Used RUDOLPH / AUGUST NSX 95 #9171287 for sale

URL successfully copied!

Tap to zoom

ID: 9171287

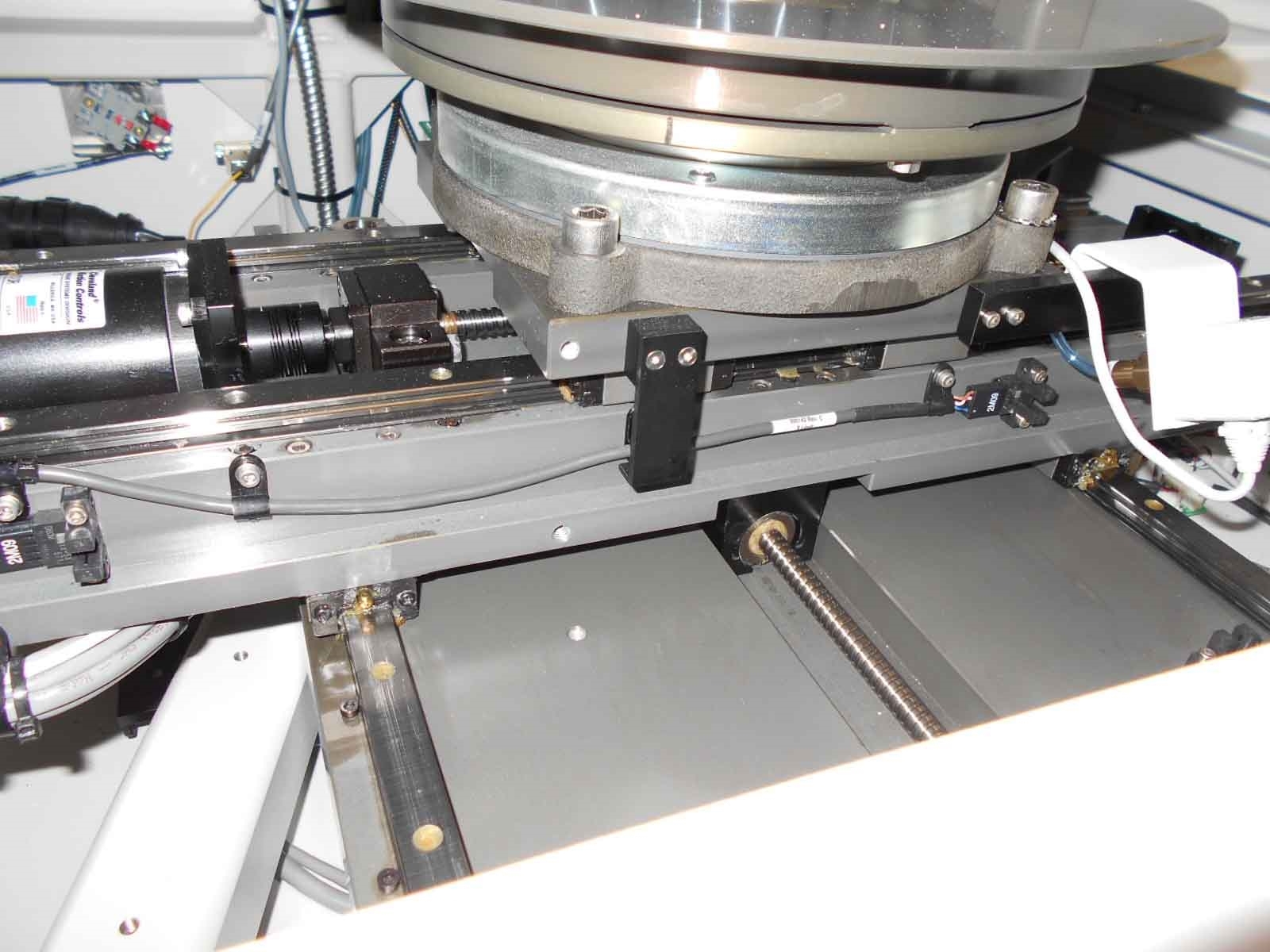

Wafer Size: 4"-8"

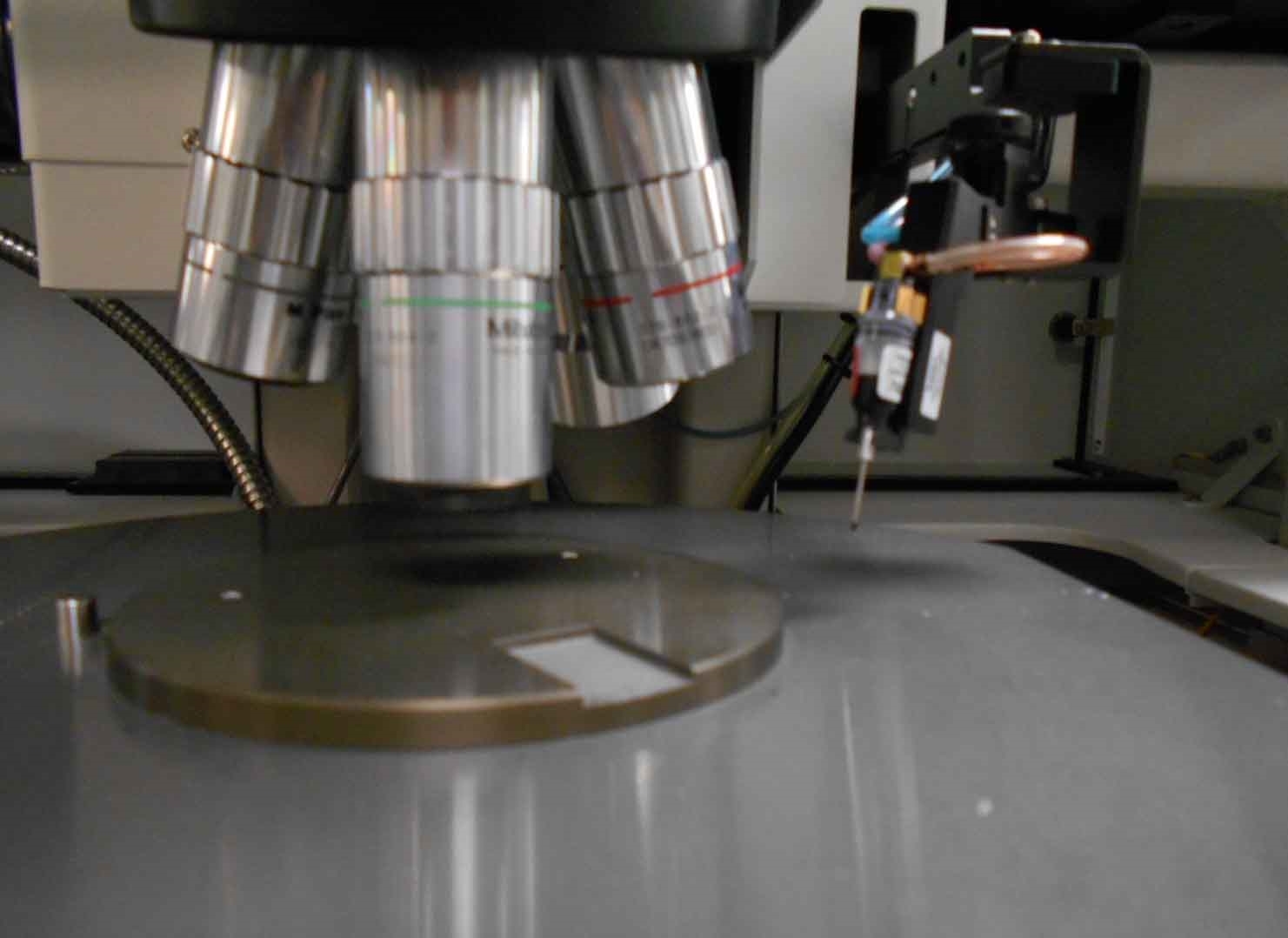

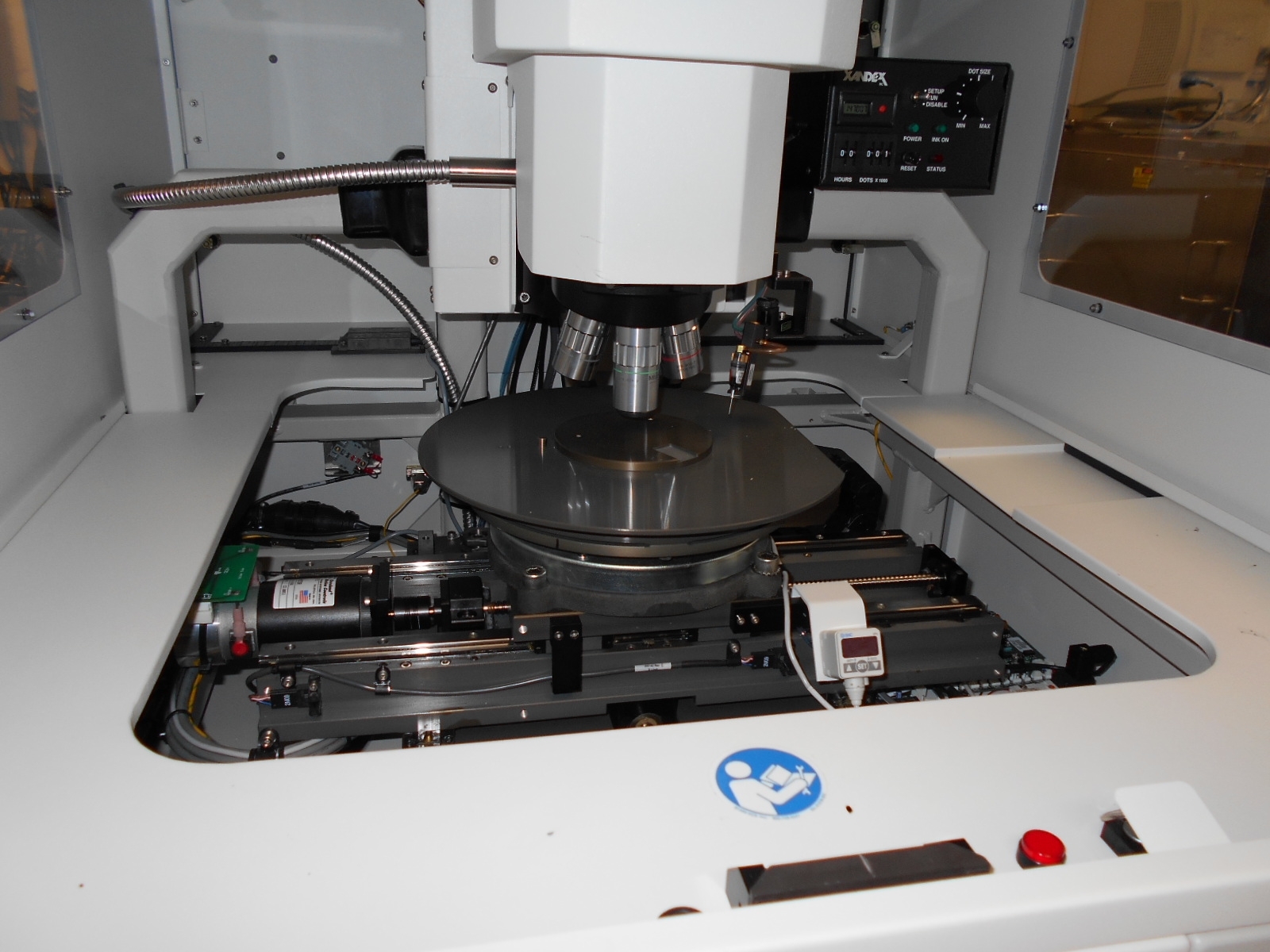

Micro defect inspection system, 4"-8"

Matrox Genesis 3.1

2D And 3D autofocus pump inspection

Operating system: Windows XP

OCR

Camera: SONY 9100P

Hard Disk Drive (HDD): 300 GB

No Ionizer

No Robot

Data transfer: Stick, floppy, CD

GENESIS Broad.

RUDOLPH / AUGUST NSX 95 mask and wafer inspection equipment is an innovative, high-performance inspection platform optimized for automated inspection of microchips. Its design supports a broad range of applications in microchip manufacturing. AUGUST NSX-95 is capable of inspecting wafers up to 450 mm in diameter and can process wafers with a range of thicknesses and materials. The system is designed to accurately measure fine features such as transfers, line dimensions, contact openings, and alignment. It is a reliable and accurate inspection unit that performs defect detection, as well as review and comparison of critical components. RUDOLPH NSX 95 includes a two-dimensional area sensor, four-dimensional surface topography, LCD display and multi-channel surface imaging which makes it ideal for optical inspection. The machine can capture the specific coordinates of multiple points on the surface of a microchip or an integrated circuit, and it can also detect a wide range of defects. The tool can be configured according to the needs of the application and it can also be programmed with specialized algorithms to inspect microchips. NSX 95 comes with a number of features that help ensure accuracy and reliability. It offers high-speed operation, a low defect inspection rate, and a low defect miss rate. The asset also includes a 500 megapixel non-contact CCD sensor to ensure more accurate measurement. The CCD sensor also helps with defect-detection accuracy and it is designed to be able to process three chips simultaneously. RUDOLPH / AUGUST NSX 95 is designed with a user-friendly interface that can be modified to suit the specific application and the user's preferences. It comes with a detailed instruction manual and is also available with a two-year warranty. AUGUST NSX 95 is a state-of-the-art mask and wafer inspection model. It is engineered for precision and accuracy, and is perfect for automated inspection of microchips. The equipment is highly reliable and can be programmed with specialized algorithms to inspect microchips. The system features a broad range of features, low defect inspection rate, and a low defect miss rate. It is user-friendly and comes with a two-year warranty, making it an excellent choice for manufacturers looking for a reliable and accurate inspection unit.

There are no reviews yet