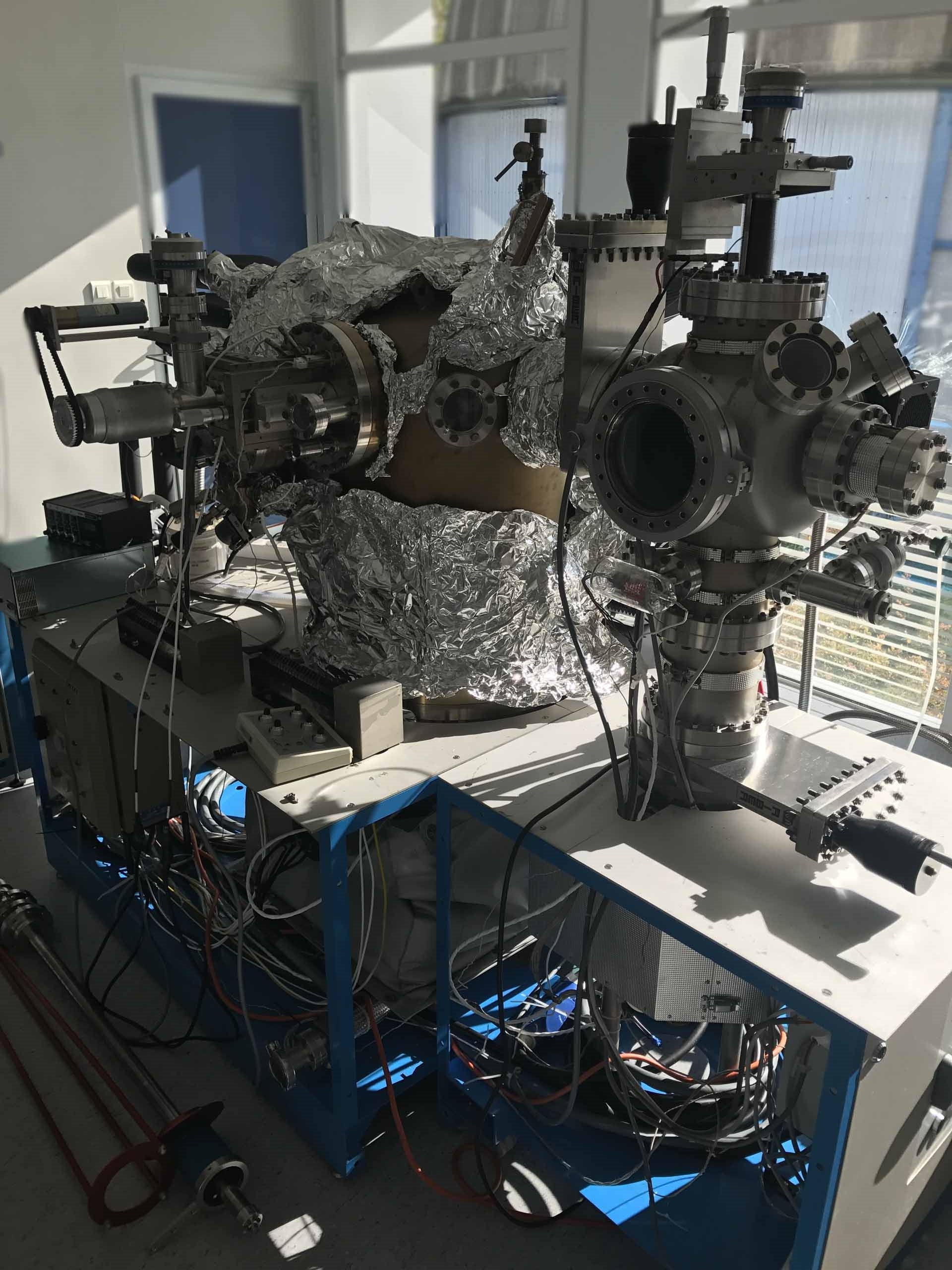

Used RIBER 32 #9227851 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9227851

Molecular beam epitaxy (MBE) system

GaN

Sources:

(6) Solid sources (Ga, Al, Mg, Eu, Er, Si)

Shutter control

SVTA RF 4.5 N2 Source

Shutter: N2

Auto-tuning

Water cooling

Ion removal power supply

Gas cabinet:

Up to (3) gas source controls

PFEIFFER Cube

MFC / Valve control

Alarm indication

Power supplies / Vacuum gauges:

Temperature control

Vacuum gauges

Shutter control

Cell / Substrate heater power supplies

RHEED

Cryo pump control

Ti sublimator

Substrate rotation

Load lock:

(4) Wafers, 2"

Soption pump / Mechanical pump station

Cryo pump CTI

RGA

Bake-out control

Ion pump

Gas purifier:

N2 purifier: <100 ppt

Liquid N2 delivery system

Computer:

Recipe editing

Source / Substrate temperature control

RGA

Vacuum

Base pressure: Main chamber

Sources:

Plasma: 600 W

HT source: Al, Ga. Er, Si, Eu

Dopant source: Eu, Mg.

Molecular Beam Epitaxy (MBE) is a technique used to grow high quality thin layers of material on a substrate. RIBER 32 is a type of MBE equipment that is used to produce thin, high quality layers of semiconductor materials, such as III-V and II-VI compounds. 32 is equipped with both thermal and atomic sources of material, and is capable of growing layers at a range of temperatures from room to ultra-high vacuum. RIBER 32 is composed of a semi-closed ultra-high vacuum (UHV) chamber, which contains an electron-beam evaporator, a filet heater, and several electron microscopes. The evaporator is used to vaporize material from solid sources, such as a solid-state source, and filet heaters are used to heat the source material to the required temperatures. The electron microscopes are used to observe and analyze the layers as they grow. The system is designed to provide an extremely high vacuum level (typically between 10-6 and 10-8 torr), an extremely clean environment, and accurate temperature control and highly uniform thin film layers. The UHV chamber is fitted with In-situ Diagnostic systems (ESCA and XRD) and capacitance manometers for precise monitoring of the unit parameters. 32 can grow high quality thin films of many semiconductor materials, including nitrides, oxides, nitrides/oxides, and other complex alloys. The machine can be operated at any temperature from room temperature to ultra-high vacuum (UHV). It is capable of providing superior uniformity of film thickness across the growth area and highly homogeneous properties of the deposited films. In addition, RIBER 32 is equipped with an Atomic Beam Tool (ABS) to enable growth of atomically smooth surfaces ideal for applications such as light-emitting OLEDs and optical waveguides. The ABS captures molecules of the target material and focuses a beam over the substrates to actively control the contaminant presence and growth conditions. 32's top-notch performance and high reliability make it an ideal choice for growing thin film layers of many semiconductor materials. It also offers low cost and enhanced productivity making it a key tool in the research and fabrication of thin films for modern electronics.

There are no reviews yet