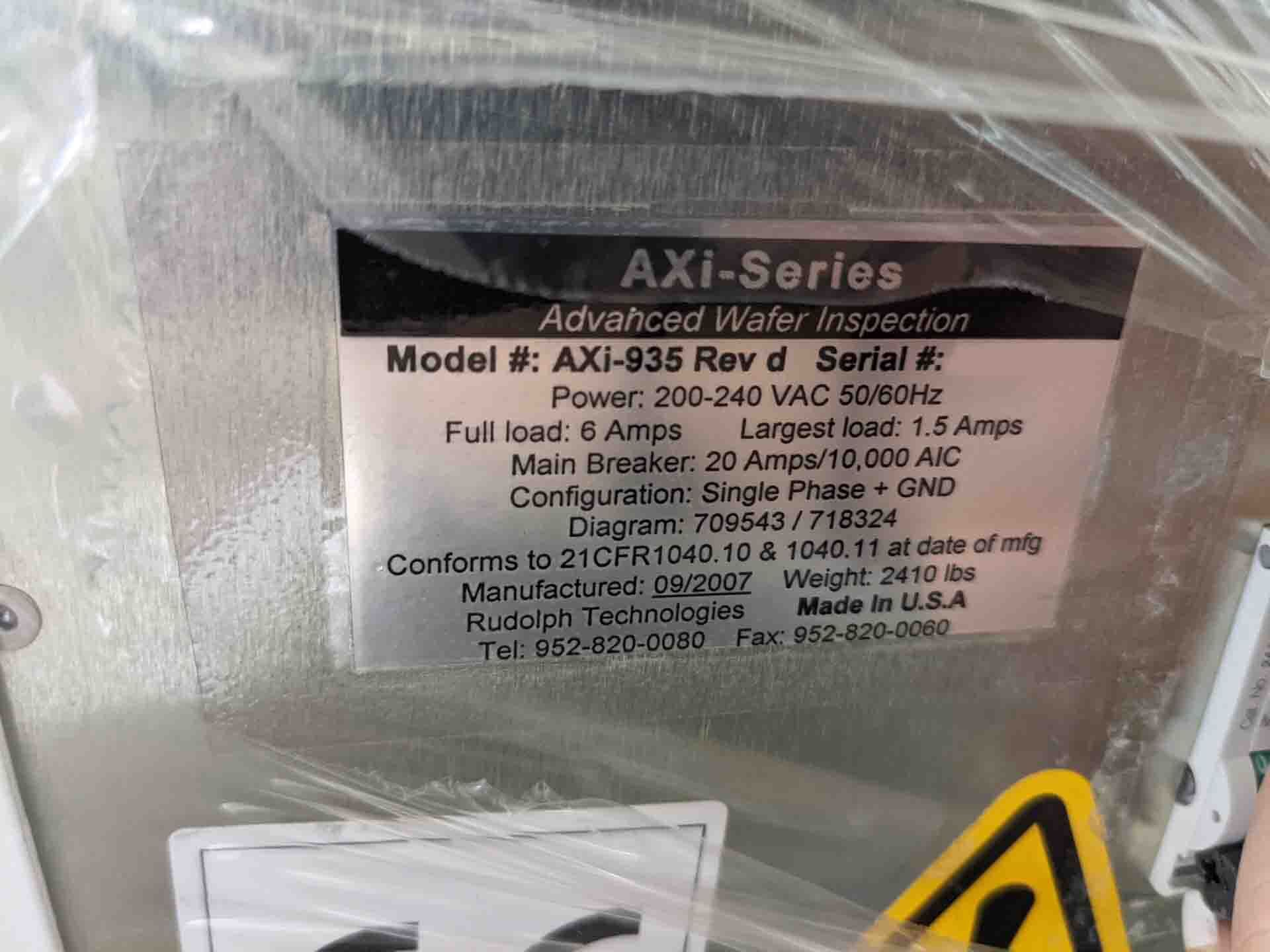

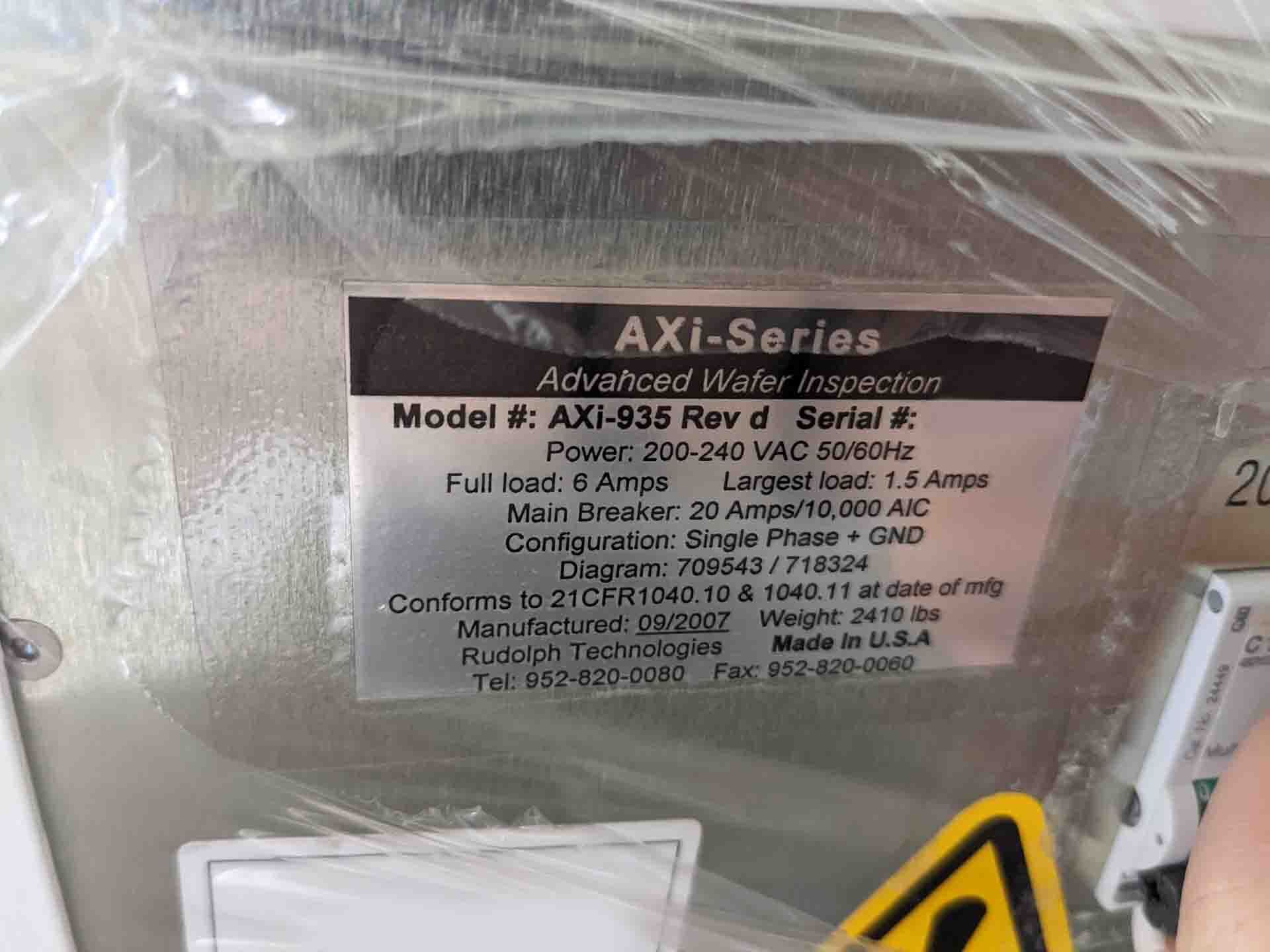

Used RUDOLPH AXI-935D #9385106 for sale

URL successfully copied!

Tap to zoom

RUDOLPH AXI-935D is a state-of-the-art Mask & Wafer Inspection Equipment designed for the semiconductor industry. It is a comprehensive system that helps to detect and analyze defects on masks and wafers. The unit consists of various components such as lens systems, laser interferometry microscopes, and other optics that help to capture and analyze high-resolution images. The machine is equipped with precision motion stages that can move the mask or wafer either mechanically or via a motor-controlled feed. It also equips a stage that can rotate the objects for 360-degree imaging. The tool is designed to support both traditional 2D imaging as well as advanced 3D imaging. It allows for a wide range of image acquisition methods such as total internal reflection, epi-illumination, dark field, and oblique viewing, and is capable of acquiring images at 10nm resolution. The subsystems of RUDOLPH AXI 935D are designed to analyze defects and compare them to a previously acquired "golden image" in order to identify which areas have been affected. It can detect defects down to 0.2 microns in size, and can provide accurate and reliable information on defects such as size, aspect ratio, contrast, and intensity. AXI 935 D also includes a comprehensive set of image processing tools for analyzing the image data and extracting critical defect parameters. These tools help to identify defects and isolate them from background limitations. It can also be used to identify process defects, determine yield losses, and identify critical defects that can cause process failure. In addition, the asset can be customized to meet specific application requirements by adding functionality such as advanced defect filtering, defect classification, and advanced pattern recognition. The model is also modular and can be easily upgraded with additional components such as higher magnification lenses, or interchangeable optics. In summary, AXI-935D is a reliable and versatile mask & wafer inspection equipment designed to guarantee the highest accuracy and productivity in mask and wafer inspection. It is highly configurable, easily upgradable, and capable of providing detailed and accurate defect analysis.

There are no reviews yet