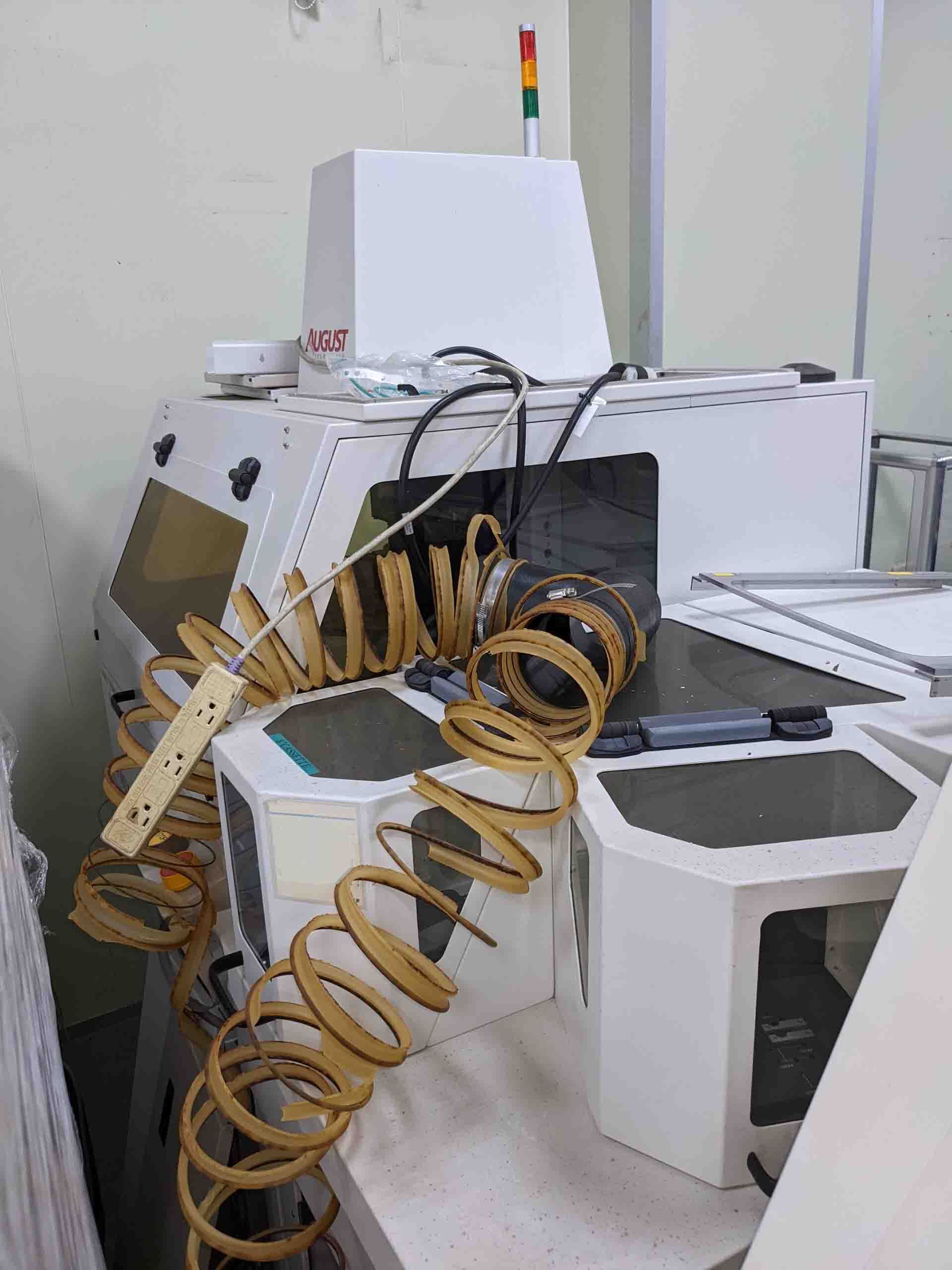

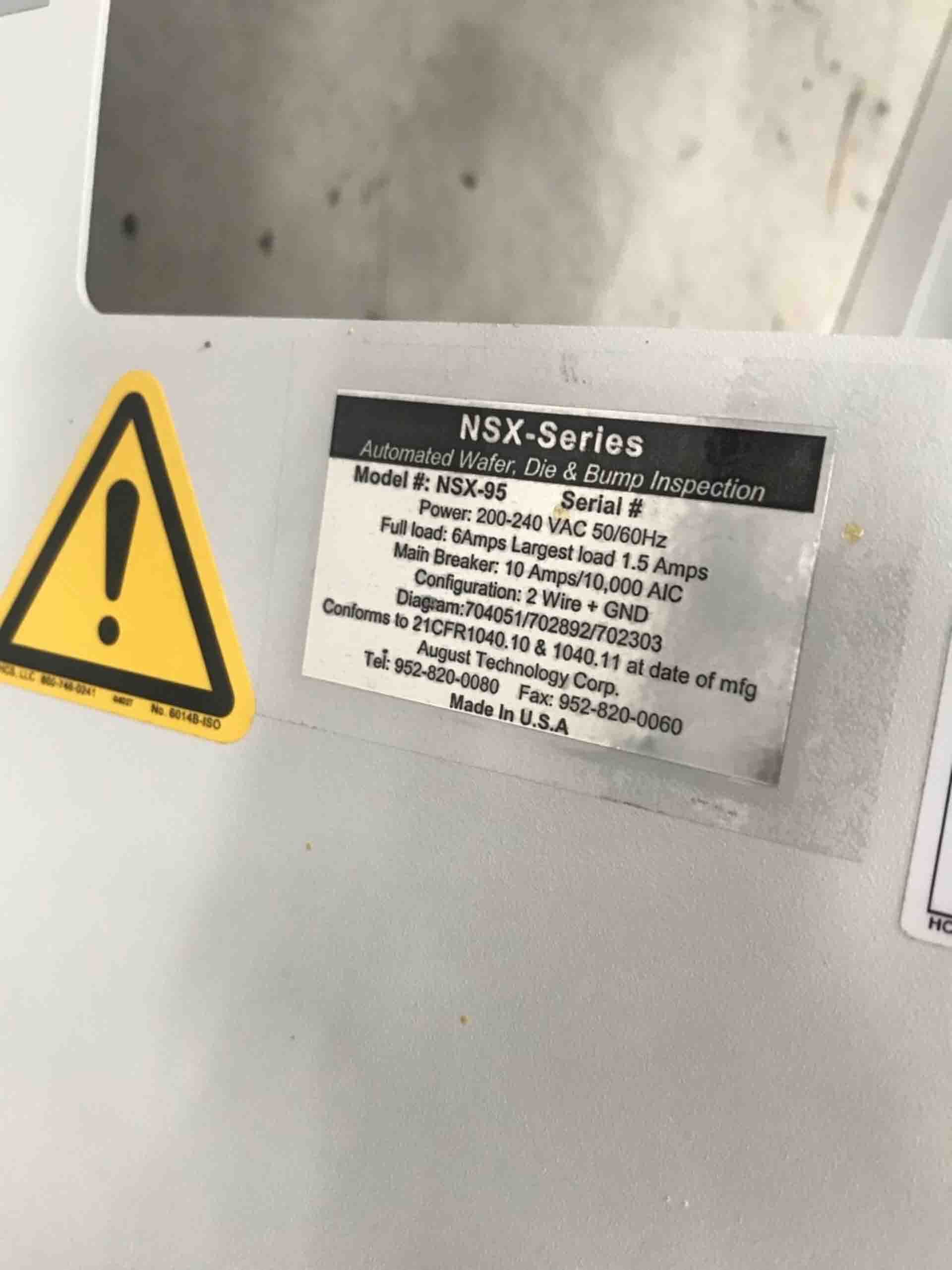

Used RUDOLPH / AUGUST NSX 95 #9206625 for sale

URL successfully copied!

Tap to zoom

RUDOLPH / AUGUST NSX 95 mask and wafer inspection equipment is a high performance, automated optical lithography tool used in semiconductor manufacturing. It is designed to perform accurate and fast inspection of reticle and wafer masks. AUGUST NSX-95 provides a comprehensive set of advanced, non-destructive defects detection, characterization, and analysis capabilities, allowing for rapid characterization and fine tuning to meet customer requirements and specifications. RUDOLPH NSX 95 consists of several setup stages to customize the inspection for a particular mask type, such as those found on reticles and wafers. The wafer transport system is used to move the mask into place and secure it on the surface stage. Next, the reticle is placed onto the surface stage and aligned so that the center of the image can be matched exactly with the surface of the wafer. Once the reticle is properly placed, an optical alignment unit scans the reticle to ensure the highest accuracy of results. The resolution of RUDOLPH / AUGUST NSX 95 machine's optical elements is higher even than competing systems to ensure quicker, more accurate inspection. This allows for more accurate checks of alignment between mask elements and the surface of the corresponding wafer. It also provides an extended depth of focus. This extended depth of focus allows the inspection tool to identify features hidden in grooves and trenches that may not be readily visible to the naked eye. Additionally, NSX 95 boasts of advanced defect detection capabilities. The asset is programmed with sophisticated algorithms to locate defects that encompass electrical, optical, or structural categories. It is capable of detecting and distinguishing between organic, inorganic, lattice, or structural defects. Various settings allow users to differentiate between different defect categories and the process time can be expedited with the automated setup. In addition to defect detection metric, AUGUST NSX 95 provides comprehensive performance analysis. It evaluates key parameters such as signal-to-noise ratio, contrast ratio, defect image contrast, and defect size. Furthermore, the model can accurately simulate print areas that are more than ten times the size of the field of view. This advanced simulation capability enables engineers to predict printability and performance of large-area designs. NSX 95 is an invaluable tool for inspecting and analyzing reticle and wafer masks. Its combination of optical alignment and advanced defect detection capabilities make it supremely suitable for high-volume production. Its extended depth of focus and in-depth performance analysis are sure to increase production reliability.

There are no reviews yet