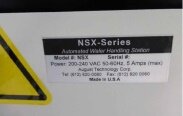

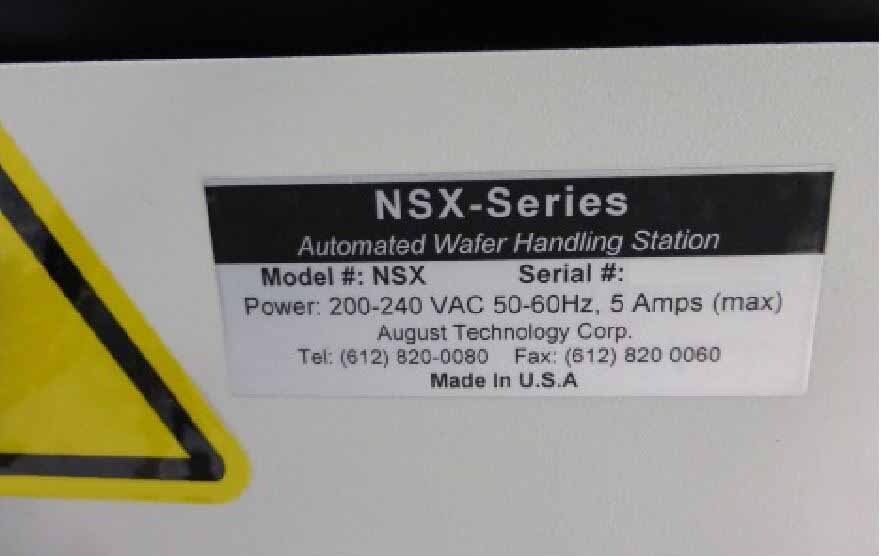

Used RUDOLPH / AUGUST NSX 90 #9175960 for sale

URL successfully copied!

Tap to zoom

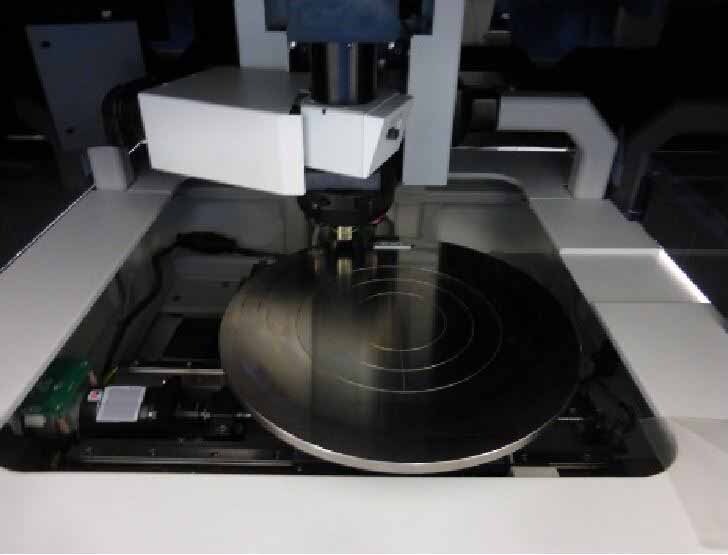

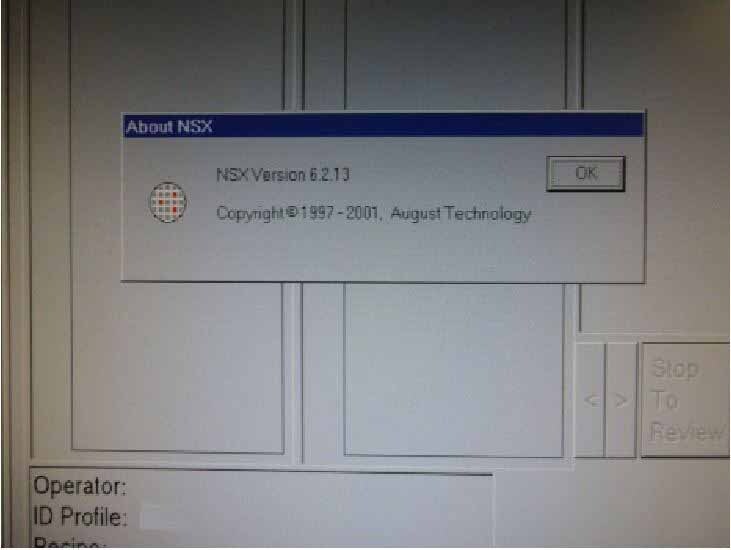

RUDOLPH / AUGUST NSX 90 Mask & Wafer Inspection Equipment is designed to detect, isolate, and measure critical defects present on semiconductor devices. The system is composed of a state-of-the-art telecentric microscope, a precision wafer stage, and four cameras, including two high-resolution CCD cameras and two infrared detectors. The unit is capable of scanning large areas over a range of magnifications, enabling advanced inspection capabilities that cover the complete wafer surface. Using the high-resolution CCD cameras, AUGUST NSX 90 is capable of detecting and isolating extremely small defects, such as line breaks, die cracks, and poly voids, with great accuracy and precision. The machine also features an automatic optical recognition tool, which utilizes proprietary algorithms to accurately locate and classify defects. Once a defect is located, the asset is able to generate a detailed picture of the defect's structure, size, shape, and position on the wafer using the CCD cameras. RUDOLPH NSX-90 Mask & Wafer Inspection Model is designed to perform advanced, advanced multi-parameter inspection with two infrared detectors. The equipment can detect and classify particles and contaminants with great accuracy and precision. By utilizing sophisticated algorithms, the system is able to recognize complex particles and classify them by size, material type, and other optical parameters. Additionally, the unit can detect and isolate critical defects and yield-limiting particles using its onboard image processing and analysis capabilities. In addition, NSX-90 Mask & Wafer Inspection Machine can provide detailed analysis of defect performance after completion of a scan. The advanced image analysis tool calculates the average defect size, defect densities, and yield. The asset is also capable of calculating average particle size, 3D topography, and defect masks. The model can also automatically generate a detailed report of its measurements, enabling engineers to quickly and accurately analyze the results of their inspections. NSX 90 Mask & Wafer Inspection Equipment is an essential tool for the semiconductor industry. By providing detailed and accurate inspection capabilities with its advanced imaging, analysis, and reporting tools, the system ensures that engineers have the information they need to develop and improve their semiconductor device manufacturing processes.

There are no reviews yet