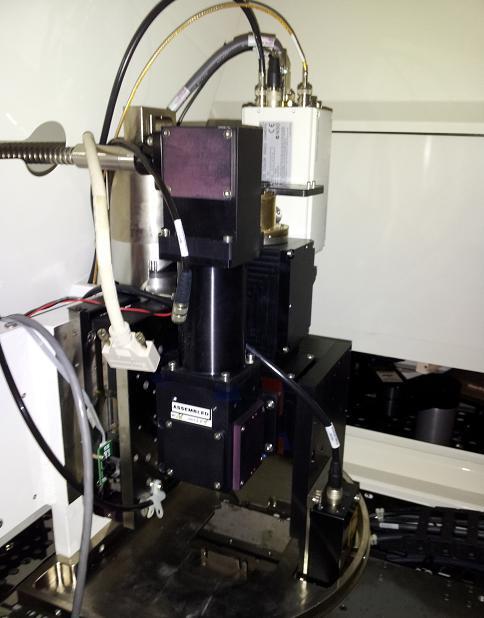

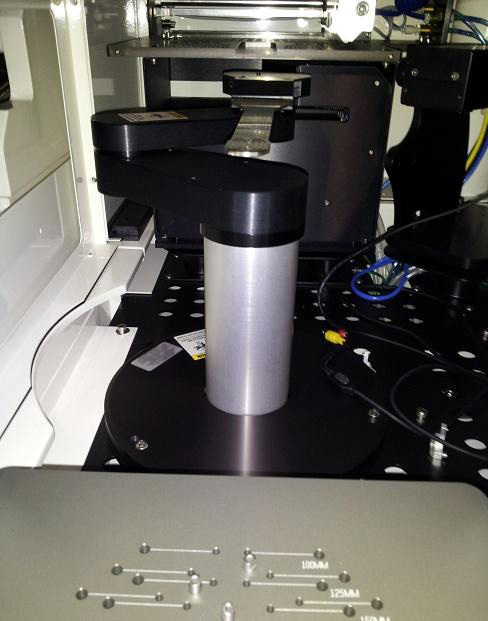

RUDOLPH / AUGUST AXI-930 Mask & Wafer Inspection Equipment combines imaging technology with sophisticated pattern recognition software to support the quick and efficient inspection of semiconductor masks and wafers. Utilizing advanced optical and motion control technology, AUGUST AXI-930 inspects up to 9 "die site" fields per microscope field-of-view across an entire wafer or mask. RUDOLPH AXI 930's automation-ready modification enables integration into various factory automation systems. AXI 930 is equipped with a pulsed 360-° laser diode line scan system, visual inspection, and metal oxide semiconductor Field Effect Transistor (MOSFET) current supply unit, providing users with a single machine for both surface and edge inspection. RUDOLPH / AUGUST AXI 930 also features a variable Magnification Drive module, capable of automatically shifting the image magnification from a minimum of 40X up to a maximum of 500X depending on the scale of the object. AXI-930's built-in drift compensation maintains the optimum image focus regardless of how wafer loading is affected by manual handling or any shift in wafer position due to thermal gradients in the wafer or mask surface. The tool's Image Acquisition and Processing driver software, designed to run on Ethernet connected PCs, provides full-field image acquisition, display, and image processing capabilities. images can be either stored as single images or as a multiple image bitmap. The pattern recognition module of AUGUST AXI 930, available in two versions, supports both FDTD (Finite Difference Time Domain) and Hough transform algorithms, and is equipped with multiple filtering and noise reduction algorithms to detect defects on semiconductor devices. RUDOLPH AXI-930 also features real-time image processing and defect recognition, which allows the asset to react quickly to changes in defect properties. Additionally, the MetaCam software application is capable of producing printable defect images in a variety of formats while automatically documenting the results of each inspection cycle. In summary, RUDOLPH / AUGUST AXI-930 Mask & Wafer Inspection Model combines sophisticated image analysis and pattern recognition software with advanced motion control technology to quickly and accurately identify and locate various defects on semiconductor wafers and masks. The equipment includes a variable magnification drive, real-time image processing technology, fast pattern recognition systems, and full-field image acquisition software. AUGUST AXI-930 is an advanced and reliable tool for identifying and measuring defects on semiconductor wafers and masks.

There are no reviews yet