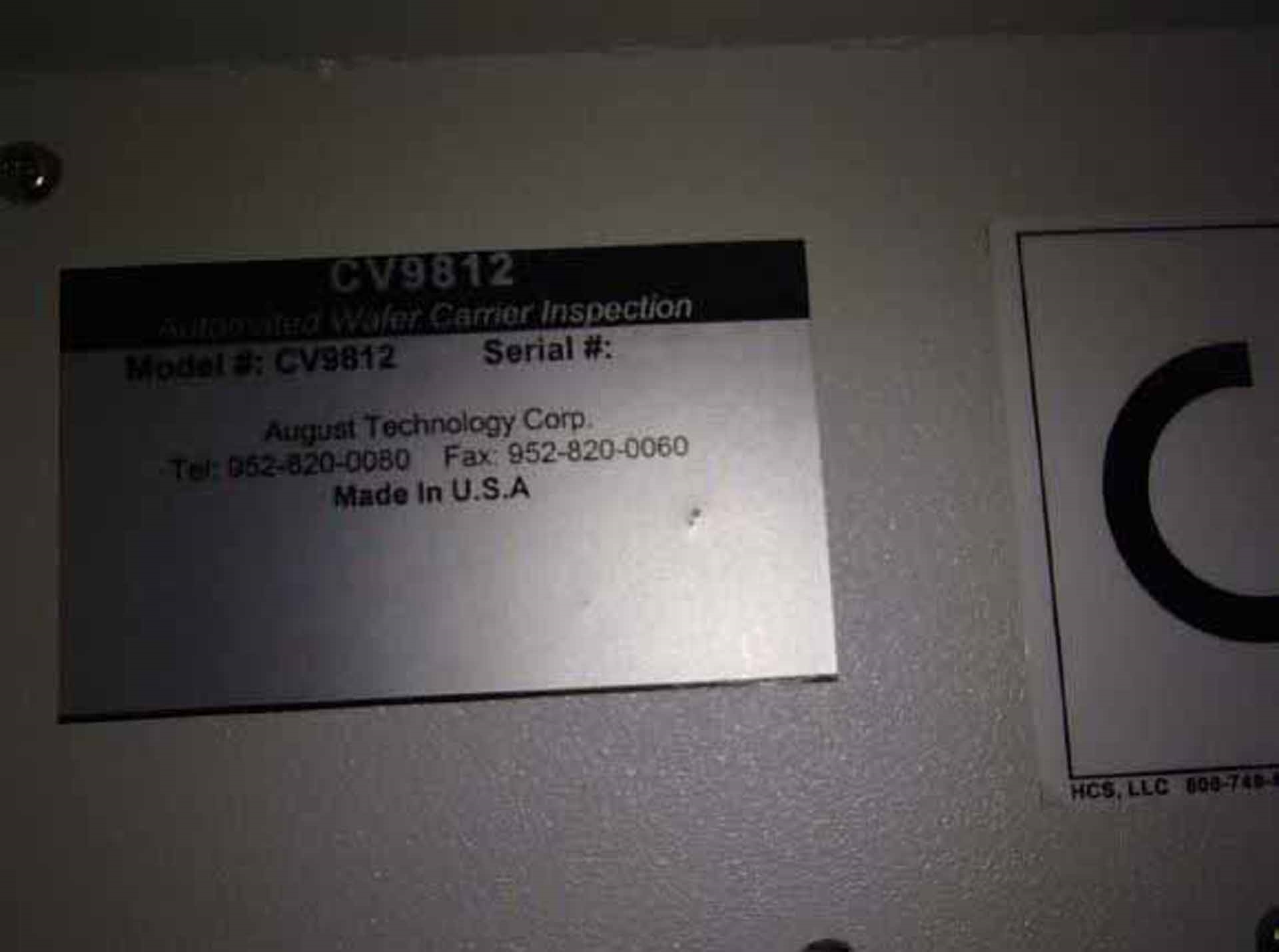

Used RUDOLPH / AUGUST CV 9812 #9223286 for sale

URL successfully copied!

Tap to zoom

ID: 9223286

Wafer Size: 12"

Wafer career inspection, 12"

High resolution CCD Camera

Probe

LCD, 15”

PC:

Processor: 300 MHz

Hard Disk Drive (HDD): 4.3 GB

Floppy Disk Drive (FDD): 3.5”

Dram: 24 x CD 32 MB

Operating system: Windows NT4.0

Power unit:

Cable

Handy barcode reader

Performance:

Measurement accuracy:

Direct measurement: ±0.0254 mm

Rear wafer position measurement: ±0.0762 mm

Repeatability: ±0.013 mm (Use STD Calibration tool, 6σ)

Operating environment: 20°C - 22°C (Volatility 0.5°C/hour ≦)

Facility:

Manual

CDA: 90 - 100 PSI 5/16” OD

Power supply: 200-240 V, 50/60 Hz, 1φ.

RUDOLPH / AUGUST CV 9812 Mask & Wafer inspection equipment is a high performance, reliable tool designed to enable efficient visual inspection and classification of lithography blocks quickly and accurately. The system offers multiple inspection capabilities, with a special focus on detecting foreign particles, bumps, scratches, and other types of defects on the components. The unit's application is applicable to the inspection of flat-panel displays, semiconductor integrated circuits (ICs), OLEDs, organic LEDs (OLEDs), LED, solar cells, and other thin substrates. The machine is equipped with a precise glassless, optically perfect inspection window which is used to measure the exact pitch of the mask layer. This allows the tool to detect tiny variations in the lithography blocks with extreme accuracy, and thus enable both analysis and remediation of the defect pattern. The asset also supports advanced algorithms for automated defect detection, as well as manual inspection. In order to detect particles and other defects on the components, the model uses advanced optical technology, which includes laser interferometry and image processing. The laser interferometer is used to accurately measure the distance between each detailed pattern on the mask layer. The image processor then analyses the images to identify defects, such as the presence of foreign particles. The images can also be used to classify defects based on size, shape, location, and other parameters. The equipment can also detect and classify multiple levels of defects. This means that a technician can get a more detailed look at the problem, helping them identify the cause of the defect or classify it accordingly. This saves time and resources, improving efficiency and preventing further product damage. AUGUST CV 9812 Mask & Wafer inspection system also integrates with test systems, allowing operators to check the production status while they assess and repair defects. Moreover, the unit is designed to provide advanced analytics capabilities to further improve defect detection accuracy. It ensures that actionable data is collected and stored in a manner that can be shared with other stakeholders, such as hardware engineers and suppliers. RUDOLPH CV 9812 Mask & Wafer inspection machine is an advanced tool for fast, precise, and accurate inspection and classification of lithography blocks. Its versatile optical technology, automated inspection capabilities, and integrated analytics enable it to detect and remediate defects in a timely and efficient manner, helping to save costs and improve product quality.

There are no reviews yet