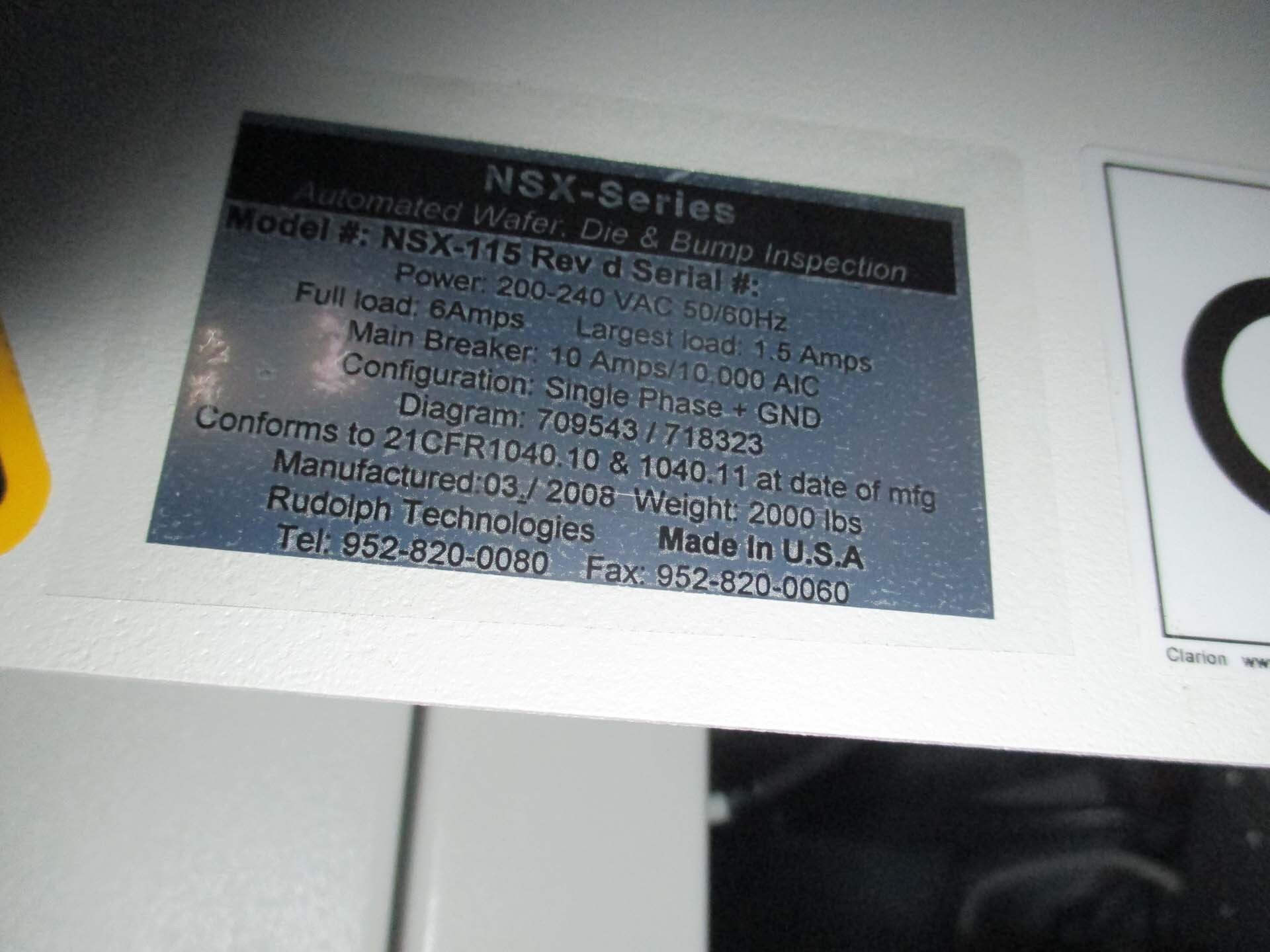

Used RUDOLPH NSX 115 #9353342 for sale

URL successfully copied!

Tap to zoom

ID: 9353342

Vintage: 2008

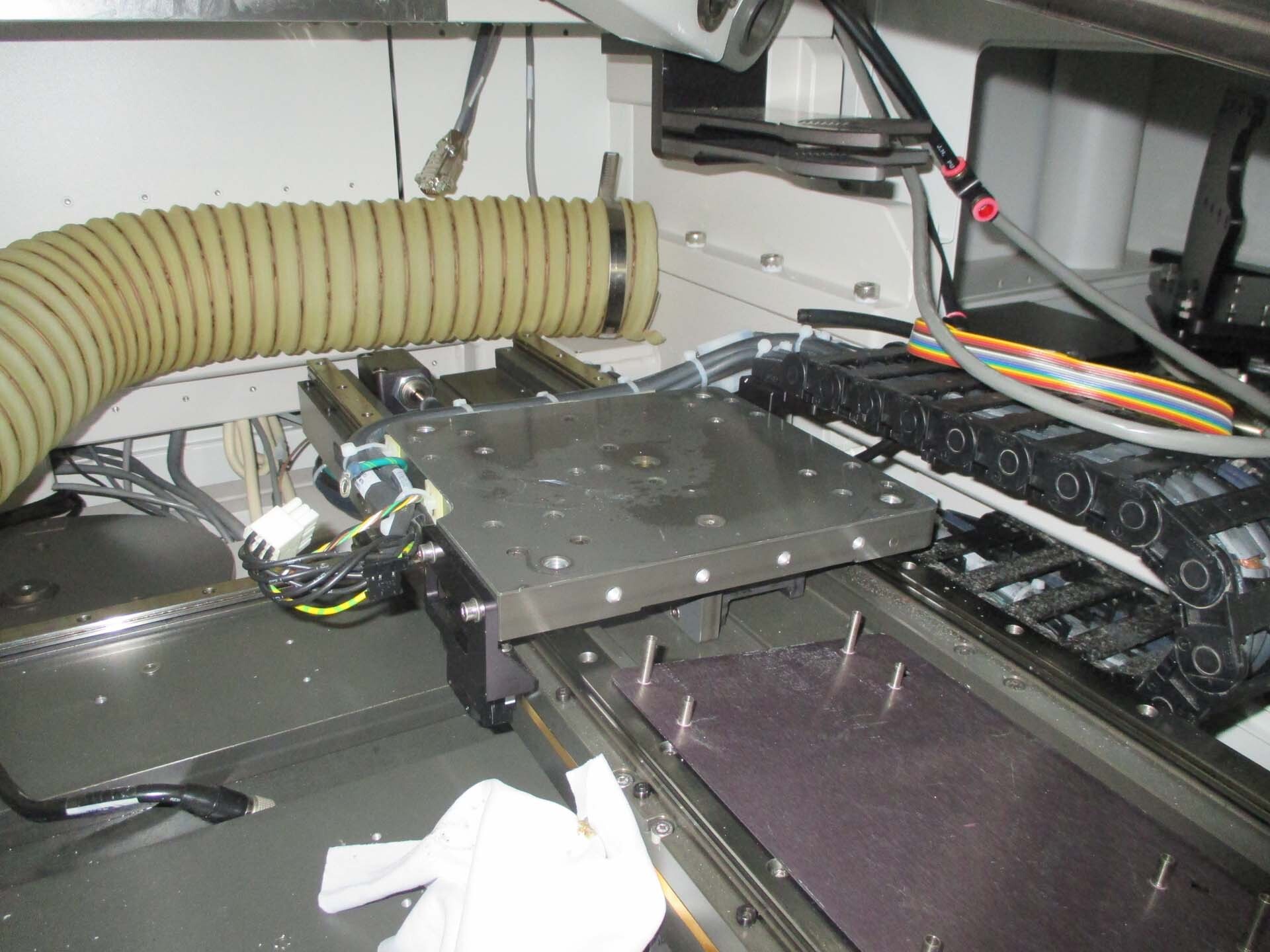

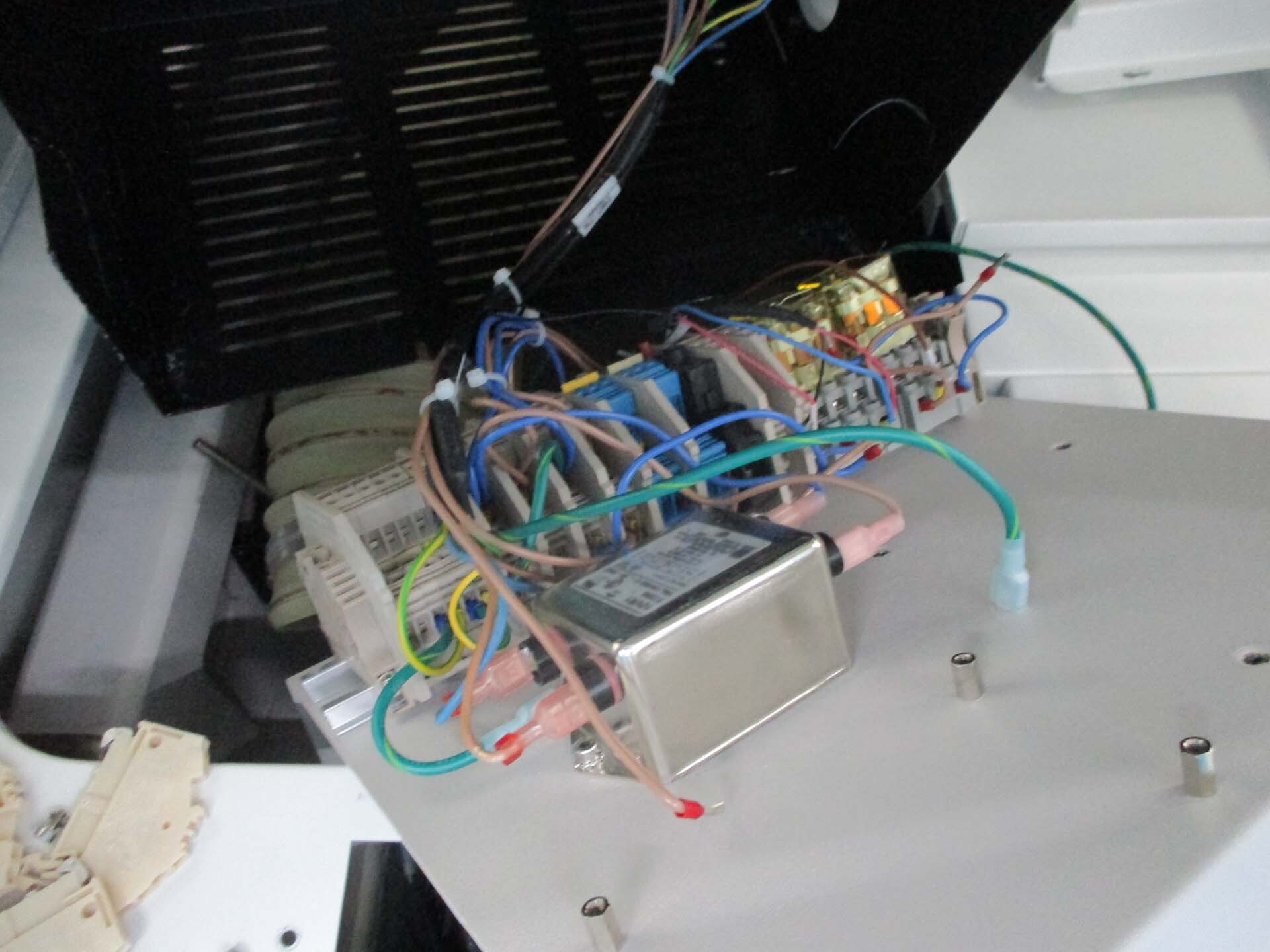

Wafer defect inspection system, parts machine

Missing parts:

Odyssey board

CCD

Turret

PC

2008 vintage.

RUDOLPH NSX 115 is a state-of-the-art mask and wafer inspection equipment designed to ensure superior precision and accuracy in the fabrication of leading-edge microelectronic products. The system is composed of a high-speed optical imaging unit, which captures images of the mask and wafer surfaces. The machine also incorporates a proprietary optics module, featuring a high-precision nanometer stage with advanced micro-pattern alignment capability. This enables quick and precise inspection setup for process optimization. NSX 115 is also equipped with a high-resolution optomask pallet which provides a reliable mask library and measurement data. An advanced mask editing capability enables automated and exacting pattern matching for a variety of mask types, including sputtered, etched and lithographic specifications. The wide field of view and high-speed scanning capabilities of the optical imaging tool enable rapid visualization of even the most intricate structures. With a high-precision 45-degree tilt adjustment, the asset operates within a large area without compromising accuracy. This allows for the inspection of large-area features, including symmetric and asymmetric contacts, over a wide range of device topographies. RUDOLPH NSX 115 is further equipped with a comprehensive array of wafer inspection optics, enabling it to image area and defect features with a precise resolution. To ensure high-precision inspection results, the model is equipped with high-resolution image capturing for enhanced wafer inspection. Additionally, the automated alignment and inspection process simplifies the setup and subsequent monitoring activities. NSX 115 is also suitable for use in a variety of process-monitoring applications. The equipment is designed to detect any subtle shifts in process parameters, including focal length, photomask characteristics, and lens distortion. With the automated image-capture feature of the system, this enables long-term process optimization and yield improvements. The automated options ensure that process-critical results are continuously monitored. In addition to its mask and wafer inspection capability, RUDOLPH NSX 115 also provides superior connectivity between various monitors and data systems. The advanced network support enables remote viewing of images, reports, and data. This is especially useful for remote teams that are closely monitoring critical process parameters from a central location. In conclusion, NSX 115 is a sophisticated imaging tool for detailed and reliable mask and wafer inspection. Its sophisticated optics module, efficient mask library, and advanced image-capturing capabilities enable quick inspection setup and reliable defect detection. The high-performance remote connectivity also ensures superior support for process optimization and long-term yield improvements.

There are no reviews yet