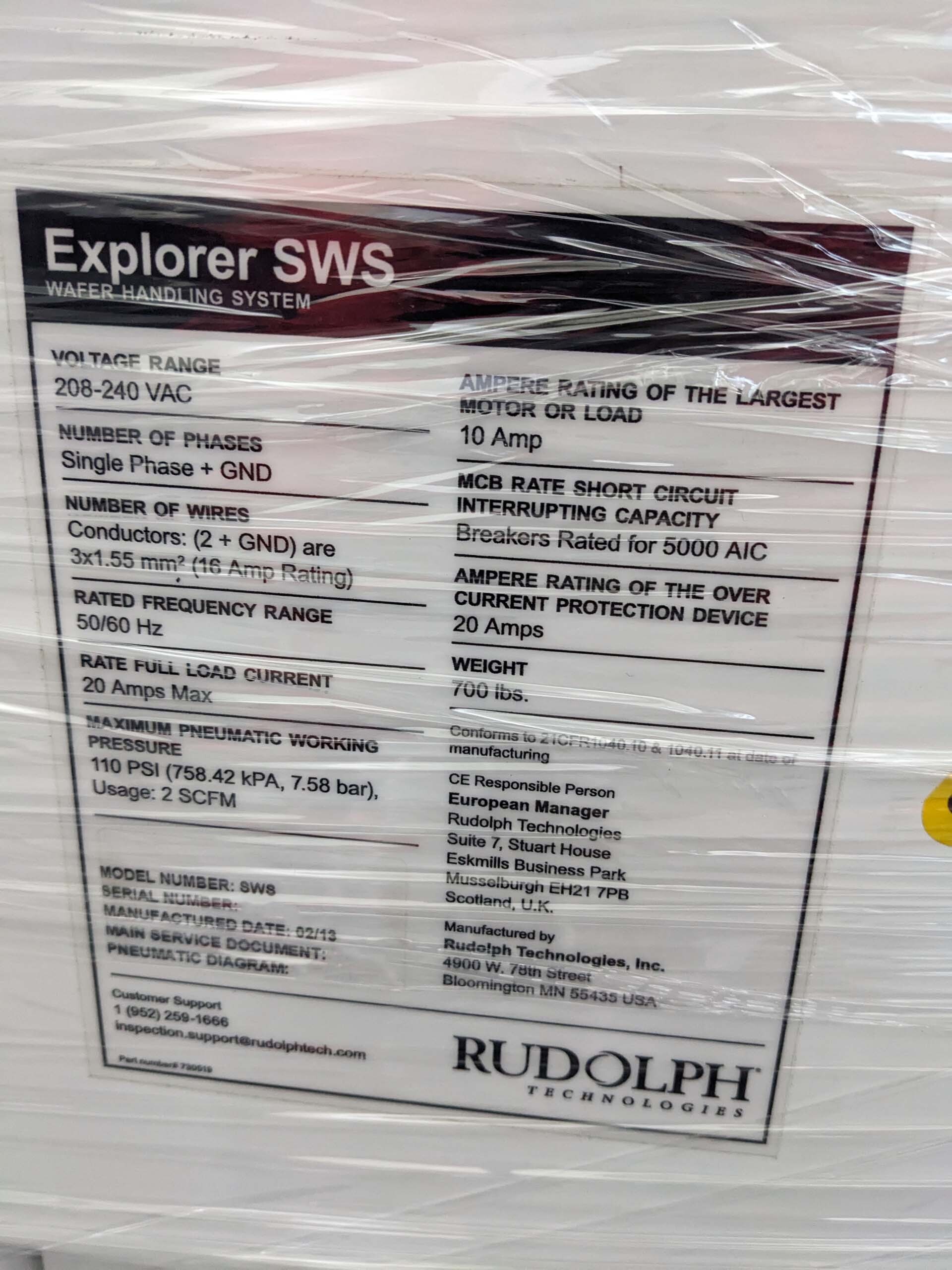

Used RUDOLPH SWS #9378745 for sale

URL successfully copied!

Tap to zoom

RUDOLPH SWS is a state-of-the-art mask & wafer inspection system from RUDOLPH Technologies, Inc. The system is designed to be used in semiconductor fabs where it provides an automated solution to the challenging task of mask & wafer inspection. SWS combines sophisticated lighting and optics with advanced software algorithms to detect any imperfections in the wafers or masks that could potentially lead to yield issues during the manufacturing process. The first stage of the mask & wafer inspection process is a wafer scan, which utilizes a robotic arm to quickly and accurately position a camera over a wafer's surface while simultaneously collecting data such as reflectance, surface topography, and binding energy between the surface and the mask. This initial scan of the wafer produces a detailed map that can be used to detect any potential defects on the surface. The second stage of the mask & wafer inspection process checks the masks themselves for faults or irregularities. The mask is placed face-down on a table and a specialized camera scans the image for any anomalies. This is done with a mixture of reflected light and microscopy to ensure that even the most minute of imperfections is detected. The third phase of the mask & wafer inspection process entails the comparison between the mask and the actual wafer. RUDOLPH SWS uses sophisticated software algorithms to compare the two images and detect any discrepancies between what the mask should look like and what the actual wafer looks like. Should any discrepancies be found, SWS is able to highlight the fault and notify human-inspectors where attention needs to be paid. Finally, the fourth phase of the mask & wafer inspection entails the review of the results. RUDOLPH SWS is able to generate detailed 3D reports of the mask & wafer inspection process, giving a detailed overview of any issues that have been identified. This helps human inspectors to quickly identify any issues they may need to address, allowing them to gain insight into the manufacturing process and help to improve yields. SWS is an impressive system that allows semiconductor fabs to automate their mask & wafer inspection processes and get an overview of an entire wafer with a much higher degree of accuracy compared to manual inspections. This presents an outstanding opportunity for optimization of manufacturing processes and improved yields.

There are no reviews yet