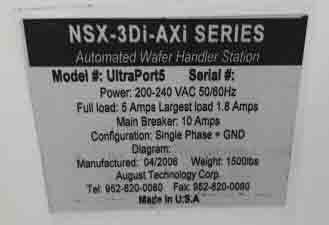

Used RUDOLPH / AUGUST NSX 105C #9378642 for sale

URL successfully copied!

Tap to zoom

RUDOLPH / AUGUST NSX 105 is a mask & wafer inspection equipment that is used for inspecting large-area flat panel display masks and wafers. This system utilizes a combination of optical, non-destructive inspection techniques to deliver precise measurements of small defects on the substrate. The unit is designed to meet a range of challenging quality assurance needs in the semiconductor, LCD display, and optoelectronics markets. AUGUST NSX-105 is equipped with a high-resolution digital camera that captures images of the substrate at up to 800 megapixels. This imaging machine is designed for high-speed inspection applications and can be used with either a normal or high-precision mode. With the normal mode, the camera bandwidth is 400 Mbps, while in high-precision mode the camera's bandwidth can reach up to 800 Mbps. The tool is also equipped with an automatic edge detection feature that allows it to scan large-area substrates without the need for manual alignment. RUDOLPH NSX 105 is capable of detecting defects as small as 5nm with its full-field broad spectrum lighting feature. It can also detect surface roughness, contaminants, pits, and other such defects. The asset is equipped with advanced pattern matching, median, and averaging algorithms to analyze the images it captures. It also has a polygonal pattern recognition feature which helps in detecting complex patterns. RUDOLPH / AUGUST NSX-105 is able to perform defect analysis, machine learning, and other such tasks. To reduce the amount of time and labor needed for inspection, RUDOLPH NSX-105 operates in a semi-automatic manner. An operator can set the parameters for the inspection and the model will automatically inspect the sample. This allows for quick, accurate inspection of large substrates. RUDOLPH / AUGUST NSX 105 also has a multi-zone data analysis feature that allows the operator to easily identify problem areas on the substrate and take corrective action if necessary. Overall, NSX 105 mask & wafer inspection equipment is a reliable and powerful inspection solution for large-area substrates that require precise and accurate measurements. Its fast imaging system, automatic edge detection, and advanced pattern recognition features make it an ideal choice for inspecting a wide range of substrates. Its semi-automatic operation and multi-zone data analysis also reduce the amount of time and labor spent on inspection.

There are no reviews yet