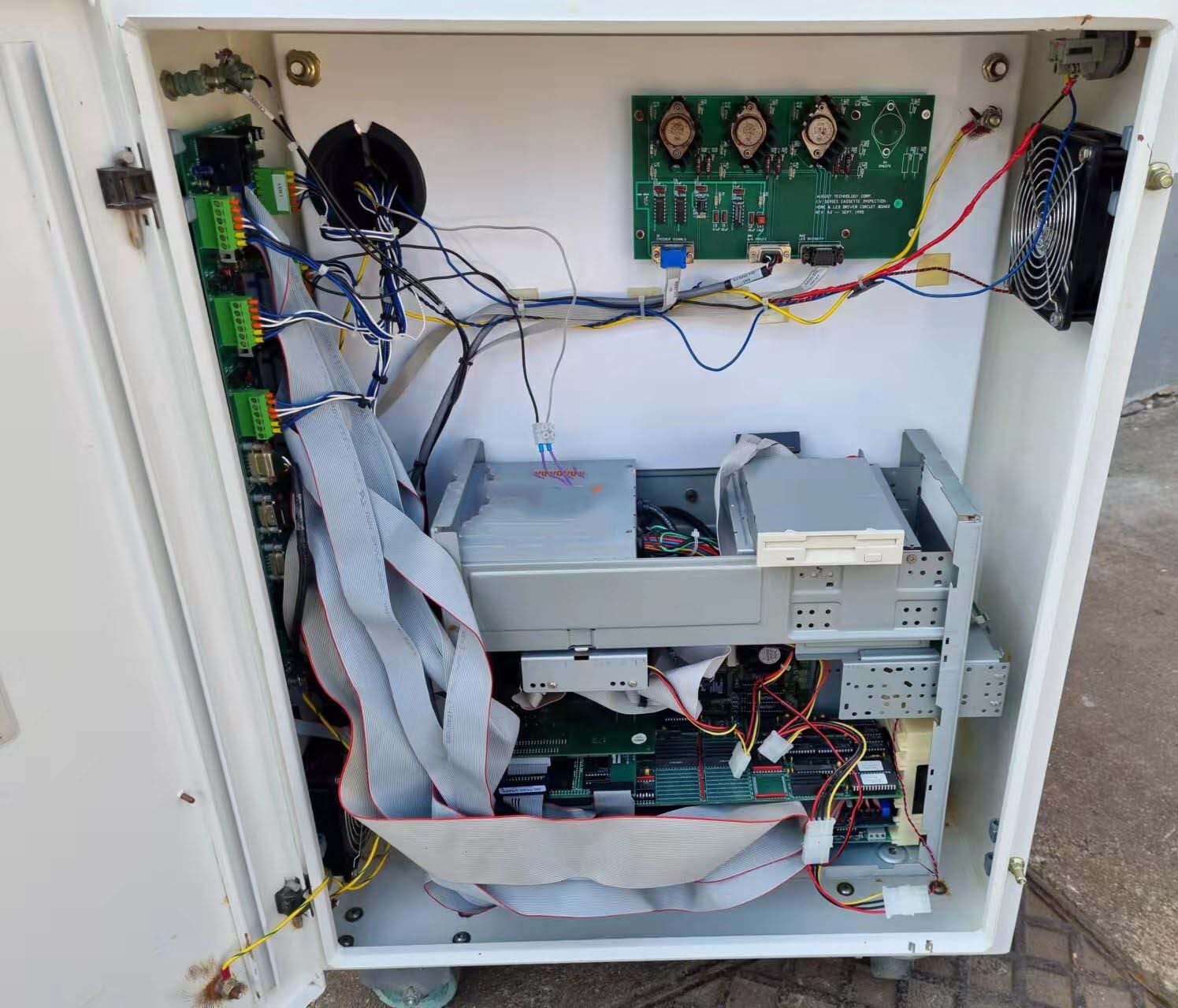

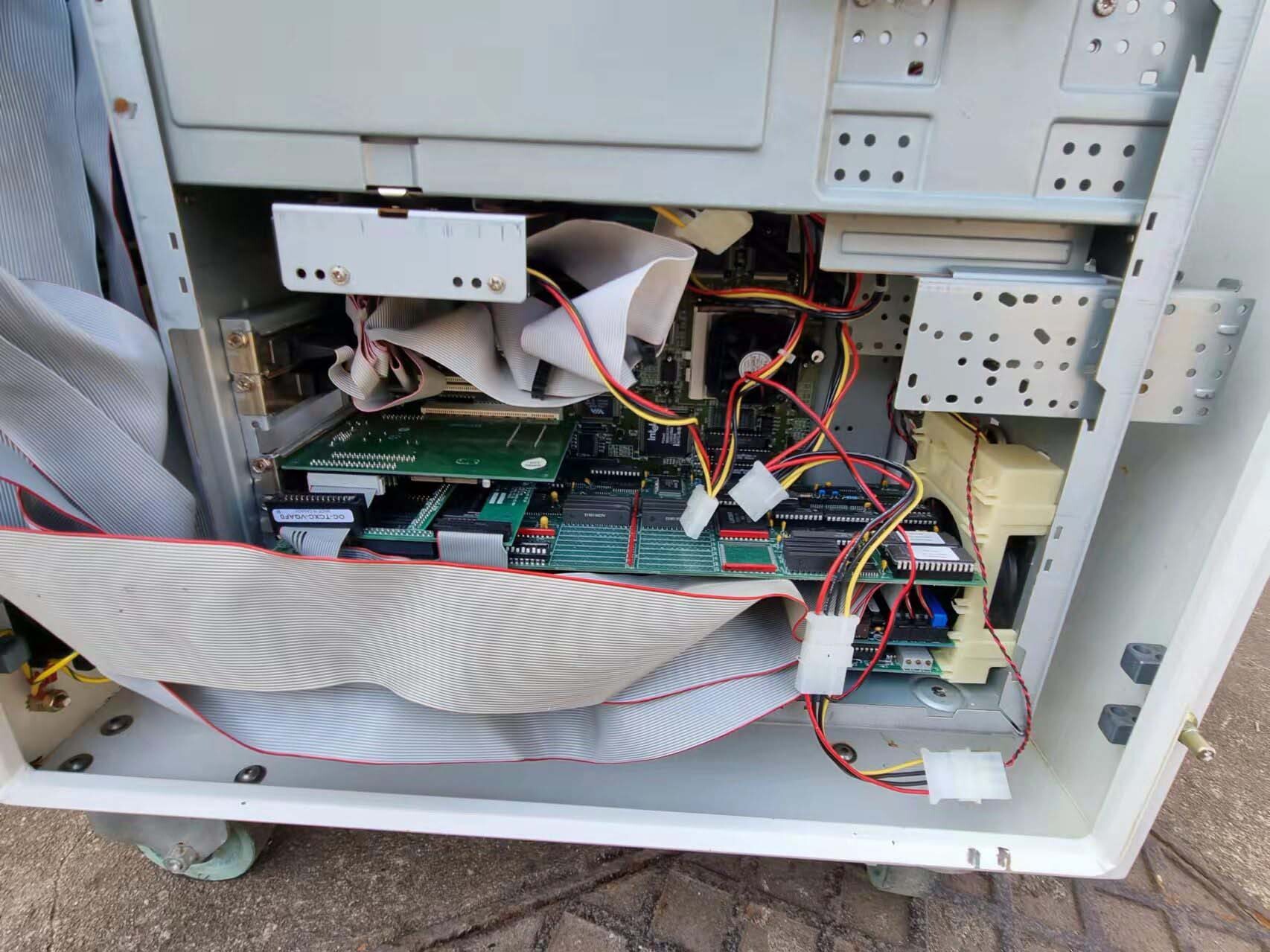

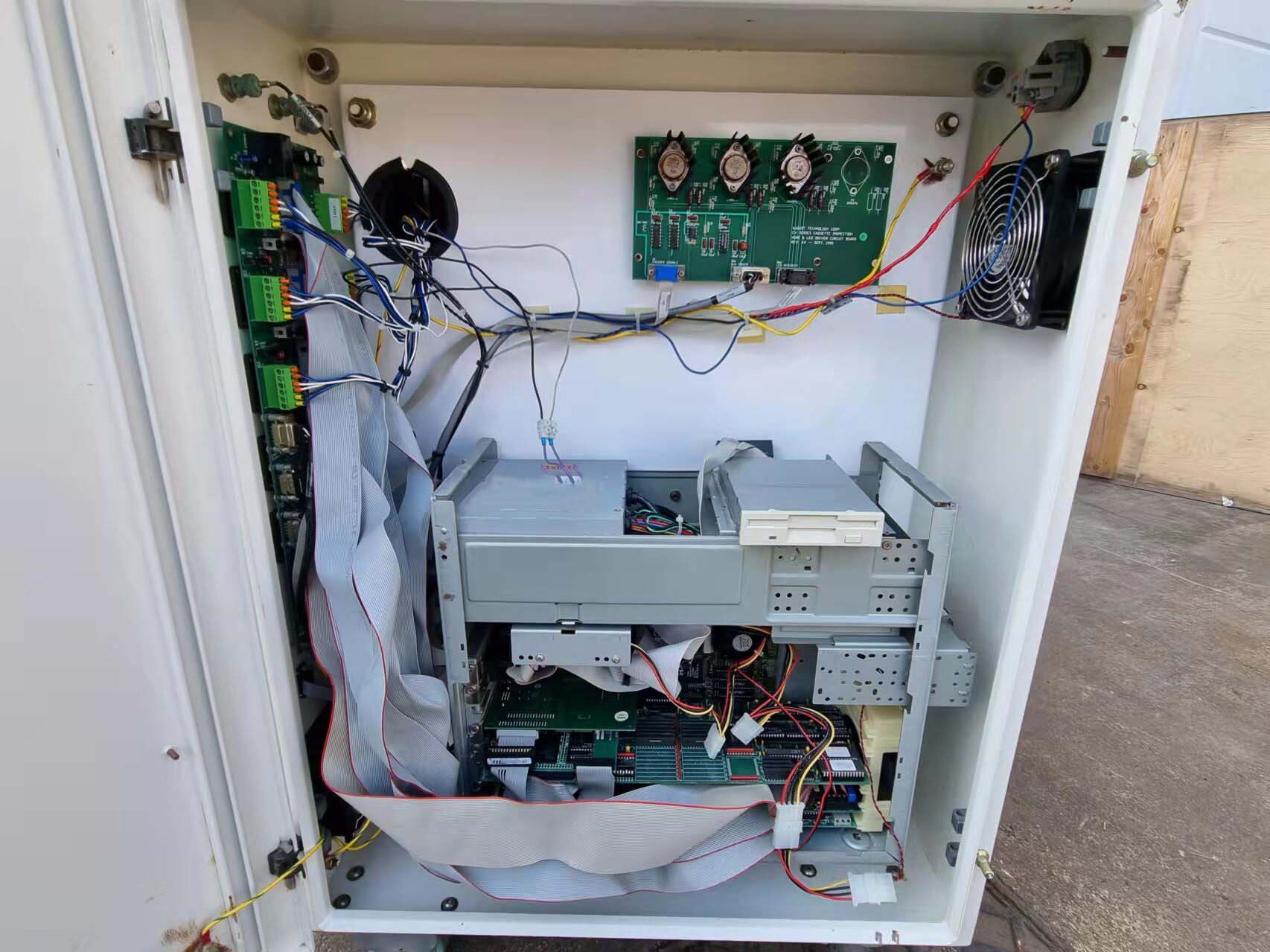

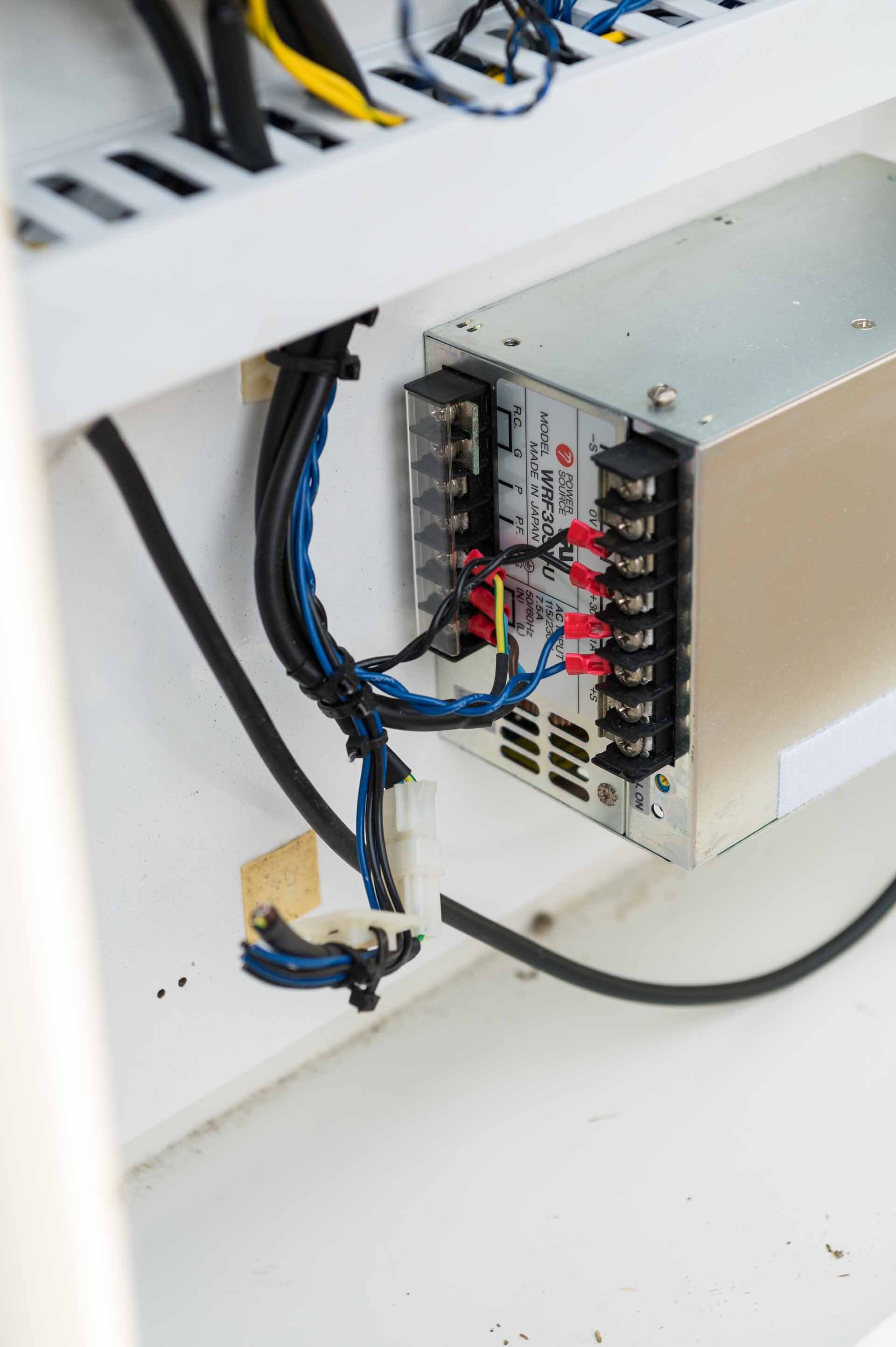

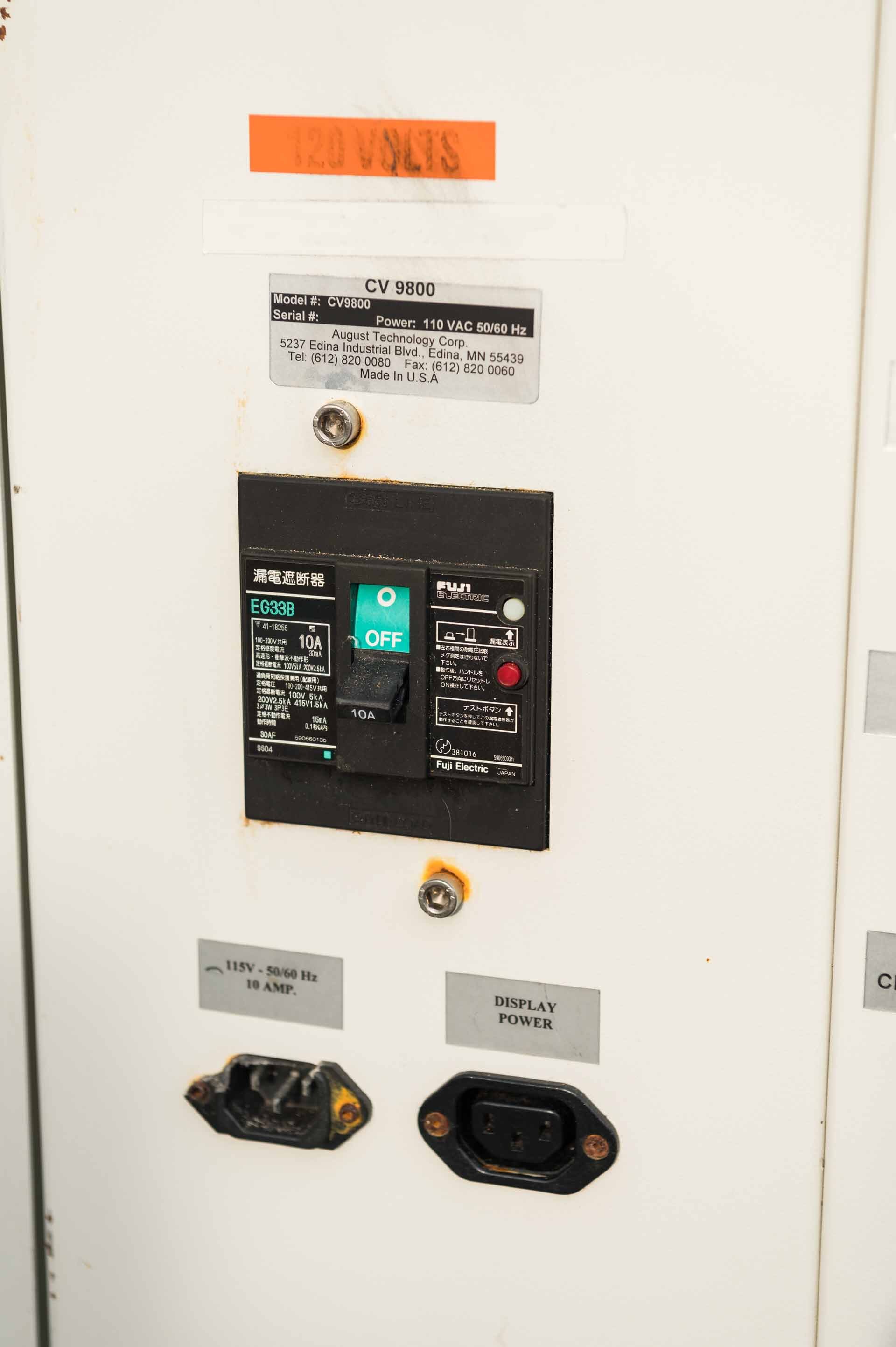

Used RUDOLPH / AUGUST CV 9800 #9410831 for sale

URL successfully copied!

Tap to zoom

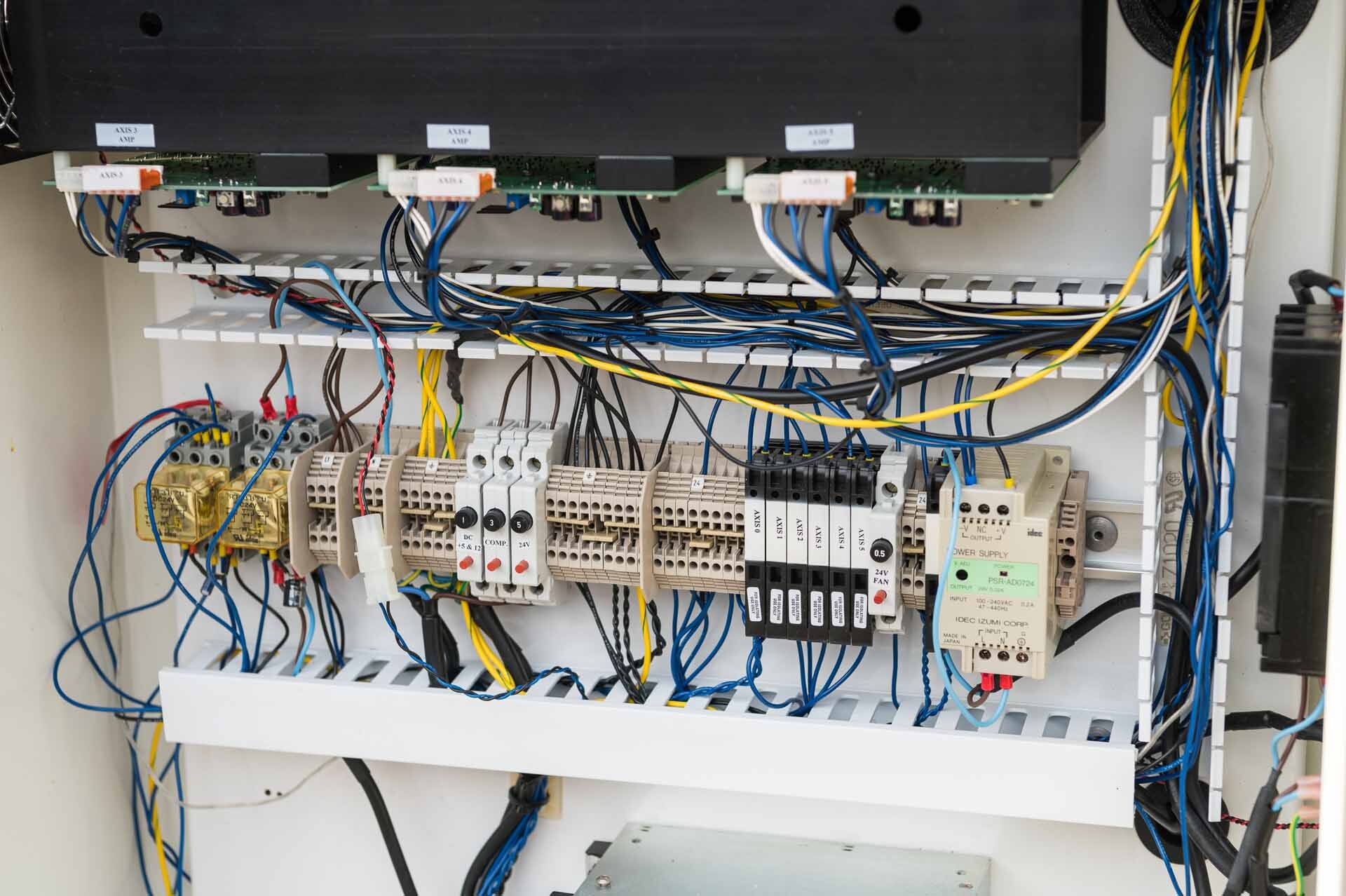

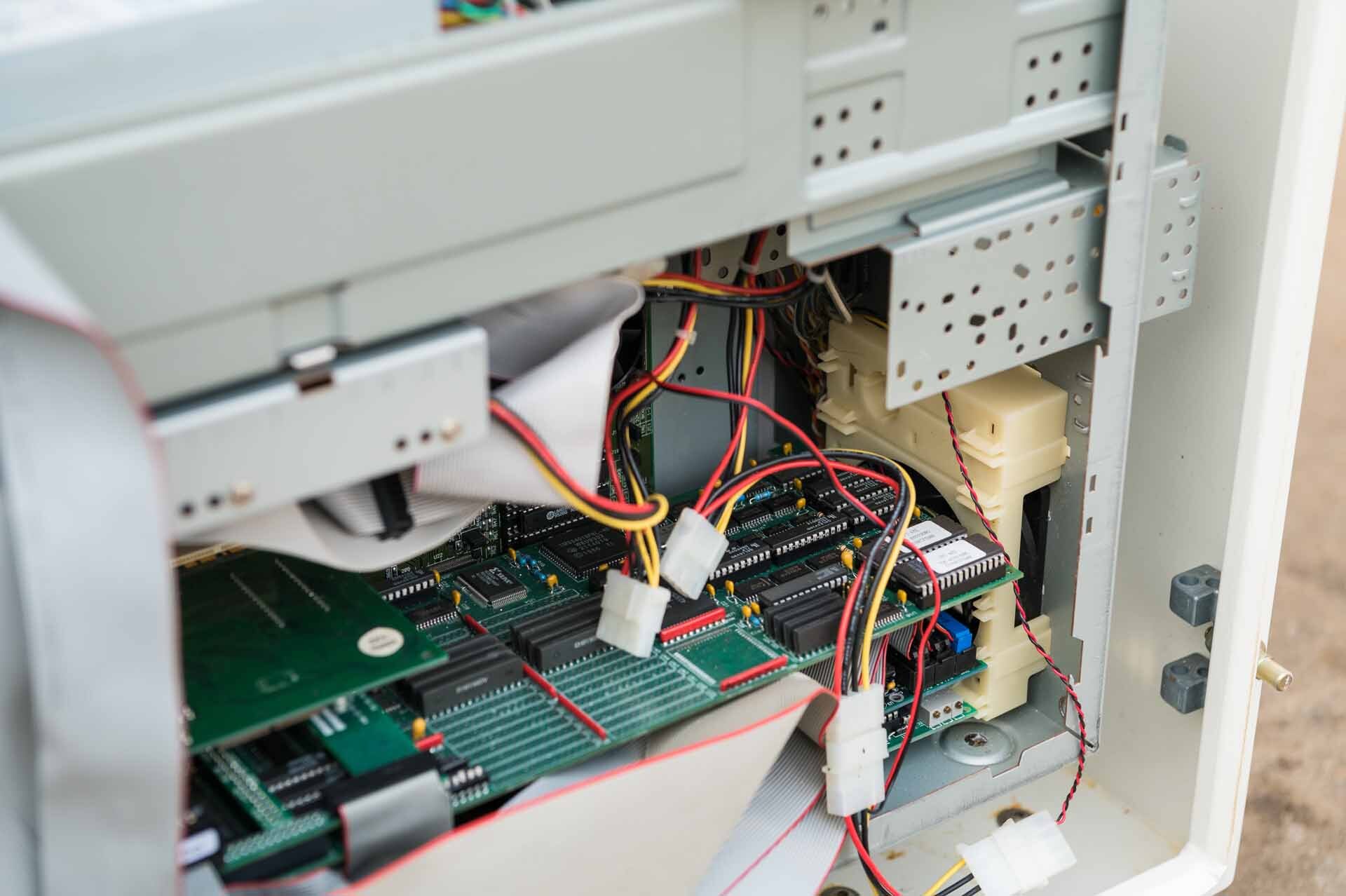

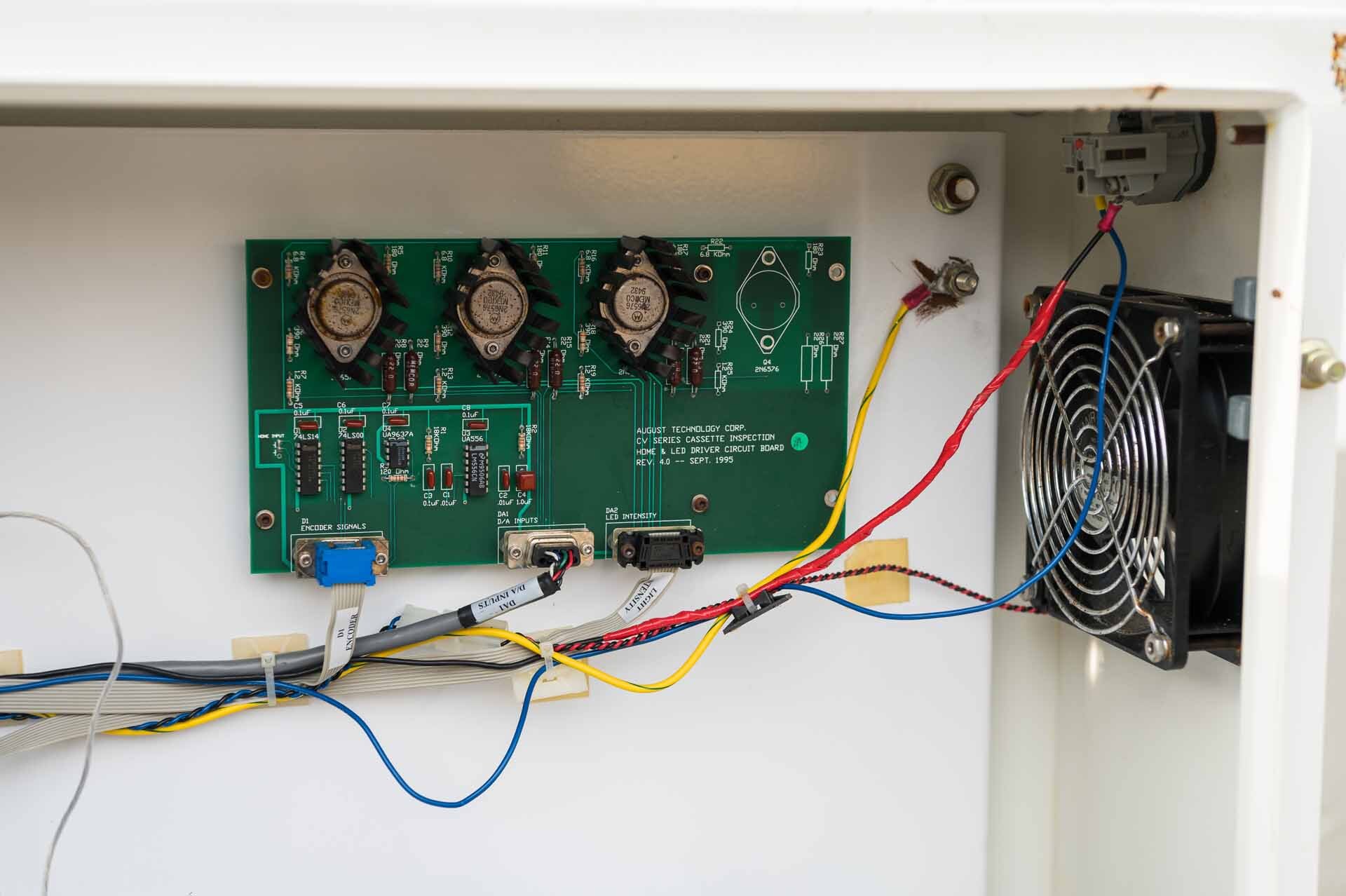

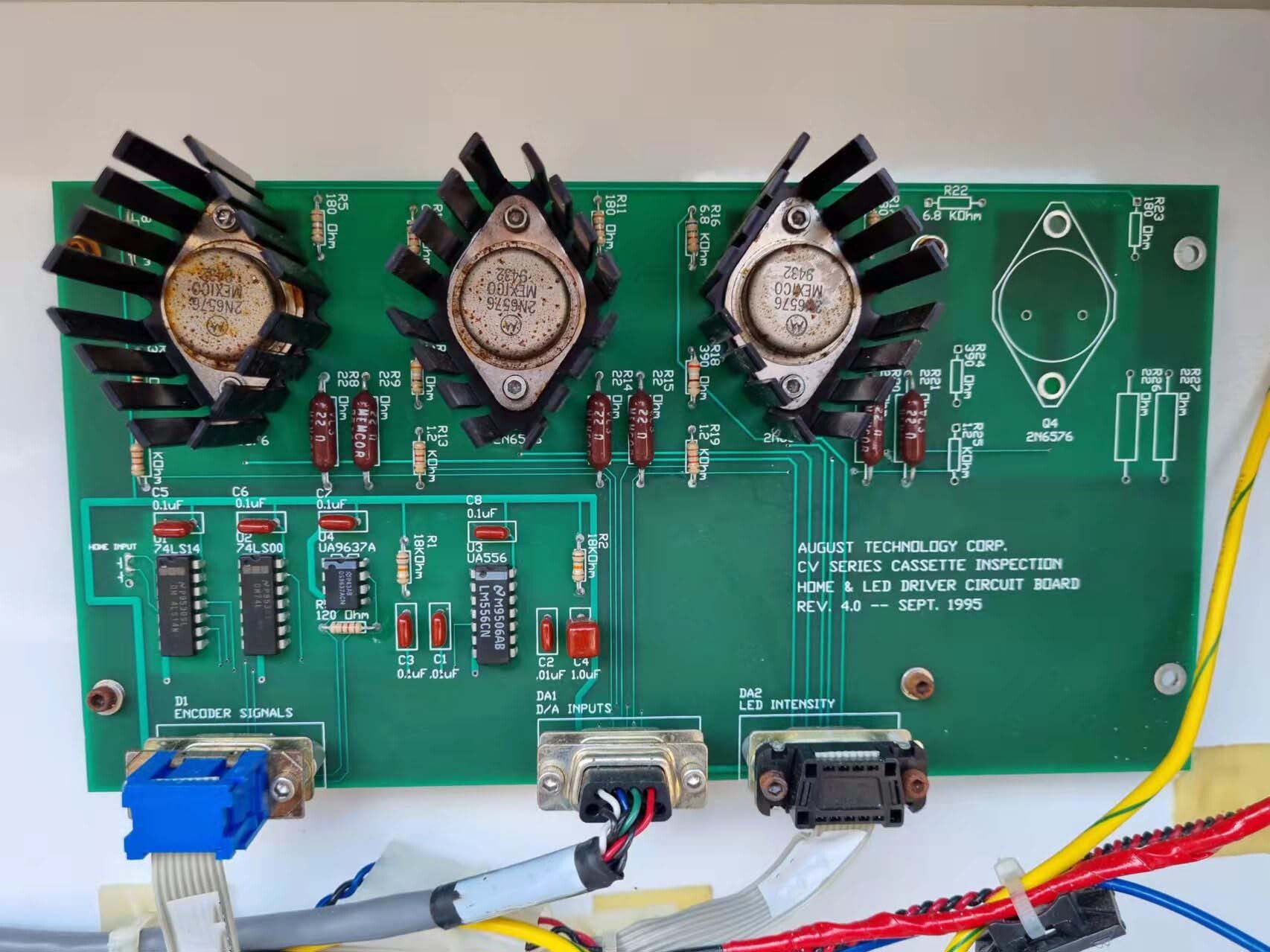

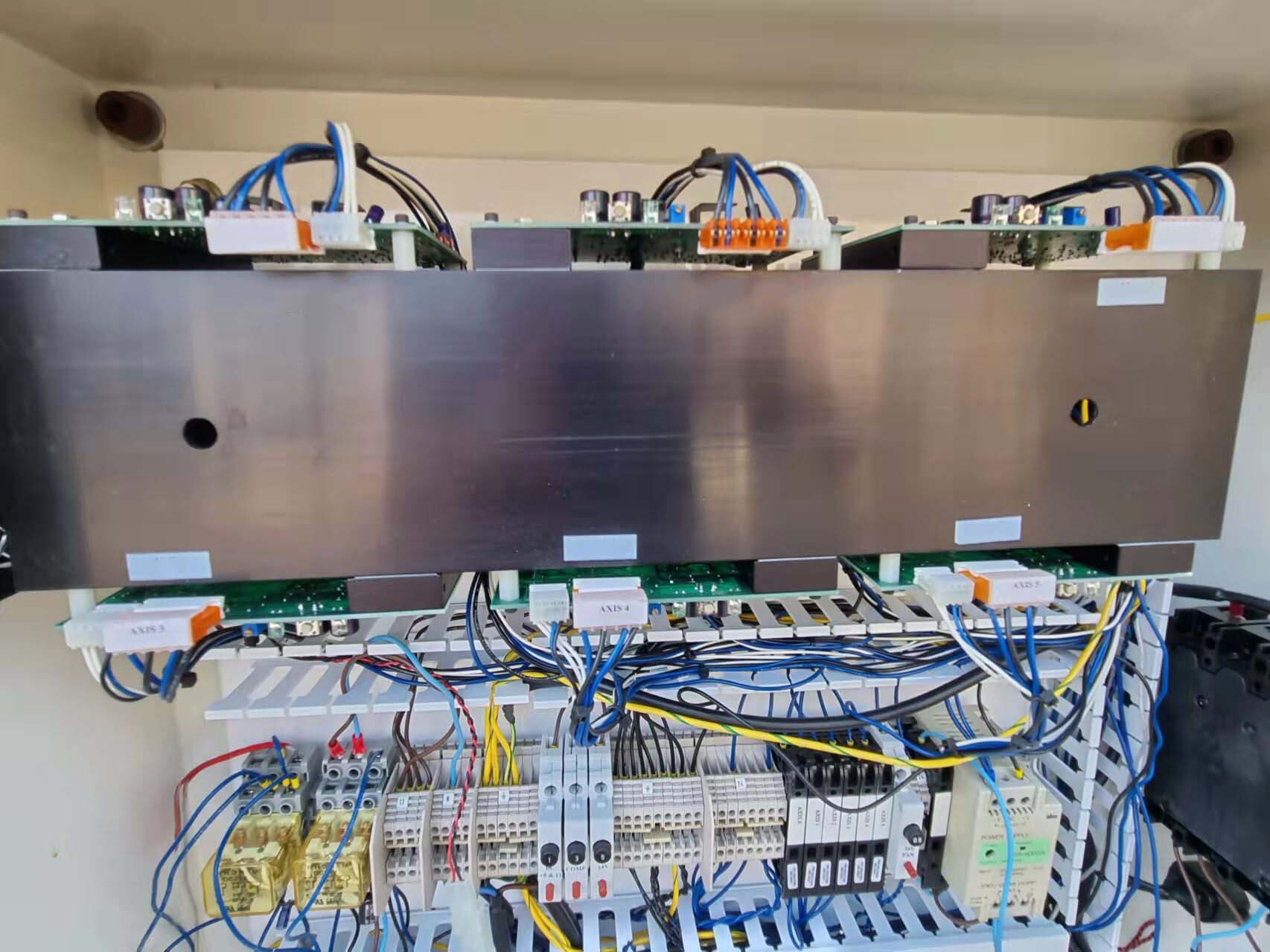

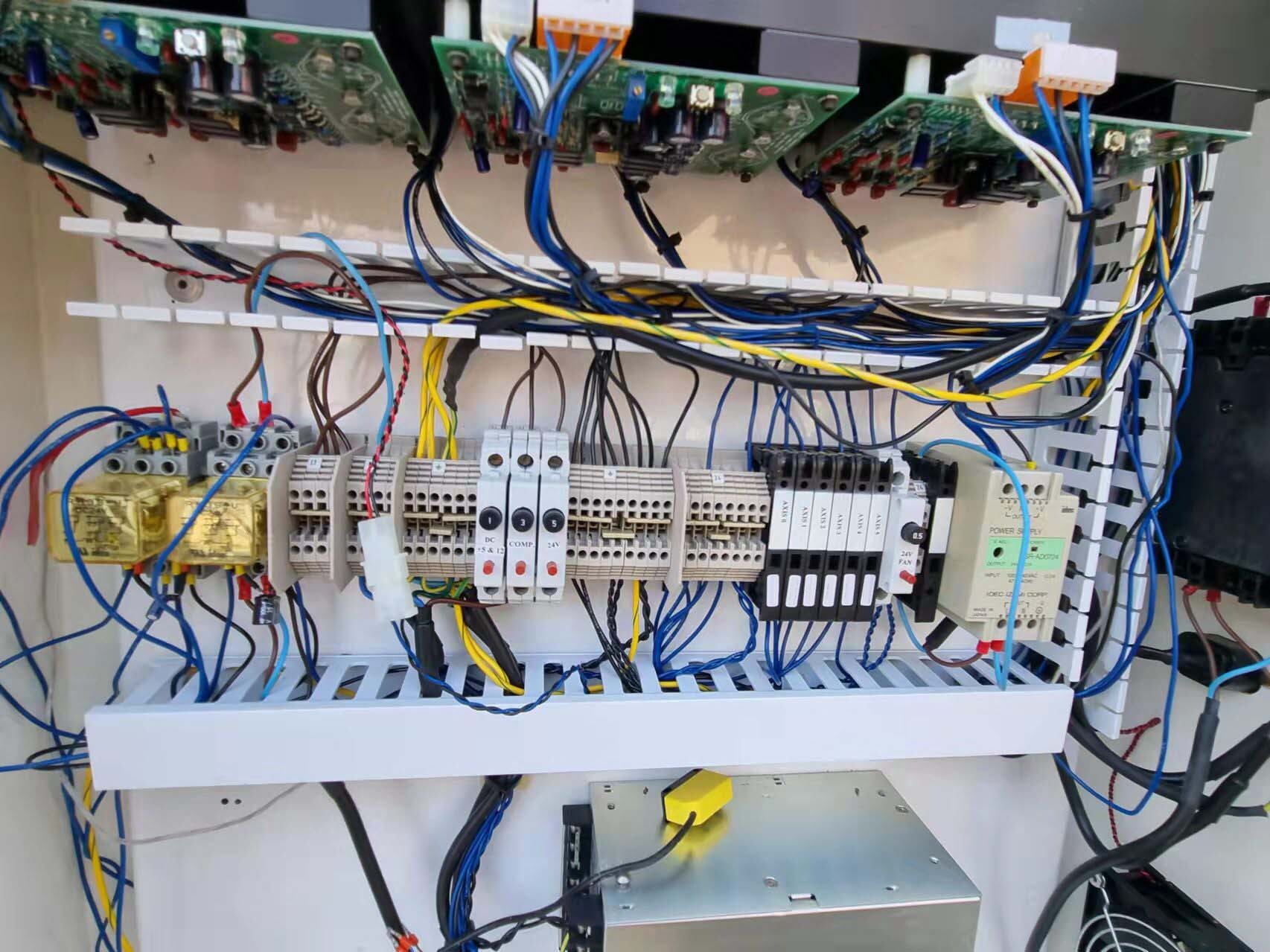

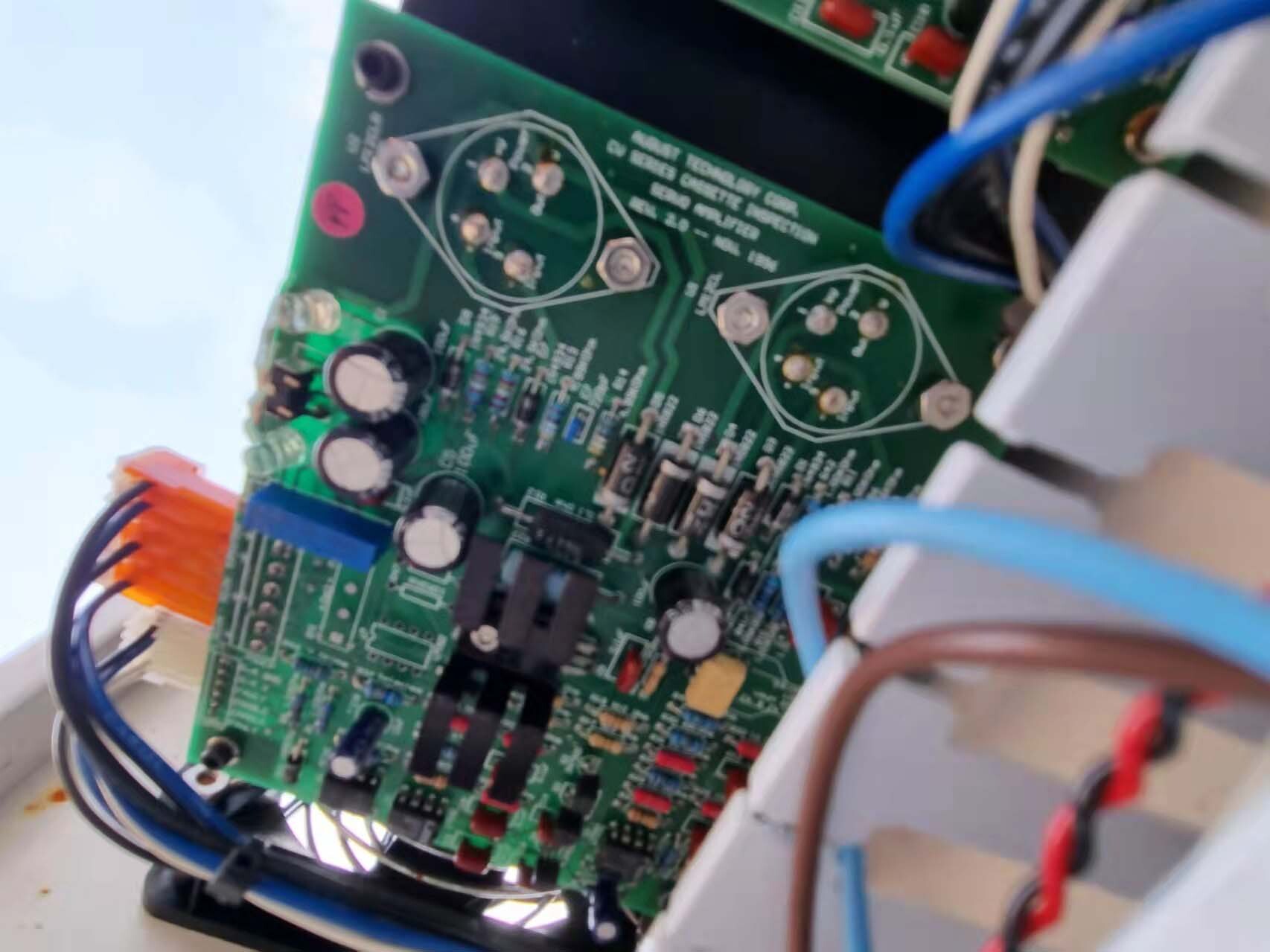

RUDOLPH / AUGUST CV 9800 is a high performance, automated mask and wafer inspection equipment. It is designed to examine a wide range of semiconductor devices, including front-end, logic and memory devices, as well as optical masks and substrates. AUGUST CV 9800 offers a complete range of hardware and software capabilities for efficient and reliable inspection of semiconductor devices. RUDOLPH CV 9800 utilizes an advanced, state-of-the-art optical imaging system to accurately detect defects on a wide range of semiconductor device surfaces. With up to 8 high-resolution cameras, the unit can inspect wafers as large as 200mm in diameter and up to 12mm in thickness. In addition, the machine can auto-focus on objects within a range of 0.1 to 6.5mm in height from the surface of the device. CV 9800 can apply advanced algorithms to analyze the images captured by the inspection tool and accurately detect both front-end and back-end defects, including contact withdrawal, reversed contacts, misnumbered topology, shorting points, and SMD parts. The asset then automatically generates detailed inspection reports with clear images of identified defects. RUDOLPH / AUGUST CV 9800 is integrated with a user-friendly software interface for easy data entry, display, and control. The software also allows for automatic identification of product topology (contact size, number of contacts, etc.), as well as the ability to store up to 1000 process recipes. Furthermore, the model supports automated full-layout feature analysis and automated mask/layout data comparison. AUGUST CV 9800 is designed to work in a wide range of compliance and research test environments. It features an isolated camera housing and rapid image transfer mechanism, enabling reliable operation in challenging temperature and humidity conditions. The operating environment can vary from 10° to 28° Celsius, and up to 75% relative humidity. In conclusion, RUDOLPH CV 9800 is a highly advanced mask and wafer inspection equipment that is designed to provide fast, reliable and high-precision results. CV 9800 offers a wide range of capabilities and features, such as automated inspection reports and feature analysis, automatic product topology identification, and storage of up to 100 recipe settings. Additionally, the system is capable of operating in a wide range of environmental conditions, ensuring efficient and reliable operation in most semiconductor fabrication processes.

There are no reviews yet