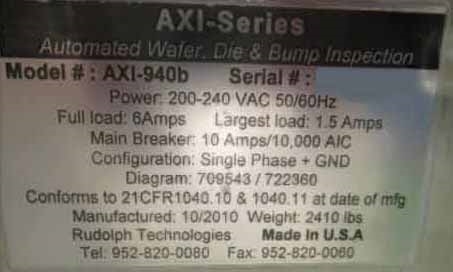

Used RUDOLPH / AUGUST AXI-940B #9282960 for sale

URL successfully copied!

Tap to zoom

ID: 9282960

Wafer Size: 12"

Vintage: 2010

Inspection system, 12"

No Hard Disk Drive (HDD)

Defected parts:

Mapping amplifier

Brightfield power supply

Silos inspection board

Review camera

Inspection camera

2010 vintage.

RUDOLPH / AUGUST AXI-940B is a mask and wafer-inspection equipment designed to help detect defects on both printed circuit boards and micro-chips. This system provides rapid, accurate and sensitive inspections of PCBs and chips on the same platform. The unit is also designed to improve detection of defects on printed circuit boards by utilizing a combination of two different technologies. The machine utilizes a two-camera configuration, one of which is a high-resolution, charge-coupled device (CCD) or Complementary Metal Oxide Semiconductor (CMOS) Camera. This camera captures images transmitted through a high-resolution optical microscope with a plenoptic camera head. These images are then saved to AUGUST AXI-940B's hard drive. The images are then examined by RUDOLPH AXI-940B's other component, R.A.I.T. (Real-Time Automated Image Analysis) software. R.A.I.T is an artificial intelligence tool, specifically designed for use with AXI-940B. R.A.I.T constantly analyzes the images for any anomalies, irregularities, or defects including scratches, pits, pinholes, shorts, and wire breaks. The software is also capable of using data from images acquired from the Micro X-ray machine to improve on its defect inspection accuracy. RUDOLPH / AUGUST AXI-940B is an effective tool for ensuring product quality and reliability during the fabrication stage of printed circuit board and micro-chip production. It has the capability to inspect multiple surfaces at once, and is able to detect minute surface variations, not visible to the naked eye. The asset also has an automated setup, meaning quick and easier setup changeovers, ensuring more efficient changeovers, and faster setup times. Its quick image analysis, combined with a high resolution microscope, and ability to detect to detect fine details, provides a comprehensive view of PCBs and micro-chip surfaces. AUGUST AXI-940B is characterized by its flexibility, built-in hardware, and software. This makes it an attractive option for anyone who wants to inspect PCBs and micro-chips for to defects. Its efficient, and accurate model helps ensure production yields are kept high, and products are produced correctly, and that those products contain no defects. Overall, RUDOLPH AXI-940B is an effective tool for mask and wafer-inspection, designed to detect and analyze surface defects on both PCBs and chips. It is efficient and accurate at detecting irregularities at a microscopic level, providing a comprehensive view of the surfaces of both printed circuit boards and chips. This equipment is also equipped with its own hardware and software, making it an attractive choice for those who need reliable and fast inspections.

There are no reviews yet