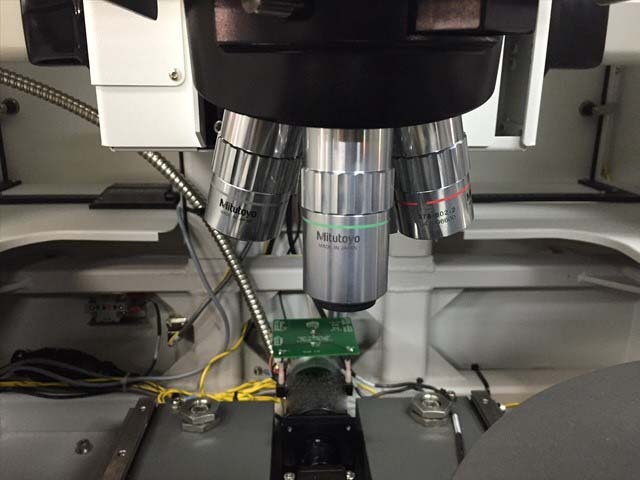

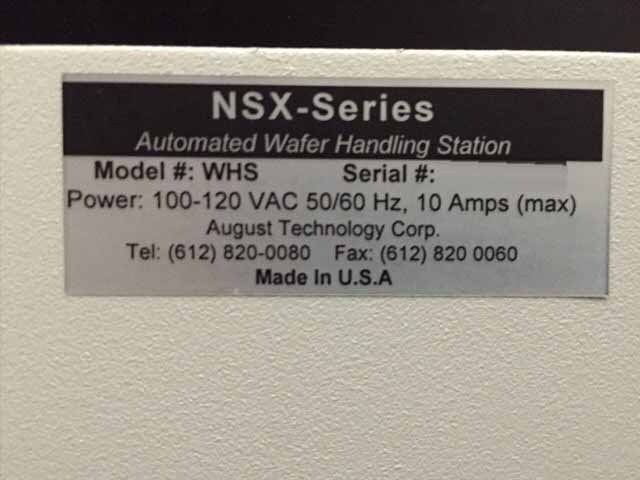

Used RUDOLPH / AUGUST NSX 95 #9150597 for sale

URL successfully copied!

Tap to zoom

RUDOLPH / AUGUST NSX 95 mask and wafer inspection equipment is an advanced and powerful machine developed to provide reliable, high-resolution images to enable detailed inspection of masks and wafers. It is a fully-integrated tool featuring color imaging, pattern alignment, wafer mapping, and image analysis capabilities. AUGUST NSX-95 is designed to inspect masks and wafers in a single step. It features an ultra-high resolution of approximately 18,000-dpi for image capture, allowing for the most detailed inspection available. It also provides high-precision pattern alignment and wafer mapping tools for identifying critical defects. RUDOLPH NSX 95 utilizes a multi-wavelength illuminator for gaining clear images of masks and wafers. This system can accommodate up to 50 wafers per job and features optical image sensors for alignment precision. It also features automatic defect analysis, statistically-based defect-sizing and measurement, defect-classification tools, and advanced defect displays to provide users with the maximum level of detail. RUDOLPH NSX 95 also includes touch-screen user interface with intuitive navigation. This helps minimize user fatigue and increase efficiency. Additionally, the software integrates defect-location data into popular standard and custom defect-tracking databases. In addition to being a reliable mask and wafer inspection unit, AUGUST NSX 95 can also analyze, classify, and optimize data. This allows users to automatically detect and resolve imperfections by analyzing patterns, determining areas of flatness, and measuring volume, length, width, and height of defects. Furthermore, users can perform accurate yield analysis, and compare test results to expected results, enabling them to quickly and accurately identify and solve problems throughout their production cycle. Overall, RUDOLPH NSX-95 mask and wafer inspection machine is an advanced machine designed for high-resolution inspection. It features color imaging, pattern alignment, wafer mapping, image analysis, and automatic defect analysis capabilities. Additionally, its user-friendly touch-screen user interface provides intuitive navigation and the integrated defect-location data into popular defect-tracking databases. These versatile features make AUGUST NSX 95 the perfect choice for all mask and wafer inspection needs.

There are no reviews yet