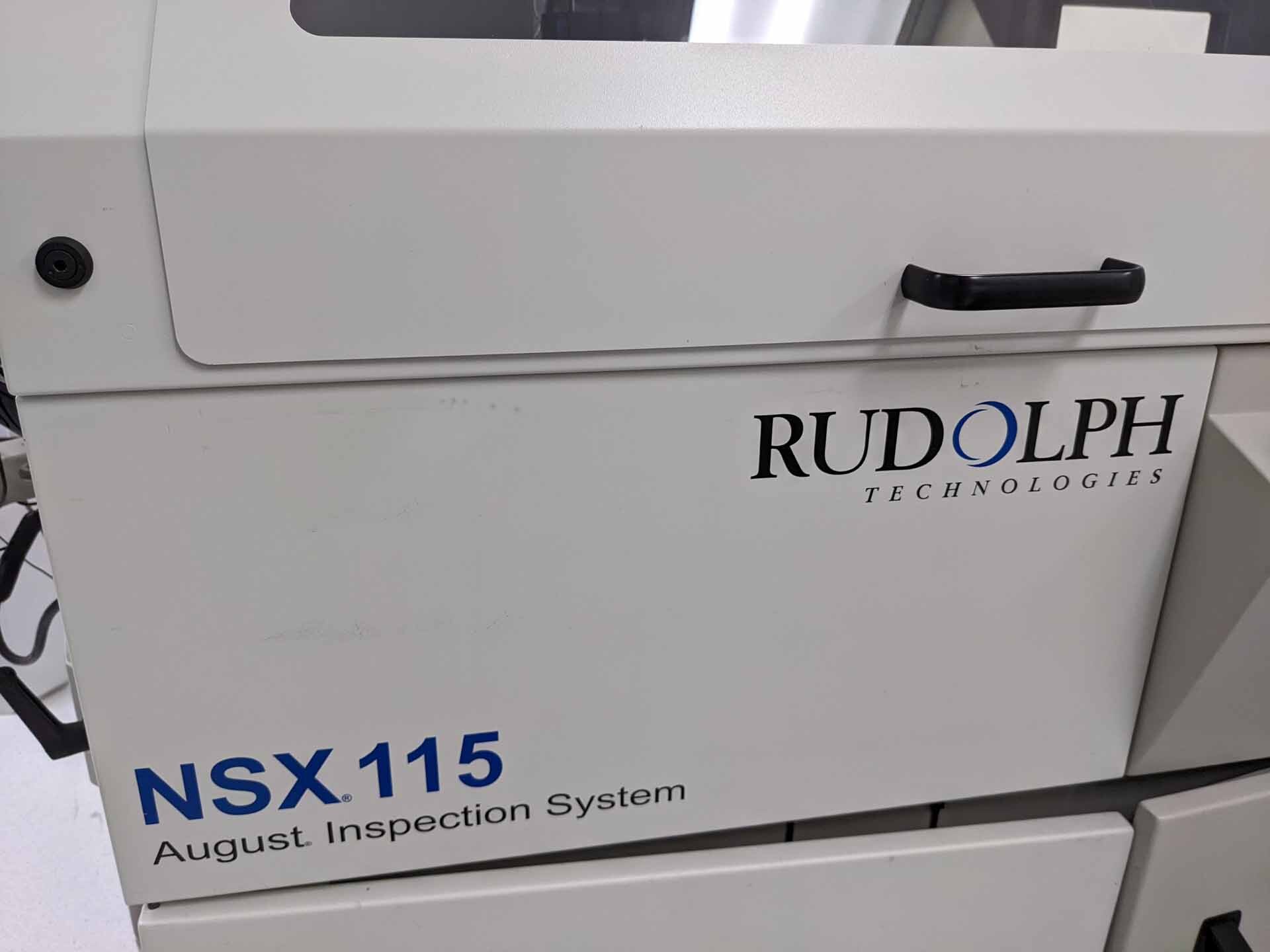

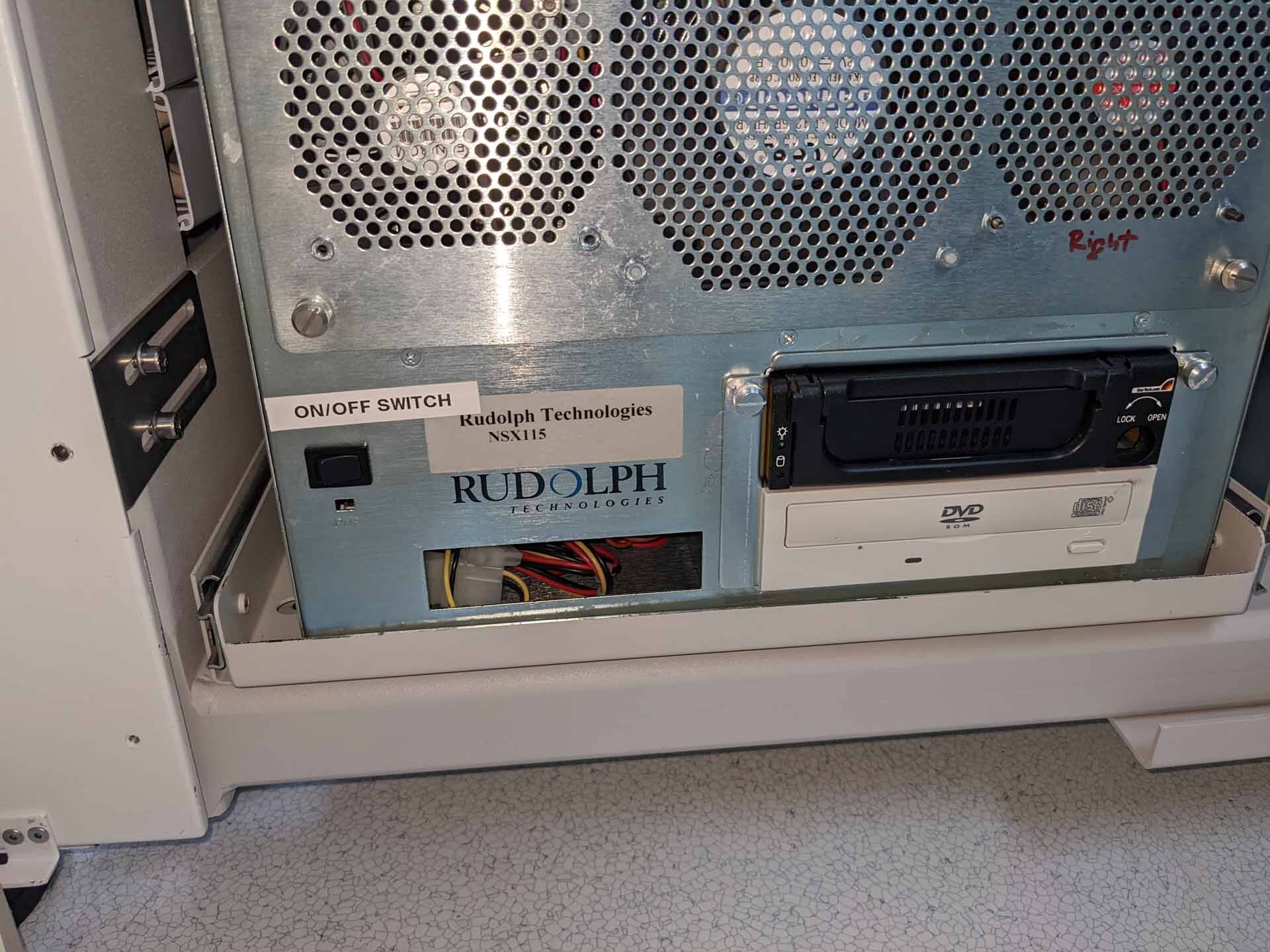

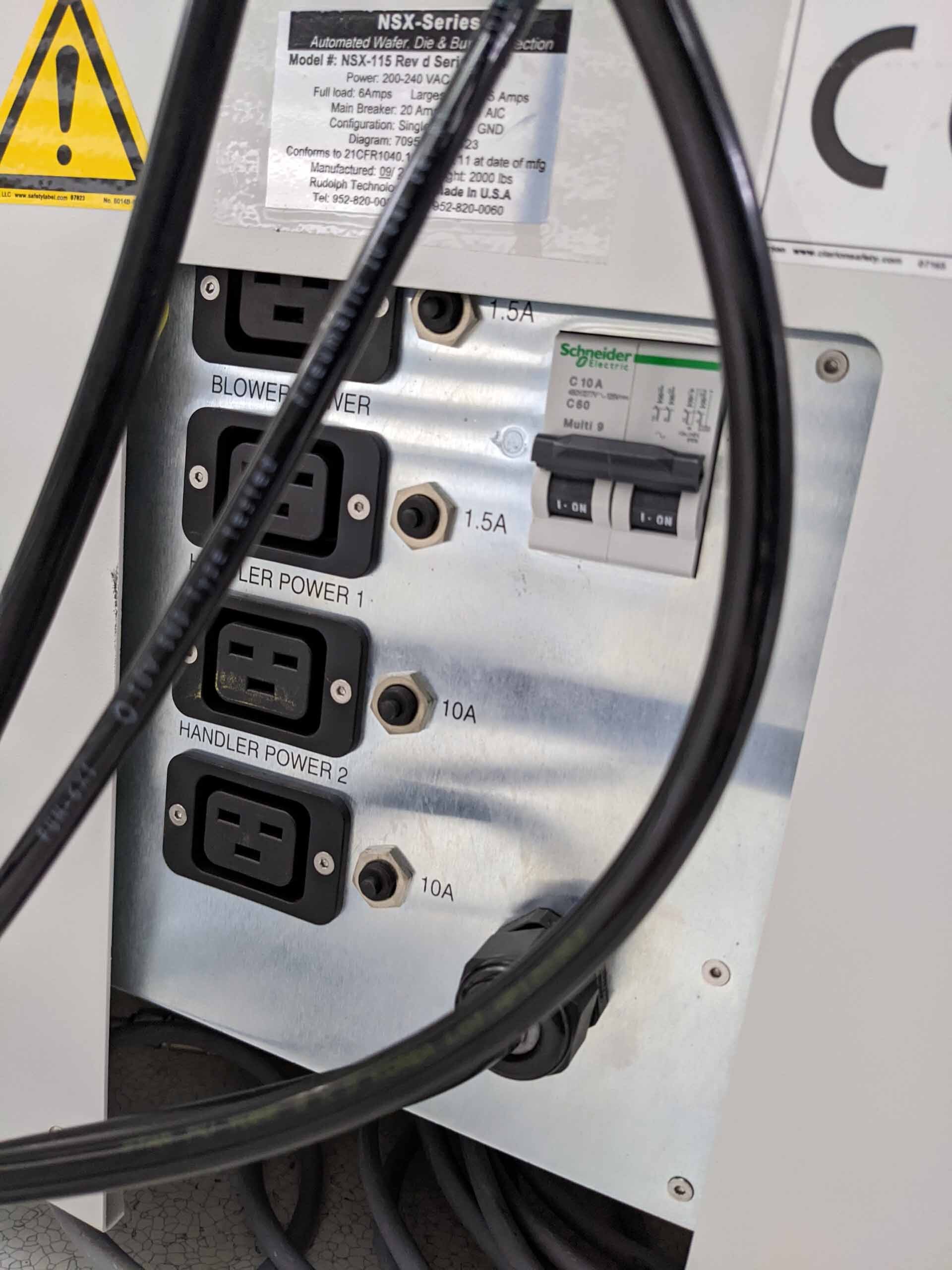

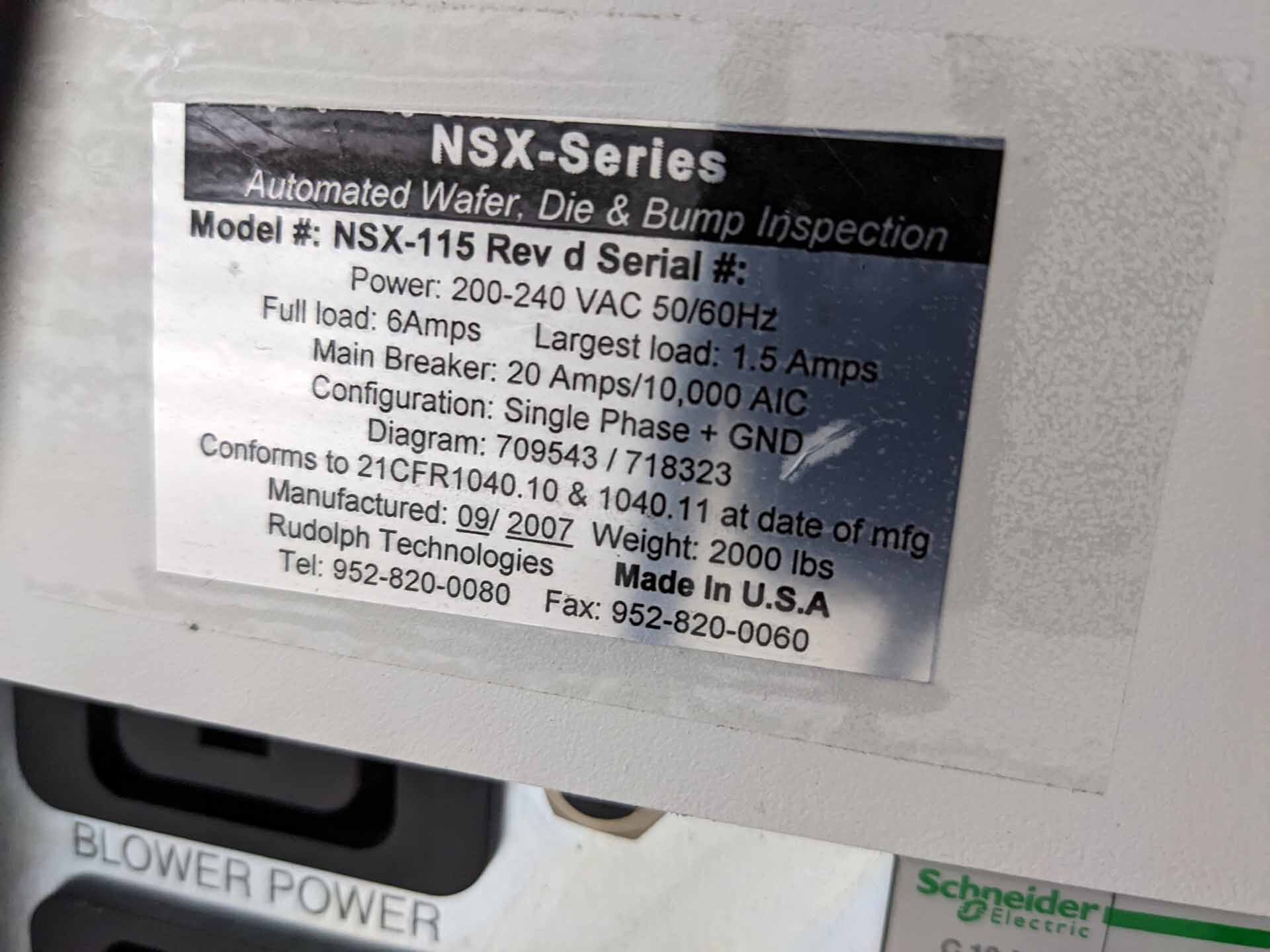

Used RUDOLPH / AUGUST NSX 115 #293618548 for sale

URL successfully copied!

Tap to zoom

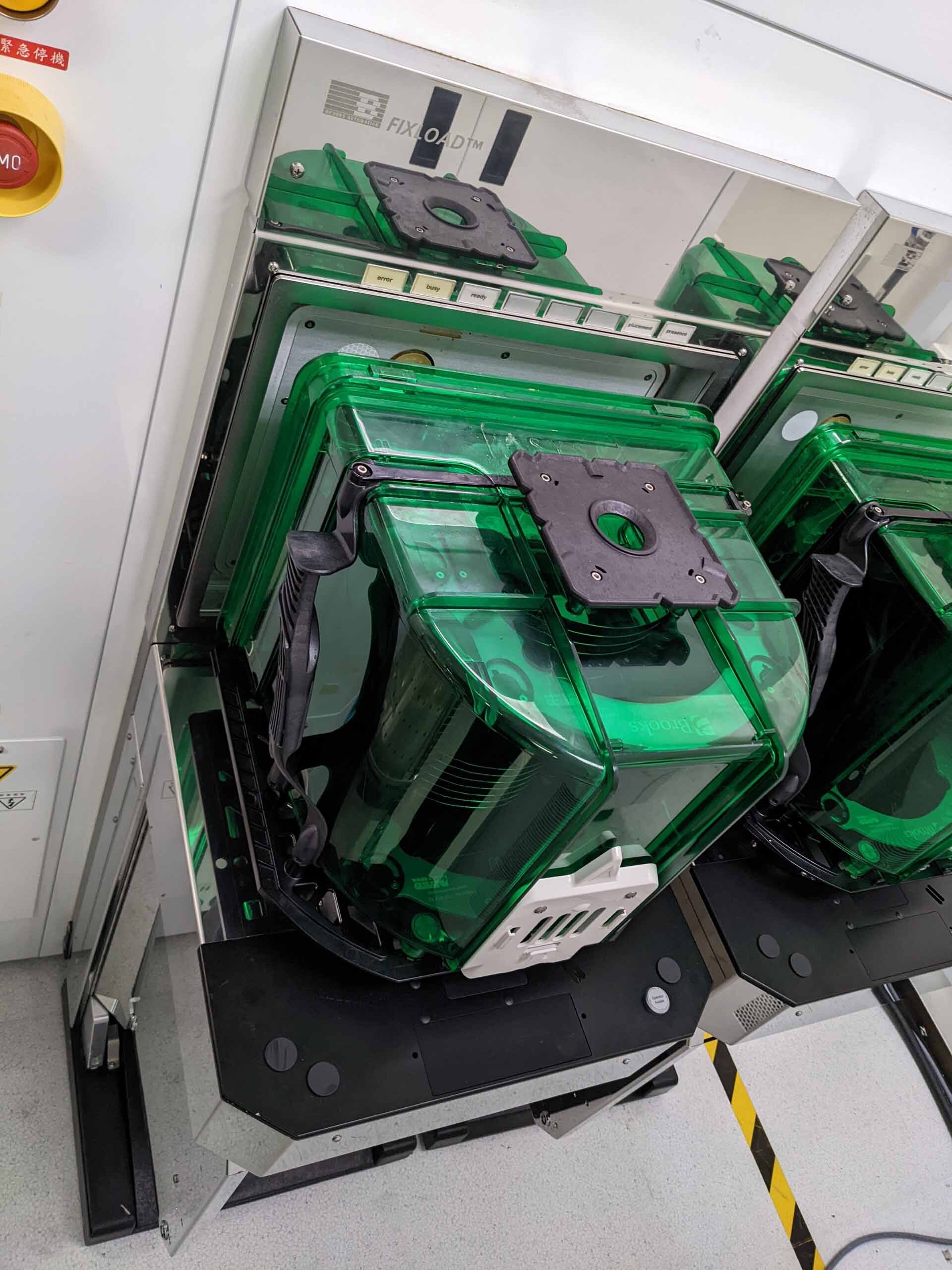

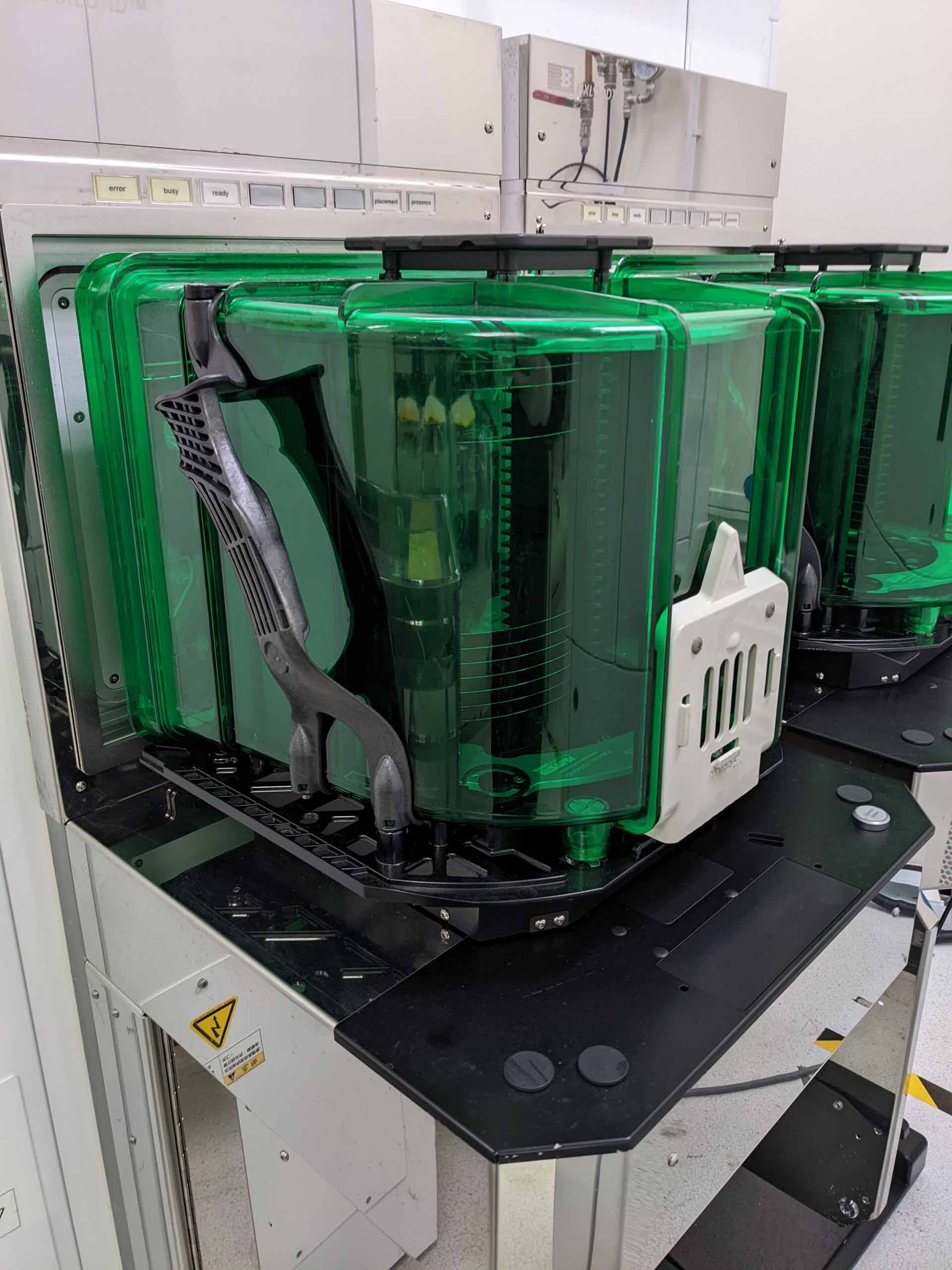

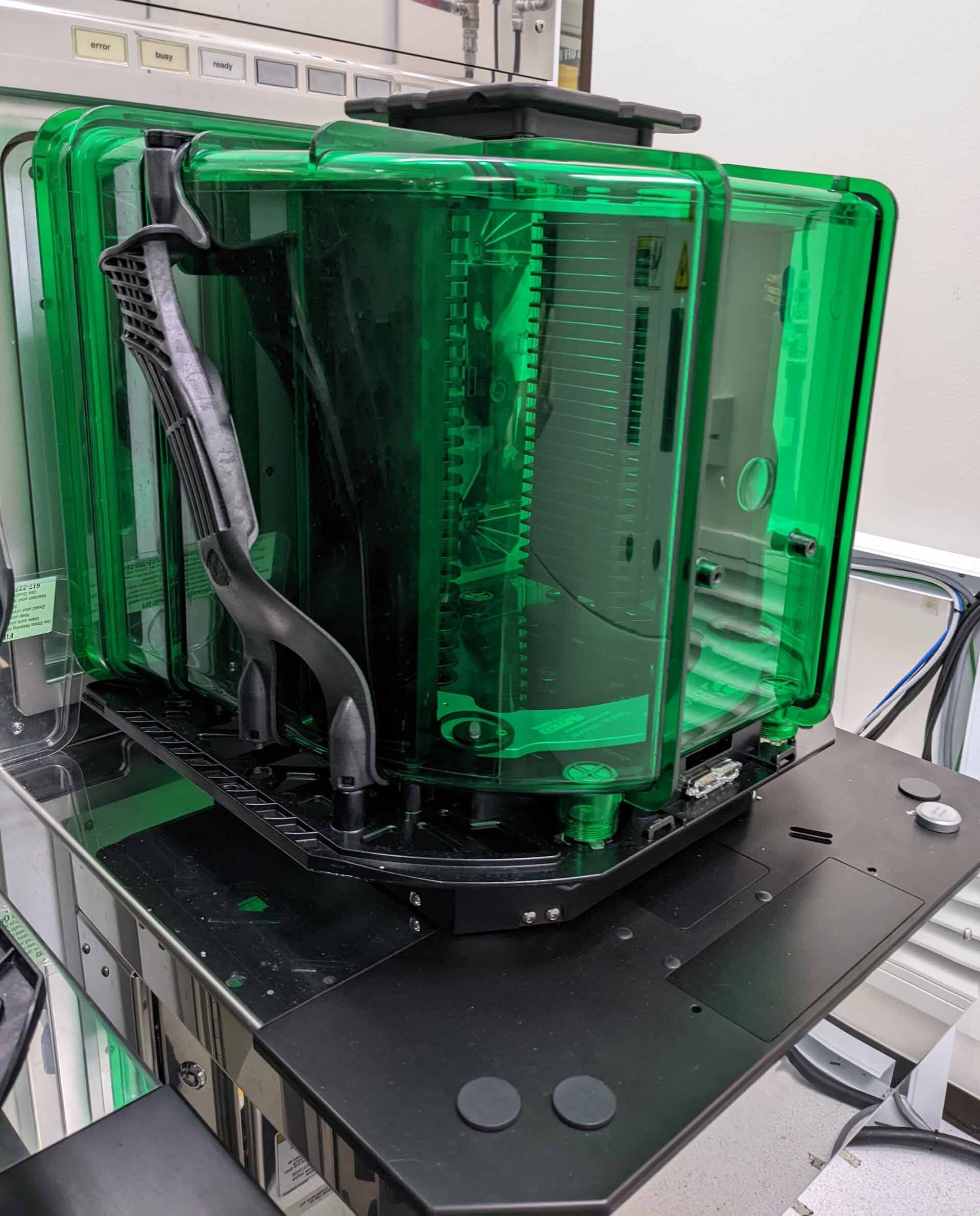

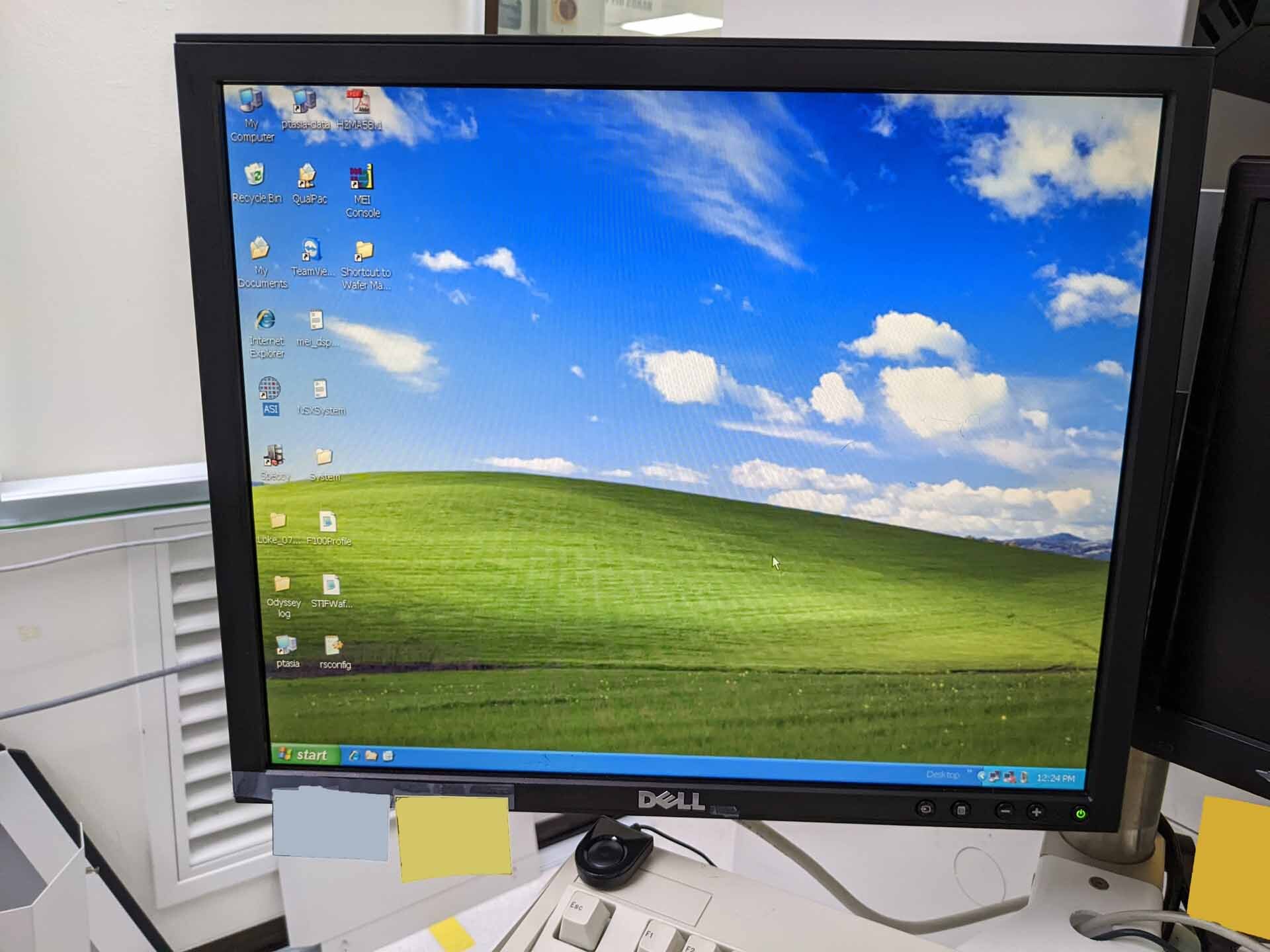

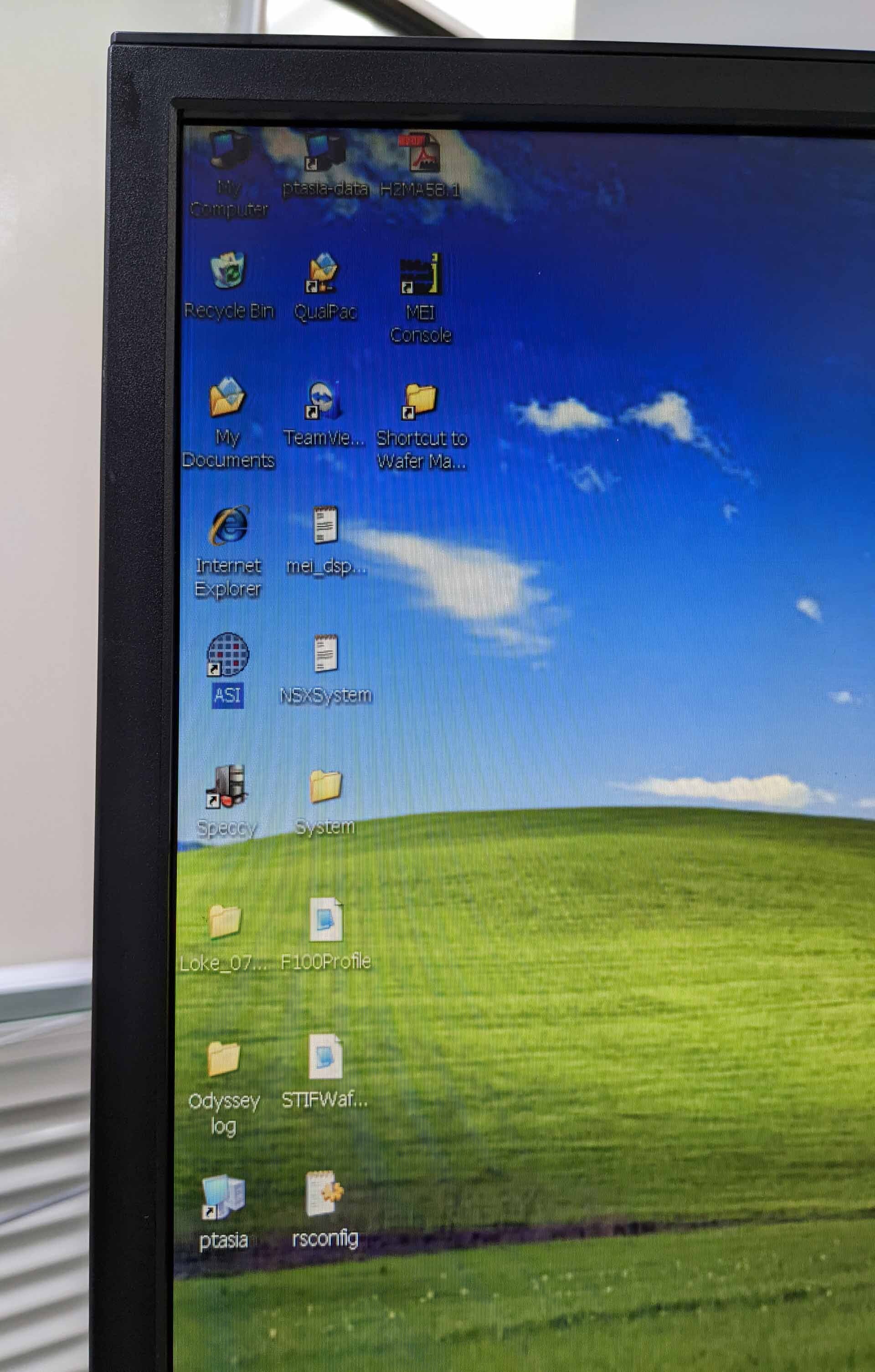

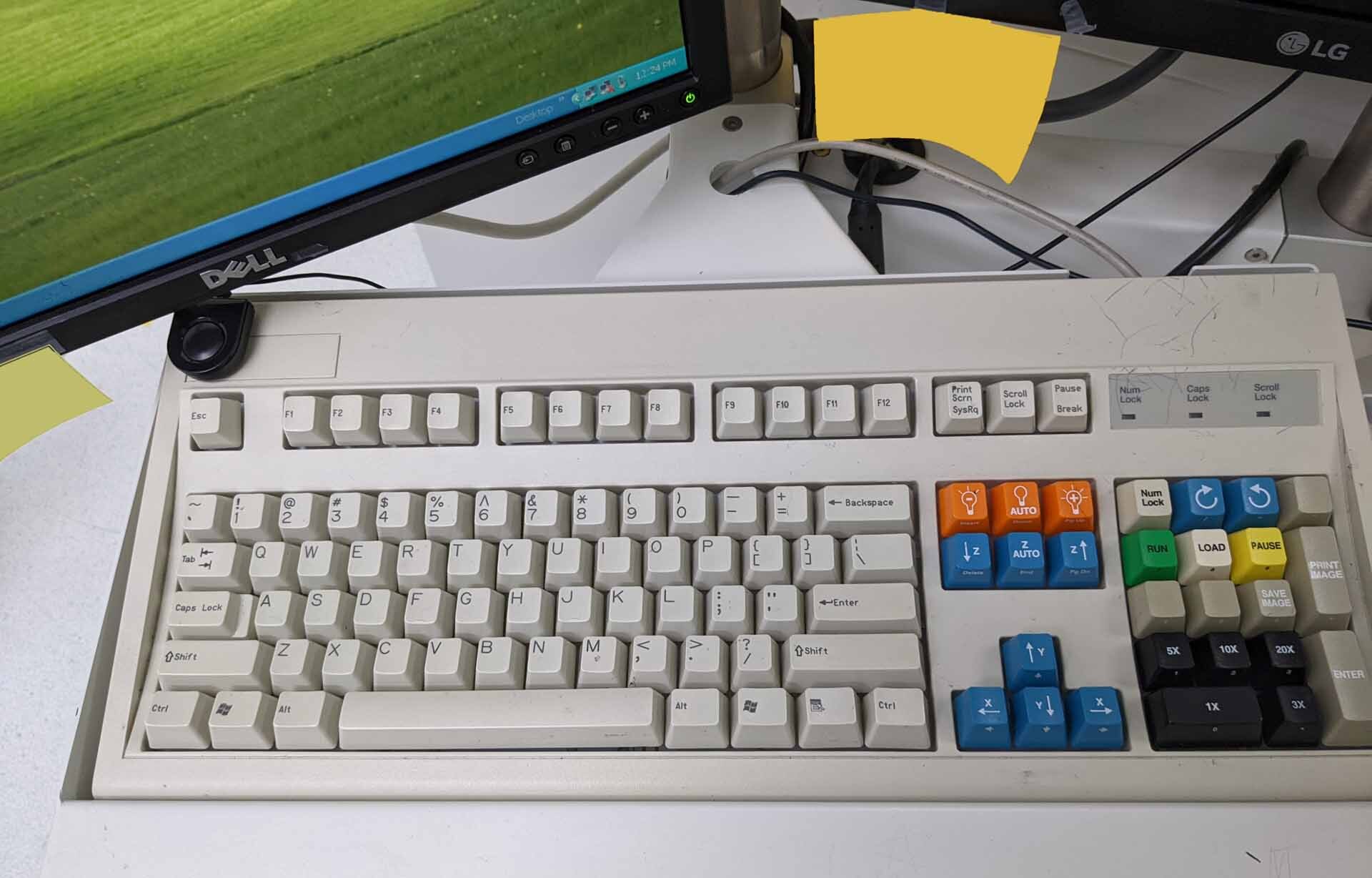

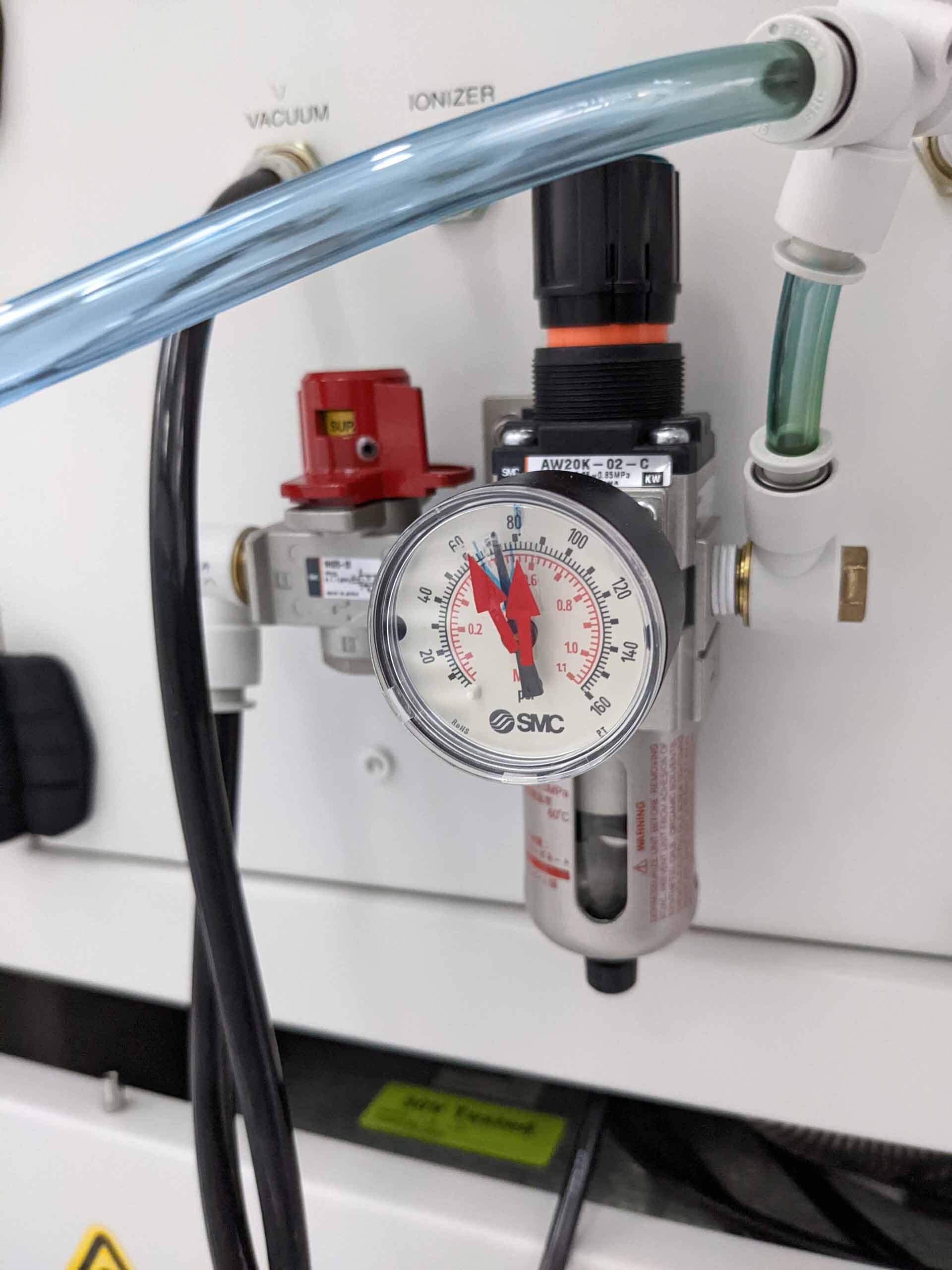

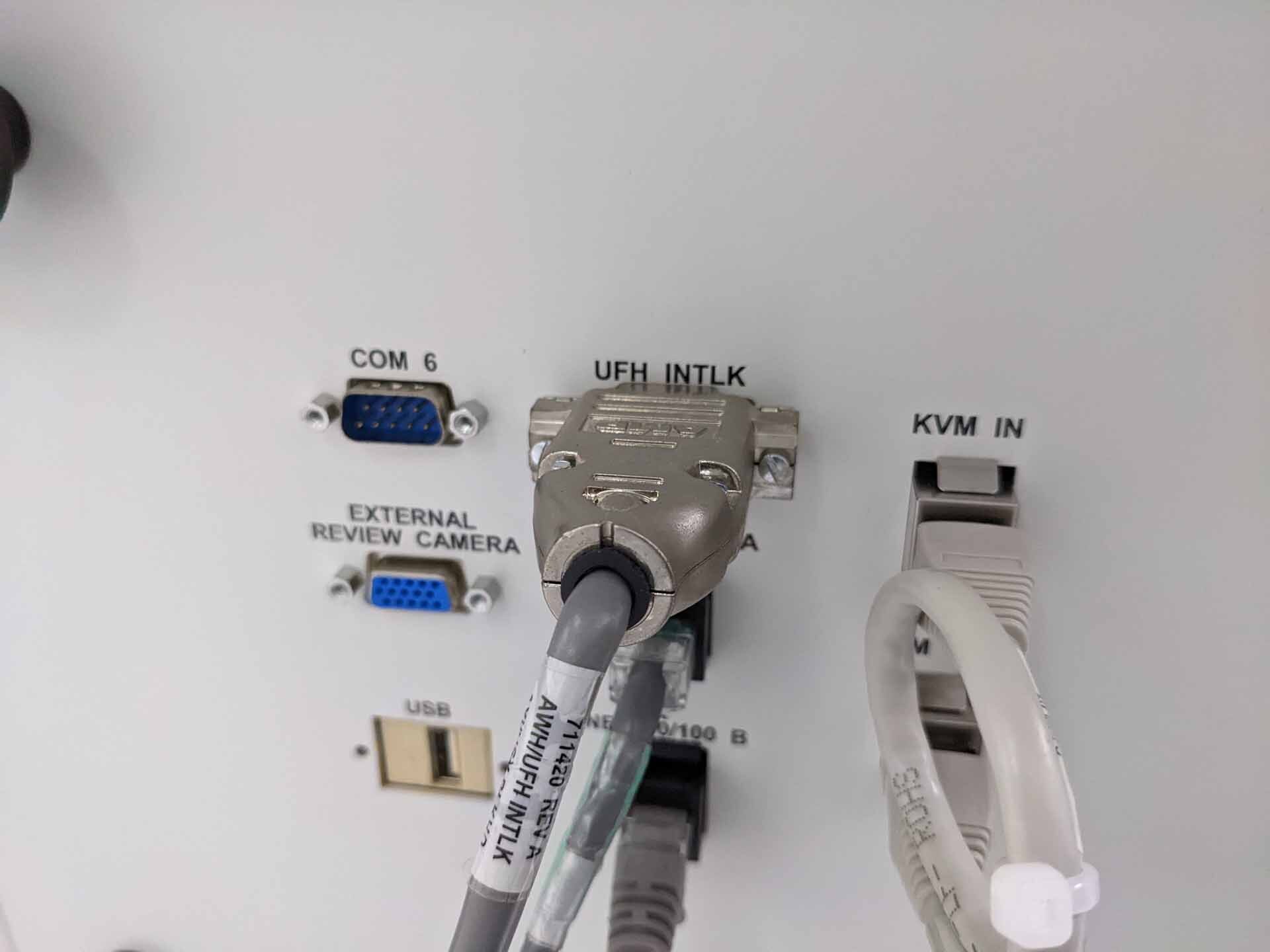

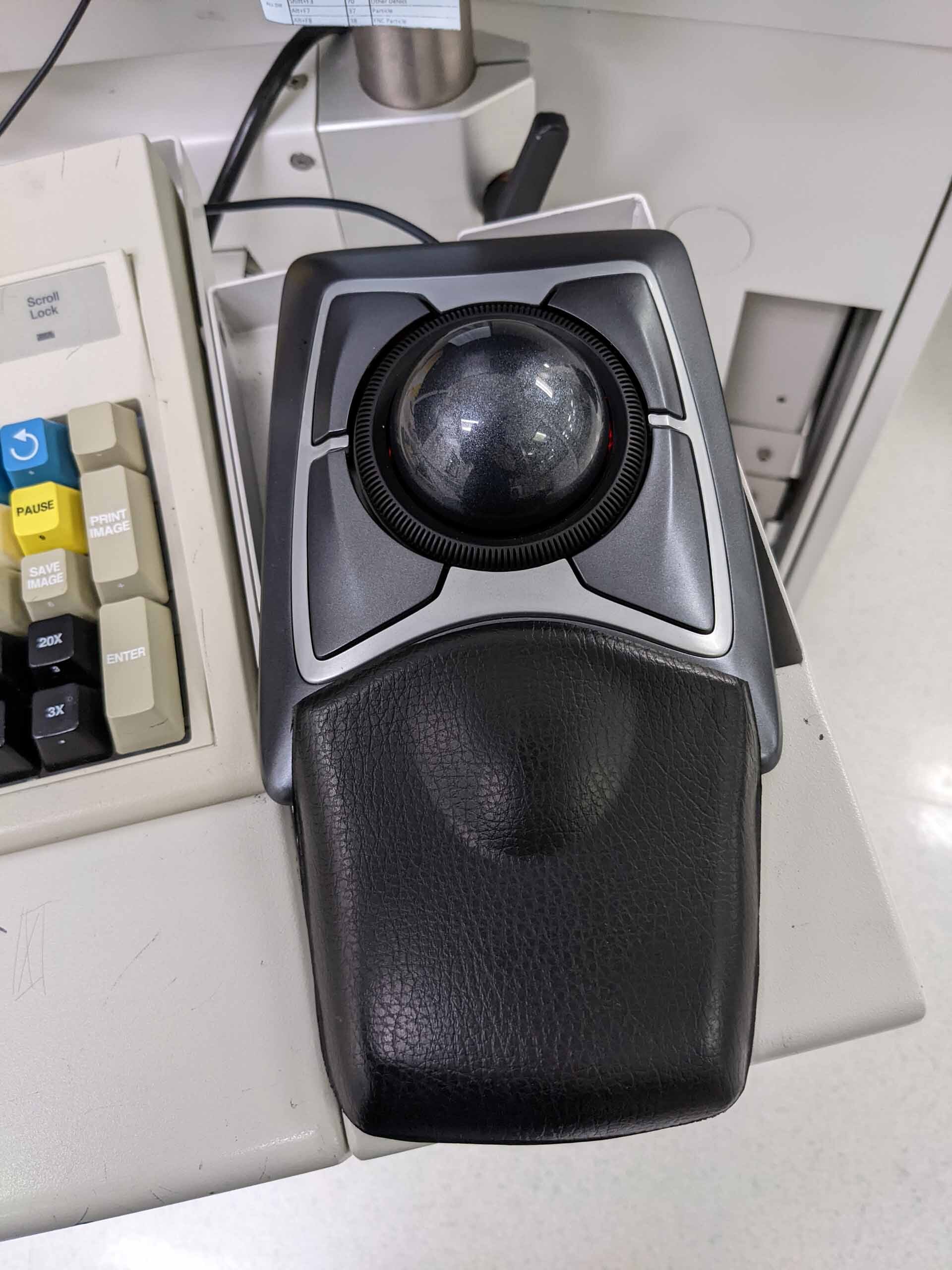

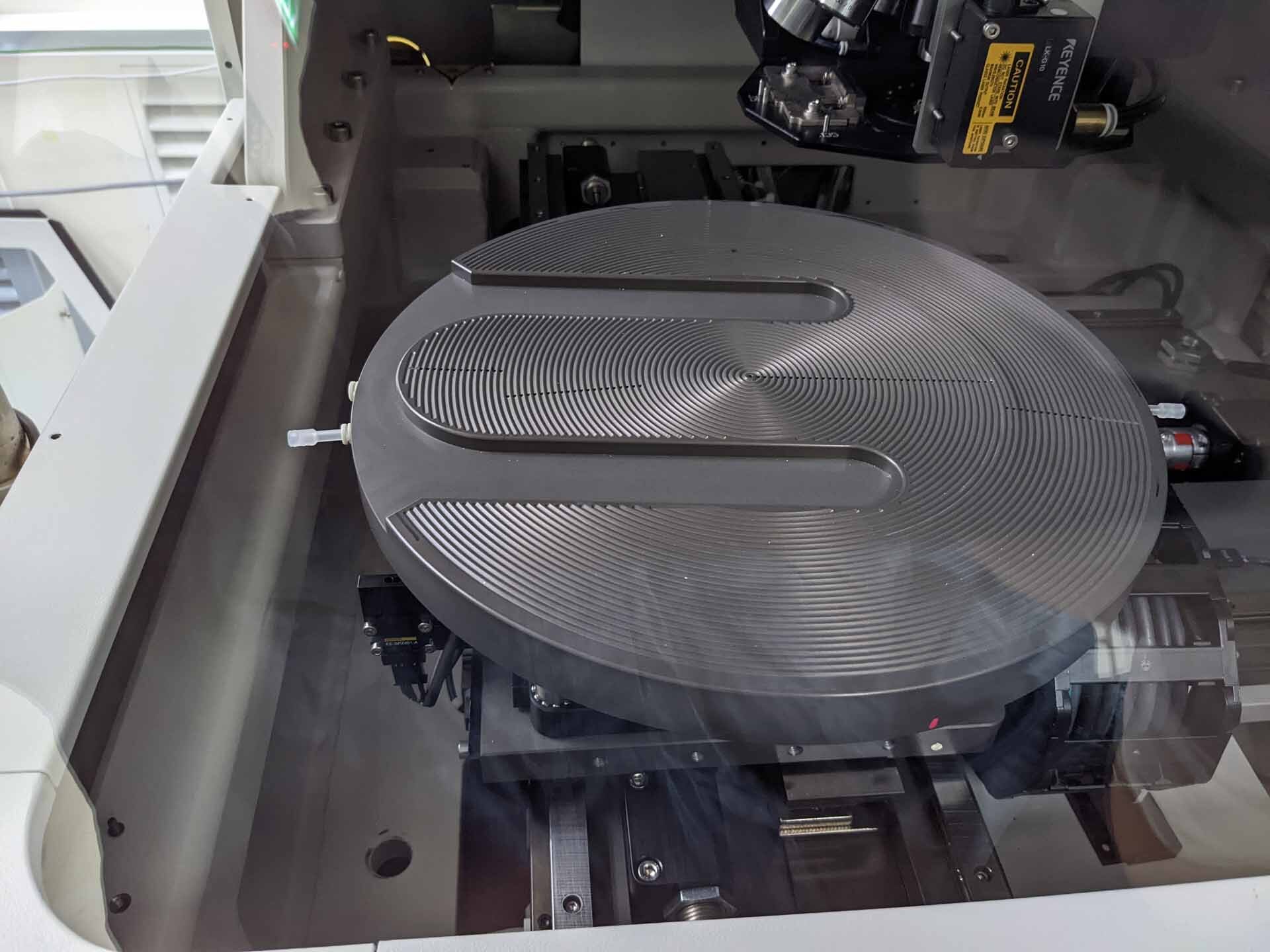

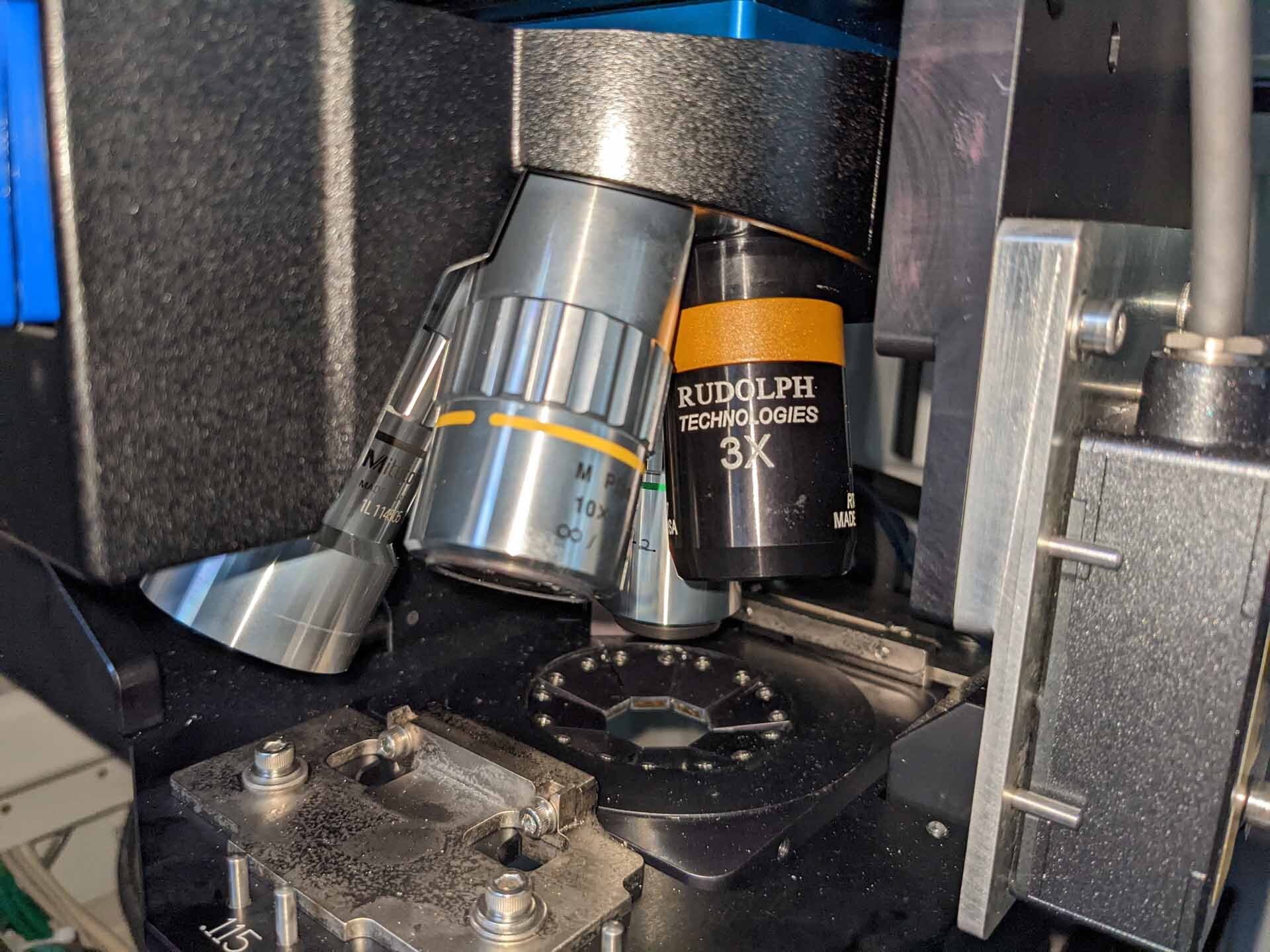

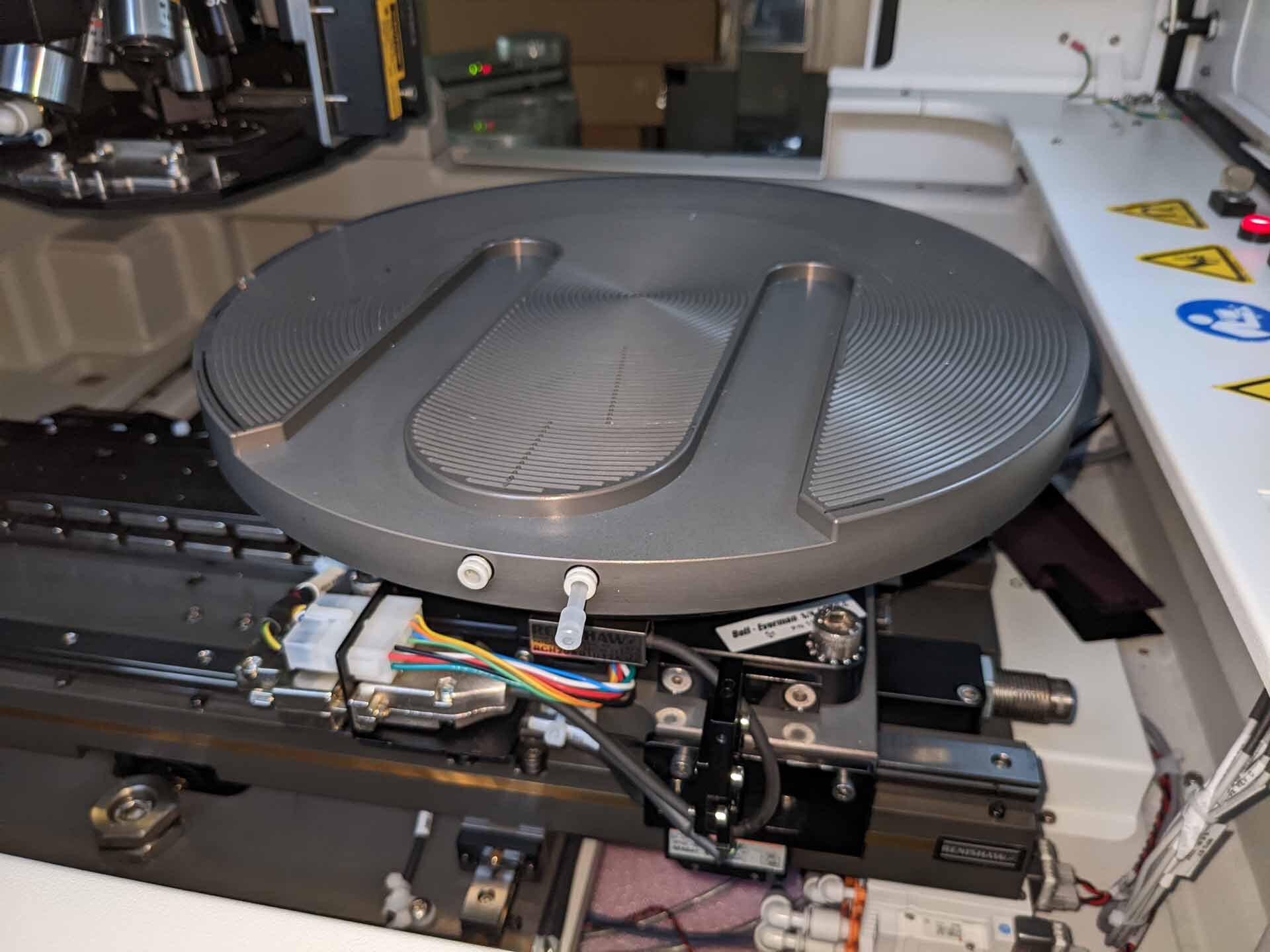

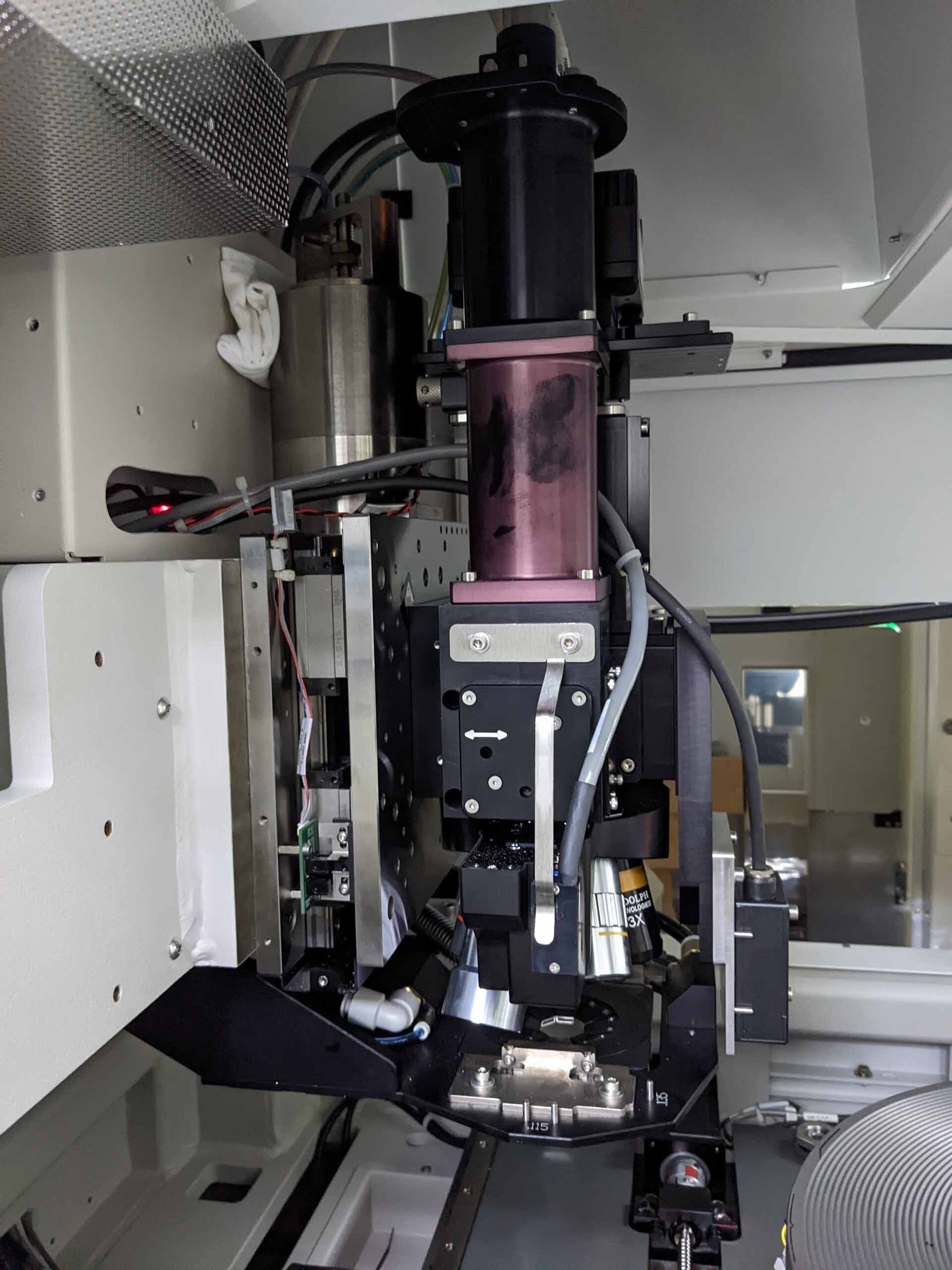

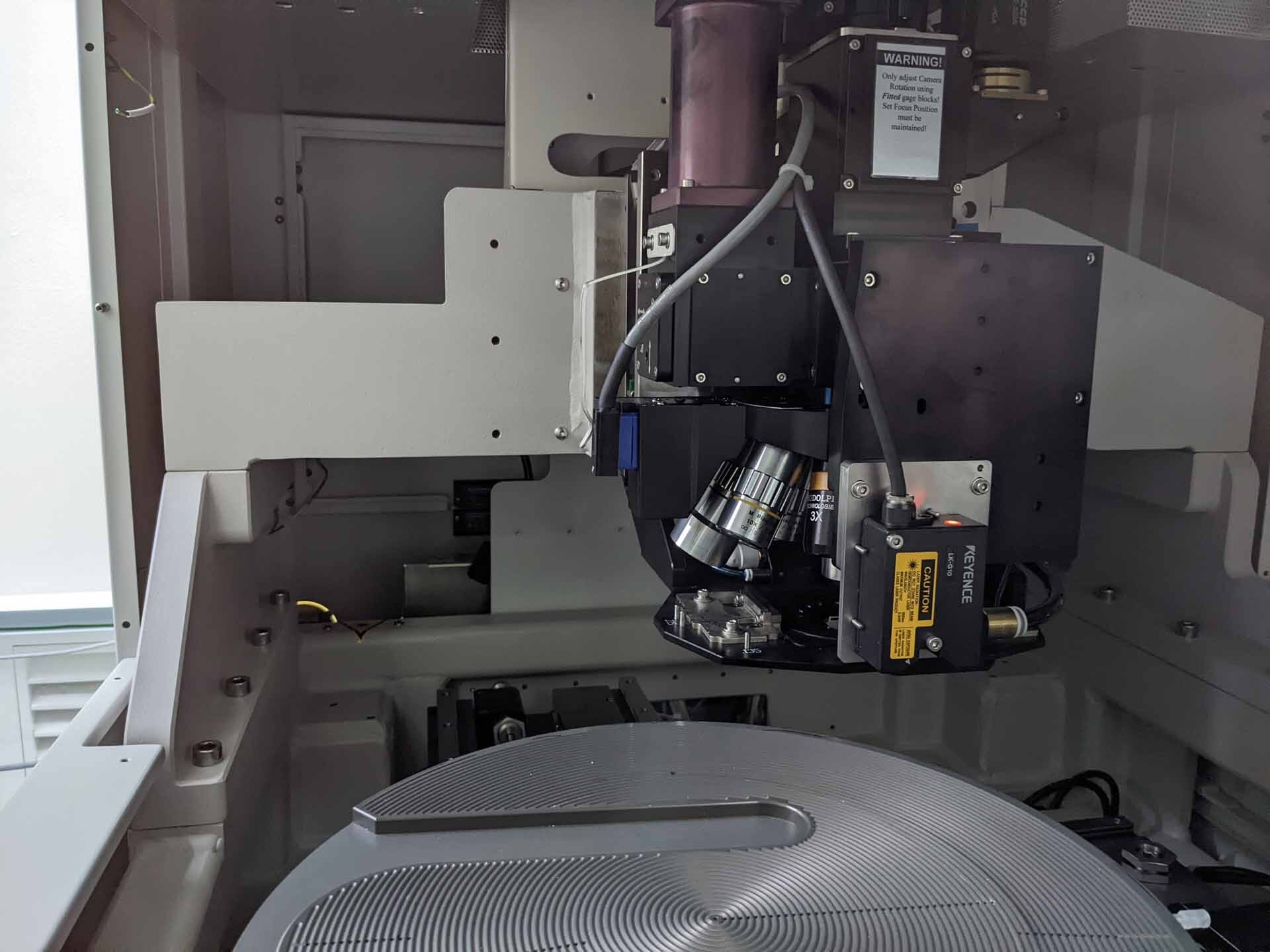

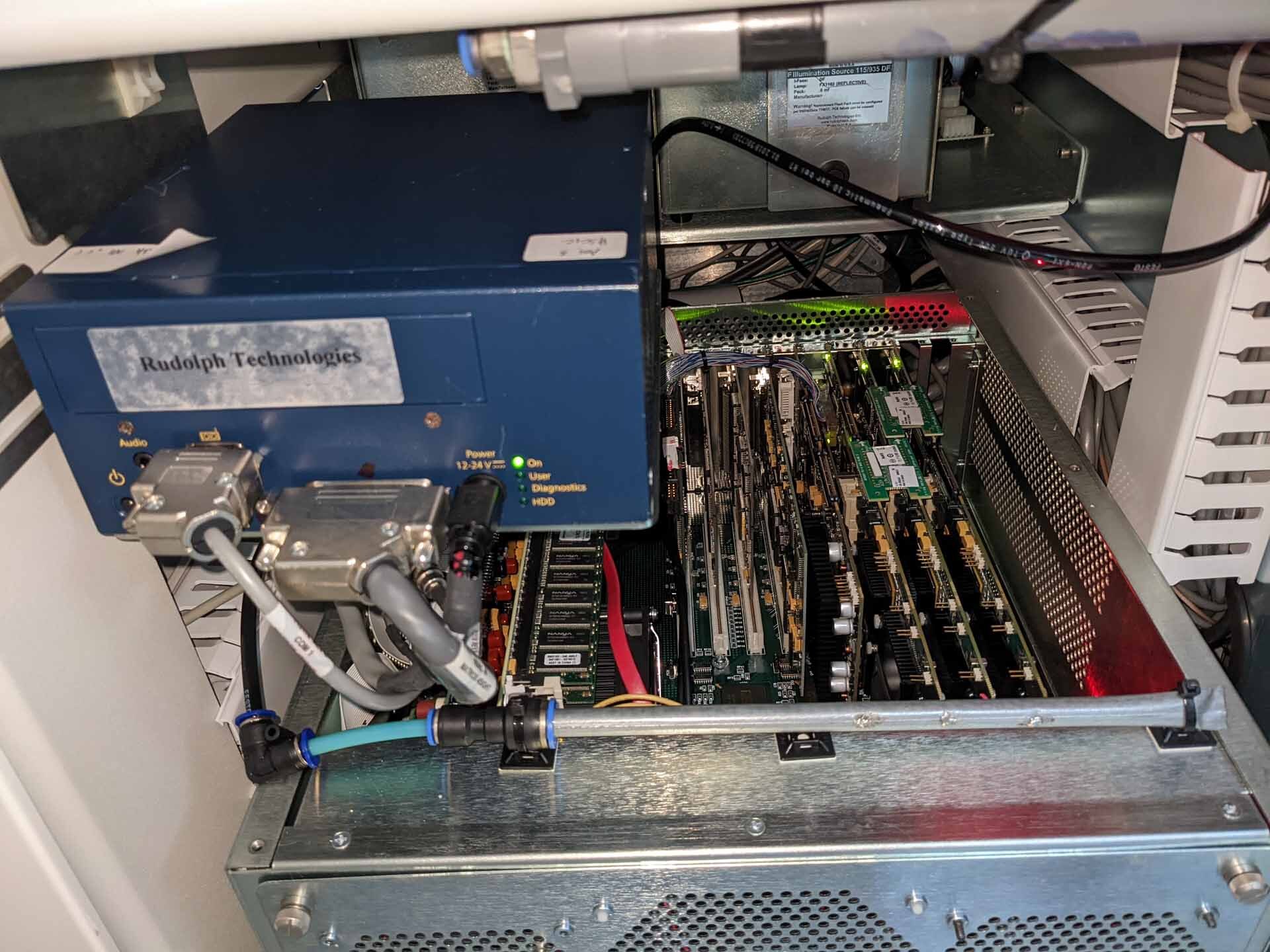

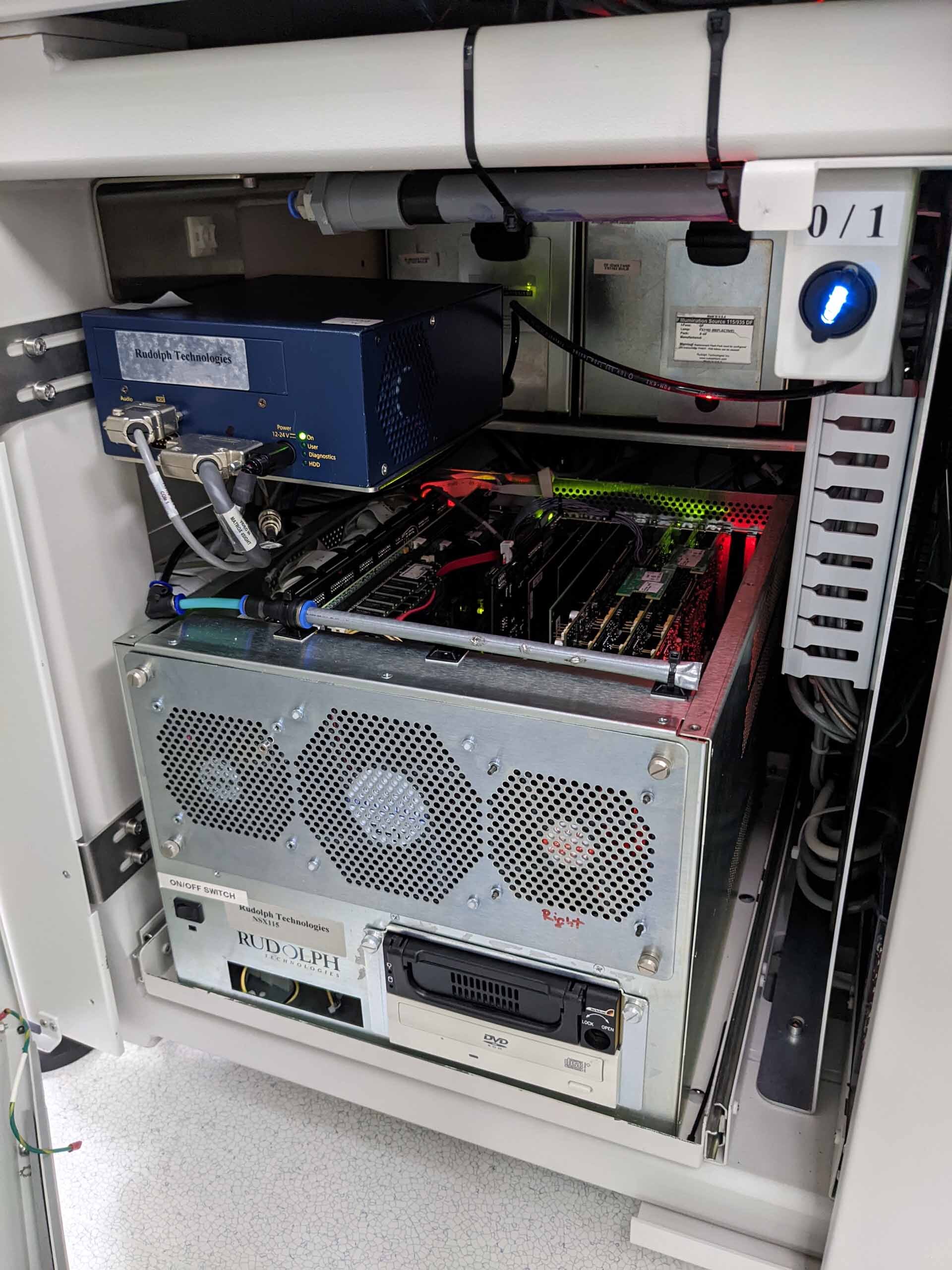

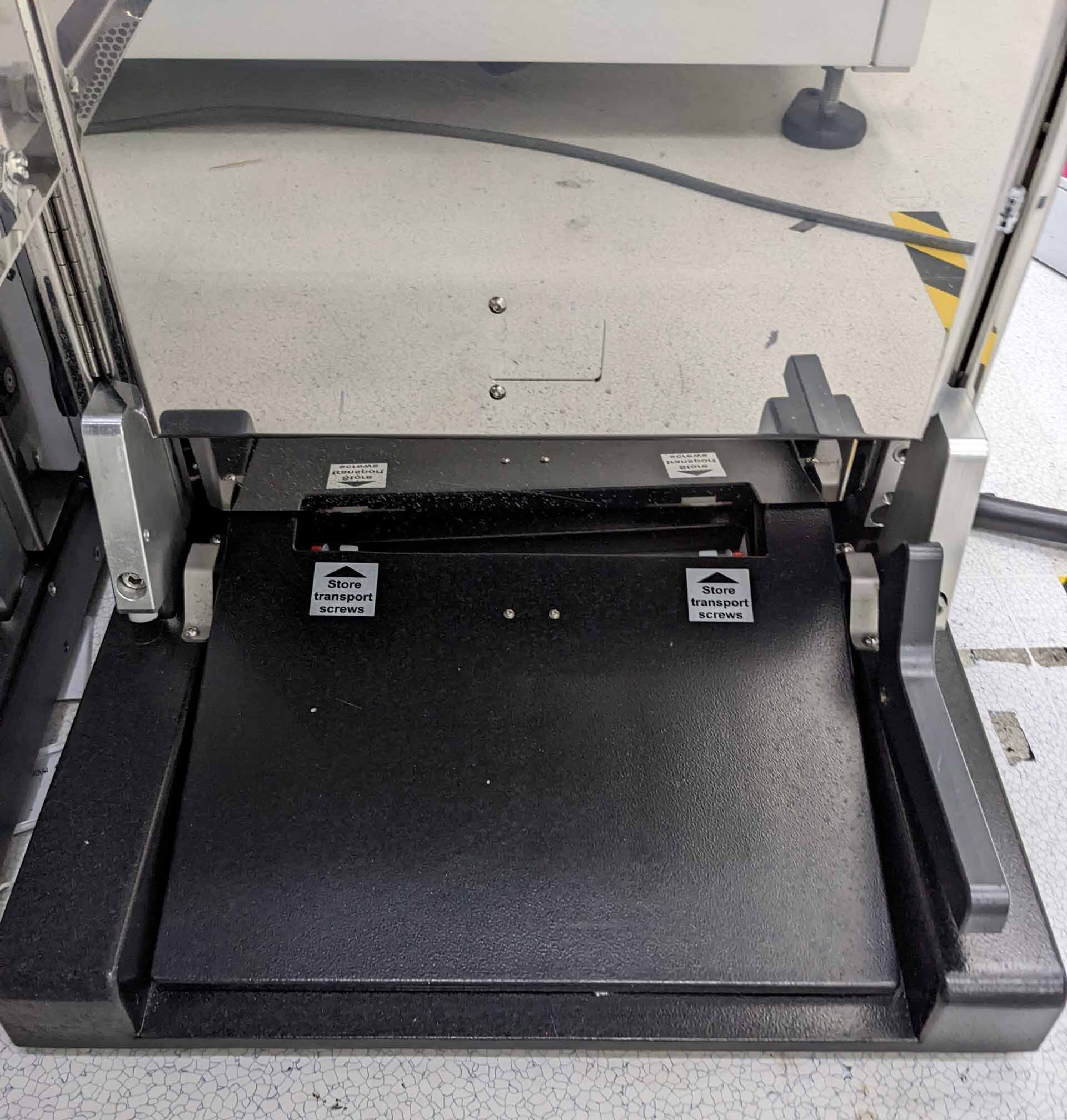

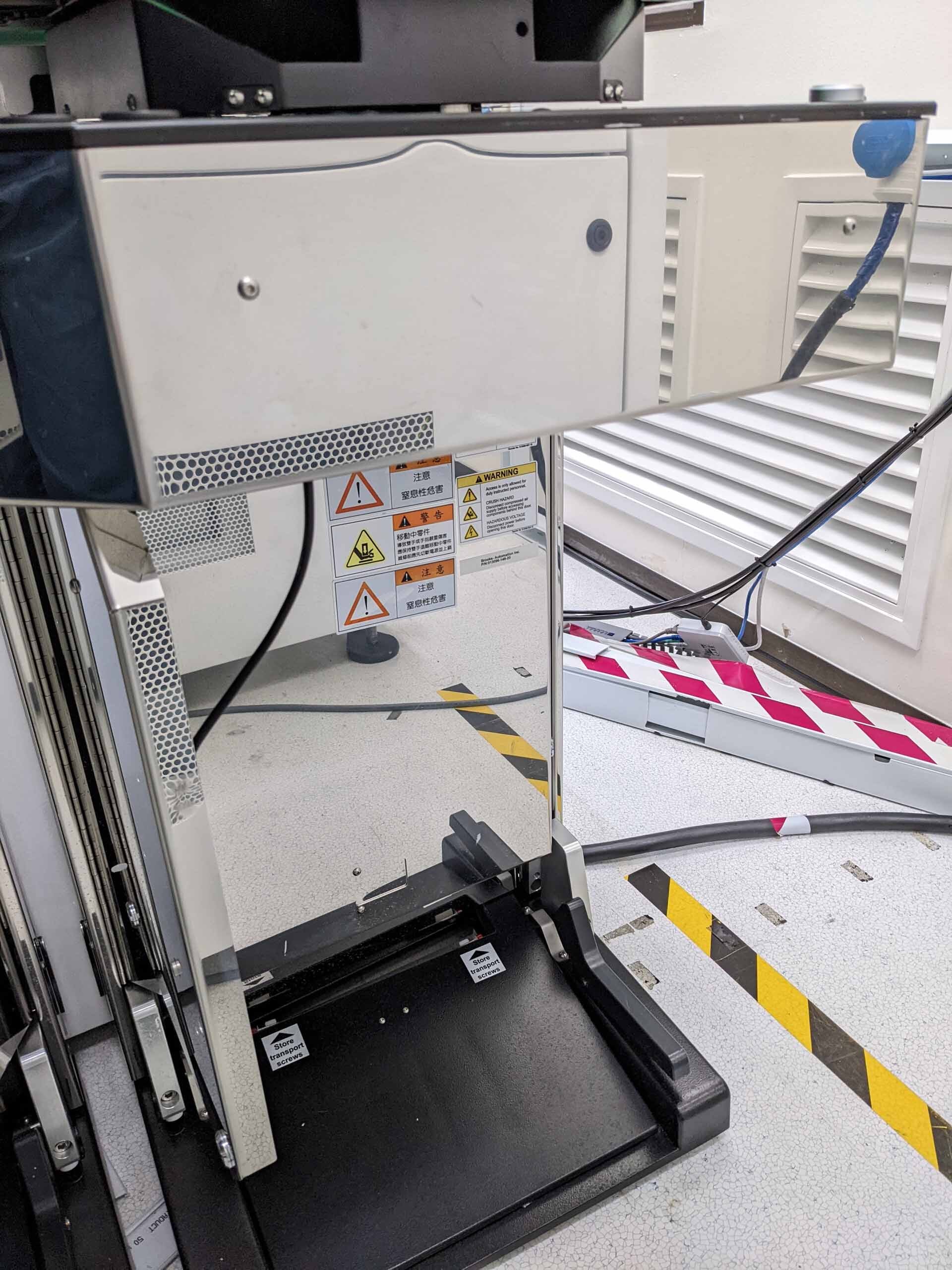

RUDOLPH / AUGUST NSX 115 is a mask and wafer inspection equipment designed for use in semiconductor production facilities. This piece of equipment is used to detect defects in masks and wafers that could detrimentally affect the function of the circuit elements, and can help manufacturers improve the quality and reliability of products. AUGUST NSX 115 utilizes brightfield and darkfield illumination, paired with advanced image processing algorithms for maximum sensitivity to structural anomalies and faults such as defects, scratches, and particles. It provides high-resolution imaging of masks and wafers, with a maximum magnification of up to 375x, to enable fast and accurate detection of errors. The system offers a user-intuitive graphical user interface, which simplifies operations and eliminates the need for extensive operator training. RUDOLPH NSX 115 is equipped with dual-axis steering, allowing high-precision alignment and movement of the wafer over the detector stages. Additionally, it is capable of creating wafer maps with varying magnifications, allowing up to 36 separate map windows to be opened. This feature is especially useful for creating images of challenging or difficult-to-analyze areas, as well as for localizing the source of defects. The NSX is further complemented by its 3D Image Stacking capabilities. By using up to 8 layers of images, it is possible to highlight errors by varying the focus level, natural brightness, and other parameters. This feature is particularly useful for detecting particles and subtle defects in small-scale elements. NSX 115 also offers a built-in calibration unit for mask alignment and analysis, as well as compatible software for error detection, report generation, defect position analysis, and other operations. Furthermore, the machine is easy to maintain, as it is equipped with an advanced cleaning tool that reduces the need for manual cleaning. All in all, RUDOLPH / AUGUST NSX 115 is a highly advanced mask and wafer inspection asset that provides users with many advantages, such as improved quality management, fault detection, and reduced maintenance times. Its intuitive user interface, highly accurate imaging capabilities, and versatile features make it an ideal choice for any semiconductor facility.

There are no reviews yet