Used RUDOLPH / AUGUST NSX 95 #9410387 for sale

URL successfully copied!

Tap to zoom

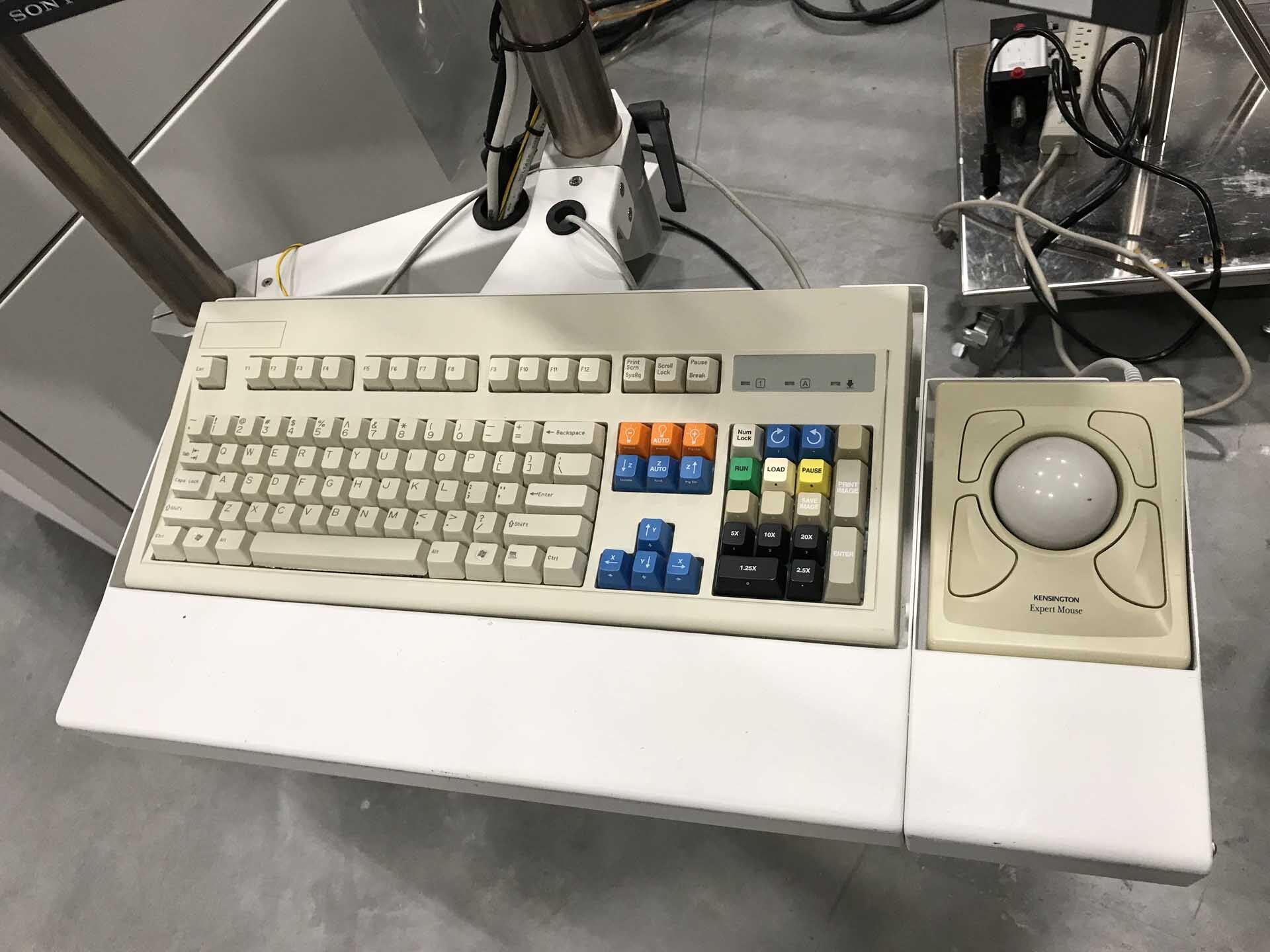

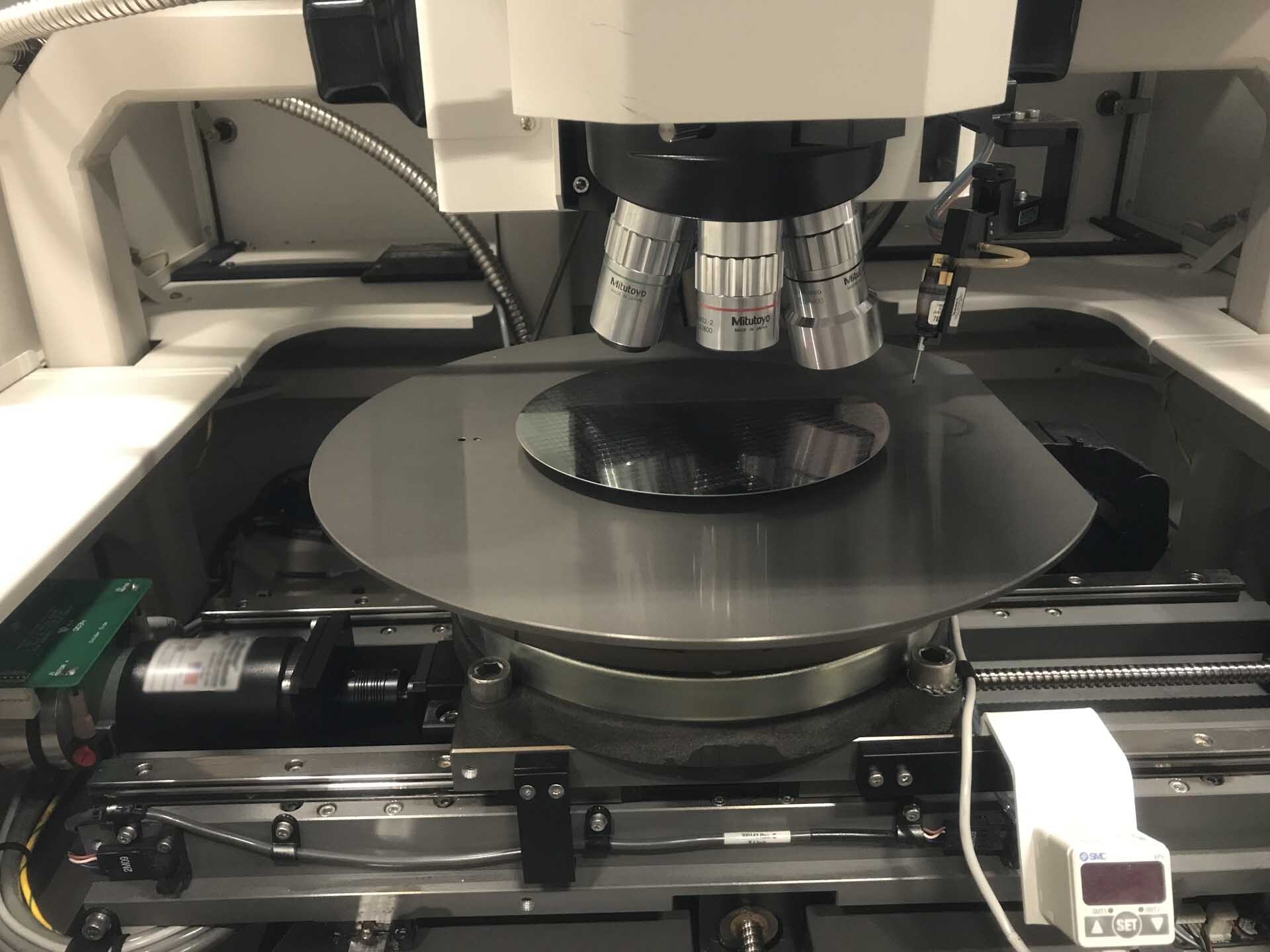

RUDOLPH / AUGUST NSX 95 is a device designed to ensure the accuracy of mask and wafer inspection in the manufacturing of micro-electronic devices. It was first developed and introduced in 1995, and has since undergone several minor updates, enhancing both its performance and user experience. AUGUST NSX-95 utilizes a set of high-precision lenses, cameras and integrated software to detect potential defects in mask and wafer panels. The device is able to recognize a variety of different defect types, including scratches, points, spots, ridges, etc. In addition, its sophisticated software is able to automatically detect and separate defect images, and simultaneously inspect multiple panels in a single operation. RUDOLPH NSX 95 offers several features which improve the efficiency of the inspection process. For example, it is able to quickly register the detected frame position, registration area and size of the wafer panel at the start of the inspection operation. Additionally, its two-axis scan axis driving mechanism enables it to simultaneously operate at a high speed and accuracy, while its built-in, adjustable lighting ensures you are able to correctly detect extremely small defects that would not be visible using ordinary lighting. Furthermore, its modular construction allows users to easily extend or customize the system by connecting an inspection system module and other units. Additionally, NSX 95's integrated software makes it easy to analyze and manage the operation, with an array of functions such as system log management, reporting and defect mark coding. Overall, NSX 95 is an incredibly reliable and versatile machine for mask and wafer inspection. Its combination of high-precision lenses, cameras and user-friendly software make it an ideal choice for those looking to efficiently manufacture high-quality micro-electronic devices.

There are no reviews yet