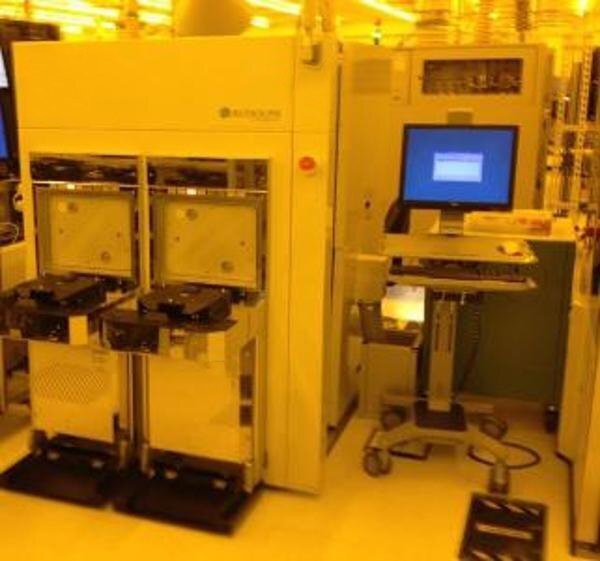

Used RUDOLPH WV 320 #9355361 for sale

URL successfully copied!

Tap to zoom

ID: 9355361

Wafer Size: 12"

Vintage: 2007

Macro defect inspection system, 12"

2007 vintage.

RUDOLPH WV 320 is a highly advanced mask and wafer inspection equipment designed for the semiconductor industry. It is equipped with the latest image processing technology to accurately capture and measure defects found on wafers and masks. The system features high-resolution optics and LED lighting to create an image of the masks and wafers with extraordinary detail. The main frame of RUDOLPH WV320 is simple to mount and flexible enough to serve a wide range of needs. It is also equipped with a monitor interface that allows operators to easily monitor wafer movements and defect locations. The unit is designed to deliver unrivaled accuracy in inspection jobs, providing superior performance in detecting defects. WV 320 utilizes advanced technologies to accurately measure wafers and masks. An integrated 20 megapixel camera takes high-resolution images with up to 16 million pixel resolution. This enables the machine to detect tiny and microscopic defects in masks and wafers. The integrated software further provides exceptional defect contrast, distinguishing even the slightest flaw. WV320 also features a specialized software that includes advanced image processing algorithms that can detect and measure features of wafers and masks. The software can analyze patterns and defects and match them to known patterns for precise measurements and results. In addition, RUDOLPH WV 320 also includes an intuitive user interface that allows operators to set wafer parameters and inspect multiple wafers in the same job. Its automatic recalibration ensures precise wafer and mask measurements, making it an invaluable asset for any semiconductor production process. Furthermore, the tool also features a wide range of output formats for data reports, ensuring efficient data storage and retrieval. In conclusion, RUDOLPH WV320 is an innovative mask and wafer inspection asset designed to meet the demands of the semiconductor industry. It is equipped with advanced image processing algorithms, 20 megapixel cameras, powerful optics, and intuitive user interfaces and output formats that makes it an incredibly reliable and versatile model. Moreover, its accuracy in measuring wafers and masks make it a valuable asset in any semiconductor production process.

There are no reviews yet