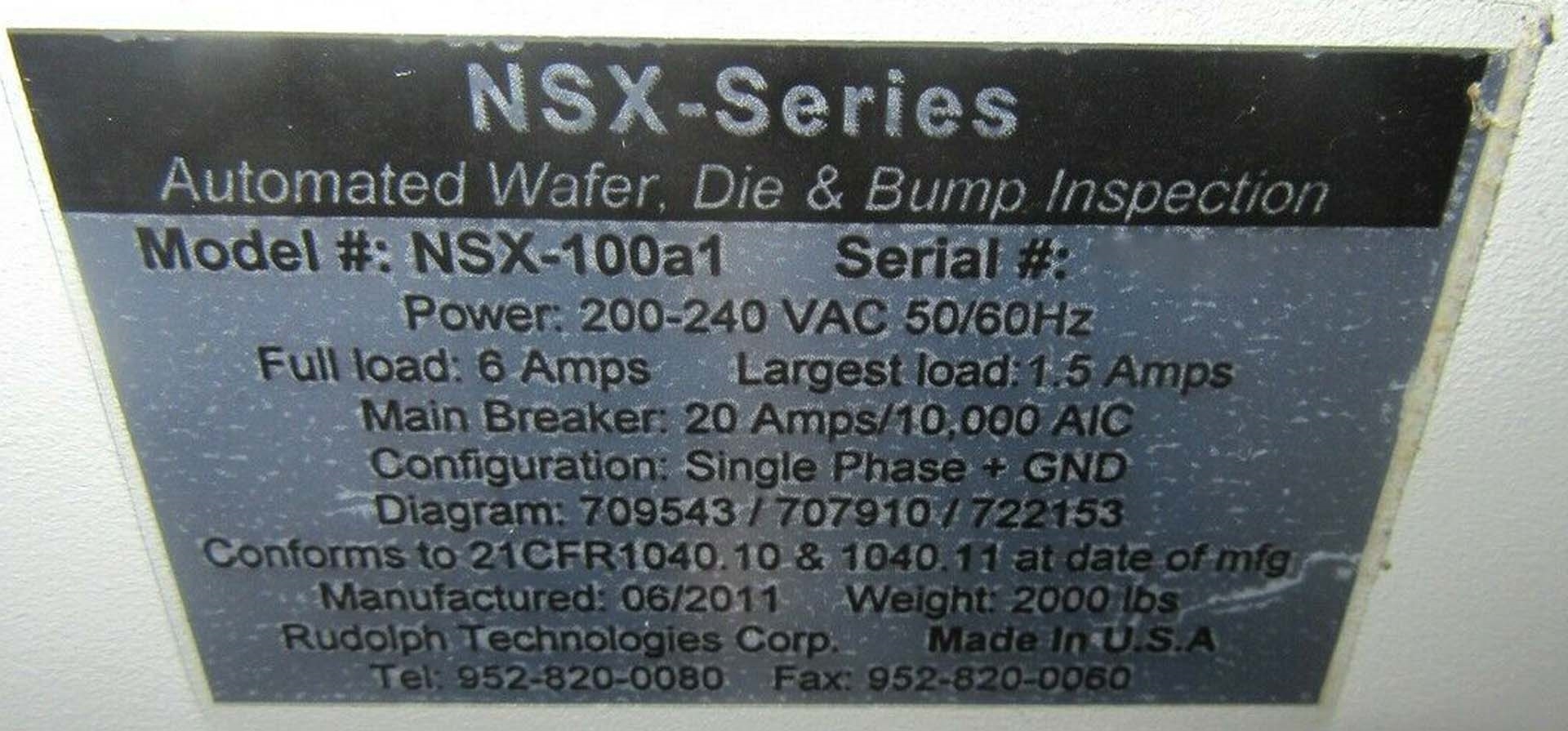

Used RUDOLPH / AUGUST NSX 100A1 #9239070 for sale

URL successfully copied!

Tap to zoom

RUDOLPH / AUGUST NSX 100A1 is a mask and wafer inspection equipment, designed to detect defects in photomasks and thin wafers used in the production of extremely small microelectronic components. This type of equipment is essential for quality control and detection of flaws that can be missed using a standard microscope. AUGUST NSX 100A1 employs patented Dynamic Observation Structures (DOF) to accurately detect small defects on both flat and irregular surfaces, such as on thin wafer layers. This system utilizes an integrated imaging unit with a high resolution and variable zoom to identify defects at the microscopic level. A Stochastic Ricochet Imaging (SRI) algorithm is used to capture images of complex surfaces using high frequency scanning in order to separate wafer features and quickly identify defects. RUDOLPH NSX 100A1 is designed to handle standard photomasks with sizes of up to 200mm and thin wafer sizes up to 300mm, all at the same resolution. The machine has an automated calibration feature that allows the operator to quickly dial in and maintain the correct focus. The user interface for NSX 100A1 is an intuitive graphical touch-screen display that can be operated with a stylus or touchpad. The interface makes it easy to quickly set and adjust inspection parameters. It also allows the operator to view the mask or wafer in both 2D and 3D images, which is perfect for applications that require a high degree of precision, such as when producing integrated circuits. RUDOLPH / AUGUST NSX 100A1 also has advanced features to help with defect classification, automated defect inspection, and defect analysis. It can detect particles as small as 2.5 microns, which is essential for quality control in the production of micro-features. The defect analysis function takes batch images acquired during the imaging process, allowing the tool to detect and classify defects quickly and accurately. AUGUST NSX 100A1 is the perfect asset for rapid mask and wafer inspection. Its advanced features and intuitive user interface make it easy to set up and use, and the ability to capture and analyze defects at an extremely high resolution make it an ideal choice for quality control in the microelectronic production process.

There are no reviews yet