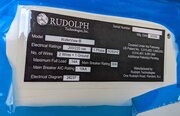

Used RUDOLPH / AUGUST WV320 #293587810 for sale

URL successfully copied!

Tap to zoom

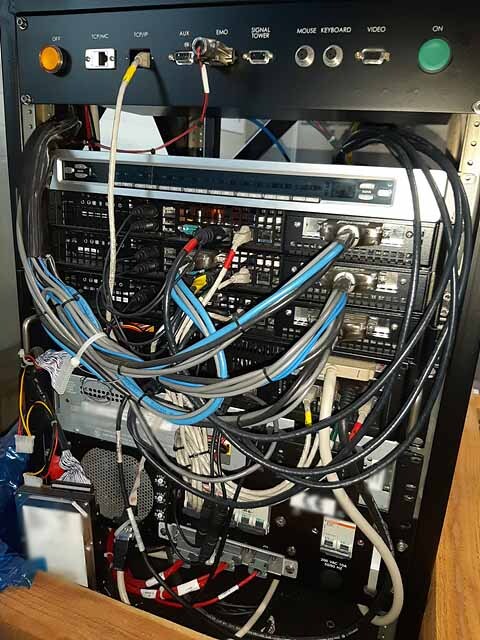

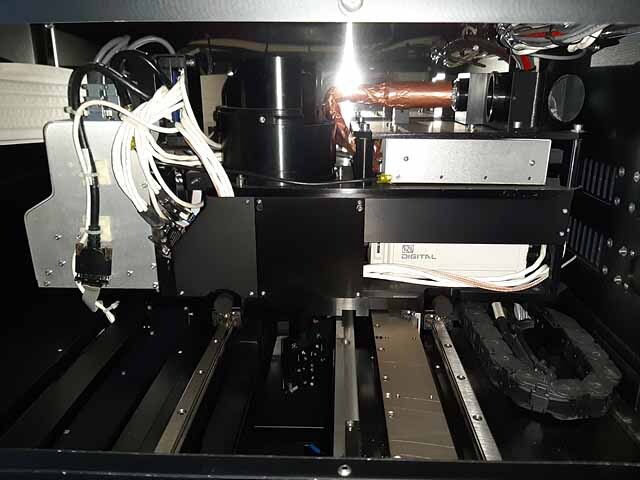

RUDOLPH / AUGUST WV320 is a revolutionary, integrated mask and wafer inspection equipment. The system consists of a unique optical interferometer based inspection head that is mounted onto a high precision CNC-controlled scanning stage. The scanning stage is computer-controlled and can move up to three independent axes. Each axis is capable of translating the head up to 5 millimeters in the x, y, and z directions. The unit uses a solid-state interferometer consisting of a light source, lens, eyepiece, and polarization cube. The polarization cube is used to direct light to and from the surface of the mask or wafer to be inspected. The light that is reflected off the surface is collected by the lens, allowing for image acquisition. AUGUST WV320 machine can inspect both flat and curved wafers and masks with high accuracy. The tool is designed for sub-micron inspections with a measurable resolution of 0.25 microns. The inspection speed is adjustable ranging from 0.5 to 3.5 Hz, dependant on the size of the wafer or mask being inspected. The asset can detect defects ranging from rounding, cracking, chipping and side wall failures, to excessive wear on the glass cover plate. The model can also measure features such as sidewall geometry, hole size and pitch, micro-vias, tracks, grids, and other features. In addition to defect and feature measurements, the equipment has the unique capacity of providing both quantitative and statistical binary data. This is especially beneficial when evaluating dispersed feature patterns. The system is also equipped with specialised software enabling it to detect defect distributions and other features when inspecting a sample. The software also features auto-calibration routines for faster defect detection. RUDOLPH WV 320 unit is a reliable and user-friendly inspection machine for wafer and mask applications. It provides fast, accurate and repeatable defect detection and feature measurements with a resolution that is suitable for all semiconductor applications. The software within the inspection tool adds the ability to identify defect distributions and complex patterns with ease, making WV 320 an ideal choice for today's demanding semiconductor industry.

There are no reviews yet