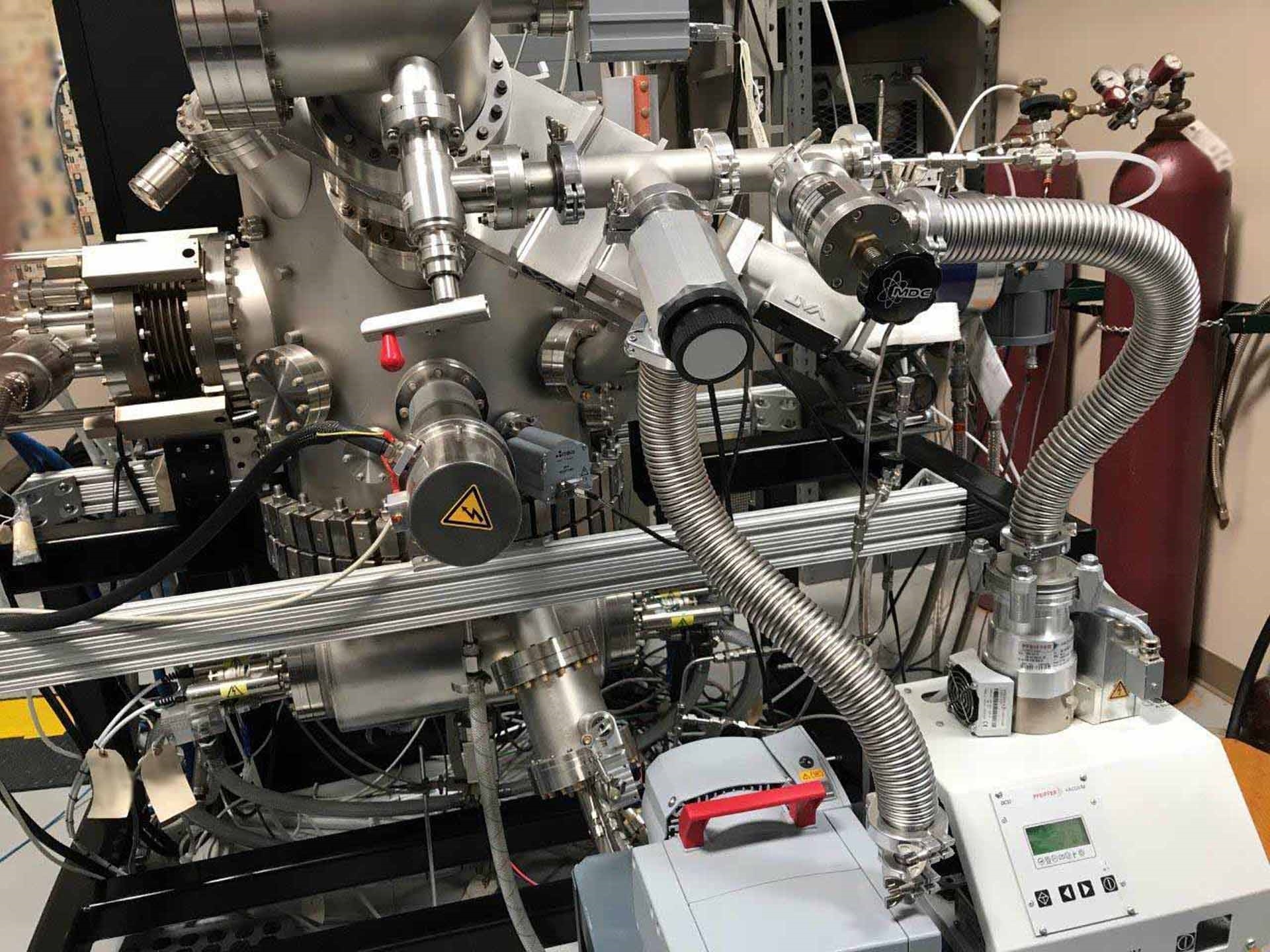

Used CUSTOM / NEXGEN 440 S1 MBE #9233063 for sale

URL successfully copied!

Tap to zoom

ID: 9233063

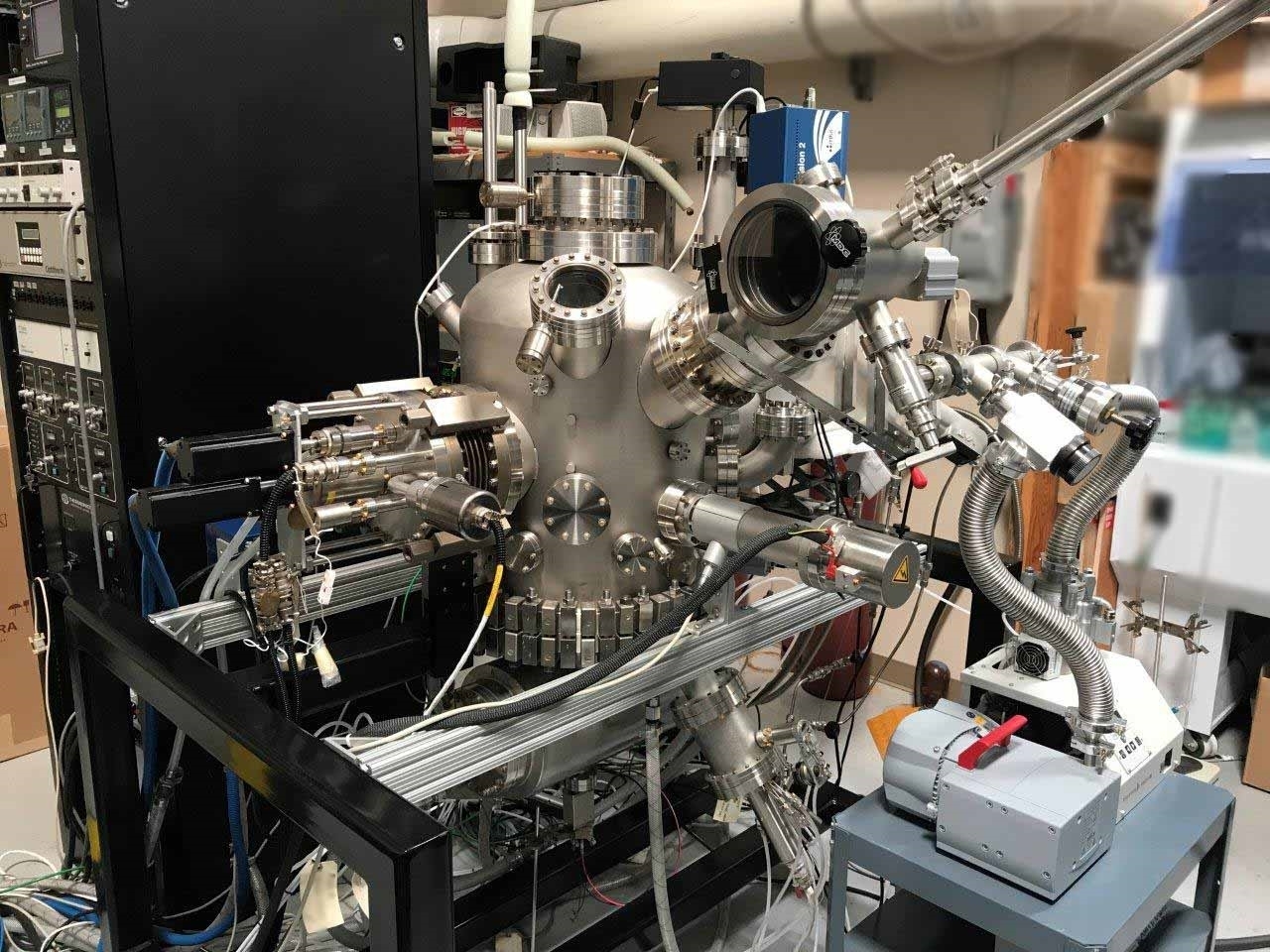

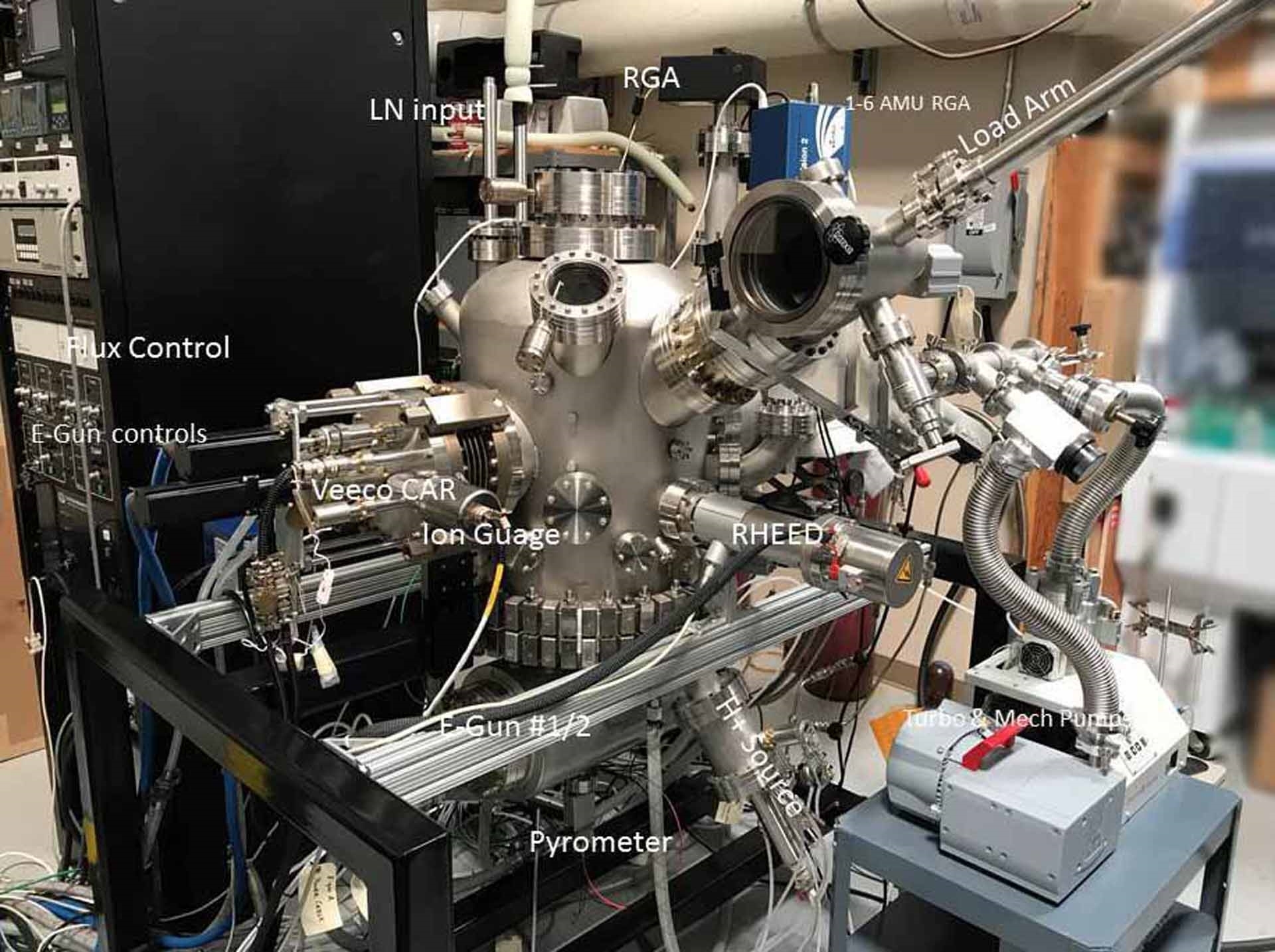

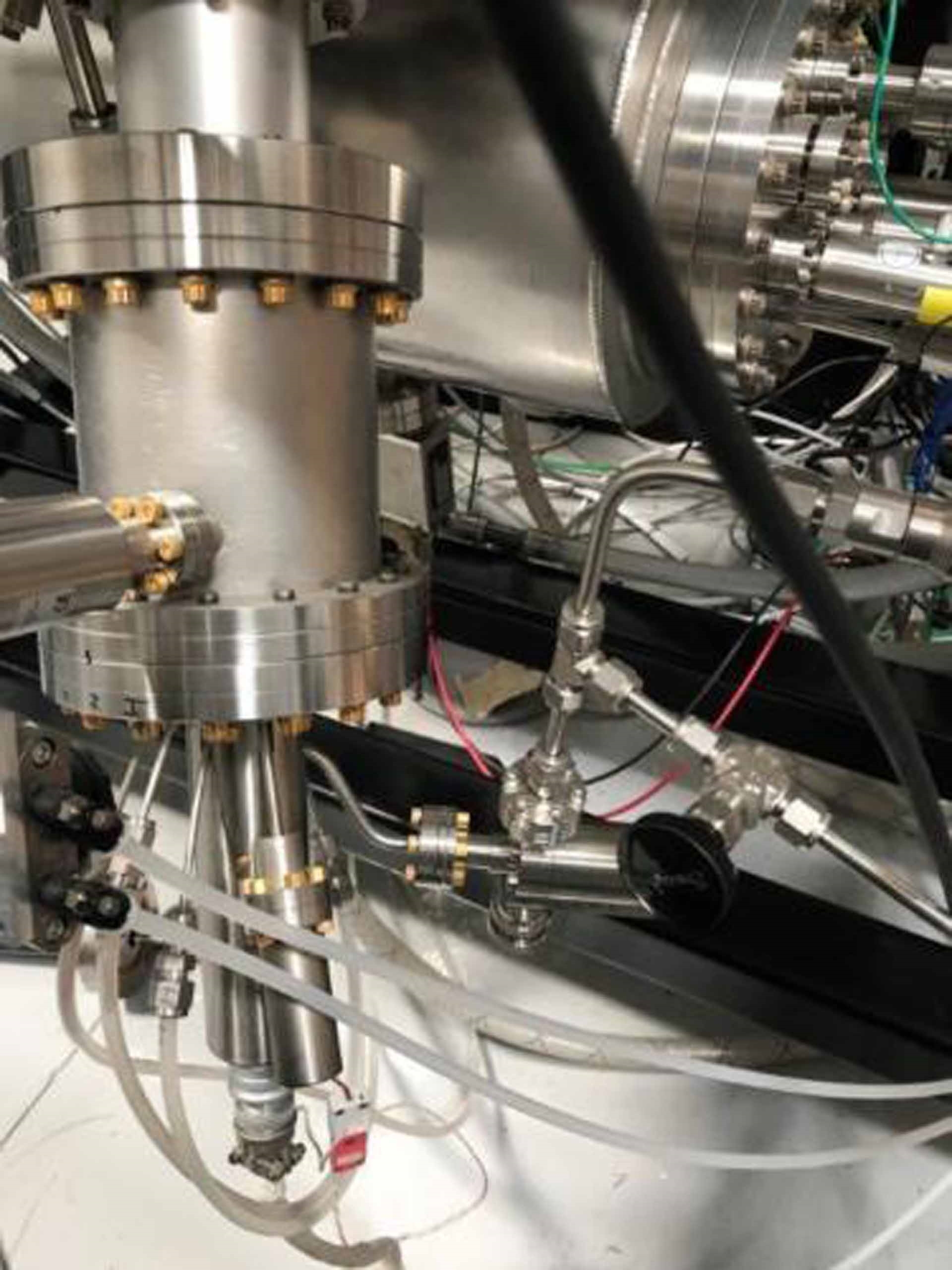

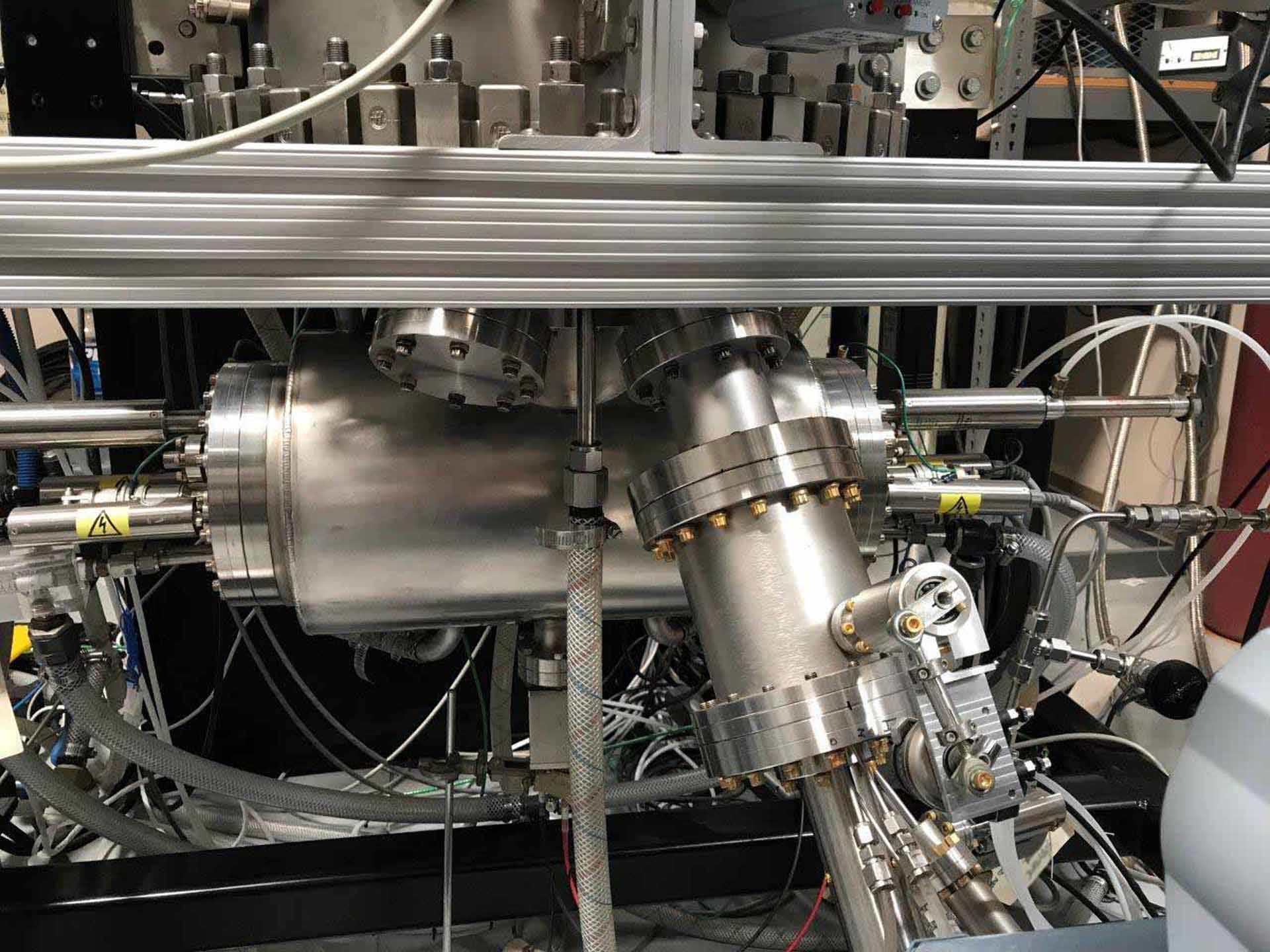

MBE Growth chamber

For eBeam deposition of metals

With loadlock

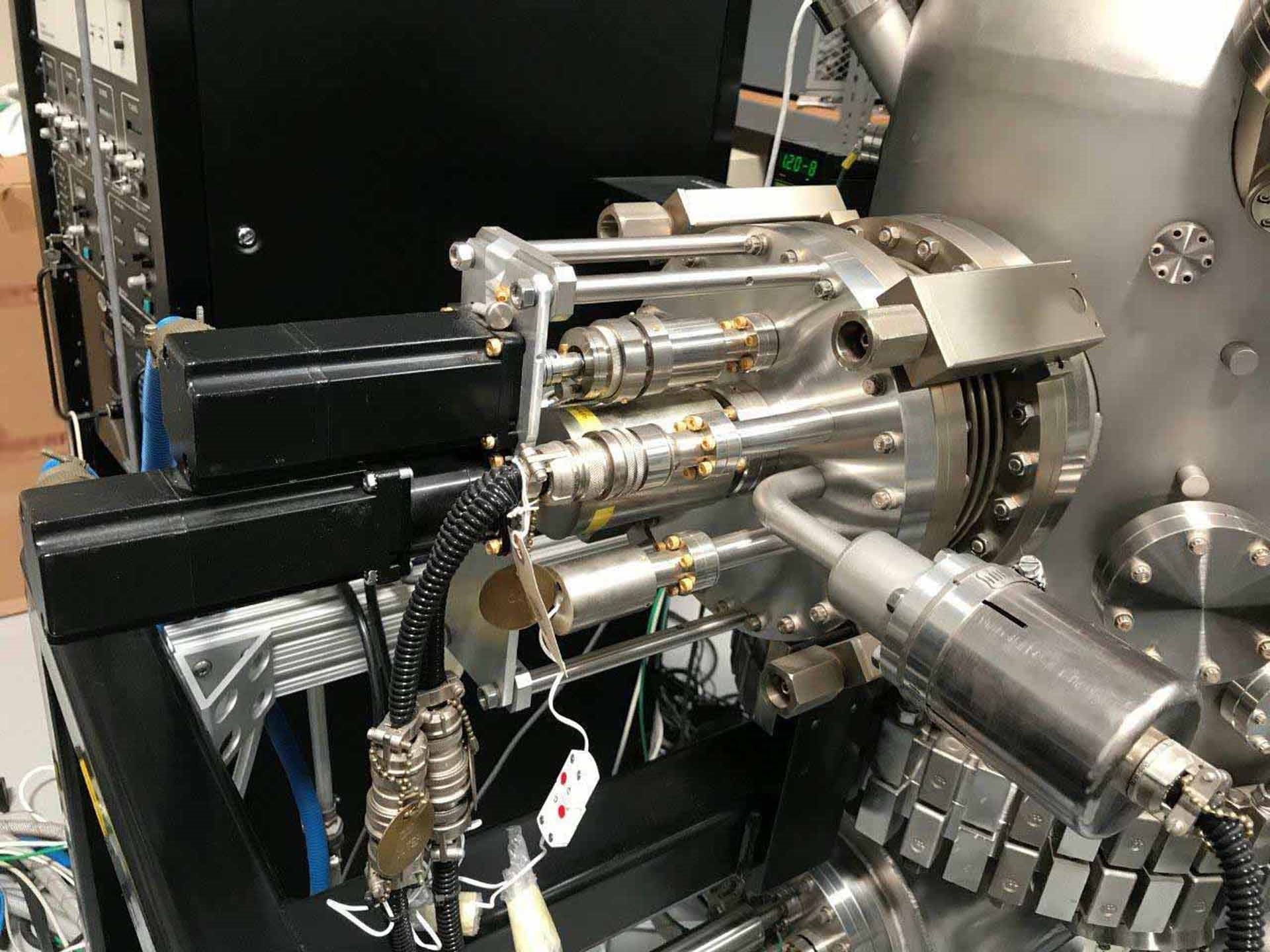

VEECO GEN II Manipulator

Includes:

(2) THERMIONICS LAB INC / TLI HM2 Series eGun TM

(2) 10CC Crucibles with 8" OD CF mounted

(2) Pneumatic shutters

(2) Water interlock switches

Switching e-Gun power supply: 15 kW

Gun controllers filament transformer & cables

(2) X-Y Beam sweep controllers

Flux monitor sigma EIES guardian

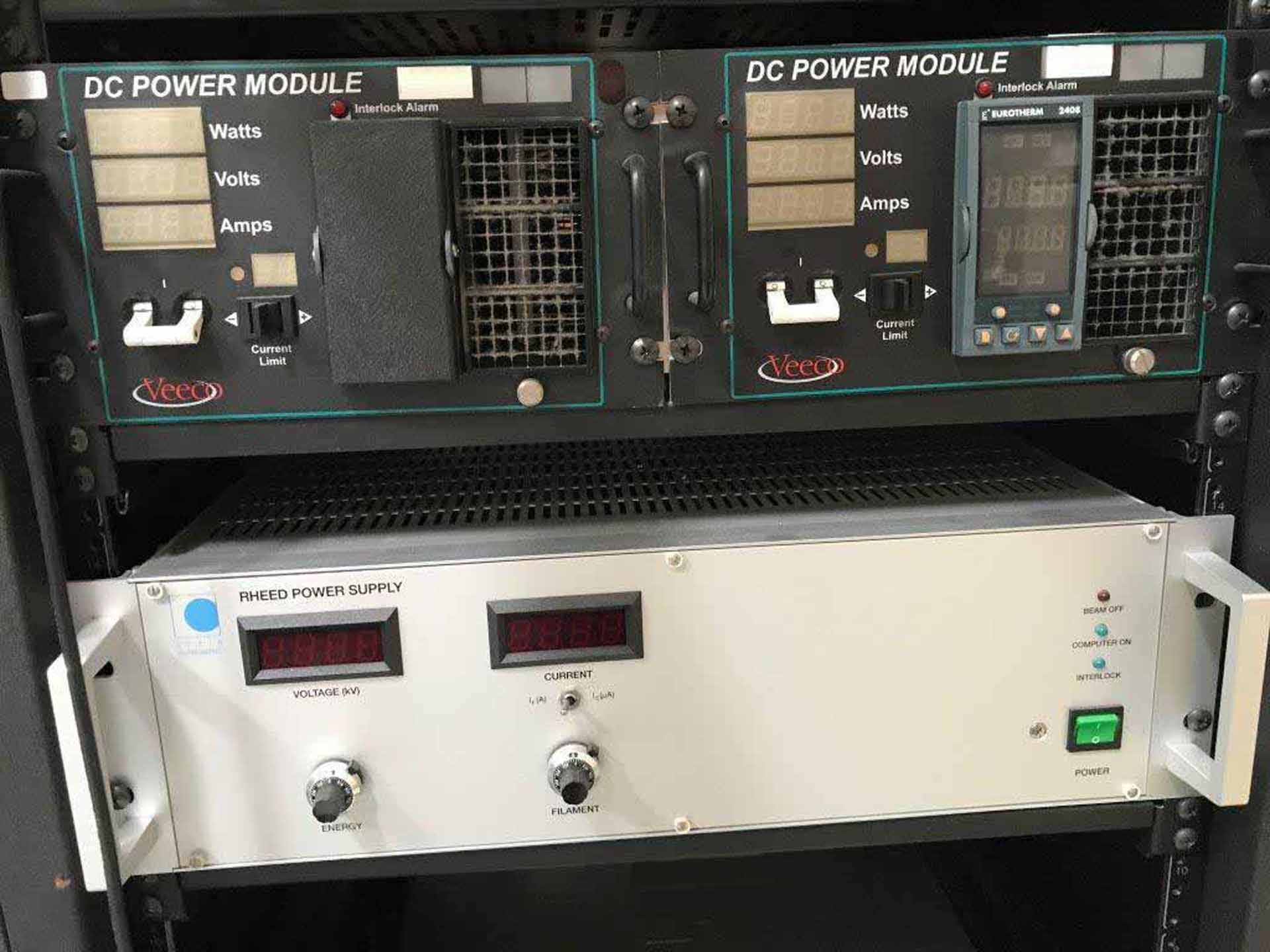

RHEED kSA 400

With 30eV power supply

STAIB Gun computer controller

With remote control box

VEECO CAR 3" Dual zone with heater

Power supplies

Controller

Substrate rotation & angle to evaporation / Loading

PFEIFFER MVP 070-3 Diaphragm vacuum pump

PFEIFFER Mechanical-turbo pump with DCU

(2) MKS 999 Quattro

EXTORR XT100 Residual gas analyzer

GRANVILLE PHILLIPS 350 Ionization gauge & controller

NESLAB HX300 E-Guns chiller

OXFORD INSTRUMENTS Cryo-Plex 8, Diode, UHV with burst disc

PFEIFFER MVP 070-3 Diaphram vacuum pump

Holding system at 10-kelvin

Chamber & E-Gun cooling

Manuals

Does not include:

MKS Microvision 1-6AMU RGA

Atomic hydrogen source with automated valve positioner

Chiller for sample & H+ source cooling

Chiller for main chamber cooling

LESKER LVM940 Leak valve

PC System

(2) XHR 60-18 XANTREX power supplies

(3) EUROTHERM controllers

Optitherm III Optical fiber pyrometer

Temperature range: 600°C to 1500°C

GAMMA Vacuum ion pump

150T

Titan DI

(6) CFF

VAT Valve.

CUSTOM / NEXGEN 440 S1 MBE equipment is a state-of-the-art molecular beam epitaxy system that is utilized in the study of growth and characterization of ultra-thin (thickness less than 1μm) semiconductor films. It is a versatile, Multi-barrier epitaxy unit with an upgradable configuration and includes components such as a load-lock chamber, sputtering kit, e-beam gun, heating elements, dual-source deposition with source-mixed mode, and an ultrahigh-vacuum (UHV) integrated machine controller. The load-lock chamber is used to minimize gas introduction and contamination and maintain a stable UHV in the main vacuum chamber. This also enables deposition of multiple test samples in the same campaign. The sputtering kit allows for the study of metals such as titanium, silver, molybdenum, and palladium by using a multi-pocket target. The e-beam gun is also used to evaporate substrate materials as and when required. Additionally, the heating elements are employed to assist in growing more intricate structures such as bilayers, while the dual-source deposition ensures precise composition and layer profile of deposited material in a source-mixed mode for multi-alloy structures. Apart from these, CUSTOM 440 S1 MBE tool also utilizes a powerful UHV asset controller. This allows for automated operation and precise control of all vacuum and deposition parameters, data logging, time-dependent operational control and much more. This also offers real-time parameter monitoring, both for model status and the material deposition, to ensure accurate experiments and accurate results. In addition, the source-mixed mode dual-source deposition enables better control over layer profiles, temperature, composition, and facilitates further manipulation of the deposited material, such as with anisotropic etching. Moreover, it also offers better precision in the growth of complex structures such as quantum dots. In short, NEXGEN 440 S1 MBE equipment is an advanced tool used to study material growth and characterization of ultra-thin films. It utilizes a versatile multi-barrier system, with an integrated UHV controller, various heating components, sputtering kit, and a powerful e-beam gun. With its sophisticated design, it provides precise control over deposition parameters and layers, and offers advanced tools for etching and manipulation of deposited materials. This makes it ideal for research and development of materials for nanodevices and electronic applications.

There are no reviews yet