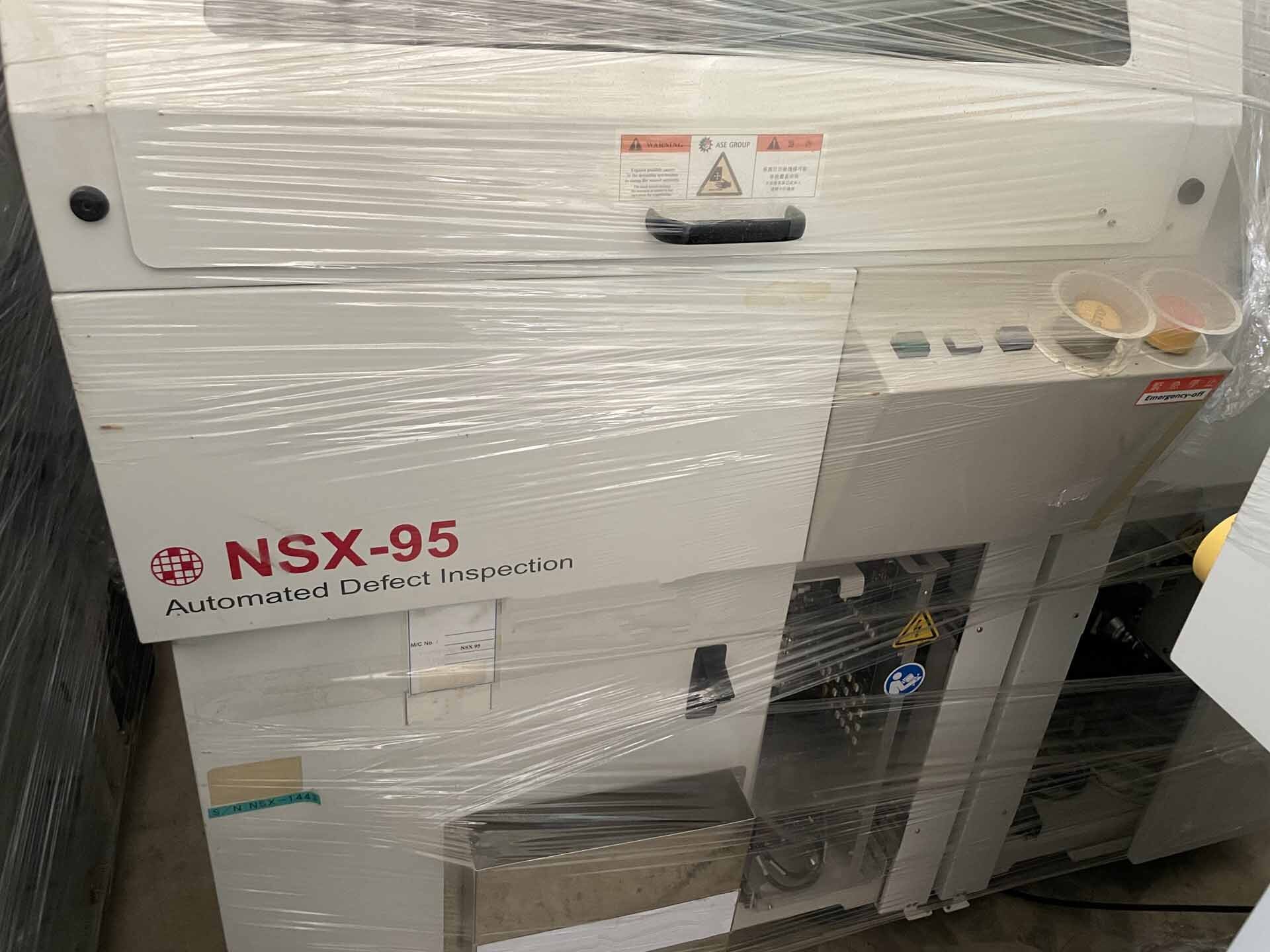

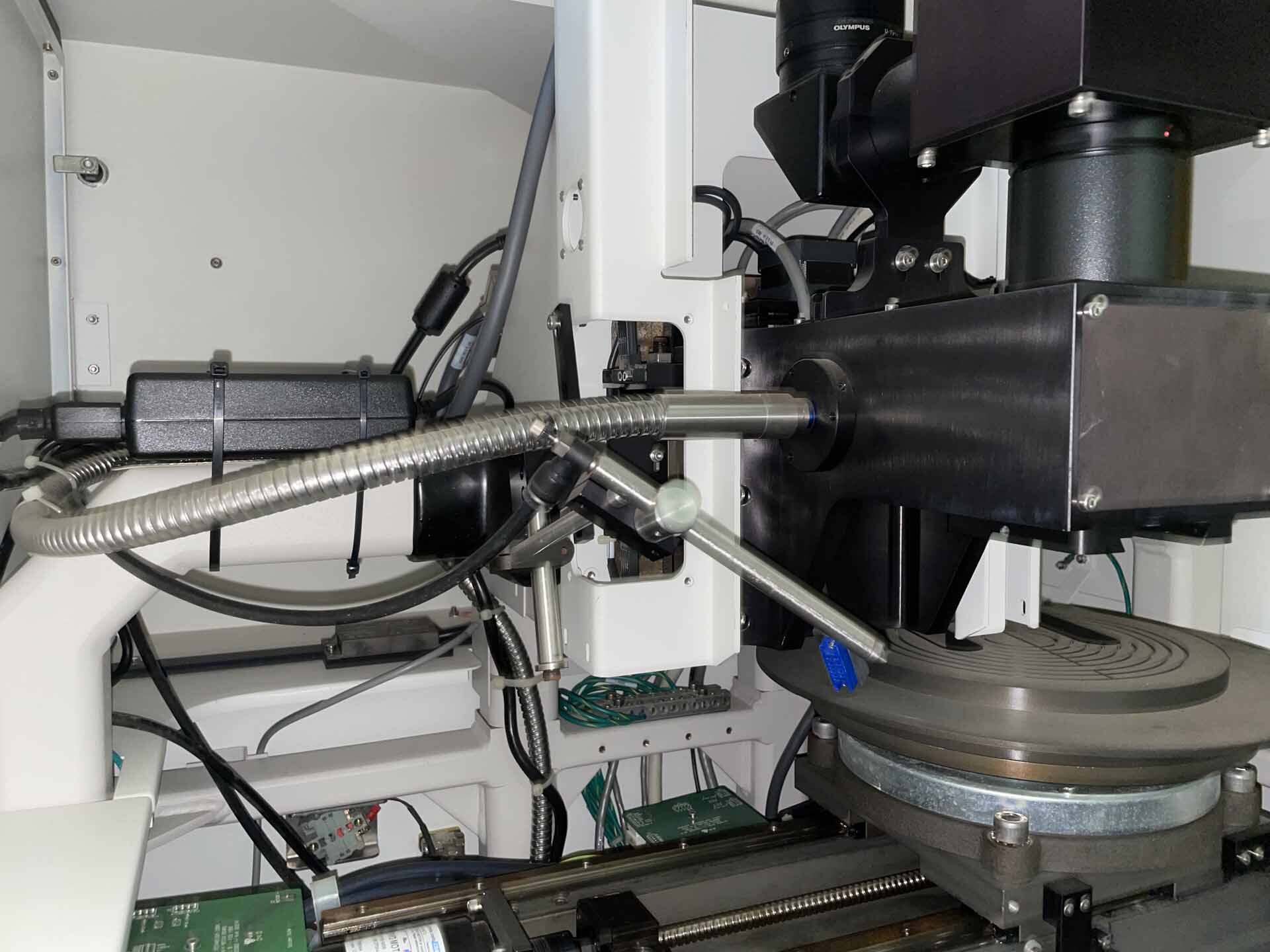

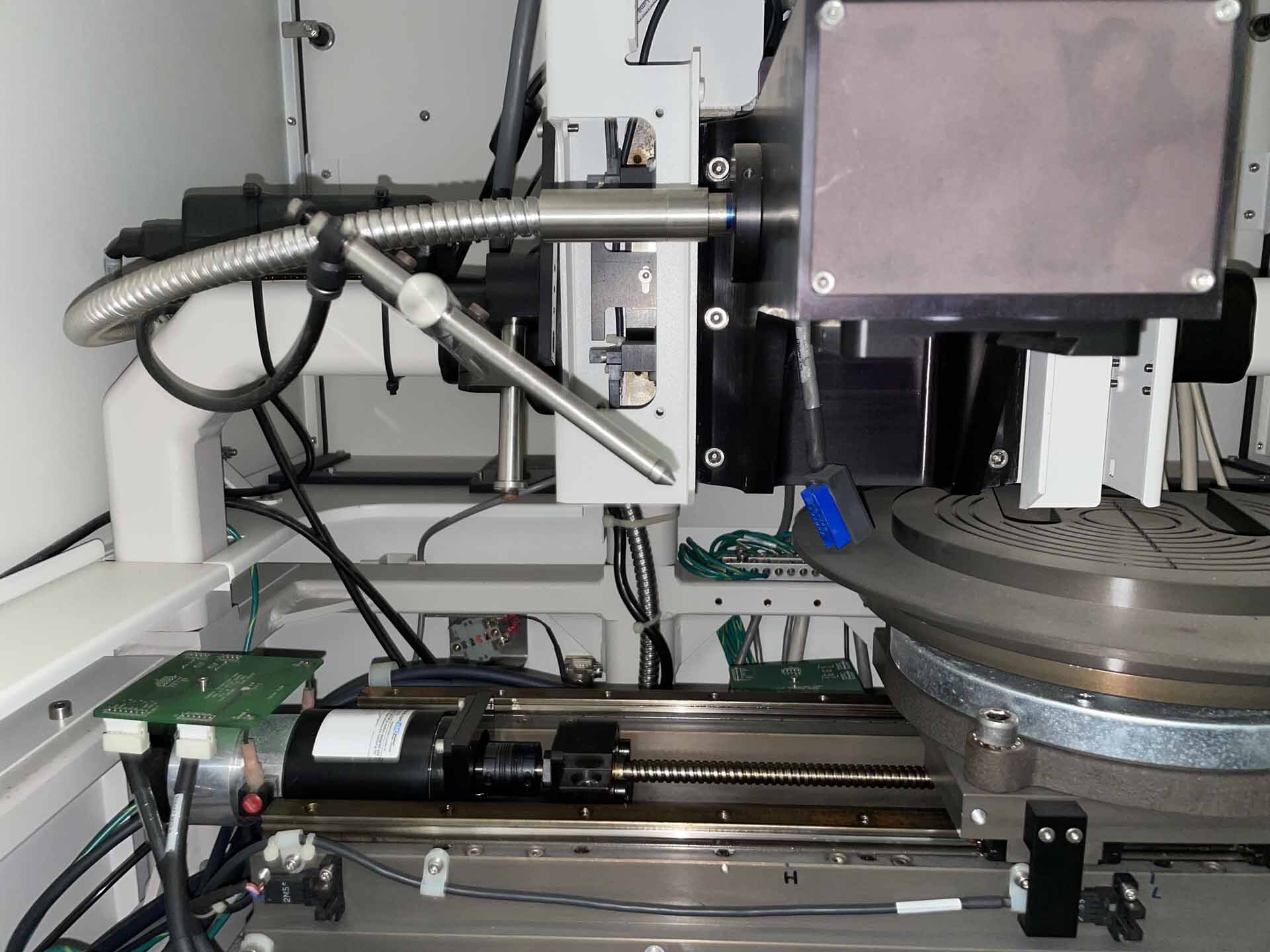

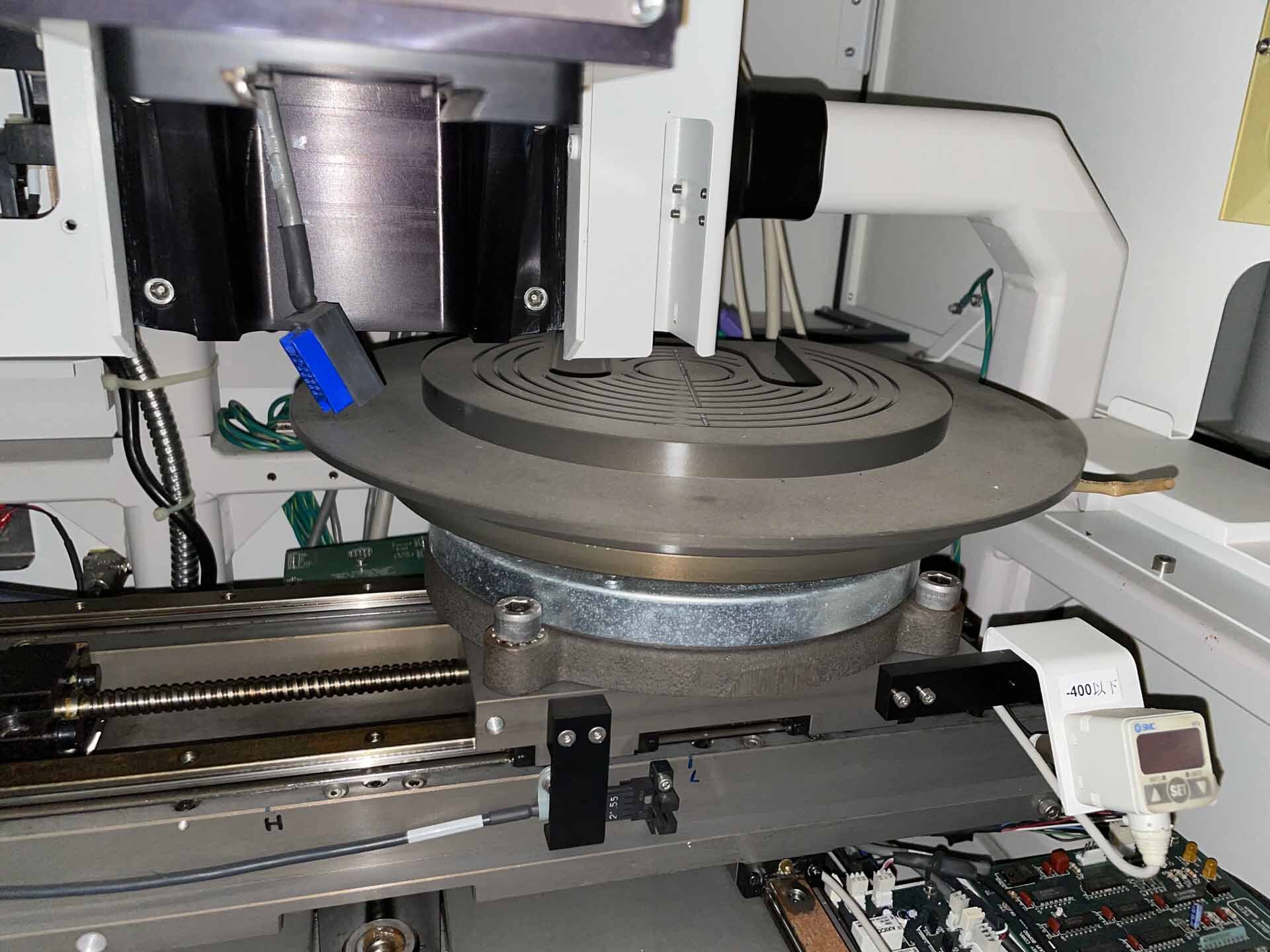

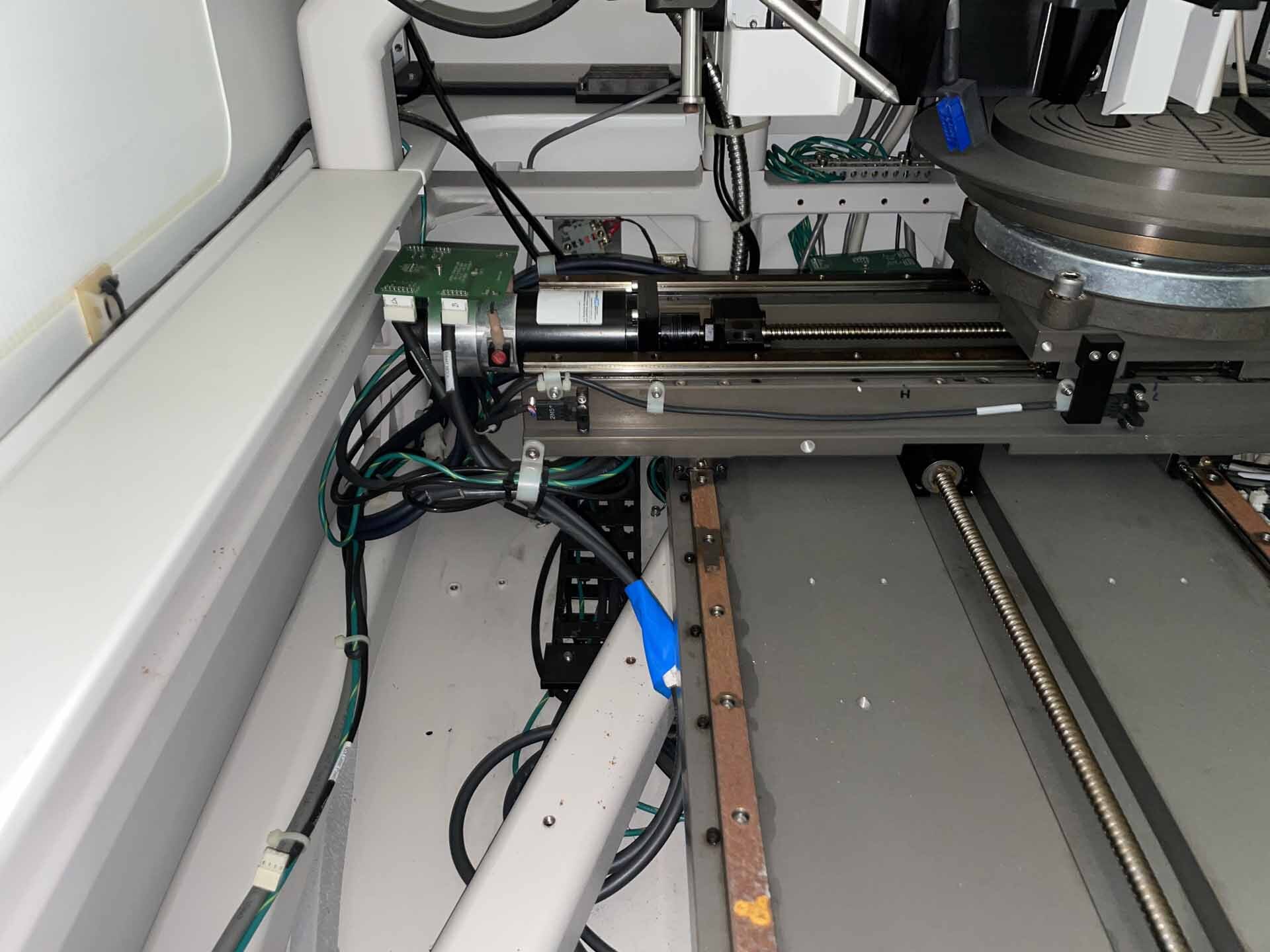

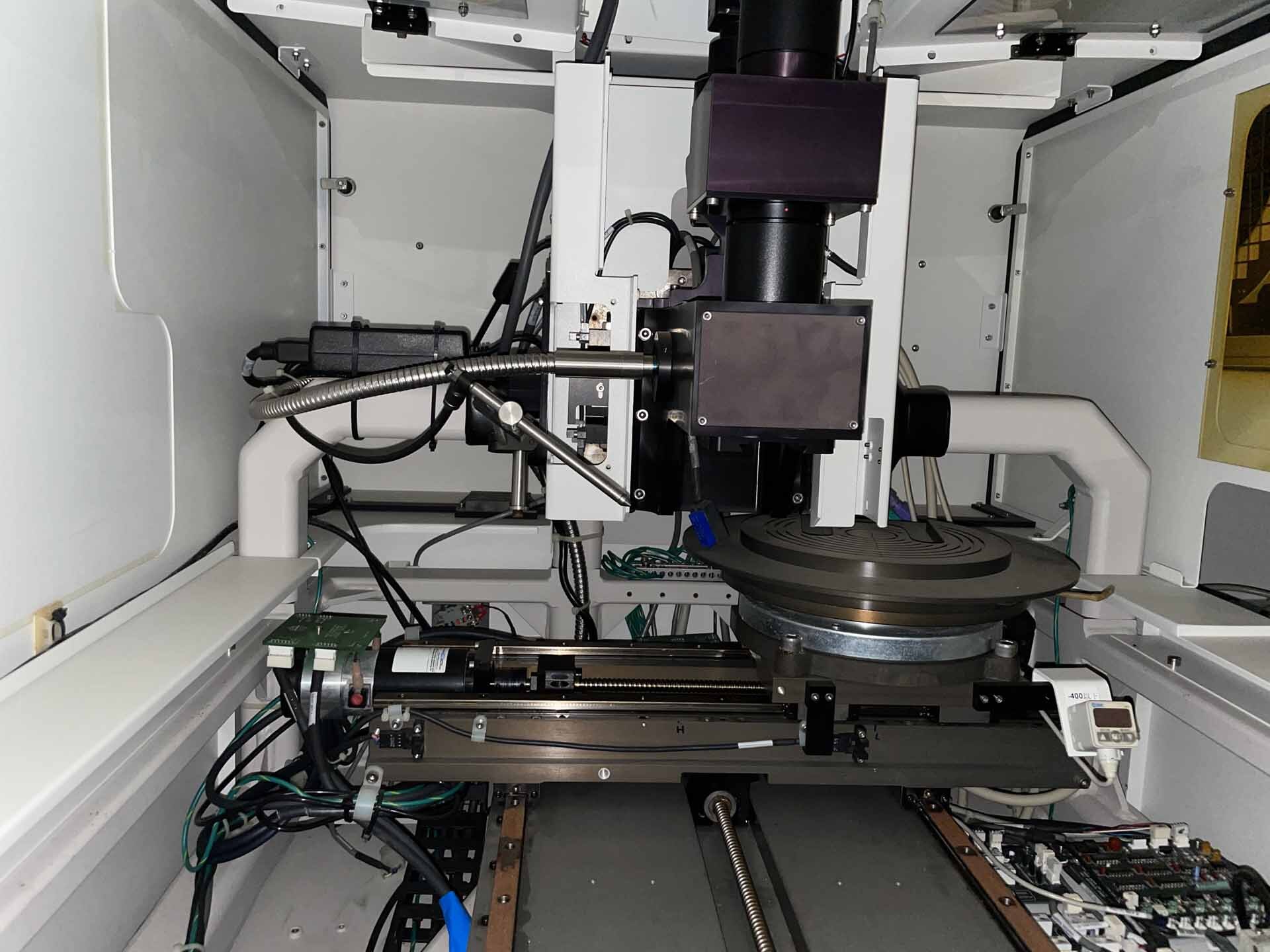

Used RUDOLPH / AUGUST NSX 95 #293635945 for sale

URL successfully copied!

Tap to zoom

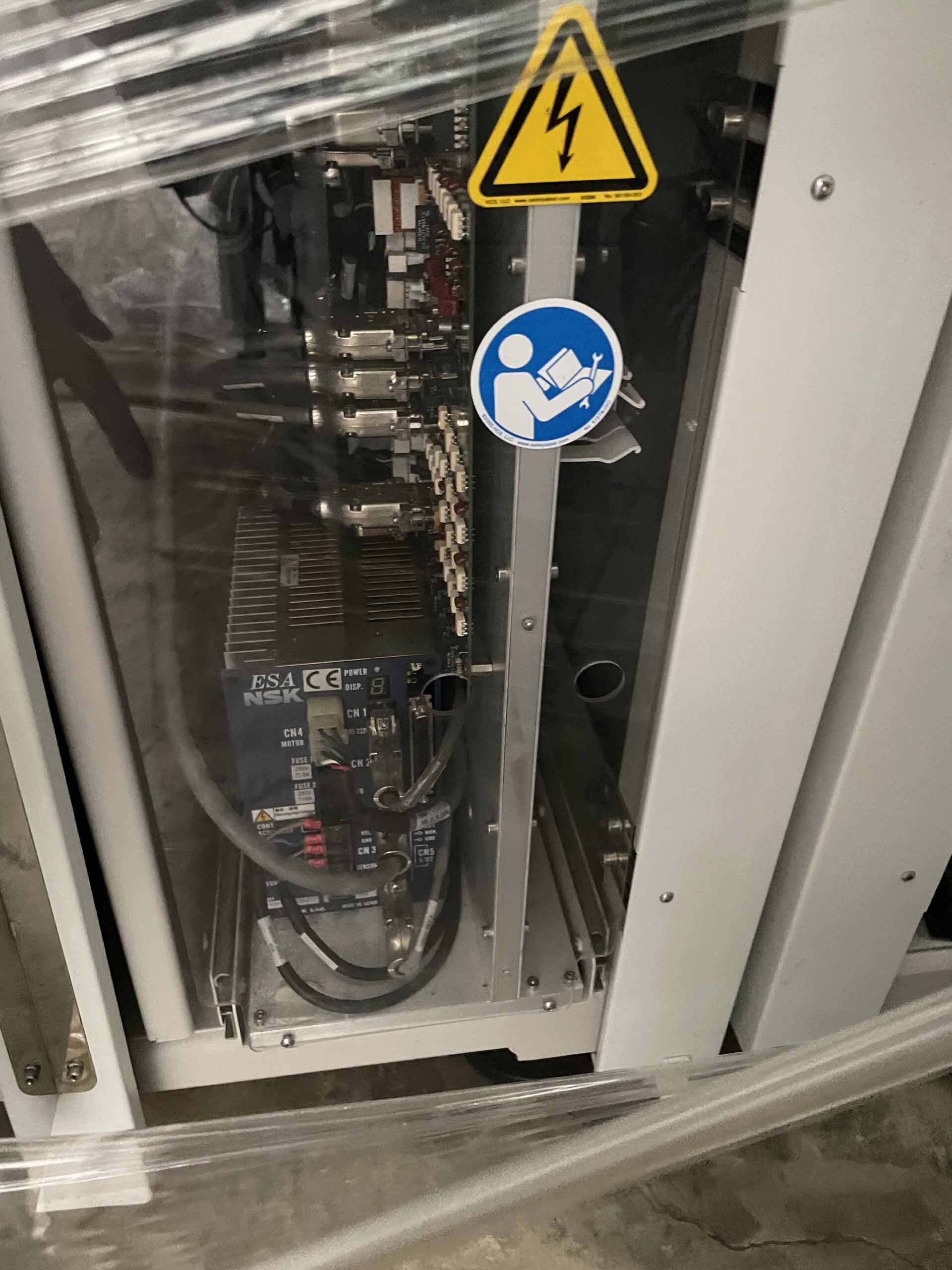

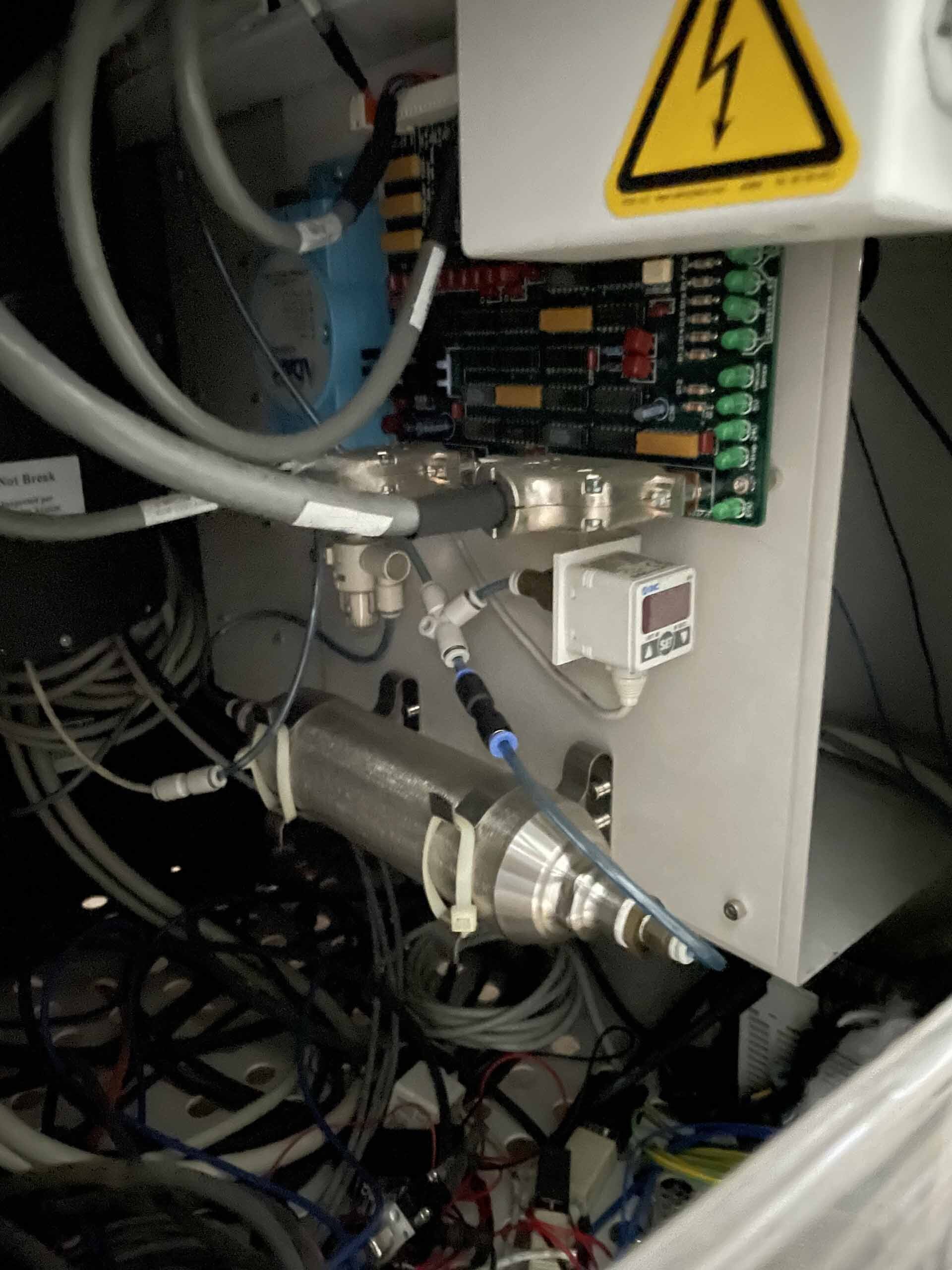

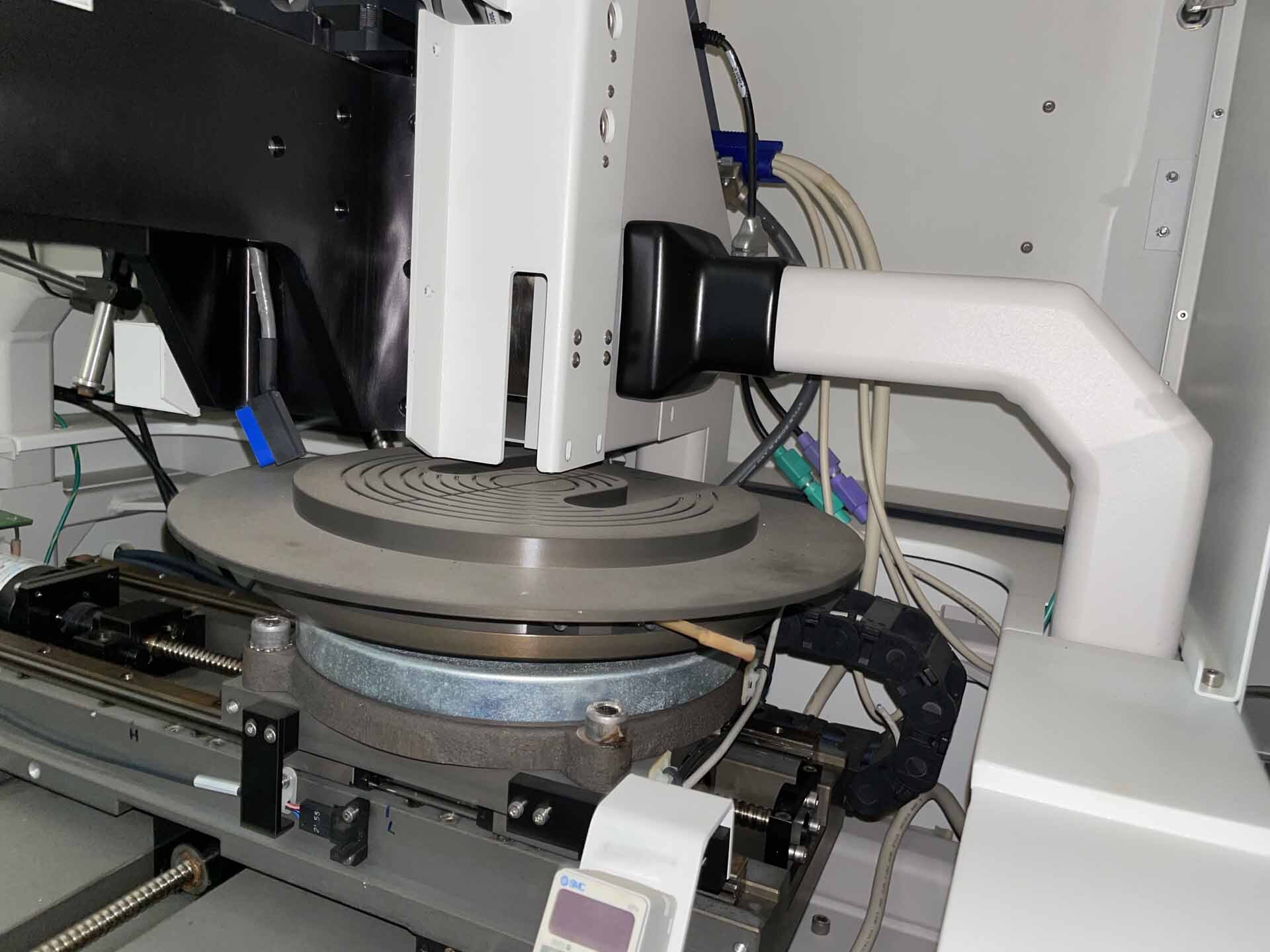

RUDOLPH / AUGUST NSX 95 is a highly advanced Mask and Wafer Inspection Equipment designed and produced by AUGUST Technologies. It is designed to improve the efficiency and accuracy of manufacture of thin-film transistors (TFTs) used in integrated circuit fabrication. AUGUST NSX-95 takes advantage of the most advanced multi-resolution optics and imaging technology, such as RGB microscopy, to identify defects and potential design problems in the mask layers and wafers of the substrates used in integrated circuit fabrication. This system provides exceptional detail, wide field of view, and long working distance for analysis of diverse TFT and device layer geometries with high position accuracy. At the heart of the unit is a high magnification objective with a long working distance, and a precision stage with a large field-of-view, maximum speed and micrometer positional accuracy. The large field of view makes it easy to identify regions with higher concentrations of defects and defects in different fields of view. Additionally, different filters are available to isolate different wavelengths to optimize the contrast of various layers and to minimize any optical aberrations. The spectral selection of a specific wavelength provides a direct comparison between images taken of the same wafer and mask layer, which helps to obtain higher fidelity false color displays. RUDOLPH NSX 95 is also equipped with an array of sophisticated tools that can be used to diagnose defects, including high speed mapping, statistical analysis, and 3D reconstructions. High speed mapping allows engineers to efficiently observe the location and intensity of defects. With this tool, engineers can quickly recognize and identify submicron features on the surface of wafers and patterns in device layers. Statistical analysis can be used to analyze trends in defect levels by comparing different areas of the substrates. 3D reconstruction helps to create a three-dimensional representation of a device or pattern layer at different angles, enabling engineers to quickly analyze deeper design problems that may otherwise have been overlooked. The machine also has a software suite to manage the complete process. RUDOLPH Technologies uses this suite to develop custom recipes for inspecting different mask and wafer layers. It provides an interface for configuring and managing different test scripts, allowing engineers to replicate the results of specific tests. Finally, the companies knowledge base and a class-leading support tool are available to provide rapid replies to customer requests. Overall, RUDOLPH NSX-95 is a powerful and versatile Mask and Wafer Inspection asset that provides engineers with the tools needed to quickly and accurately identify design flaws in mask and wafer layers, allowing them to maximize device production and minimize defects.

There are no reviews yet