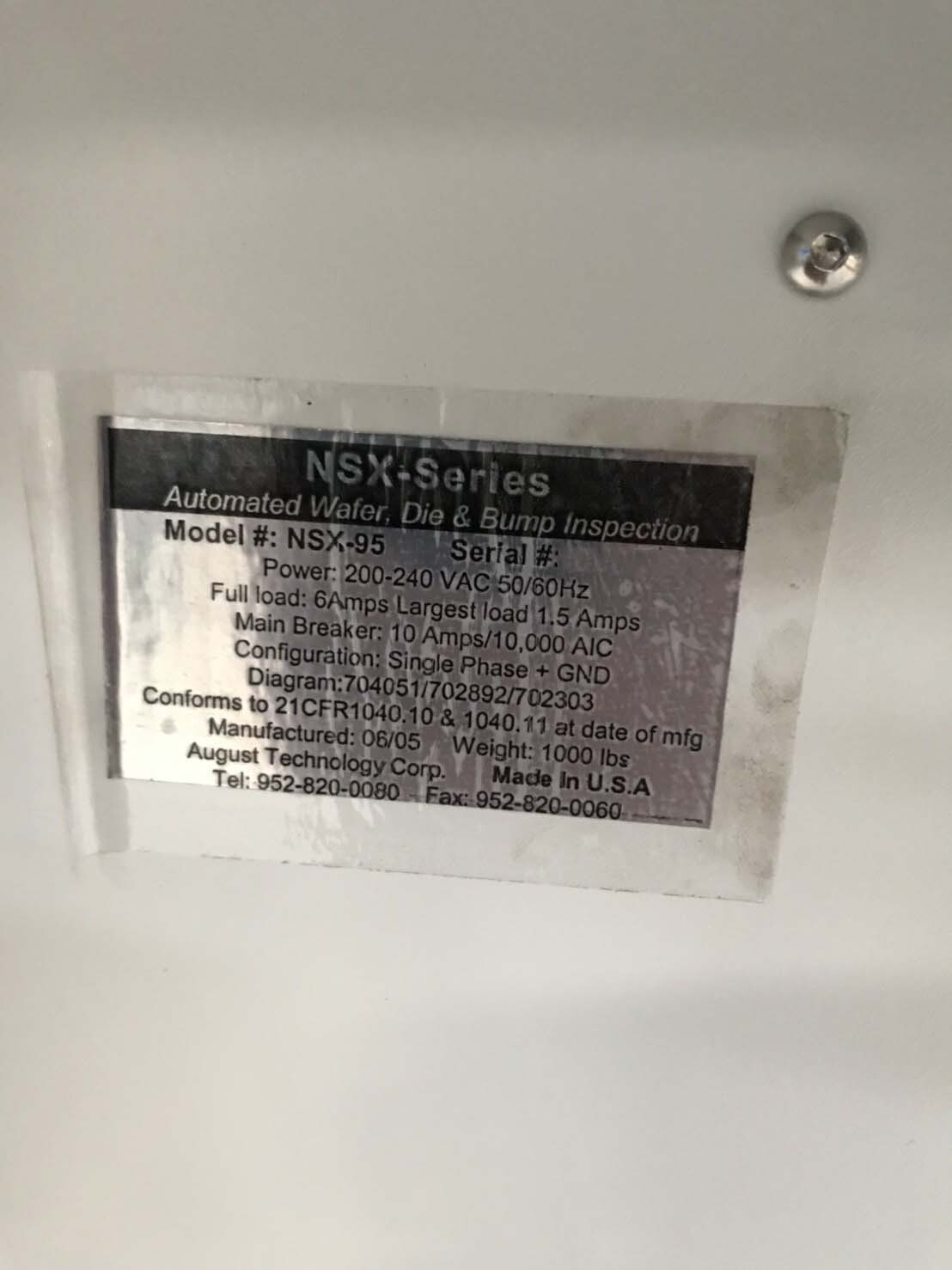

Used RUDOLPH / AUGUST NSX 95 #9253101 for sale

URL successfully copied!

Tap to zoom

ID: 9253101

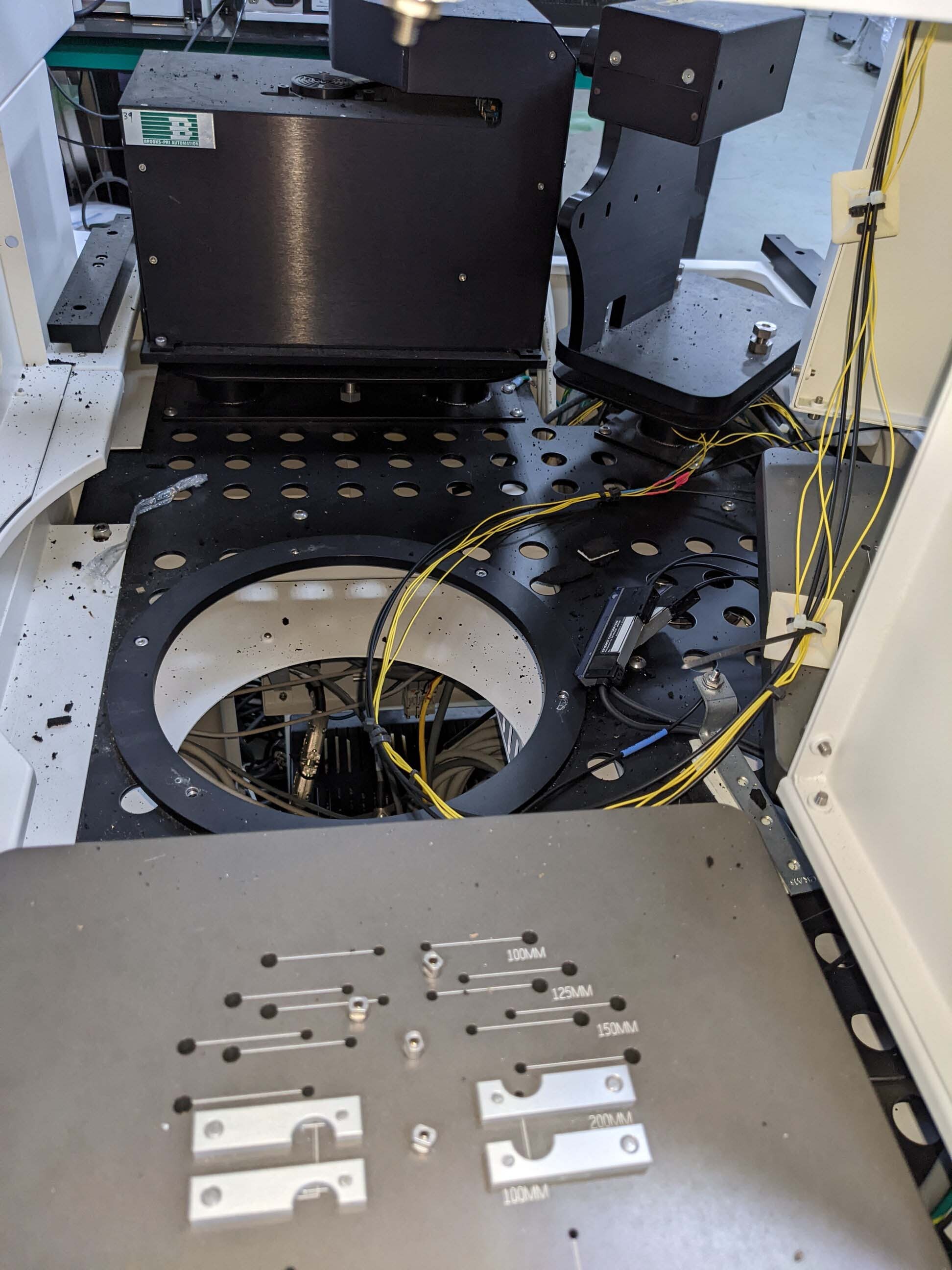

Wafer Size: 8"

Vintage: 2005

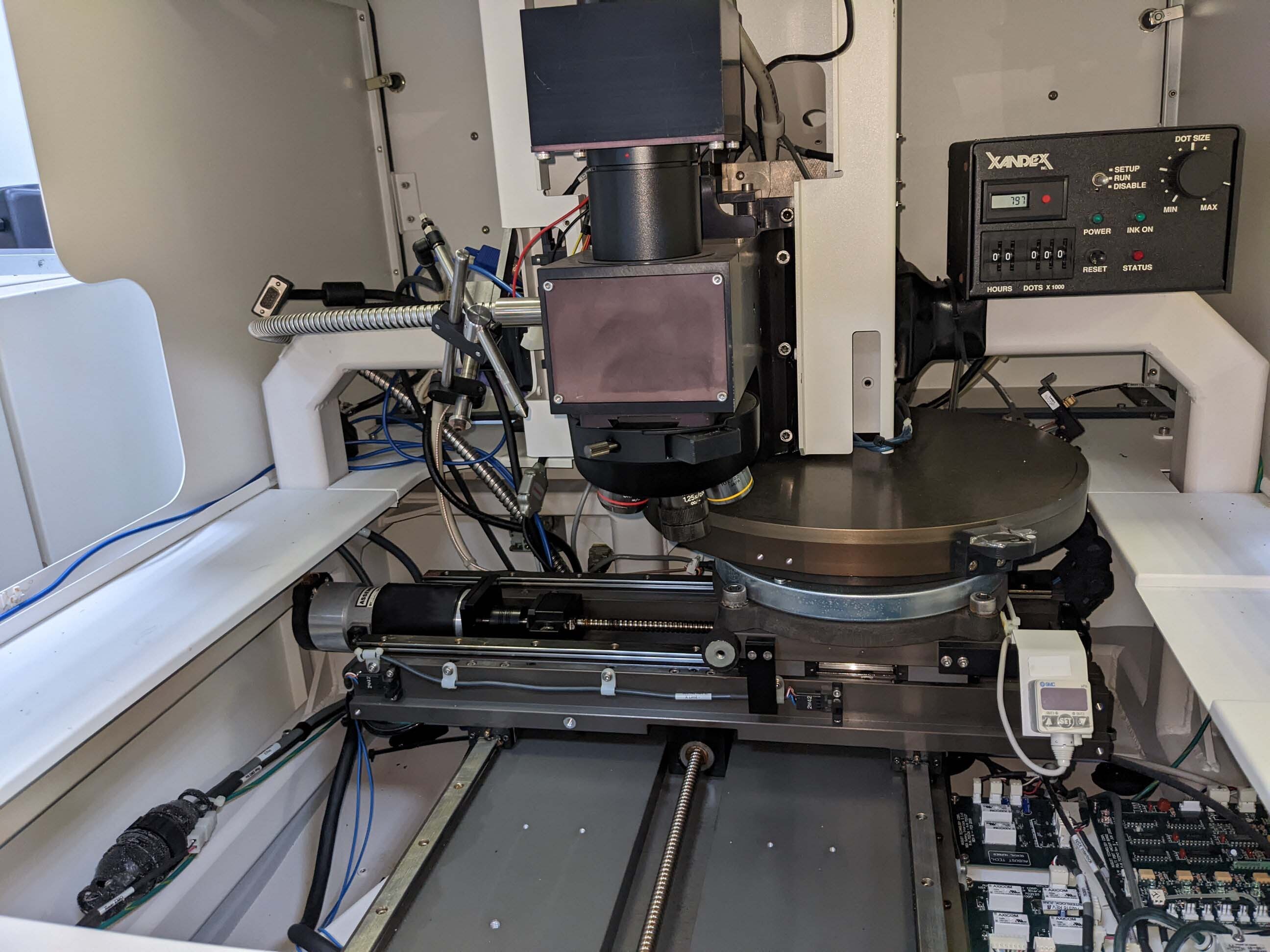

Defect inspection systems, 8"

Manual load type

2005 vintage.

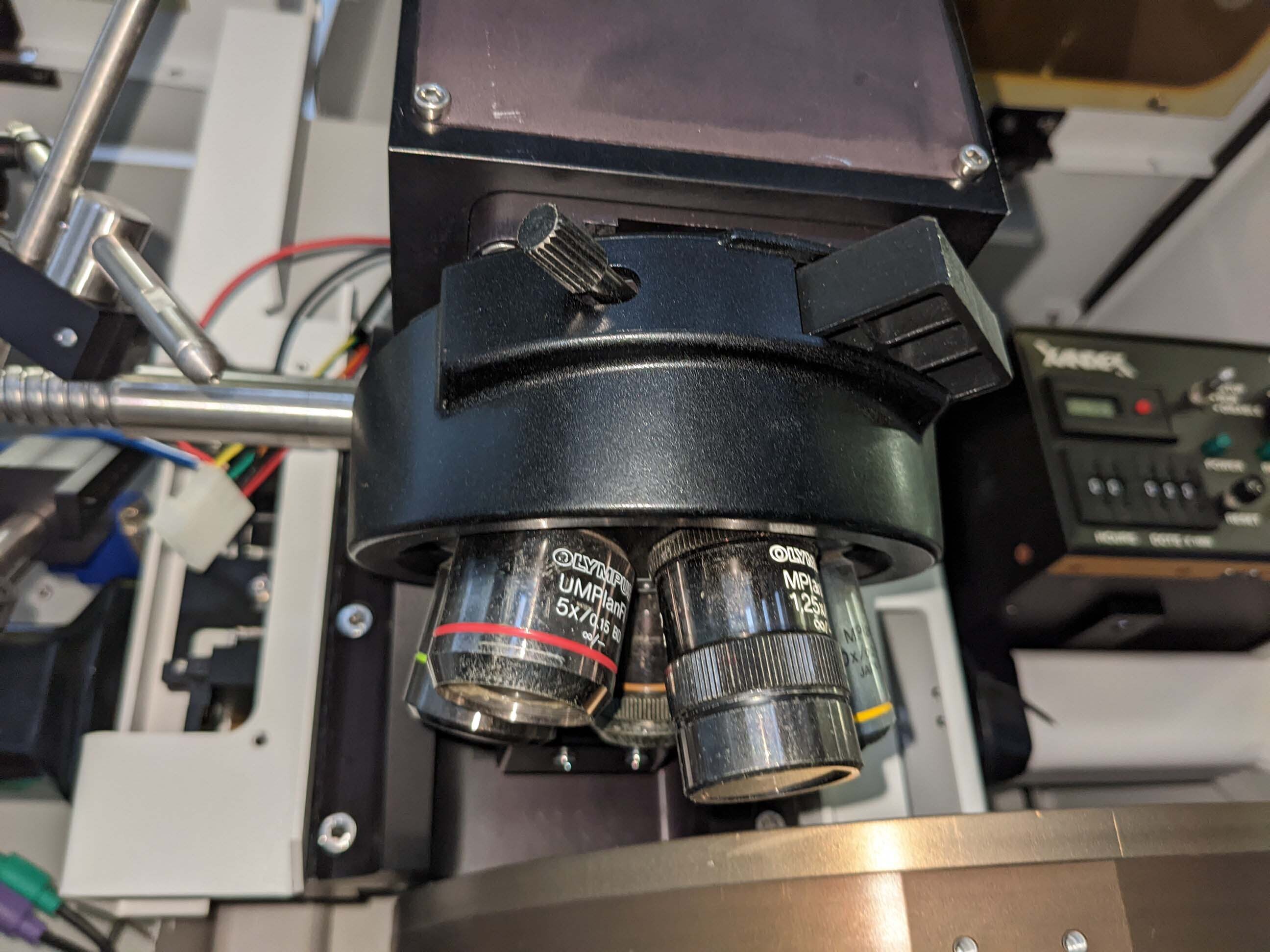

RUDOLPH / AUGUST NSX 95 is a highly advanced, state-of-the-art mask and wafer inspection equipment. It is designed to inspect lithography masks and their corresponding wafers within minimum time, in order to detect any potential defects that could affect their performance. AUGUST NSX-95 comes with a high resolution optical system, featuring an impressive Magnification rate (up to 400x). It includes both an emission and a fluorescence subsystem, allowing it to detect various types of defects. The whole image-capture process is fully automated. The unit is equipped with a number of advanced processing algorithms, that allow for a fast and precise inspection. This includes identifying defective devices, and highlighting them for possible redraw or repair. The algorithms are highly configurable, allowing for a wide range of material content and pattern sizes. The inspection machine can be integrated with other external devices, such as a SMIF (Standard Mechanical Interface Format) load-lock, and other automated systems. This allows for a more efficient cycling process, and reduces the time between individual device inspections. RUDOLPH NSX 95 tool is highly reliable, and can operate 24 hours a day, 7 days a week, or even continuously if required. This is due to its self-monitoring processes and specific protective features. It features a fully documented Software Development Kit and API, as well as integration with the third-party software. Overall, AUGUST NSX 95 is an advanced, cost-effective, and reliable mask and wafer inspection asset. It ensures a fast, accurate, and automated inspection process, and can easily be integrated with other devices. Its advanced algorithms guarantee high-quality and defect-free devices, and its flexibility allows for customized inspections.

There are no reviews yet